Station controller m-Pro

advertisement

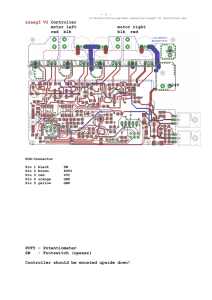

Instruction Manual P2043BA/EN 2009-07 Station controller m-Pro-400SE mini Order No. S961450-015 For additional product information visit our website at http://www.cooperpowertools.com Notes on this instruction manual This instruction manual is the – translation of the original Instruction Manual – • It provides important instructions for safe and effective operation. • It describes the function and operation of the station controller m-Pro-400SE (hereinafter referred to simply as m-Pro-400SE). • It serves as a reference work for technical data and service intervals. • It points out options. Additional information for operation can be found in: • Programming manual of software for tightening controller station, No. P2044PA • Reference manual of software for tightening controller station, No. P2045RH In the text: ➔ Identifies instructions to be followed. • Identifies lists. In graphics: Identifies movement in a direction. Identifies function and force. Disclaimer: Cooper Tools reserves the right to modify, supplement or improve this document or the product without prior notice. 2 P2043BA/EN 2009-07 en00b421.fm, 29.09.2009 Contents 1 Safety 5 1.1 1.2 1.3 1.4 1.5 Symbols ................................................................................................ Safety instructions ................................................................................ Intended use ......................................................................................... EMC measures ..................................................................................... Operator training................................................................................... 5 5 6 6 6 2 General information 7 2.1 2.2 2.3 2.4 2.5 2.6 Overview............................................................................................... Description............................................................................................ Field of application................................................................................ Ambient conditions ............................................................................... Maintenance ......................................................................................... Transport and storage .......................................................................... 7 7 7 8 8 8 3 Mechanical data 9 3.1 3.2 3.3 Size....................................................................................................... 9 Installation guidelines ........................................................................... 9 Connections........................................................................................ 10 4 Electrical Data 4.1 4.2 System data........................................................................................ 11 Power supply ................................................................................. 12 5 Maintenance 12 6 Technical data 13 6.1 6.2 6.3 Connections........................................................................................ 13 Storage access, portable memory ..................................................... 18 MAC address ...................................................................................... 19 P2043BA-EN_2009-07_m-Pro-400SE-mini-HWIVZ.fm, 29.09.2009 11 P2043BA/EN 2009-07 3 4 P2043BA/EN 2009-07 P2043BA-EN_2009-07_m-Pro-400SE-mini-HWIVZ.fm, 29.09.2009 Safety 1 Safety Do not operate the m-Pro-400SE mini unless you have carefully read and fully understood the following safety instructions and the instruction manual for your model. We do not claim that these safety notes are complete. Read and observe all applicable, general and local safety and accident prevention rules. 1.1 Symbols The purpose of the following notes is to guarantee preservation of personal safety as well as to protect the station controller m-Pro-400SE from damage. The symbols defined below highlight safety notes and warnings in this instruction manual, which alert to hazards endangering health and life of maintenance staff and causing property damage. DANGER! A symbol combined with the word DANGER warns of an impending health risk or risk of fatal injury to personnel. If this danger note is not adhered to, severest injury that may lead to the death of people, is the consequence. WARNING! A symbol combined with the word WARNING warns of a potentially dangerous situation for the health of personnel, which, if not avoided, could result in death or serious injury. CAUTION! A symbol combined with the word CAUTION warns of a potentially harmful situation for the health of personnel or damage to property or the environment. If this warning is not observed, injuries, property or environmental damage may occur. This sign warns of a possibly damaging situation. ATTENTION! If the note is not adhered to, the product or parts of it may be damaged. NOTE This symbol indicates a general instruction. General instructions include application tips and special useful information, but no warnings against dangers. 1.2 Safety instructions The station controller described in this instruction manual m-Pro-400SE mini was developed, manufactured, inspected and documented according to the relevant safety standards. Therefore, the m-Pro-400SE mini does not normally represent a danger to property or persons as long as the handling instructions and safety notes are adhered to during installation and first operation. • The company operating the product must make this instruction manual available to operators and must ensure that operators have read and understood it. • Do not attempt to repair possible faults on the m-Pro-400SE mini by yourself if you do not have the required knowledge! Inform the local repair center or your Cooper Tools representative. • Follow a safety-conscious maintenance program which takes into account the local regulations for maintenance and servicing in all phases of operation of the tightening controller. en01b411_bedingt.fm, 29.09.2009 P2043BA/EN 2009-07 5 1 1 Safety 1.3 Intended use The station controller m-Pro-400SE mini may be used only under the following conditions: • Industrial environment EMC limit class A (EN 55011). • Enclosed housing IP54. • Only ARCNET cables of types authorized by Cooper Tools may be used. • Furthermore, only accessory parts authorized by Cooper Tools may be used. • Unauthorized alterations, repairs and modifications are prohibited for reasons of safety and product liability. • The temperature inside the control cabinet may not exceed 50 °C (122°F). 1.4 EMC measures • • • The filters and measures required to satisfy the EMC regulations are built into the design. The enclosed metal housing provides substantial protection against irradiated and radiated interference. The tool complies with the following EMC standards: Emissions - EN 55011:1998 + A1:1999 + A2:2002 Cl. A Noise immunity - EN 61000-4-2:1995 + A1:1998 + A2:2001 - EN 61000-4-3:2002 + A2:2002 - EN 61000-4-4:2004 - EN 61000-4-5:1995 + A1:2002 - EN 61000-4-6:1996 + A1:2001 - EN 61000-4-8:1993 + A1:2001 - EN 61000-4-11:2004 - EN 61000-6-2: 2005 Circuit feedback - EN 61000-3-2:2000 + A2:2005 - EN 61000-3-3:1995 + A1:2001 • This is a Class A device. The device may cause signal interference; in this case, the operator may be required to implement suitable EMC measures. Operation while the housing is open is prohibited, since the properties of the shielding would change and the noise emission would increase. WARNING! • 1.5 Operator training • • • 6 The station controller m-Pro-400SE mini may only be commissioned by personnel who have specialized training (electrical/mechanical engineering). The owner's operating and service personnel will be trained by qualified employees of Cooper Tools. A repair is only permitted by Cooper Tools authorized personnel. P2043BA/EN 2009-07 en01b411_bedingt.fm, 29.09.2009 General information 2 General information 2.1 Overview Station controller … for m-Pro-400SE mini Additional internal serial interface for control Two-line display Order number (without software) Designation Usable software S961450-015 Controller SE, basic with serial display interface Standard, hand-held application S168851 Allowed range of numbers S168800 – S168899. For more information, contact the Cooper Tools Sales & Service Center. 2.2 Description The station controller m-Pro-400SE mini includes the following functions: • Communication with resource control (for example, digital I/O, Profibus, Interbus, etc.). • Communication with computer networks (for example, Ethernet). • Communication with the TM tightening modules via ARCNET high-performance fieldbus. • Printer control • Tightening process control 2.3 Field of application • • The station controller m-Pro-400SE mini is used as the master computer, data concentrator and interface concentrator in conjunction with the TM and TMH tightening modules. Communication with the TM tightening modules takes place using an ARCNET serial high-performance fieldbus. A decentralized setup of the m-Pro-400SE and TMs at distances of up to 100 m can be realized. en02b411_bedingt.fm, 29.09.2009 P2043BA/EN 2009-07 7 2 2 General information 2.4 Ambient conditions Features Data Ambient temperature 0 – 50 °C (32 – 122 °F) Storage temperature -20 – 60 °C (-4 – 140 °F) Cooling type Convection (self-cooling) Relative humidity 0 – 90 % non-condensing Working height Up to 3000 m (9,842.5 ft) above sea level1) Dust, dirt Required enclosure (IP20, without installation) 1) For use with TM modules: 1000 m (3,280.8 ft) above sea level 2.5 Maintenance • • 2.6 Transport and storage • • • 8 Always replace the station controller m-Pro-400SE mini completely. When the station controller is replaced for service, observe the software instruction manual. Transport and store in suitable packaging only. If necessary, request packaging from Cooper Tools. The packaging can be recycled. Check the m-Pro-400SE mini for any visible damage if the packaging is damaged. Inform the transport company, and, if applicable, Cooper Tools. P2043BA/EN 2009-07 en02b411_bedingt.fm, 29.09.2009 Mechanical data 3 Mechanical data 3.1 Size Features Data Weight 1,2 kg (2.6 lbs) Mean time between failures (lamps) Protection class 3.2 100.000 h IP20, without installation Installation guidelines • • en03b421.fm, 29.09.2009 An enclosed housing made of sheet steel must be used. Don’t cover the opening of the housing above and below the m-Pro-400SE mini with components (wireway e. g.). P2043BA/DE 2009-07 9 3 3 Mechanical data 3.3 Connections For technical data, siehe 6.1 Connections, Seite 13 On top • • • • • • • • • Inputs / Outputs USB version 1.1 Ethernet1, RJ45 ARCNet system bus CAN bus (currently without function) Profibus slave (DP) RS232 for auxiliary equipment Supply CF card Schnittstelle zum 2-Zeilen-Display Sidewards Serial interfaces are not galvanically isolated. RS232-4_4 interface with 24 VDC on pin1 + 9: this interface ATTENTION! can be used as the operating voltage for simple devices. This may cause damage to a standard modem or a PC connected via a null modem cable! 10 P2043BA/DE 2009-07 en03b421.fm, 29.09.2009 Electrical Data 4 Electrical Data 4.1 System data Hardware Nonvolatile memory 1 CF card for system and application with 256 MB (internal) Interfaces ARCNET interface (system bus) 4 serial data interfaces RS232 incl. printer (CON3) 1 10/100 Base-T network interface on RJ45 1 Ethernet Process interface I/O (process) 16-bit inputs/outputs 24 V opto-decoupled Profibus DP (slave) CAN bus (not enabled) System functions RTC real-time clock with calendar Watchdog: voltage monitoring Battery Varta CR2025: 170 mAh / 3.0 V or order No. 941555 Lithium battery Display Via two-line display, order No. S961787 Operating system OS-9000 real-time operating system, bootable without mechanically moving drives, no UPS required HMI (human-machine interface) • • Data protection User access authorization, configurable (remote program) Window-oriented, graphical user interface via PC via remote program Via two-line display Parts to be dismounted Optional en04b411_bedingt.fm, 29.09.2009 ProfiNet, second Profibus port (more can be added on request) P2043BA/EN 2009-07 11 4 5 Maintenance 4.2 Power supply Attempting to operate the station controller m-Pro-400SE at a voltage other than 24 VDC (e. g. 15 VAC / ATTENTION! 230 VAC) will result in immediate and irreparable total loss! Features Data Order number S961450-015 Nominal supply voltage 24 VDC Nominal supply voltage limits 15 – 30 DC Rated supply current 0.4 A Internal fusing (slow blow) 2A Power loss (standby) 9A CAUTION! The fuse on the power plug connector protects the lines in the m-Pro-400SE in the event of faults or an oversized external fuse. The fuse on the main board protects the conducting paths to the power adapter. ➔ Internal fuses may only be changed by Cooper Tools. 5 Maintenance Interval Measures Annual Battery change The battery supplies the real-time clock with power and ensures data retention when the power supply is switched off. Type of battery: Varta CR2025: 170 mAh / 3.0 V or order No. 941555 (typical duration for data retention = 1.4 years) Lithium battery ➔ Replace the battery when the station controller is switched off. For battery location, see 3.4 Connections on the front panel, page 8. NOTE The battery change must be completed within 15 minutes, as continuous operation without battery can trigger a RESET signal. Exceeding this limit will result in data loss of parameters, counter readings and time of day. ➔ Have the replacement battery ready. If in storage, do not short-circuit the battery or exceed the storage time. ➔ Provide access to the station controller in the interior. Open the control cabinet or housing. ➔ Wait for a pause in production. ➔ Remove the battery using insulated tongs. Caution: Do not cause a short-circuit or ground fault. ➔ Insert the new battery with the positive pole facing towards the battery compartment lid. The positive pole can be identified by the smaller contact area. ➔ Carry out a test with production monitoring. 12 P2043BA/EN 2009-07 en04b411_bedingt.fm, 29.09.2009 Technical data 6 Technical data 6.1 Connections All connections are short-circuit proof. 6.1.1 Station controller inputs/outputs The required signal circuits are connected to these input/output connectors. The signal groups are not galvanically connected to the power supply; galvanic isolation is required. Type: DIO16 (10 pole MICRO Combicon RM2.5 on processing unit) 16-bit digital inputs/outputs, opto-isolated for 24V level / 0.5 A Pin DIO8-15 Pin DIO1-7 11 +24 VDC 1 +24 VDC 12 I0 8 Bit 9 2 OK 0 Bit 1 13 OK 9 Bit 10 3 OK 1 Bit 2 14 OK 10 Bit 11 4 OK 2 Bit 3 15 OK 11 Bit 12 5 OK 3 Bit 4 16 OK 12 Bit 13 6 OK 4 Bit 5 17 OK 13 Bit 14 7 OK 5 Bit 6 18 OK 14 Bit 15 8 OK 6 Bit 7 19 OK 15 Bit 16 9 OK 7 Bit 8 20 GND 10 GND en07b411_bedingt.fm, 29.09.2009 P2043BA/EN 2009-07 13 6 6 Technical data Digital input/output There are 16 available lines for 24V technology that can be programmed as inputs or outputs as desired. 6.1.2 Ethernet RJ45 Access is obtained internally or via cable bushings and connected directly to the processing unit. 10/100 BASE-T 14 Pin Signal 1 TPOP 2 TPON 3 TPIP 4 nc 5 nc 6 TPIN 7 nc 8 nc P2043BA/EN 2009-07 en07b411_bedingt.fm, 29.09.2009 Technical data 6.1.3 ARCNet system bus An ARCNet cable can be connected to this interface. The station controller has an integrated bus termination; therefore, no external termination is necessary. Access is obtained internally or via cable bushings and connected directly to the station controller. Type: 9-pole D-Sub pin with slide lock Pin 1 PE 2 nc 3 DATA-B (ARC L) 4 nc 5 GND (ARCNet) 6 +5 V (ARCNet) max. 100 mA 7 nc 8 DATA-A (ARC H) 9 nc Housing 6.1.4 Signal PE shield connection CAN bus Type: 9-pole D-Sub pin Pin Signal 1 – 2 CAN L 3 CAN GND 4 – 5 – 6 CAN GND2 (close LB22 for this) 7 CAN H 8 9 en07b411_bedingt.fm, 29.09.2009 CAN +5 V Max. 100 mA (close LB21 for this) P2043BA/EN 2009-07 15 6 6 Technical data 6.1.5 Profibus slave (DP) The Profibus of a higher-level unit can be connected to this interface. Access is obtained internally or via cable bushings and connected directly to the processing unit. Type: 9-pole D-Sub plug with screw lock Pin 6.1.6 Signal 1 CHGND 2 nc 3 IO+ (PRO H) 4 nc 5 GND 6 +5 V max. 100 mA 7 nc 8 IO-(PRO L) 9 nc Housing PE RS232 for auxiliary equipment • • • • All outputs provide signals conforming to RS232. The inputs allow voltages in the range from -15 V to +15 V. - Voltages < 0.8 V correspond to a zero. - Voltages > 2.4V are interpreted as a one. - Open inputs are preset to zero using a pulldown resistor. The power supply pins are connected directly to the main board power supply. A consumer should not require current of more than 500 mA. - Do not connect or tighten consumers during operation. Doing so may result in a system reset! A conventional barcode scanner, for example, can be connected to this interface (depending on the software used). Access is obtained internally or via cable bushings and connected directly to the station controller. Type: 9-pole D-Sub pin with screw lock Serial interfaces are not galvanically isolated. RS232-4_4 interface with 24 VDC on pin1 + 9: this interface ATTENTION! can be used as the operating voltage for simple devices. This may cause damage to a standard modem or a PC connected via a null modem cable! D-Sub pin 16 RS232_1 RS232_2 RS232_3 RS232_4 1 – 2 RxD PSC1_1 RxD PSC2_1 RxD 3 TxD PSC1_0 TxD PSC2_0 TxD 4 – – – – 5 GND GND GND GND – – P2043BA/EN 2009-07 +24V2. 500mA PSC3_1 RxD PSC6_0 PSC3_0 TxD PSC6_2 en07b411_bedingt.fm, 29.09.2009 Technical data D-Sub pin 6.1.7 RS232_1 RS232_2 RS232_3 RS232_4 6 – 7 RTS PSC1_2 RTS PSC2_2 RTS PSC3_2 RTS PSC6_3 8 CTS PSC1_3 CTS PSC2_3 CTS PSC3_3 CTS PSC6_1 9 – – – – – – GND Supply Type: 4-pole Mini Combicon PHOENIX 1827 729 Order No. S961397 6.1.8 Pin Signal 1 +24V 2 +24V 3 GND 4 GND Mini display Internal board Type: 10-pole female connector (P5200) RS232-5 station controller housing Type: 9-pole D-Sub pin Male IDE connector D-Sub TTL mode Pin 1 Pin 1 Input Mode pin (open or > 2.4V) Input Mode pin (connected to GND) Pin 2 Pin 6 Input TTL IN3 Input TTL IN3 Pin 3 Pin 2 Input TTL IN1 Input RxD Pin 4 Pin 7 Input TTL IN0 Output RTS Pin 5 Pin 3 Output – Output TxD en07b411_bedingt.fm, 29.09.2009 ISPL232 mode P2043BA/EN 2009-07 17 6 6 Technical data 6.2 Male IDE connector D-Sub TTL mode ISPL232 mode Pin 6 Pin 8 Input TTL IN2 Input CTS Pin 7 Pin 4 Supply +5 V max. 500 mA Supply +5 V max. 500 mA Pin 8 Pin 9 Input TTL IN4 Input TTL IN4 Pin 9 Pin 5 Supply GND Supply GND Pin 10 –- Supply +5 V max. 500 mA Supply +5V max. 500 mA Storage access, portable memory Interface m-Pro-400SE mini S961450-015 6.2.1 USB × Plug for compact flash × Empty compact flash slot (internal) – USB (version 1.1) Not intended for serial devices or networking. Only USB sticks can be used here. Only a limited number of products can be used for this embedded PC. USB sticks that can be used Due to continuous product changes for commercial USB sticks, an advance performance test is required. We recommend Cooper Tools stick, 1 GB, order No. S981007. 6.2.2 Plug for compact flash Function for S961450-050 for operating system and application. A CF card (internal) is required for operation. 18 Type Size 1 128 MB 2 256 MB 3 512MB 4 Up to 2 GB P2043BA/EN 2009-07 en07b411_bedingt.fm, 29.09.2009 Technical data 6.3 MAC address 6.3.1 Network access The MAC address (Media Access Control address) is the hardware address of the station controller, which is used for unambiguous identification of the device in the Ethernet network. The MAC address is on the rear side of the station controller, but can also be formed from the serial number. MAC = 00.12.91.50.xx.xx. xx.xx is determined by multiplying the last 4 digits of the serial number by 2 and converting the result into hexadecimal format. Example: Serial number A20035: 0035 × 2 = 70 = 0x0046 ➔ MAC = 00.12.91.50.00.46 Serial number A20080: 0080 × 2 = 160 = 0x00A0 ➔ MAC = 00.12.91.50.00.A0 A second Ethernet access is possible via the station controller's graphic card. The MAC address of this interface is one higher than that of the first interface. Example: Serial number A20035: 0035 × 2 = 70 = 0x0046 + 1 = 0x0047 ➔ MAC = 00.12.91.50.00.47 Serial number A20080: 0080 × 2 = 160 = 0x00A0 + 1 = 0x00A1 ➔ MAC = 00.12.91.50.00.A1 en07b411_bedingt.fm, 29.09.2009 P2043BA/EN 2009-07 19 6 Sales & Service Centers Note: All locations may not service all products. Please contact the nearest Sales & Service Center for the appropriate facility to handle your ser vice requirements. Dallas, TX Cooper Tools Sales & Service Center 1470 Post & Paddock Grand Prairie, TX 75050 Tel: (972) 641-9563 Fax: (972) 641-9674 Detroit, MI Cooper Tools Sales & Service Center 4121 North Atlantic Blvd. Auburn Hills, MI 48326 Tel: (248) 391-3700 Fax: (248) 391-6295 Cooper Tools P.O. Box 1410 Lexington, SC 29071-1410 USA Phone: 800-845-5629 803-359-1200 Fax: 803-359-0822 Cooper Tools 4121 North Atlantic Blvd. Auburn Hills, MI 48326 USA Phone: (248) 391-3700 Fax: (248) 391-6295 Cooper Tools 5925 McLaughlin Road Mississauga, Ontario Canada L5R 1B8 Phone: (905) 501-4785 Fax: (905) 501-4786 Houston, TX Cooper Tools Sales & Service Center 6550 West Sam Houston Parkway North, Suite 200 Houston, TX 77041 Tel: (713) 849-2364 Fax: (713) 849-2047 Lexington, SC Cooper Tools 670 Industrial Drive Lexington, SC 29072 Tel: (800) 845-5629 Tel: (803) 359-1200 Fax: (803) 358-7681 Cooper Tools de México S.A. de C.V. Libramiento La Joya No. 1 Bodega No. 2 Esq. Politécnico Barrio San José Cuautitlán, Edo de México C.P. 54870 Phone: +52-55-5899-9510 Fax: +52-55-5870-5012 Cooper Tools Industrial Ltda. Av. Liberdade, 4055 Zona Industrial - Iporanga 18087-170 Sorocaba, SP Brazil Tel: +55-15-3238-3929 Fax: +55-15-228-3260 Cooper Industries, Ltd. 600 Travis, Ste. 5800 Houston, TX 77002-1001 P: 713-209-8400 www.cooperindustries.com PL12EN-1660 101008 Specifications subject to change without notice. © 2008 COOPER INDUSTRIES, INC. Los Angeles, CA Cooper Tools Sales & Service Center 15503 Blackburn Ave Norwalk, CA 90650 Tel: (562) 926-0810 Fax: (562) 802-1718 York, PA Cooper Tools Sales & Service Center 3990 East Market Street York, PA 17402 Tel: (717) 755-2933 Fax: (717) 757-5063 Seattle, WA Cooper Tools Sales & Service Center 2865 152nd Ave N.E. Redmond, WA 98052 Tel: (425) 497-0476 Fax: (425) 497-0496 Canada Cooper Tools Sales & Service Center 5925 McLaughlin Road Mississauga, Ont. L5R 1B8 Canada Tel: (905) 501-4785 Fax: (905) 501-4786 Cooper Power Tools SAS Zone industrielle – B.P. 28 77831 Ozoir-la-Ferrière Cedex France Téléphone: +33-1-6443-2200 Téléfax: +33-1-6440-1717 Cooper Tools Hungária Kft. Berkenyefa sor 7 H-9027 Györ Hungary Tel: +36-96-505 300 Fax: +36-96-505 301 Cooper Power Tools Cooper (China) Co., Ltd. GmbH & Co. OHG 955 Sheng Li Road, Postfach 30 Heqing Pudong, Shanghai D-73461 Westhausen China 201201 Germany Tel: +86-21-28994176 Phone: +49 (0) 73 63/ 81-0 +86-21-28994177 Fax: +49 (0) 73 63/ 81-222 Fax: + 86-21-51118446 E-Mail: htwe.sales@cooperindustries.com www.coopertools.com