innovative materials for integrated solutions

advertisement

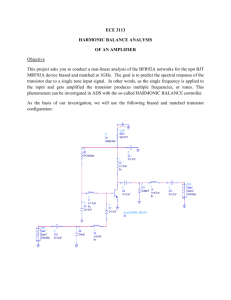

RF Absorbers | Microwave Absorbers | EMI Shielding Elastomers | High Temperature Coatings | Specialty Caulks | Customized Inks innovative materials for integrated solutions innovative materials for integrated solutions RF Absorbers | Microwave Absorbers | EMI Shielding Elastomers | High Temperature Coatings | Specialty Caulks | Customized Inks RF Absorbers Microwave Absorbers EMI Shielding Elastomers High Temperature Coatings Potting Compounds Specialty Caulks Customized Inks MAST Technologies is a global innovator and manufacturer of RF and microwave absorbing materials, EMI solutions, and high temperature coatings. MAST is a customer driven organization that prides itself on the ability to offer prompt and effective solutions from product selection through post sale support. MAST Technologies’ products are used by many of the world’s largest OEMs in industries from consumer electronics, military vehicles, military electronics, automotive, telecommunications, space, instrumentation, wireless communication, and medical devices. Demonstrating MAST Technologies’ commitment to innovation and new product development, MAST has been the recipient of multiple Small Business Innovation and Research (SBIR) contracts, and is proud to have brought the developed products to market. MAST Technologies was founded on the principles of providing best in class service with the highest quality products at prices that every customer can afford. CUSTOMER COMMITMENT MAST Technologies is unequivocally dedicated to the pursuit of one hundred percent customer satisfaction. Our goal is to continue to impress from our first interactions with a customer’s design, to prototyping, production, and post sale support. MAST Technologies is committed to prompt delivery of quotations, samples, and orders, commonly within 24 hours. ENGINEERING SUPPORT MAST Technologies is committed to providing a cost effective high performance solution. Engineering resources are always made available for customers to utilize whether it is simply for material selection or new product development. CUSTOMIZATION MAST Technologies prides itself on being a low cost leader in custom die cutting, kiss cutting, and fabricating products into ship-sets or kits. MAST Technologies also offers material “tuning”, wherein a material is optimized for a specific customer frequency, for little or no charge. ORDER YOUR FREE SAMPLE KIT TODAY! SAMPLE KITS MAST Technologies also offers a FREE sample kit program, where customers may evaluate several material options completely free of charge. ORDER YOUR FREE SAMPLE KIT TODAY! Please contact a MAST Technologies representative via email at: sales@masttechnologies.com or by completing our quick and easy Sample Kit Request Form at: www.masttechnologies.com w w w . m a s t t e c h n o l o g i e s . c o m RF ABSORBERS ) ncy absorbers, Tuned Frequency Absorbers (MR1 Series) y offering 20dB of can tune an Tuned Frequency Absorbers, also known as resonant frequency absorbers, provide great reflection nging the loss at a discrete frequency, typically offering 20dB of attenuation in a thin elastomeric solution. MAST Engineers can tune an absorber to any frequency from 1 to 100 GHz, by simply changing the formulation and thickness. (GHz) Thickness (in) 0.065 0.060 0.056 0.051 0.047 0.045 0.043 equency absorbers, 0.041 pically offering 20dB of 0.040 ries) Performance Specifications 0.010” to Operating 0.150” Temp (°F): Thicknesses: RoHS Compliant: Yes Sheet Sizes: UL94‐V0 Rated: Yes PSA Available: Tuned Frequency Absorbers Reflectivity Performance ‐60 to 375 12”x12”, 24”x24” 2 0.125 Frequency (GHz) 10 12 14 16 18 Frequency (GHz) 1.0 Thickness (in) Part Number Frequency (GHz) MR11-0012-00 12.0 0.135 MR11-0013-00 13.0 0.128 MR11-0014-00 14.0 0.095 MR11-0015-00 15.0 0.078 MR11-0016-00 16.0 0.081 MR11-0017-00 17.0 6.0 0.070 MR11-0018-00 18.0 7.0 0.062 Performance Specifications MR11-0031-00 20.6 8.0 0.053 0.010” to Operating MR11-0041-00 24.0 9.0 0.072 Thicknesses: ‐60 to 375 0.150” Temp (°F): MR11-0039-00 30.0 10.0 0.065 MR11-0034-00 12”x12”, 24”x24” 35.0 11.0 0.060 RoHS Compliant: Yes Sheet Sizes: Standard with ‐ UL94‐V0 Rated: Yes PSA Available: 01 suffix eries) Thickness (in) 0.056 0.051 0.047 0.045 0.043 0.041 0.040 0.043 0.042 0.038 0.035 Reflectivity (dB) -10 s and are intended to be MR11-0002-00 2.0 MR11-0003-00 3.0 e the Q of the cavity. Cavity MR11-0004-00 4.0 ngles of incidence at equency (GHz) Thickness (in) MR11-0005-00 5.0 0.065 MR11-0006-00 0.060 MR11-0007-00 0.056 MR11-0008-00 Thickness (in) 0.051 MR11-0009-00 0.047 0.070 MR11-0010-00 0.045 0.080 MR11-0011-00 0.090 0.043 0.100 0.041 0.040 8 -5 s) 10.0 11.0 12.0 GHz) 13.0 14.0 15.0 16.0 17.0 18.0 6 0 Standard with ‐ 01 suffix eers can tune an y changing the Part Number MR11-0001-00 4 -15 -20 -25 -30 -35 MR11-0004-00 MR11-0006-00 MR11-0008-00 MR11-0010-00 MR11-0012-00 MR11-0014-00 MR11-0016-00 MR11-0018-00 Performance Specifications 0.010” to Operating 0.150” Temp (°F): Cavity Resonance Absorbers (MR2 Series) Thicknesses: ‐60 to 375 gh loss and are intended to be RoHS Compliant: Yes Sheet Sizes: 12”x12”, 24”x24” reduce the Q of the cavity. Cavity Cavity Resonance Absorbers are designed to exhibit high loss and are Standard with ‐ high angles of incidence at UL94‐V0 Rated: Yes PSA Available: 01 suffix intended to be applied to metal surfaces inside microwave cavities to reduce the Q of the cavity. Cavity Resonance Absorbers attenuate quency (GHz) energy Thickness (in) at normal and high angles of incidence at frequencies from 1 GHz 4‐7 0.070 Wave Absorbers are designed to exhibit the highest loss and are 3‐7 0.080 to 40 GHz. d to be applied to metal surfaces for traveling or surface wave 2‐5 0.090 Cavity Resonance Absorbers 2‐5 0.100 ion. Surface Wave Absorbers attenuate traveling wave energy at 1‐3 0.125 cies from 1 GHz to 40 GHz. RoHS Compliant: Yes Sheet Sizes: UL94‐V0 Rated: Yes PSA Available: ‐60 to 375 Part Number MR31‐0001‐00 MR31‐0002‐00 MR31‐0003‐00 MR31‐0004‐00 MR31‐0005‐00 4‐7 MR21-0007-00 MR21-0006-00 MR21-0005-00 MR21-0004-00 Frequency (GHz) 14‐18 10‐14 8‐12 5‐8 4‐7 0.060 3-7 4-7 5-9 6-11 Thickness (in) 0.020 0.030 0.040 0.050 0.060 MR31‐0010‐00 0.080 0.070 0.060 0.050 Part Number MR31‐0006‐00 MR31‐0007‐00 MR31‐0008‐00 MR31‐0009‐00 MR31‐0010‐00 1‐3 MR21-0012-00 MR42-0008-00 MR42-0007-00 6 Frequency (GHz) 10 12 14 16 -5 -10 Standard with ‐ 01 suffix 0.125 16-26 0.5-18 0.8-18 Thickness (in) 0.040 0.030 0.020 0.010 0.080 0.040 -15 -20 -25 -30 MR21-0001-00 - 0.020 thk MR21-0003-00 - 0.040 thk MR21-0005-00 - 0.060 thk MR21-0007-00 - 0.080 thk MR21-0010-00 - 0.125 thk MR21-0002-00 - 0.030 thk -35 Frequency (GHz) 3‐6 3‐6 2‐4 2‐4 1‐3 8 12”x12”, 24”x24” rface Wave Absorbers are designed to exhibit the highest loss and are Number Frequency (GHz) Thickness (in) Part Number Frequency (GHz) Thickness (in) ‐0001‐00 14‐18 0.020 MR31‐0006‐00 3‐6 0.070 ended to be applied to metal surfaces for traveling or surface wave Part Number Frequency (GHz) Thickness (in) Part Number Frequency (GHz) ‐0002‐00 10‐14 0.030 MR31‐0007‐00 3‐6 0.080 MR21-0003-00 9-14 MR21-0010-00 1-3 0.125 enuation. Surface Wave Absorbers attenuate traveling wave energy at ‐0003‐00 8‐12 0.040 MR31‐0008‐00 2‐4 0.090 MR21-0002-00 13-17 MR21-0008-00 2-5 0.090 quencies from 1 GHz to 40 GHz. ‐0004‐00 5‐8 0.050 MR31‐0009‐00 2‐4 0.100 MR21-0001-00 14-18 MR21-0009-00 2-5 0.100 ‐0005‐00 4 0 Reflectivity (dB) ) Performance Specifications 0.010” to Operating 0.150” Temp (°F): Thicknesses: Reflectivity Performance 2 Thickness (in) 0.070 0.080 0.090 0.100 0.125 w w w . m a s t t e c h n o l o g i e s . c o m 18 Part Number MR11‐0001‐00 MR11‐0002‐00 MR11‐0003‐00 MR11‐0004‐00 MR11‐0005‐00 MR11‐0006‐00 MR11‐0007‐00 MR11‐0008‐00 MR11‐0009‐00 Frequency (GHz) 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 Thickness (in) 0.135 0.128 0.095 0.078 0.081 0.070 0.062 0.053 0.072 Part Number MR11‐0010‐00 MR11‐0011‐00 MR11‐0012‐00 MR11‐0013‐00 MR11‐0014‐00 MR11‐0015‐00 MR11‐0016‐00 MR11‐0017‐00 MR11‐0018‐00 Frequency (GHz) 10.0 11.0 12.0 13.0 14.0 15.0 16.0 17.0 18.0 Thickness (in) 0.065 0.060 0.056 0.051 0.047 0.045 0.043 0.041 0.040 Performance Specifications 0.010” to Operating 0.150” Temp (°F): Thicknesses: RF ABSORBERS asttechnologies.com Cavity Resonance Absorbers Series) Low Frequency Absorbers (MR5(MR2 Series) RoHS Compliant: Yes Sheet Sizes: UL94‐V0 Rated: Yes PSA Available: ‐60 to 375 12”x12”, 24”x24” Standard with ‐ 01 suffix MR51 Series Relative Permeability 60 50 MAST Technologies’ Low Frequency EMI Absorber product series is Cavity Resonance Absorbers are designed to exhibit high loss and are intended to be a magnetically loaded sheet stock having high loss at sub-microwave applied to metal surfaces inside microwave cavities to reduce the Q of the cavity. Cavity frequencies. Resonance Absorbers attenuate energy at normal and high angles of incidence at Low Frequency Absorbers are designed with shaped magnetic particles that exhibit high permeability at frequencies from frequencies from 1 GHz to 40 GHz. 500 MHz to 4 GHz. The Low Frequency Absorber product line is the Part Number Frequency (GHz) Part Number of Frequency (GHz) Thickness (in) thinnest of the MR series products, withThickness (in) standard thicknesses MR21‐0012‐00 16‐26 0.010 MR21‐0006‐00 4‐7 0.070 ) 0.006”, 0.010”, 0.020” and 0.040; other thicknesses and configurations MR21‐0001‐00 14‐18 0.020 MR21‐0007‐00 3‐7 0.080 MR21‐0002‐00 13‐17 0.030 MR21‐0008‐00 2‐5 0.090 are also available. MR21‐0003‐00 9‐14 0.040 MR21‐0009‐00 2‐5 0.100 Low Frequency EMI Absorber product series is a magnetically loaded MR5 Low Frequency Absorbers MR21‐0004‐00 0.050 Thickness MR21‐0010‐00 1‐3 0.125 Part Number6‐11 Frequency (GHz) (in) igh loss at sub‐microwave frequencies. Low Frequency Absorbers are Attenuation vs. Frequency Performance MR51 0001-005‐9 0.1-4.0 0.060 0.006 MR21‐0005‐00 MR51 0003-00 0.1-4.0 0.010 d magnetic particles which exhibit high permeability at frequencies from MR51 0002-00 0.05-4.0 0.020 Performance Specifications he Low Frequency Absorber product line is the thinnest of the MR series MR51 0006-00 0.05-4.0 0.040 0.010” to Operating Thicknesses: ard thicknesses of 0.006”, 0.010” and 0.020”; other thicknesses and Surface Wave Absorbers (MR3 Series) 0.150” Temp (°F): Relative Permeability 40 μ' μ'' 30 20 10 0 1 10 100 1000 Frequency [MHz] 14 12 ‐60 to 375 10 cy (GHz) 4.0 4.0 4.0 Thicknesses: Thickness (in) 0.006 0.020 0.010 ‐60 to 250 Attenuation (dB/cm) Performance Specifications 0.006” to 0.010” to Operating 0.040” 0.040” Temp (°F): 8 6 RoHS Compliant: Yes Sheet Sizes: 12”x12”, 24”x24” UL94‐V0 Rated: Yes PSA Available: Standard with ‐ 01 suffix RoHS Compliant: Yes Sheet Sizes: 12”x12”, 12”x24” Standard with ‐ UL94‐V0 Rated: Yes PSA Available: 01 suffix 02 Surface Wave Absorbers are designed to exhibit the highest loss and are o available. intended to be applied to metal surfaces for traveling or surface wave attenuation. Surface Wave Absorbers attenuate traveling wave energy at frequencies from 1 GHz to 40 GHz. Surface Wave Absorbers (MR3 Series) Surface Wave Absorbers Attenutaion vs. Frequency Performance Surface Wave Absorbers are designed to exhibit the highest loss and es) are intended to be applied to metal surfaces for traveling or surface wave attenuation. Surface Wave Absorbers attenuate traveling wave eries is a lightweight conductive energy at frequencies from 1 GHz to 40 GHz. crowave frequencies. Reticulated coating to exhibit high reflection Performance Specifications Part Number Frequency (GHz) Thickness (in) Part Number Frequency (GHz) Thickness (in) 0.010” to Operating de microwave cavities, housings, Thicknesses: ‐60 to 375 MR31‐0001‐00 14‐18 0.020 MR31‐0006‐00 3‐6 0.070 0.150” Temp (°F): oam Absorbers attenuate energy at MR31‐0002‐00 10‐14 0.030 MR31‐0007‐00 3‐6 0.080 RoHS Compliant: Yes Sheet Sizes: 12”x12”, 24”x24” 4 2 0 0.00 0.25 0.50 0.75 1.00 Frequency (GHz) 100 90 80 70 UL94‐V0 Rated: Yes PSA Available: Attenuation (dB/cm) 60 MR31‐0003‐00 MR31‐0004‐00 MR31‐0005‐00 Standard with ‐ 01 suffix Performance Specifications frequencies from 1 GHz to 100 0.375” – Operating ‐60 to 250 Part Number Frequency (GHz) Thickness (in) Part Number Frequency (GHz) GHz. 2.5” Temp (°F): MR31-0010-00 1-3 0.125 MR31-0005-00 4-7 Yes Sheet Sizes: 24”x24” MR31-0008-00 2-4 0.090 MR31-0004-00 5-8 Standard with ‐ MR31-0009-00 2-4 0.100 MR31-0003-00 8-12 No PSA Available: 01 suffix MR31-0006-00 3-6 0.070 MR31-0002-00 10-14 MR31-0007-00 3-6 0.080 MR31-0001-00 14-18 8‐12 5‐8 4‐7 40 30 0.040 0.050 0.060 1 2 3 4 5 Thicknesses: RoHS Compliant: UL94-V0 Rated: w.masttechnologies.com Yes 10-18Sheet Sizes: 6-18 N 2-18 PSA Available: 0.7-18 0.5-18 Performance Specificaons 0.125” – Opera ng 2.0” Temp (°F): Yes No Sheet Sizes: PSA Available: 0.125 24”x24” 0.250Standard with ‐ 0.500 01 suffix 1.0 1.5 6 7 8 9 10 11 12 13 14 15 16 17 18 Frequency (GHz) Lossy Foam Absorbers Insertion Loss Performance 0 2 4 6 Frequency (GHz) 8 10 12 14 16 0 -5 -10 -15 -20 Insertion Loss (dB) Thicknesses: Part Number RoHS Compliant: MF22-0001-00 MF22-0002-00 UL94‐V0 Rated: MF22-0003-00 MF22-0009-00 MF22-0014-00 0.090 0.100 0.125 0 insertion loss. Lossy Foam absorbers are the lowest cost solution Performance Specifications for attenuating energy at frequencies from 1 GHz to 100 GHz. Thickness (in) 0.125 0.250 0.500 2‐4 2‐4 1‐3 10 Lossy Foam Absorbers (MF2 Series) 0.125” – Operating ‐60 to 250 2.0” Frequency Temp (°F): (GHz) Thickness (in) MR31‐0008‐00 MR31‐0009‐00 MR31‐0010‐00 20 Thickness (in) 0.060 0.050 0.040 0.030 0.020 s’ Lossy Foam Absorber product series is a lightweight conductive carbon MAST Technologies’ Lossy Foam Absorber product series is a stock providing broadband insertion loss at microwave frequencies. Lossy lightweight conductive carbon impregnated sheet stock providing e designed with a constant coating to exhibit high insertion loss. Lossy broadband insertion loss at microwave frequencies. Lossy Foam e the lowest cost solution for attenuating energy at frequencies from 1 Absorbers are designed with a constant coating to exhibit high ncy (GHz) 0‐18 ‐18 ‐18 50 -25 -30 -35 -40 -60 to 250 -45 24”x24” -50 Standard with 01 suffix -55 MF22-0003-00 MF22-0002-00 MF22-0001-00 MF22-0009-00 18 sheet stock having high loss at sub‐microwave frequencies. Low Frequency Absorbers are designed with shaped magnetic particles which exhibit high permeability at frequencies from 500 MHz to 3 GHz. The Low Frequency Absorber product line is the thinnest of the MR series MAST Technologies’ Low Frequency EMI Absorber product series is a magnetically loaded products, with standard thicknesses of 0.006”, 0.010” and 0.020”; other thicknesses and uency Absorbers (MR5 Series) sheet stock having high loss at sub‐microwave frequencies. Low Frequency Absorbers are designed with shaped magnetic particles which exhibit high permeability at frequencies from Thicknesses: Part Number Frequency (GHz) Thickness (in) 500 MHz to 3 GHz. The Low Frequency Absorber product line is the thinnest of the MR series MR51‐0001‐00 0.05‐4.0 0.006 RoHS Compliant: products, with standard thicknesses of 0.006”, 0.010” and 0.020”; other thicknesses and MR51‐0002‐00 0.05‐4.0 0.020 Performance Specifications 0.010” to Operating 0.040” Temp (°F): SPECIALTY ABSORBING MATERIALS MR51‐0003‐00 0.05‐4.0 UL94‐V0 Rated: 0.010 Performance Specifications configuration are also available. 0.010” to Operating Part Number MR51‐0001‐00 MR51‐0002‐00 MR51‐0003‐00 Frequency (GHz) 0.05‐4.0 0.05‐4.0 0.05‐4.0 Thicknesses: Thickness (in) 0.006 0.020 0.010 0.040” Temp (°F): RoHS Compliant: Yes Sheet Sizes: UL94‐V0 Rated: Yes PSA Available: Reticulated Foam Absorbers (MF1 Series) Frequency (GHz) 8‐40 6‐40 5‐40 4‐40 Thickness (in) 0.500 0.750 1.000 1.250 RoHS Compliant: Sheet Sizes: UL94‐V0 Rated: No PSA Available: Yes Sheet Sizes: No PSA Available: ‐60 to 250 Frequency (GHz) 8 10 12 14 16 frequencies from 1 GHz to 100 GHz. 24”x24” Standard with ‐ 01 suffix -30 24”x24” -45 -50 Standard with ‐ MAST Technologies’ Lossy Foam Absorber product series is a lightweight conductive carbon MF11-0002-00 - 0.50 thk PN MF-11-0003-00 - 0.75 thk PN MF11-0004-00 - 1.0 thk PN MF11-0005-00 - 1.25 thk 01 suffix impregnated sheet stock providing broadband insertion loss at microwave frequencies. Lossy Foam Absorbers are designed with a constant coating to exhibit high insertion loss. Lossy Convoluted Foam Absorbers (MF3 Series) Foam absorbers are the lowest cost solution for attenuating energy at frequencies from 1 (MF3 Series) am Absorbers (MF2 Series) GHz to 100 GHz. Convoluted Foam Absorbers (MF3 Series) Performance Specifications Convoluted Foam Absorbers with ‐ ffix 18 Reflectivity (dB) 0.125” – Operating Reflectivity Performance Thicknesses: ‐60 to 250 orber product series is a lightweight conductive MAST Technologies’ Lossy Foam Absorber product series is a lightweight conductive carbon MAST Technologies’ Convoluted Foam Absorber product series is a lightweight conductive 2.0” Temp (°F): Part Number Frequency (GHz) Thickness (in) Frequency (GHz) MAST Technologies’ Convoluted Foam Absorber product series is a lightweight MF22‐0001‐00 10‐18 0.125 RoHS Compliant: Yes Sheet Sizes: broadband reflection loss at microwave impregnated sheet stock providing broadband insertion loss at microwave frequencies. Lossy 2 4 6 8 10 12 14 24”x24” 16 carbon impregnated sheet stock providing broadband reflection loss at microwave MF22‐0002‐00 6‐18 0.250 0 Standard with ‐ conductive carbon impregnated sheet stock providing broadband reflection UL94‐V0 Rated: N PSA Available: Foam Absorbers are designed with a constant coating to exhibit high insertion loss. Lossy MF22‐0003‐00 0.500 on Convoluted Foam Absorbers, they exhibit 01 suffix Convoluted Foam Absorbers (MF3 Series) 2‐18 frequencies. Due to the shape of the cones on Convoluted Foam Absorbers, they exhibit loss at microwave frequencies. Due to the shape of the cones on Convoluted -5 Foam absorbers are the lowest cost solution for attenuating energy at frequencies from 1 applied to metal surfaces inside test boxes, Foam Absorbers, they exhibit high reflection loss and are intended to be GHz to 100 GHz. high reflection loss and are intended to be applied to metal surfaces inside test boxes, -10 antennae. Reticulated Foam Absorbers MAST Technologies’ Convoluted Foam Absorber product series is a lightweight conductive inside test boxes, housings, radomes, network applied to metal surfaces Performance Specifications housings, radomes, network enclosures, or antennae. Reticulated Foam Absorbers -15 s of incidence at frequencies from 1 GHz to 100 0.125” – Operating Convoluted Foam Absorbers enclosures,carbon impregnated sheet stock providing broadband reflection loss at microwave orPart Number antennae.Frequency (GHz) attenuate energy at Thicknesses: ‐60 to 250 2.0” Temp (°F): Thickness (in) -20 attenuate energy at normal and high angles of incidence at frequencies from 1 GHz to 100 normal andfrequencies. Due to the shape of the cones on Convoluted Foam Absorbers, they exhibit high angles of incidence at0.125 frequencies from 1 GHz to 100 MF22‐0001‐00 10‐18 RoHS Compliant: Yes GHz. Sheet Sizes: 24”x24” GHz. MF22‐0002‐00 6‐18 0.250 -25 high reflection loss and are intended to be applied to metal surfaces inside test boxes, Standard with ‐ UL94‐V0 Rated: N PSA Available: MF22‐0003‐00 2‐18 0.500 01 suffix housings, radomes, network enclosures, or antennae. Reticulated Foam Absorbers www.masttechnologies.com GHz. -30 250 Part Number Frequency (GHz) Thickness (in) Performance Specifications attenuate energy at normal and high angles of incidence at frequencies from 1 GHz to 100 MF32‐0001‐00 10‐100 1.500 -35 24” 18 frequencies from 1 GHz to 100 -40 Performance Specifications Operating ‐60 to 250 Series) Lossy 0.375” – Foam Absorbers (MF2 GHz. 2.5” Temp (°F): Yes Standard with ‐ 01 suffix Reticulated Foam Absorbers Reflectivity Performance -35 Thicknesses: RoHS Compliant: PSA Available: Standard with ‐ 01 suffix Performance Specifications -20 0.375” – Operating 2.5” Temp (°F): -25 UL94‐V0 Rated: Yes ‐60 to 250 12”x12”, 12”x24” ‐60 to 250 Reflectivity (dB) Thicknesses: Sheet Sizes: 12”x12”, 12”x24” MAST Technologies’ Reticulated Foam Absorber product series is a Series) lightconfiguration are also available. Reticulated Foam Absorbers (MF1 weight conductive carbon loaded sheet stock providing broadband loss at microwave frequencies. Reticulated Foam Absorbers are designed with a MAST Technologies’ Reticulated Foam Absorber product series is a lightweight conductive 2 4 6 carbon loaded sheet stock providing broadband loss at microwave frequencies. Reticulated continuous gradient coating to exhibit high reflection loss and are in0 Foam Absorbers are designed with a continuous gradient coating to exhibit high reflection tended to be applied to metal surfaces inside microwave cavities, housings, -5 ed Foamradomes, Absorbers (MF1 Series) loss and are intended to be applied to metal surfaces inside microwave cavities, housings, network enclosures, or antennae. Reticulated Foam Absorbers -10 radomes, network enclosures, or antennae. Reticulated Foam Absorbers attenuate energy at attenuate energy at normal and high angles of incidence at frequencies normal and high angles of incidence at ologies’ Reticulated Foam Absorber product series is a lightweight conductive -15 from 1 GHz to 100 GHz. d sheet stock providing broadband loss at microwave frequencies. Reticulated Part Number Frequency (GHz) Thickness (in) ers are designed with a continuous gradient coating to exhibit high reflection MF11‐0002‐00 8‐40 0.500 ntended to be applied to metal surfaces inside microwave cavities, housings, MF11‐0003‐00 6‐40 0.750 MF11‐0004‐00 5‐40 1.000 work enclosures, or antennae. Reticulated Foam Absorbers attenuate energy at MF11‐0005‐00 4‐40 1.250 igh angles of incidence at Yes MF32‐0003‐00 Thicknesses: Operating 4‐40 1.5” – 4.0” 3.000 Temp (°F): Performance Specifications RoHS Compliant: Yes Thicknesses: 1.5” – 4.0” Operating Temp (°F): N Yes Sheet Sizes: UL94‐V0 Rated: RoHS Compliant: Sheet Sizes: ‐60 to 250 PSA Available: 24”x24” Standard with ‐ www.masttechnologies.com N PSA Available: 01 suffix ‐60 to 250 GHz. Standard with ‐ 01 suffix Series) Absorber Compounds (MC10 Series) s are magnetically loaded RF absorber / microwave UL94‐V0 Rated: 24”x24” Part Number MF32‐0001‐00 MF32‐0003‐00 -40 -45 -50 Frequency (GHz) 10‐100 4‐40 Part Number MF32‐0001‐00 MF32‐0003‐00 Thickness (in) 1.500 MF32-0001-00 3.000 Frequency (GHz) 10‐100 4‐40 MF32-0002-00 ally equivalent to the MAST Technologies MR2 Cavity MAST Technologies’Absorber absorptive compounds are magnetically loaded Series) RF absorber / Compounds (MC10 Absorber Compounds (MC10 Series) m tailored to a specific electrical performance. The microwave absorber materials fabricated to be electrically equivalent to the MAST r two part systems in a variety of viscosities. Technologies MR2 Cavity Resonance sheet products, or can be custom tailored to MAST Technologies’ absorptive compounds are magnetically loaded RF absorber / microwave MAST Technologies’ absorptive compounds are magnetically loaded RF absorber / microwave ntities for prototyping and test, or in production via a specific electrical performance. The materials can be manufactured using one or absorber materials fabricated to be electrically equivalent to the MAST Technologies MR2 Cavity two part systems inabsorber materials fabricated to be electrically equivalent to the MAST Technologies MR2 Cavity a variety of viscosities. Absorber caulk can be used for protoResonance sheet products, or can be custom tailored to a specific electrical performance. The Part Number Frequency (GHz) Resonance sheet products, or can be custom tailored to a specific electrical performance. The typing and test, or in production via automated dispensing systems. MC10‐0014‐03 ‐20 dB @ 6 GHz materials can be manufactured using one or two part systems in a variety of viscosities. kages: (0.070″) materials can be manufactured using one or two part systems in a variety of viscosities. Absorber caulk can be used for in small quantities for prototyping and test, or in production via MC10‐0018‐03 ‐20 dB @ 10 GHz 5, 2.5, 6, 8 oz. (0.065″) Absorber caulk can be used for in small quantities for prototyping and test, or in production via automated dispensing systems. Typical Applications: Product Packages: Part Number Frequency (GHz) • Potting Compound • SEM-Kits: 1.5, 2.5, 6,MC10‐0014‐03 8 oz. automated dispensing systems. ‐20 dB @ 6 GHz Product Packages: Typical Applications: • Quart • Electrical Encapsulant Part Number Frequency (GHz) (0.070″) MC10‐0018‐03 ‐20 dB @ 10 GHz MC10‐0014‐03 SEM‐Kits: 1.5, 2.5, 6, 8 oz. Potting Compound ‐20 dB @ 6 GHz • Gallon • Form-In-Place Product Packages: (0.065″) Typical Applications: (0.070″) Quart • 5 gal Pail Electrical Encapsulant • Caulk MC10‐0018‐03 ‐20 dB @ 10 GHz SEM‐Kits: 1.5, 2.5, 6, 8 oz. Potting Compound Gallon Form‐In‐Place • Sheet Seams (0.065″) nds (MC10 Series) 5 gal Pail Quart Caulk Electrical Encapsulant Sheet seams Gallon Form‐In‐Place and ink materials can meet a variety of demanding electrical and 5 gal Pail Caulk resistive fillers to achieve specific surface or volume Electrically Resistive Compounds (MC10 Series) Sheet seams ypes and viscosities. MAST Technologies has standard off the Thickness (in) 1.500 3.000 www.masttechnologies.com www.masttechnologies.com m Absorber product series is a lightweight conductive EMI SHIELDING SOLUTIONS PICTURE HERE EMI SHIELDING SOLUTIONS PICTURE HERE iding broadband reflection loss at microwave MAST-O-Shield™ Conductive Elastomers (ME1 Series) cones on Convoluted Foam Absorbers, they exhibit to be applied to metal surfaces inside test boxes, MAST Technologies’ MAST‐O‐Shield™ solid silicone elastomers are specially impregnated with es, or antennae. Reticulated Foam Absorbers electrically conductive fillers to provide shielding against electromagnetic interference (EMI). These angles of incidence at frequencies from 1 GHz to 100 MAST-O-Shield™ Conductive Elastomers (ME1 Series) EMI SHIELDING SOLUTIONS MAST-O-Shield™ Conductive Elastomers (ME1time Series) ilicone based elastomers offer EMI shielding for extended and temperature exposure applications, while resisting compression set. The nickel graphite impregnated materials offer a MAST Technologies’ MAST‐O‐Shield™ solid silicone elastomers are specially impregnated with GHz. MAST Technologies’ MAST‐O‐Shield™ solid silicone elastomers are specially impregnated with MAST-O-Shield™ Conductive Elastomers (ME1 Series) moderate cost shielding material which provides excellent shielding effectiveness for aluminum and electrically conductive fillers to provide shielding against electromagnetic interference (EMI). These electrically conductive fillers to provide shielding against electromagnetic interference (EMI). These tainless housing gaskets. offer These materials are available in sheet stock, die‐cut, or custom conductive fillers to pro‐60 to 250 steel silicone based elastomers offer EMI shielding for extended time temperature exposure MAST Technologies’ MAST-O-Shield™ silicone elastomers are specially impregnated with electrically Part Number Frequency (GHz) Thickness (in) silicone based elastomers EMI solid shielding for extended time and and temperature exposure applications, while resisting compression set. The nickel graphite impregnated materials offer MF32‐0001‐00 10‐100 1.500 molded forms. shieldingwhile against electromagnetic interference (EMI). graphite These silicone based elastomers offera EMIa shielding for extended time and applications, resisting compression set. The nickel impregnated materials offer 24”x24” vide MF32‐0003‐00 4‐40 3.000 moderate cost shielding material which provides excellent shielding effectiveness for aluminum and exposure applications while resisting compression set. The nickel graphite impregnated materials offer a moderate cost moderate cost shielding material which provides excellent shielding effectiveness for aluminum and Standard with ‐temperature stainless steel housing gaskets. These materials are available in sheet stock, or custom 01 suffix shielding material that provides shielding effectiveness aluminum and die‐cut, stainless steel housing gaskets. These materials are stainless steel housing gaskets. excellent These materials are available in for sheet stock, die‐cut, or custom Part Number Compound Thickness (in) molded forms. Typical Properties by Compound available in sheet stock, die-cut, or custom molded forms. molded forms. ME11‐0001‐00 SNiG45 0.032 Test Method SNiG45 SNiG55 SNiG65 Elastomer Type Silicone Silicone Silicone Typical Properties by Compound Typical Properties by Compound Conductive Filler Nickel/Graphite Nickel/Graphite Nickel/Graphite Test Method SNiG45 SNiG55 SNiG65 SNiG45 SNiG55 SNiG65 Sheet Thickness (in) Test Method 0.020 – 0.125 0.020 – 0.125 0.020 – 0.125 Elastomer Type Silicone Silicone Silicone Elastomer Type Silicone Silicone Silicone Volume Resistivity (ohm‐cm max) ASTM D991 0.1 0.1 0.1 Conductive Filler Nickel/Graphite Nickel/Graphite Nickel/Graphite Conductive Filler Nickel/Graphite Nickel/Graphite Nickel/Graphite Hardness (Shore A) 65 ±7 Sheet Thickness (in) ASTM D2240 45 ±7 0.020 – 0.125 55 ±7 0.020 – 0.125 0.020 – 0.125 Sheet Thickness (in) 0.020 – 0.125 0.020 – 0.125 0.020 – 0.125 Volume Resistivity (ohm‐cm max) ASTM D991 0.1 Specific Gravity ASTM D297 2.0 0.1 0.1 2.2 2.3 0.1 Volume Resistivity (ohm‐cm max) ASTM D991 0.1 0.1 Hardness (Shore A) ASTM D412 ASTM D2240 55 ±7 Tensile Strength (PSI) 300 45 ±7 45 ±7 300 300 65 ±7 Hardness (Shore A) ASTM D2240 55 ±7 65 ±7 Specific Gravity ASTM D297 2.2 Elongation (%) ASTM D412 300 2.0 2.0 300 300 2.3 Specific Gravity ASTM D297 2.2 2.3 ounds are magnetically loaded RF absorber / microwave Tensile Strength (PSI) ASTM D412 300 300 300 Tensile Strength (PSI) ASTM D412 300 300 300 Tear Strength Die B ASTM D624 65 65 65 Elongation (%) ASTM D412 300 300 300 Elongation (%) 300 300 300 lectrically equivalent to the MAST Technologies MR2 Cavity Color ASTM D412 Dark Grey Dark Grey Dark Grey Tear Strength Die B ASTM D624 65 65 65 C10 Series) Tear Strength Die B ASTM D624 65 Color Dark Grey custom tailored to a specific electrical performance. The Color Dark Grey one or two part systems in a variety of viscosities. all quantities for prototyping and test, or in production via 65 65 Dark Grey Dark Grey Dark Grey Dark Grey ME11‐0002‐00 SNiG45 Electrically Conductive Compound (MC10 Series) Electrically Conductive Compound (MC10 Series) Series) Electrically Conductive Compound (MC10 Series) Electrically Conductive Compound (MC10 Part Number MC10‐0014‐03 Frequency (GHz) ‐20 dB @ 6 GHz MASTMAST Technologies’ suite of conductive caulk and ink materials can meet a variety of demanding Technologies’ suite of conductive caulk and ink materials can meet a variety ct Packages: (0.070″) MAST Technologies’ suite of conductive caulk and ink materials can meet a variety of demanding of demanding electrical and environmental specifications. MAST utilizes electrically MC10‐0018‐03 ‐20 dB @ 10 GHz electrical and environmental specifications. MAST utilizes electrically conductive fillers to its: 1.5, 2.5, 6, 8 oz. electrical and environmental specifications. MAST utilizes electrically conductive fillers to (0.065″) conductive fillers to achieve specific surface or volume conductivities in a variety of achieve specific surface or volume conductivities in a variety of different binder types and MAST Technologies’ suite of conductive caulk and ink materials can meet a variety of demanding electrical and environmental specifications. MAST utilizes electrically conductive fillers to achieve specific surface or volume conductivities in a variety of different binder types and achieve specific surface or volume conductivities in a variety of different binder types and different binder types and viscosities. MAST Technologies has standard off the shelf viscosities. MAST Technologies has standard off the shelf products but specialized in customizing viscosities. MAST Technologies has standard off the shelf products but specialized in customizing products but specializes in customizing these materials for targeted applications, viscosities. MAST Technologies has standard off the shelf products but specialized in customizing these materials for targeted applications, levels of resistivity, and environmental attributes. these materials for targeted applications, levels of resistivity, and environmental attributes. ail levels of resistivity, and environmental attributes. hese materials for targeted applications, levels of resistivity, and environmental attributes. Part Number Volume Resistivity Elastomer Filler Type Part Number Volume Resistivity Elastomer Filler Type MC10‐0019‐03 <100mΩ‐cm Silicone Nickel/Graphite Caulk MC10‐0019‐03 <100mΩ‐cm Silicone Nickel/Graphite Caulk Part Number mpounds (MC10 Series) Volume Resistivity MC10‐0019‐03 <100mΩ‐cm Elastomer Silicone Filler Nickel/Graphite Type Caulk caulk and ink materials can meet a variety of demanding electrical and Oriented Wire Elastomers (ME2 Series) utilizes resistive fillers to achieve specific surface or volume Oriented Wire Elastomers (ME2 Series) (MC10 Electrically Resistive Compounds Series) nder types and viscosities. MAST Technologies has standard off the MAST Technologies’ Oriented Wire Silicone is a solid silicone elastomer filled with micro‐wires MAST Technologies’ suite of resistive caulk and ink materials can meet a variety of demanding MAST Technologies’ Oriented Wire Silicone is a solid silicone elastomer filled with micro‐wires Oriented Wire Elastomers (ME2 Series) omizing these materials for targeted applications, levels of resistivity, providing high levels of EMI shielding effectiveness. Each wire is positioned normal to the electrical and environmental specifications. MAST utilizes resistive fillers to achieve specific surface providing high levels of EMI shielding effectiveness. Each wire is positioned normal to the flange mating surface and is crimped at the end to ensure proper contact with the surface of or volume resistivities in a variety of different binder types and viscosities. MAST Technologies has flange mating surface and is crimped at the end to ensure proper contact with the surface of the elastomer. The outer silicone provides environmental or pressure sealing, making the MAST Technologies’ Oriented Wire Silicone is a solid silicone elastomer filled with micro‐wires standard off the shelf products but specializes in customizing these materials for targeted the elastomer. The outer silicone provides environmental or pressure sealing, making the entire product useful in industrial, military and commercial applications that require EMI providing high levels of EMI shielding effectiveness. Each wire is positioned normal to the ct Packages: entire product useful in industrial, military and commercial applications that require EMI applications, levels of resistivity, and environmental conditions. shielding and environmental sealing with moderate closure force. shielding and environmental sealing with moderate closure force. lange mating surface and is crimped at the end to ensure proper contact with the surface of its: 1.5, 2.5, 6, 8 oz. Typical Properties Volume Typical Properties Part Number Compound Type Resin Type he elastomer. The outer silicone provides environmental or pressure sealing, making the Solid Silicone: A‐A‐59588, Class II, Grade 40 Resistivity (Ω‐cm) Solid Silicone: A‐A‐59588, Class II, Grade 40 Thickness: 0.032” or 0.062” (0.81 or 1.58 mm) MC10‐0016‐01 Caulk Silicone 25 entire product useful in industrial, military and commercial applications that require EMI Thickness: 0.032” or 0.062” (0.81 or 1.58 mm) Part Number Thickness (in) Length (in) MC10‐0017‐01 Caulk Silicone 50 Compression Set (@ 50psi): 2% Part Number Thickness (in) Length (in) Compression Set (@ 50psi): 2% hielding and environmental sealing with moderate closure force. ail 0.032 36 MT‐3 Series Water Based Ink Latex ME21‐0001‐00 100‐1000 ME21‐0001‐00 Color/Seal: Grey / Waterproof Color/Seal: Grey / Waterproof Typical Properties MT‐10 Series Ink Drum Operating Temperature: ‐60°C to 260°C Operating Temperature: ‐60°C to 260°C MTL‐21 Series Water‐Based Ink EMP Survivability: Yes Solid Silicone: A‐A‐59588, Class II, Grade 40 EMP Survivability: Yes MT‐29 Series Ink Monel Wire: QQ‐N‐281 Class A Thickness: 0.032” or 0.062” (0.81 or 1.58 mm) Monel Wire: QQ‐N‐281 Class A Density/sq in.: 900 ±15% Density/sq in.: 900 ±15% Compression Set (@ 50psi): 2% Diameter: 0.0035’’/0.0045 Diameter: 0.0035’’/0.0045 Color/Seal: Grey / Waterproof Typical Applications: Operating Temperature: ‐60°C to 260°C • Concealment EMP Survivability: Yes • Sprayable Paint Monel Wire: QQ‐N‐281 Class A • Caulk Density/sq in.: 900 ±15% • RF Components Diameter: 0.0035’’/0.0045 • Resistive Ink ME21‐0002‐00 ME21‐0002‐00 Phenolic ME21‐0003‐00 ME21‐0003‐00 Phenolic ME21‐0004‐00 ME21‐0004‐00 Polyimide ME21‐0005‐00 ME21‐0005‐00 ME21‐0006‐00 Part Number ME21‐0006‐00 ME21‐0001‐00 0.032 0.032 0.032 200‐1000 0.032 0.032 200‐1000 0.062 0.062 200‐1000 0.062 0.062 0.062 Thickness (in) 0.062 0.032 ME21‐0002‐00 Product Packages: 0.032 0.032 • ME21‐0003‐00 SEM-Kits: 1.5, 2.5, 6, 8 oz. 0.062 • ME21‐0004‐00 Quart ME21‐0005‐00 0.062 • ME21‐0006‐00 Gallon 0.062 • 5 gal Pail • 30 gal Drum 0.062 Part Number Compound Thickness (in) ME11‐0003‐00 0.093 Part Number Compound SNiG45 Thickness (in) ME11‐0001‐00 SNiG45 0.032 0.125 ME11‐0004‐00 SNiG45 ME11‐0001‐00 SNiG45 0.032 ME11‐0002‐00 SNiG45 0.062 ME11‐0002‐00 SNiG45 ME11‐0005‐00 SNiG55 0.062 0.093 0.032 ME11‐0003‐00 SNiG45 ME11‐0003‐00 SNiG45 0.093 ME11‐0006‐00 SNiG55 ME11‐0004‐00 SNiG45 0.125 0.062 ME11‐0004‐00 SNiG45 0.125 ME11‐0007‐00 SNiG55 ME11‐0005‐00 SNiG55 0.032 0.093 ME11‐0005‐00 SNiG55 0.032 ME11‐0006‐00 SNiG55 ME11‐0008‐00 SNiG55 0.062 0.062 0.125 ME11‐0006‐00 SNiG55 ME11‐0007‐00 SNiG55 ME11‐0007‐00 SNiG55 ME11‐0009‐00 SNiG65 0.093 0.093 0.032 ME11‐0008‐00 SNiG55 0.125 ME11‐0008‐00 ME11‐0010‐00 SNiG55 SNiG65 0.125 0.062 ME11‐0009‐00 SNiG65 0.032 ME11‐0009‐00 SNiG65 0.032 ME11‐0011‐00 SNiG65 ME11‐0010‐00 SNiG65 0.062 0.093 ME11‐0010‐00 SNiG65 0.062 ME11‐0012‐00 SNiG65 ME11‐0011‐00 SNiG65 0.093 0.125 ME11‐0011‐00 SNiG65 0.093 ME11‐0012‐00 SNiG65 0.125 ME11‐0012‐00 SNiG65 0.125 36 36 36 36 36 36 36 36 36 36 36 Length (in) 36 36 36 36 36 36 Width (in) Width (in) 3 3 6 6 9 9 3 3 6 6 9 Width (in) 9 w w w . m a s t t e c h n o l o g i e s . c o m 3 6 9 3 6 9 w w w . m a s t t e c h n o l o g i e s . c o m w w w . m a s t t e c h n o l o g i e s . c o m MANUFACTURING OPERATIONS MAST Technologies’ manufacturing operations are centered in its San Diego, California, USA state of the art manufacturing facility. MAST Technologies continues to invest in the latest manufacturing technologies providing the following in house production and test capabilities: • • • • • • • • • • • Compression Molding Liquid Injection Molding Elastomer Compounding Two Roll Milling Planetary Mixing Ball Milling High Shear Dispersion Spray Coating Application Dip Coating Application Die Cutting Kiss Cutting MAST Technologies’ complete in-house capabilities allow for quick turn prototypes and high volume production while maintaining full accountability and quality. In house die cutting capability allows for MAST to produce high precision die cut and kiss cut parts either in small volume or in mass production. QUALITY At MAST Technologies, quality begins with product design. Every new design, raw material, manufacturing process, quality inspection, and shipment is held to the highest quality control standards. MAST Technologies believes that quality is not an opportunity, but rather an expectation. MAST Technologies works closely with customers to establish a quality control program for their specific needs while adhering to the ISO 9001:2008 and AS9100 standards. MAST Technologies has invested in precision measurement equipment and tools for in process and final product quality control testing. Some of our test capabilities are: • • • • • • • • • • • Vector Network Analyzer (0.2-20 GHz) NRL Arch Testing (0.7 – 20 GHz) Transmission Tunnel Testing (0.7 – 20 GHz) 7mm Airline Testing Bulk Resistivity Testing Universal Tester - Tensile, Elongation & Tear Precision Thickness Mapping Durometer Box Furnace (RT - 2000°F) Hegman Grind Gauge Viscometer 1S09001:2008, AS9100C Certified. ITAR Registered. w w w . m a s t t e c h n o l o g i e s . c o m RF Absorbers | Microwave Absorbers | EMI Shielding Elastomers | High Temperature Coatings | Specialty Caulks | Customized Inks MAST Technologies 6370 Nancy Ridge Drive, Ste 103 San Diego, CA 92121 p: (858) 452-1700 | f: (858) 452-1702 General Inquiries: info@masttechnologies.com Sales Inquiries: sales@masttechnologies.com © MAST TECHNOLOGIES 2013 REV 5-2013 w w w . m a s t t e c h n o l o g i e s . c o m