Bulletin No. 42.2:RP

March 2000

42000 Series Rotary Eccentric-Plug

Control Valve

The 42000 Series control valve features Technology, Economy,

and Compact Size. The package is a state-of-the-art rotary

eccentric-plug control valve, available with an integral digital

controller. The 42000 control valve can be used for a variety of

fluids in both industrial process and utility applications.

Technology

Aerodynamically Contoured Plug-Eliminates flow-induced

torque reversals.

Stepped Seat Ring-Provides staged pressure drop to reduce

noise, vibration, or cavitation at small plug openings.

CoCr-A (Alloy 6) Hard Facing on Seat and Plug (optional)Available for mildly erosive applications (small size valves

include cast CoCr-A plug as standard).

PTFE Seat for Class VI Shutoff (optional)-Metal backup seat

helps prevent cold flow of the seat and provides a backup Class

IV shutoff.

NACE Construction (optional)-Materials in compliance with

the National Association of Corrosion Engineers (NACE)

standard MR0175.

Gasketed Seat Ring-Prevents wire-draw erosion between valve

body and seat ring, permitting use of carbon steel bodies in

saturated condensate and wet steam services.

Noise Attenuator Disc (optional)-Can be installed on new or

existing installations to reduce noise. Special body or piping

modifications are not required (available for 2”-6”sizes).

Digital Control and Remote Diagnostics- FIELDVUETM digital valve controller maximizes flexibility by providing auto calibration, programmable flow characteristics, adjustable gain,

travel limits, and position transmission.

Excellent Sealing Capabilities-Optional ENVIRO-SEAL®

packing systems are designed to provide excellent sealing,

guiding, and loading force transmission. The superior seal of

the ENVIRO-SEAL system can control emissions to below

the EPA (Environmental Protection Agency) limit of 500 ppm

(parts per million). Available with single PTFE or graphite packing materials.

H.D. BAUMANN, INC. 2000; All Rights Reserved

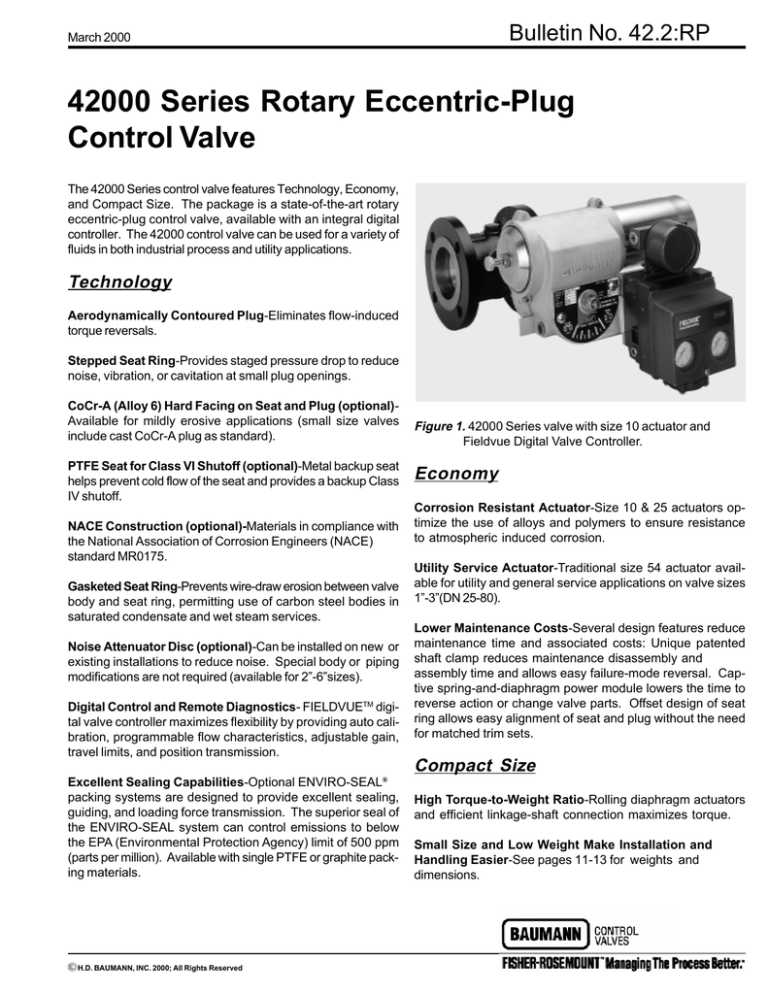

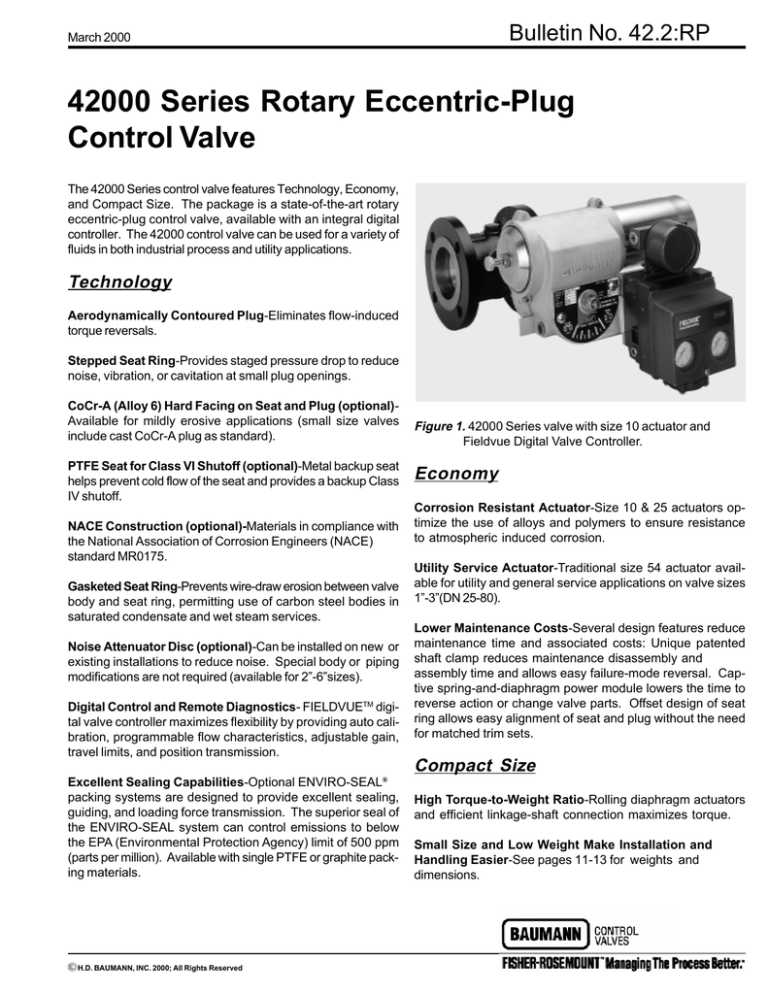

Figure 1. 42000 Series valve with size 10 actuator and

Fieldvue Digital Valve Controller.

Economy

Corrosion Resistant Actuator-Size 10 & 25 actuators optimize the use of alloys and polymers to ensure resistance

to atmospheric induced corrosion.

Utility Service Actuator-Traditional size 54 actuator available for utility and general service applications on valve sizes

1”-3”(DN 25-80).

Lower Maintenance Costs-Several design features reduce

maintenance time and associated costs: Unique patented

shaft clamp reduces maintenance disassembly and

assembly time and allows easy failure-mode reversal. Captive spring-and-diaphragm power module lowers the time to

reverse action or change valve parts. Offset design of seat

ring allows easy alignment of seat and plug without the need

for matched trim sets.

Compact Size

High Torque-to-Weight Ratio-Rolling diaphragm actuators

and efficient linkage-shaft connection maximizes torque.

Small Size and Low Weight Make Installation and

Handling Easier-See pages 11-13 for weights and

dimensions.

Figure 2. Valve Body Cross Section

Table 1: Materials of Construction: Valve Body Subassembly

ITEM QTY

1

1

Valve Body

2

1

Seat Ring Retainer

3

2

DESCRIPTION

1

MATERIAL

WCC steel

DIN 1.0619 steel

CF8M / 316 stainless steel

DIN 1.4408 stainless steel

CF8M / 316 stainless steel

Seat Ring, Metal Seat

S31600 stainless steel (standard for all sizes)

Solid Alloy 6 (optional for sizes1" & 1-1/2")

S31600 stainless steel with CoCr-A (Alloy 6) seating surface (optional for sizes 2"- 6")

Seat Ring, PTFE Seat

S31600 stainless steel / PTFE insert

S31600 stainless steel (standard for sizes 1" & 1-1/2")

Graphite (standard for sizes 2"- 6")

Solid Alloy 6 (standard for sizes 1" & 1-1/2")

Chrome-plated CF8M (316 stainless steel) (standard for sizes 2"-6")

CF8M / 316 stainless steel with CoCr-A (Alloy 6) overlay (optional for sizes 2"- 6")

4

1

Gasket

5

1

Valve Plug

6

1

Noise Attenuator Disc

7

1

Shaft

8

1

Guide Bushing

9

1

Guide Bushing

440C stainless steel (standard for WCC valve body)

PEEK/PTFE (standard for 316 stainless steel valve body, optional for WCC valve body) NACE compliant

Alloy 6 (optional) NACE compliant

10

2

Shaft Retainer

CF8M / 316 stainless steel

11

1

Spacer

S31600 stainless steel

12

6

Packing Ring

PTFE / graphite split ring

13

1

CF8M / 316 stainless steel (optional 2"- 6")

S31600 stainless steel (condition A)

Packing Follower Assembly S30400 stainless steel, fiberglass/PTFE, fluoroelastomer o-rings

14

1

Packing Flange

15

1

Bracket

16

2

Bolt

17

2

Packing Box Stud

18-8 stainless steel

CF8 (304 stainless steel)

A193 B8M (stainless steel)

18

2

Hex Nut

19

2

Lock Washer

S30400 stainless steel

A194 Grade 8M (stainless steel)

20

1

Retention Bolt

F738M Class A4-70 316 stainless steel

21

1

Gasket

S31600 stainless steel

22

2

Spacer

18-8 stainless steel

23

1

Packing Box Ring

S31600 stainless steel

Table 2: Valve Body Specifications

SPECIFICATION DATA

(1)

SIZES

1", 1-1/2", 2", 3", 4", 6"

DN 25, 40, 50, 80, 100, 150

END CONNECTIONS

ANSI 150 RF and 300 RF

DIN PN 10, 16, 25, 40

MAXIMUM INLET PRESSURE

Consistent with applicable ANSI (B16.34) or DIN flange ratings and body materials.

MAXIMUM PRESSURE DROPS

See Tables 9 - 11

SHUT-OFF CLASSIFICATION

ANSI/FCI 70-2 1991 and per IEC 534-4

Metal Seat - Class IV, PTFE Seat - Class VI

FLOW CHARACTERISTICS

Linear (1)

FLOW DIRECTION

Forward Flow (Into the face of the plug)

RANGEABILITY

100:1

VALVE PLUG ROTATION

60 degrees

OPTIONAL

Noise Attenuator Disc (2"- 6")

Additional flow characteristics available depending on choice of positioner.

Table 3: Actuator Specifications

SPECIFICATION DATA

ACTUATORS

10, 25

STYLE

54R

Spring return rolling diaphragm, single acting

MAXIMUM DESIGN PRESSURE

150 psi (10 bar)

35 psi (2.5 bar)

RECOMMENDED OPERATING PRESSURE

70 psig (4.8 bar)

See Tables 9 - 11

20 psig (1.4 bar)

AMBIENT TEMPERATURE RANGE

-40o F to 180o F (-40o C to 82o C)

-20o F to 160o F (-40o C to 82o C)

OPTIONAL

Handwheel, Travel Stops (see table 22)

Table 4: Operating Temperature Range

BODY

SEAT

GUIDE BUSHING

Metal

440C SST

PEEK/PTFE (optional)

Alloy 6 (optional)

WCC Steel

-20 to 750

-29 to 400

-20 to 450

-29 to 232

-320 to 500

-320 to 750

-196 to 260

-196 to 400

-320 to 450

-196 to 232

440C SST

PTFE

(optional)

Metal

316 SST

PROCESS TEMPERATURE RANGE

o

o

F

C

-20 to 750

-29 to 400

-20 to 500

-29 to 260

PTFE

(optional)

PEEK/PTFE (optional)

Alloy 6 (optional)

PEEK/PTFE

Alloy 6 (optional)

PEEK/PTFE

Alloy 6 (optional)

3

Figure 3. 42000 series valve with size 10 actuator and

Fieldvue Digital Valve Controller

Figure 4. 42000 series valve with size 54R actuator

and 3660 Pneumatic Valve Positioner

Table 5: Packing Systems

PROCESS TEMPERATURE RANGE

TYPE

o

Standard Packing

(1) (2)

DESCRIPTION

o

F

C

PTFE/Graphite split ring

-320 to 750

-196 to 400

Single PTFE V-ring

-50 to 450 (500 PPM Service)

-46 to 232

Graphite

20 to 600 (500 PPM Service)

-7 to 316

ENVIRO-SEAL

(1)

Packing temperature ranges are not material property ratings but reflect acceptable process temperature ranges, assuming valve body neck is

uninsulated and the proper valve constructions are selected (see table 4).

(2)

See Fisher bulletin 59.1:062 for specific material temperature ratings for ENVIRO-SEAL® packing system temperatures.

Braided PTFE/Graphite

Split Rings

Figure 5.

Standard Packing System

4

PTFE

ENVIRO-SEAL

Graphite

ENVIRO-SEAL

Figure 6.

Optional Packing Systems

MODEL NUMBERING SYSTEM

ACTUATOR

10

VALVE

BODY MATERIAL

42

25

42S

TRIM

NUMBER

WCC

477

316 SST

54R

VALVE SIZE

in

DN

1 & 1-1/2

25 & 40

2, 3, 4, & 6 50, 80, 100, & 150

1 & 1-1/2

488

499

500

25 & 40

2, 3, 4, & 6 50, 80, 100, & 150

SEAT RING

SEAT

LEAKAGE

316 Stainless Steel with

PTFE seating surface

CL VI

PLUG

Solid Alloy 6

Chrome-Plated 316

Stainess Steel

Solid Alloy 6

Chrome-Plated 316

Stainess Steel

316 Stainless Steel

316 Stainless Steel with

CoCr-A (Alloy 6)

seating surface

1 & 1-1/2

25 & 40

Solid Alloy 6

Solid Alloy 6

316 Stainless Steel with

316 Stainess Steel with

CoCr-A (Alloy 6)

2, 3, 4, & 6 50, 80, 100, & 150

CoCr-A (Alloy 6) overlay

seating surface

2, 3, 4, & 6 50, 80, 100, & 150

Chrome-Plated 316

Stainess Steel

CL IV

Table 6: Flow Coefficients for sizes 1” & 1-1/2” (ANSI/ISA/IEC)

Valve

Size

Port Diameter

in

mm

CV

0.32

0.50

1"

12.70

DN25

0.58

0.72

0.50

0.75

1-1/2"

8.12

14.73

18.29

12.70

19.05

DN40

0.91

1.06

23.11

26.92

Disk Angle of Opening - Degrees

Coefficients

10

20

30

40

50

60

0.5

0.9

1.4

1.9

2.3

2.8

KV

0.4

0.8

1.2

1.6

2.0

2.4

FL

0.95

0.95

0.94

0.93

0.93

0.93

XT

0.57

0.69

0.74

0.77

0.75

0.70

CV

0.9

1.9

2.8

3.7

4.7

5.6

KV

0.7

1.6

2.4

3.2

4.1

4.8

FL

0.95

0.95

0.93

0.93

0.93

0.93

XT

0.58

0.68

0.71

0.76

0.72

0.69

CV

1.4

2.8

4.2

5.6

7.0

8.4

KV

1.2

2.4

3.6

4.8

6.1

7.3

FL

0.94

0.94

0.93

0.93

0.92

0.92

0.69

XT

0.65

0.69

0.72

0.75

0.74

CV

2.3

4.7

7.0

9.3

12

14

KV

2.0

4.1

6.1

8.0

10

12

FL

0.88

0.89

0.87

0.87

0.86

0.86

XT

0.54

0.57

0.63

0.62

0.65

0.57

CV

1.0

2.0

3.0

4.0

5.0

6.0

KV

0.9

1.7

2.6

3.5

4.3

5.2

FL

0.94

0.94

0.95

0.94

0.93

0.93

XT

0.52

0.68

0.70

0.76

0.70

0.68

CV

2.0

4.0

6.0

8.0

10

12

KV

1.7

3.5

5.2

6.9

8.7

10

FL

0.95

0.94

0.94

0.93

0.93

0.92

XT

0.55

0.67

0.71

0.75

0.69

0.67

CV

3.0

6.0

9.0

12

15

18

KV

2.6

5.2

7.8

10

13

16

FL

0.94

0.94

0.93

0.93

0.92

0.92

XT

0.60

0.66

0.69

0.74

0.70

0.66

CV

5.0

10

15

20

25

30

KV

4.3

8.7

13

17

22

26

FL

0.88

0.87

0.87

0.86

0.86

0.86

XT

0.52

0.55

0.61

0.61

0.63

0.56

Fd

0.27

0.29

0.31

0.45

0.27

0.29

0.31

0.45

5

Table 7: Flow Coefficients for sizes 2” - 6” (ANSI/ISA/IEC)

Valve

Size

Port Diameter

in

1.25

2"

DN50

1.56

1.81

3"

2.31

45.97

57.15

58.67

DN100

3.00

3.38

6"

39.62

DN80

2.25

4"

31.75

DN150

4.00

4.50

76.20

85.85

101.60

114.30

* Installe d with Noise Attenuator Disc

6

Disk Angle of Opening - Degrees

Coefficients

mm

10

20

30

40

50

60

CV

5.5

12

19

23

27

30

KV

4.8

10

16

20

23

26

C V*

5.5

12

19

22

25

28

K V*

4.8

10

16

19

22

24

FL

0.94

0.94

0.93

0.93

0.92

0.92

XT

0.47

0.64

0.67

0.75

0.69

0.56

CV

6.6

14

21

31

39

45

KV

5.7

12

18

27

34

39

C V*

6.6

14

21

29

35

39

K V*

5.7

12

18

25

30

34

FL

0.87

0.87

0.86

0.86

0.86

0.86

0.57

XT

0.47

0.41

0.56

0.60

0.62

CV

14

29

45

59

70

77

KV

12

25

39

51

61

67

C V*

13

27

44

56

63

67

K V*

11

23

38

48

54

58

FL

0.94

0.94

0.89

0.89

0.88

0.90

XT

0.59

0.69

0.74

0.65

0.59

0.60

CV

15

30

51

75

96

107

KV

13

26

44

65

83

93

C V*

15

29

50

69

80

86

K V*

13

25

43

60

69

74

FL

0.92

0.92

0.88

0.87

0.87

0.86

XT

0.61

0.62

0.55

0.58

0.57

0.56

CV

19

48

69

87

107

118

KV

16

42

60

75

93

102

C V*

19

48

68

85

102

110

K V*

16

42

59

74

88

95

FL

0.94

0.90

0.88

0.88

0.88

0.88

XT

0.67

0.59

0.69

0.73

0.60

0.61

CV

27

57

94

142

177

195

KV

23

49

81

123

153

169

C V*

27

57

93

128

148

162

K V*

23

49

80

111

128

140

FL

0.92

0.88

0.87

0.86

0.86

0.85

XT

0.49

0.46

0.57

0.56

0.57

0.58

CV

38

87

142

179

200

224

KV

33

75

123

155

173

194

C V*

37

86

138

170

190

210

K V*

32

74

119

147

164

182

FL

0.92

0.91

0.91

0.90

0.88

0.88

XT

0.70

0.68

0.70

0.68

0.66

0.66

CV

39

89

167

215

270

310

KV

34

77

144

186

234

268

C V*

38

88

162

204

248

281

K V*

33

76

140

176

215

243

FL

0.90

0.90

0.90

0.89

0.88

0.88

0.63

XT

0.71

0.77

0.66

0.70

0.66

CV

69

125

204

272

354

410

KV

60

108

176

235

306

355

C V*

64

124

199

260

325

362

K V*

55

107

172

225

281

313

FL

0.89

0.88

0.88

0.87

0.87

0.85

XT

0.71

0.60

0.67

0.68

0.60

0.60

Fd

0.31

0.45

0.31

0.45

0.31

0.45

0.31

0.40

0.45

Table 8: Noise Calculation Coefficients for Valve with Noise Attenuator Disc Installed

Factors for calculating noise when using the

optional attenuator disc

PORT DIAMETER

VALVE SIZE

2"

DN50

3"

DN80

4"

DN100

6"

DN150

EXAMPLE:

in

mm

1.25

31.75

1.56

39.62

1.81

45.97

2.25

57.15

FL *

Fd *

X T*

0.69

0.084

0.71

0.62

0.65

0.6

2.31

58.67

3.00

76.20

0.65

3.38

85.85

4.00

101.60

0.58

4.50

114.30

0.63

0.58

0.071

0.61

Sizing a 42000 for required Cv and calculating noise with and without a noise attenuator disc.

(Note: Results obtained from Fisher’s IEC Noise Sizing Program.)

A) Service Conditions

Process:

Mass Flow:

P1:

DP:

T:

Saturated Steam

22,000 lb/hr.

150 psig

75 psi

366 0F

Line Size:

Molecular Weight:

Fluid Compressibility Factor:

Ratio of Specific Heats:

4” schedule 40 piping

18

1

1.33

B) Sizing for Required Cv

Referring to Table 7, assume a 4” reduced port 42000 with a rated Cv = 118 and pick

FL, XT and Fd for a given valve opening.

FL = 0.88

XT = 0.73

Fd = 0.31

(40o open)

Result: Required Cv = 89

(Approximately 41 degrees open for valve without attenuator disc or

43 degrees open with attenuator)

C) Calculating Noise

1) Valve installed without the noise attenuator disc

Using the flow coefficients from Table 7 (same as part (B) above.)

FL = 0.88

XT = 0.73

Fd = 0.31

Result: Valve noise = 103 dBA

2) Valve installed with the noise attenuator disc.

Using Table 8, select the following values for a 4” reduced port valve (Note: Table 8

is to be used only for calculating noise of the valve with the attenuator disc installed.

Ignore the resultant Cv from this calculation.)

FL*= 0.60

XT* = 0.65

Fd*= 0.071

Result: Valve noise with attenuator disc installed = 89 dBA

D) Summary

Valve selected:

4” Reduced Port

Required Cv:

89

Noise:

103 dBA (without attenuater disc)

89 dBA (with attenuator disc)

7

Table 9:

Size 10 Actuator

ACTUATOR

SIZE

VALVE SIZE

- Air Supply and Maximum Pressure Drops for CLIV and CLVI Seat Leakage

TRIM

CAPACITY

Cv

SPRING*

Kv

AIR

SUPPLY

PRESSURE

PSI

BAR

40

2.8

L

1"

DN25

14

8.4

5.6

2.8

12

7.3

4.8

2.4

S

1 1/2"

DN40

26

16

10

5.2

S

50

3.4

60

4.1

70

4.8

80

5.5

40

2.8

39

S

10

2"

50

3.4

60

4.1

70

4.8

80

5.5

40

2.8

BAR

PSI

750

BAR

51.7

25-57 1.7-3.9

750

51.7

25-57 1.7-3.9

20-35 1.4-2.4

PSI

BAR

5-20

0.3-1.4

8-23

0.6-1.6

10-42

0.7-2.9

11-43

0.8-3.0

21-53

1.4-3.7

5-20

0.3-1.4

8-23

0.6-1.6

10-42

0.7-2.9

11-43

0.8-3.0

21-53

1.4-3.7

5-20

PSI

BAR

750

51.7

750

51.7

750

51.7

706

0.3-1.4

694

47.9

48.7

3.4

8-23

0.6-1.6

750

51.7

60

4.1

10-42

0.7-2.9

626

43.2

70

4.8

11-43

0.8-3.0

80

5.5

21-53

1.4-3.7

40

2.8

5-20

0.3-1.4

750

51.7

25-57 1.7-3.9

DN50

30

26

S

20-35 1.4-2.4

107

93

S

750

51.7

50

3.4

8-23

0.6-1.6

60

4.1

10-42

0.7-2.9

70

4.8

11-43

0.8-3.0

80

5.5

21-53

1.4-3.7

40

2.8

5-20

0.3-1.4

184

12.7

L

25-57 1.7-3.9

20-35 1.4-2.4

187

12.9

50

3.4

8-23

0.6-1.6

280

19.3

60

4.1

10-42

0.7-2.9

162

11.2

70

4.8

11-43

0.8-3.0

280

19.3

80

5.5

21-53

1.4-3.7

40

2.8

5-20

0.3-1.4

305

21.0

25-57 1.7-3.9

253

17.4

DN80

L

77

67

S

20-35 1.4-2.4

311

21.4

50

3.4

8-23

0.6-1.6

454

31.3

60

4.1

10-42

0.7-2.9

271

18.7

70

4.8

11-43

0.8-3.0

454

31.3

80

5.5

21-53

1.4-3.7

25-57 1.7-3.9

413

28.5

Note: Do not exceed valve pressure rating.

* "L" refers to the spring that accomodates lower air supplies . "S" refers to the standard spring that accomodates higher air supplies.

ALWAYS specify air supply when ordering to ensure proper bench range.

8

Max.

Pressure

Drop

50

L

3"

PSI

Bench

Range

20-35 1.4-2.4

L

45

Bench

Range

AIR-TO-CLOSE

Max.

Pressure

Drop

20-35 1.4-2.4

L

30

18

12

6.0

AIR-TO-OPEN

Table 10:

Size 25 Actuator - Air Supply and Maximum Pressure Drops for CLIV and CLVI Seat Leakage

ACTUATOR

SIZE

VALVE SIZE

TRIM

CAPACITY

Cv

SPRING*

Kv

AIR

SUPPLY

PRESSURE

PSI

BAR

40

2.8

AIR-TO-OPEN

Bench

Range

PSI

BAR

AIR-TO-CLOSE

Max.

Pressure

Drop

PSI

BAR

Max.

Pressure

Drop

Bench

Range

PSI

BAR

PSI

BAR

233

16.1

432

29.8

20-35 1.4-2.4

441

30.4

6-47

0.4-3.2

403

27.8

15-55 1.0-3.8

441

30.4

414

28.6

750

51.7

0.4-3.2

701

48.3

15-55 1.0-3.8

750

51.7

59

4.1

126

8.7

20-35 1.4-2.4

129

8.9

6-47

0.4-3.2

116

8.0

15-55 1.0-3.8

129

8.9

80

5.5

164

11.3

20-35 1.4-2.4

168

11.6

6-47

0.4-3.2

152

10.5

15-55 1.0-3.8

168

11.6

121

8.3

240

16.6

20-35 1.4-2.4

244

16.8

6-47

0.4-3.2

222

15.3

15-55 1.0-3.8

244

16.8

10-25 0.7-1.7

L

195

169

50

3.4

60

4.1

70

4.8

S

4"

19-34 1.3-2.3

25-65 1.7-4.5

80

5.5

40

2.8

321

440

22.1

30.3

DN100

L

118

102

10-25 0.7-1.7

50

3.4

60

4.1

70

4.8

S

19-34 1.3-2.3

5.5

40

2.8

38.8

20-35 1.4-2.4

6-47

25-65 1.7-4.5

80

562

750

51.7

10-25 0.7-1.7

L

410

355

50

3.4

60

4.1

70

4.8

19-34 1.3-2.3

89

6.1

25

S

25-65 1.7-4.5

80

5.5

40

2.8

128

8.8

10-25 0.7-1.7

L

6"

DN150

310

268

50

3.4

60

4.1

70

4.8

S

19-34 1.3-2.3

25-65 1.7-4.5

80

5.5

40

2.8

117

167

8.1

11.5

10-25 0.7-1.7

L

224

194

50

3.4

60

4.1

70

4.8

S

19-34 1.3-2.3

25-65 1.7-4.5

80

5.5

173

244

11.9

16.8

Note: Do not exceed valve pressure rating.

* "L" refers to the spring that accomodates lower air supplies . "S" refers to the standard spring that accomodates higher air supplies .

ALWAYS specify air supply when ordering to ensure proper bench range.

9

Table 11: Size

54R Actuator for General Utiltiy Applications - Air Supply and Maximum Pressure Drops

AIR-TO-OPEN

AIR-TO-CLOSE

Maximum Shutoff Pressure

ACTUATOR

SIZE

VALVE

SIZE

1"

1-1/2"

DN25

TRIM

CAPACITY

Cv

Kv

14

8.4

5.6

2.8

12

7.3

4.8

2.4

18

12

6.0

16

10

5.2

54R

PSI

BAR

PSI

BAR

7-15

0.5-1.0

750

51.7

8-16

0.6-1.1

---

---

7-15

0.5-1.0

750

51.7

8-16

0.6-1.1

---

---

7-15

0.5-1.0

600

41.4

8-16

0.6-1.1

---

---

7-15

0.5-1.0

361

24.9

606

41.8

8-16

0.6-1.1

---

---

678

46.8

7-15

0.5-1.0

245

16.9

421

29.0

8-16

0.6-1.1

---

---

473

32.6

7-15

0.5-1.0

73

5.0

138

9.5

8-16

0.6-1.1

---

---

159

11.0

7-15

0.5-1.0

40

2.8

84

5.8

8-16

0.6-1.1

---

---

100

6.9

WITH

POSITIONER

20 psig

(1.4 bar)

AIR SUPPLY

PRESSURE

PSI

BAR

PSI

BAR

PSI

BAR

750

51.7

5-10

0.3-0.7

750

51.7

750

51.7

750

51.7

750

51.7

51.7

5-10

0.3-0.7

26

26

67

5-10

93

Nominal bench spring range of 8-16 psi (7.6-16 psi actual). 0.6-1.1 bar (0.52-1.1 bar actual).

Note: Do not exceed valve pressure rating.

687

47.4

418

28.8

750

51.7

286

19.7

599

41.3

92

6.3

217

15.0

53

3.7

140

9.7

0.3-0.7

39

DN80

107

3-15 psi

(0.21-1.0 bar)

SIGNAL

TO ACTUATOR

BAR

5-10

77

10

BENCH

RANGE

PSI

DN50

45

(1)

WITH

POSITIONER

20 psig

(1.4 bar)

AIR SUPPLY

PRESSURE

750

30

3"

3-15 psi

(0.21-1.0 bar)

SIGNAL

TO ACTUATOR

DN40

30

2"

BENCH

RANGE(1)

Maximum Shutoff Pressure

0.3-0.7

Table 12: Actuator Orientations - Viewed With Actuator In Front of Valve (For size 10 and 25 actuators only)

Air-to-Open

(ATO)

Fails Closed

Mounting

Option

Air-to-Close

(ATC)

Fails Open

Flow Direction

Actuator In Front Of Pipeline

1

Standard

2

3

4

Table 13: Actuator Orientations for Size 54R Actuator

Air-to-Open (ATO)

Fails Closed

Air-to-Close (ATC)

Fails Open

Actuator Orientation In Front Of Pipeline

(Position No. 1 Standard)

Table 14: Approximate Valve and Actuator Weights

APPROXIMATE VALVE WEIGHT

VALVE SIZE

Class 150

Class 300

ACTUATOR

SIZE

PN 10-40

in

DN

Pounds

Kilograms

Pounds

Kilograms

Pounds

Kilograms

1

1-1/2

2

3

4

6

25

40

50

80

100

150

13

17

19

34

70

105

6

8

9

15

32

48

17

20

23

44

84

135

8

9

10

20

38

61

19

20

21

42

82

133

9

9

10

19

37

60

54R

10

25

APPROXIMATE

ACTUATOR WEIGHT

Pounds

Kilograms

25

25

65

11

11

30

11

Table 15: Dimensions for Valves with Size 10 and 25 Actuator

VALVE SIZE

A

ACTUATOR SIZE

CL 150

CL 300

PN 10-16

in

(1)

PN 25-40

Inches

B

1

1-1/2

2

3

4

6

DN

10

10

10

10

25

25

2.13

2.50

3.00

3.75

4.50

5.50

2.44

3.06

3.25

4.13

5.00

6.25

2.27

2.96

3.25

3.94

4.33

5.61

9.47

2.27

9.97

2.96

10.22

3.25

11.35

3.94

15.66

4.63

16.91

5.91

Millimeters

25

40

50

80

100

150

10

10

10

10

25

25

54

64

76

95

114

140

62

78

83

105

127

159

58

75

83

100

110

143

58

75

83

100

118

150

241

253

260

288

398

430

C (1)

D

E(2)

F(3)

15.80

15.80

15.80

15.80

21.70

21.70

4.00

4.50

4.88

6.50

7.62

9.00

7.60

7.60

7.60

7.60

8.50

8.50

9.20

9.20

9.20

9.20

10.30

10.30

401

401

401

401

551

551

102

114

124

165

194

229

193

193

193

193

216

216

234

234

234

234

262

262

Maximum dimension; (2) With Fieldvue; (3) With 3700

Shown with Fieldvue

Digital Valve Controller

Size 10 Actuator with Handwheel and

Fieldvue Digital Valve Controller

Flow

Shown for ATO

(Air to Open)

Shown with 3700 Positioner

12

Size 25 Actuator with Handwheel and

Fieldvue Digital Valve Controller

Table 13: Dimensions for Valves with Size 54R Actuator

VALVE SIZE

ACTUATOR SIZE

A

CL 150

CL 300

54R

2.13

2.50

3.00

3.75

2.44

3.06

3.25

4.13

2.27

2.96

3.25

3.94

Millimeters

54R

54

64

76

95

62

78

83

105

58

75

83

100

in

1

1-1/2

2

3

DN

25

40

50

80

PN 10-16

Inches

B

C

2.27

2.96

3.25

3.94

9.50

10.00

10.22

11.35

4.00

4.50

4.88

6.50

58

75

83

100

241

254

260

288

102

114

124

165

PN 25-40

Size 54 Actuator with Handwheel

Top View

1-00006 REV1

Front View

13

Table 17: Positioner Options

POSITIONER MODEL

TYPE

for 54R-42000

AVAILABLE

SIGNAL RANGES

865-3

865-1

3-15 psi

Direct

Linear

3710

3660

3-15 psi

3-9 psi

9-15 psi

Direct

or

Reverse

Linear

or

EQ % (optional)

863-3

863-1

4-20 mA

Direct

Linear

3720

3661

4-20 mA

4-12 mA

12-20 mA

Direct

or

Reverse

Linear

or

EQ % (optional)

4-20 mA

or

User Defined Span

Direct

or

Reverse

Linear

or

User Defined

Pneumatic

Electropneumatic

Digital

Controller

(1)

VALVE FLOW

CHARACTERISTICS

for 10/25-42000

DVC5030

ACTION

(1)

Direct - Increasing input signal, increasing air output to actuator; Reverse - Increasing input signal, decreasing air output to actuator.

Table 18: Fisher Fieldvue Digital Valve Controller Electrical Certifications

CE MARK

INTRINSIC SAFETY

LCIE

EMC Directive

(electromagnetiEEx ia IIC

c compatibility)

T5

EN 50081, EN

50082

(1)

CSA(1) or FM(1)

FLAMEPROOF

DIVISION 2

LCIE

Cl I, Div. 1, Grp EEx d IIB

A, B, C, D

+H2 T5

EXPLOSION-PROOF

CSA

FM

Cl 1, Div. 2,

Grp A, B,

C, D

Cl II, Div. 2,

Grp E, F, G

Cl 1 Div. 2,

Grp A, B,

C, D

Cl II, Div. 2,

Grp F, G

CSA

FM

ENCLOSURE RATINGS

CSA

FM

EUROPEAN

Cl I, Div. 1, Cl I, Div. I,

Grp B, C, D Grp B, C, D

Cl II, Div. 1, Cl II, Div. 1, Type 4X NEMA 4X

Grp E, F, Grp E, F, G

G T5

T6

IP65

Also available for Class II, Division 1, Groups E,F, and G, if barrier approval permits. Contact your nearest Fisher sales office for the

appropriate FM entity rating parametric ratings for each group.

Table 19: Fisher Type 3720 Electro-Pneumatic Positioner Electrical Certifications

INTRINSIC SAFETY

CE MARK

LCIE

EMC Directive

(electromagnetic EEx ia IIC

compatibility) EN T4/T5/T6

50081, EN 50082

(1)

CSA(1) or FM(1)

Cl I, Div. 1, Grp

A, B, C, DT5

FLAMEPROOF

DIVISION 2

EXPLOSION-PROOF

LCIE

CSA

FM

CSA(2)

FM(2)

EEx d

IIC T6

Cl 1, Div. 2,

Grp A, B,

C, D

Cl II, Div. 2,

Grp E,

F, G

Cl 1 Div. 2,

Grp A, B, C,

D

Cl II, III, Div.

2, Grp E, F,

G

Cl I, Div. 1,

Grp A, B,

C, D

Cl II, Div. 1,

Grp E, F, G

Cl I, Div. I,

Grp A, B,

C, D Cl II, III,

Div. 1,

Grp E, F, G

ENCLOSURE RATINGS

CSA

FM

EUROPEAN

ENC 3 NEMA 3

IP54

Also available for Class II, Division 1, Groups E,F, and G, if barrier approval permits. Contact your nearest Fisher sales office for the

appropriate FM entity ratings and CSA parametric ratings for each group.

Table 20: Fisher Type 3661 Electro-Pneumatic Positioner Electrical Certifications

CE MARK

INTRINSIC SAFETY

LCIE

EMC Directive

(electromagnetic

compatibility) EN

50081, EN 50082

(1)

EEx ia IIC

T6

FLAMEPROOF

DIVISION 2

EXPLOSION-PROOF

ENCLOSURE RATINGS

CSA(1) or FM(1)

LCIE

CSA

FM

CSA

FM

CSA

FM

EUROPEAN

Cl I, Div. 1, Grp

A, B, C, D

N/A

N/A

N/A

N/A

N/A

ENC 3

NEMA 3

IP65

Also available for Class II, Division 1, Groups E,F, and G, if barrier approval permits. Contact your nearest Fisher sales office for the

appropriate FM entity rating parametric ratings for each group.

Table 21: Baumann Type 863-1 & 863-3 Electro-Pneumatic Positioner Electrical Certifications

CE MARK

EMC Directive (electromagnetic compatibility)

EN 50081, EN 50082

14

INTRINSIC

SAFETY

ELECTRICAL CLASS

LCIE

FM/CSA

N/A

N/A

ENCLOSURE RATINGS

CSA

FM

EUROPEAN

For General Purpose Applications Only

Table 22: Accessory Mounting Options

ACTUATOR

POSITIONER

HANDWHEEL

865-3

863-3

Size 10

ATO

Fail Closed

3710

3720

TRAVEL STOP LIMITS

PLUG OPENING

TRAVEL STOP LIMITS PLUG

CLOSURE

LIMIT SWITCHES

Optional

(if no handwheel)

Optional

Not

Available

Optional

Optional

DVC5030

Standard

None-ON/OFF

Optional

865-3

863-3

Optional

Size 10

ATC

Fail Open

(1)

Optional

(if no handwheel)

3710

3720

Not

Available

Optional

DVC5030

Optional(2)

Optional

Standard

None-ON/OFF

Optional

Optional

(if no handwheel)

Optional

Optional

Optional

Optional

(if no handwheel)

Optional

Optional

(if no handwheel)

Optional

865-3

863-3

Size 25

ATO

Fail Closed

3710

3720

Optional

DVC5030

None-ON/OFF

865-3

863-3

Optional

Size 25

ATC

Fail Open

3710

3720

Optional

DVC5030

Standard

None-ON/OFF

Optional

865-1

863-1

54R

ATO

Fail Closed

3710

3720

Optional

Standard

Standard

Optional

Optional

Standard

Standard

Optional

3660

3661

DVC5030

865-1

863-1

54R

ATC

Fail Open

3710

3720

3660

3661

DVC5030

(1)

(2)

For Handwheel: ATO Construction - handwheel limits valve closure only; ATC Construction - handwheel limits valve opening only.

Requires shaft - mounting of DVC digital controller.

15

This product is covered under one or more of the following patents 5924671, 06024125 or pending patent applications.

FIELDVUE, ENVIRO-SEAL and Managing The Process Better are marks owned by H.D. Baumann Inc., Fisher Controls International, Inc., or Fisher-Rosemount Systems, Inc. All other marks are the property of

their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or

guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

For information, contact :

H.D. Baumann Inc.

35 Mirona Road

Portsmouth, NH 03801

Tel: (603) 436-2044 / Fax: (603) 436-4901

16

H.D. Baumann Inc.

Subsidiary of Fisher Controls International, Inc.