Section 6. Tray Cables

advertisement

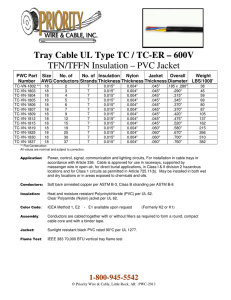

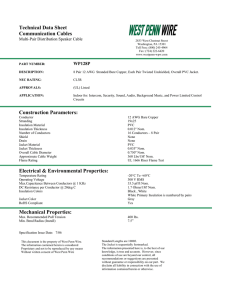

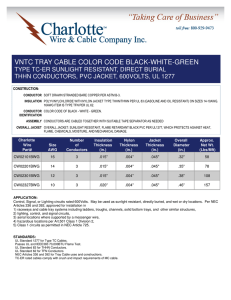

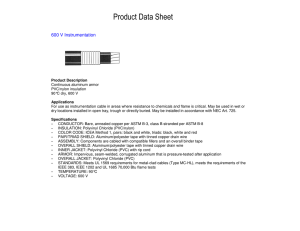

Section 6. Tray Cables Tray Cables 800.633.6339 • www.lapptannehill.com 149 Table of Contents Lapp Group ÖLFLEX® TRAY II & TRAY II CY .................................................................................151 ÖLFEX® FORTIS .........................................................................................................152 ÖLFEX® CONTROL TM/ TM CY .................................................................................153 Instrumentation Cables 300V Type PLTC Single Pair or Triad Non-Shielded .............................................................154 Type PLTC Single Pair or Triad Shielded .....................................................................154 Type PLTC Multiple Pairs, Overall Shield .....................................................................155 Type PLTC Multiple Pairs, Individual and Overall Shield . .................................... 156-157 Type PLTC Multiple Triads, Individual and Overall Shield ............................................158 Tray Cable-Control Cable 600V Type TC-ER Multiple Pairs, Overall Shield....................................................................159 Type TC-ER Multiple Pairs, Individual and Overall Shield..................................... 160-161 Type TC-ER Multiple Triads, Individual and Overall Shield ..........................................162 Type TC-ER TFN Insulation PVC Jacket, Copper Conductors......................................163 Type TC-ER THHN or THWN Insulation PVC Jacket ...................................................164 Type TC-ER THHN or THWN Insulation PVC Jacket ...................................................165 Type TC-ER THHN or THWN Insulation PVC Jacket ...................................................166 Type TC-ER TFN Insulation PVC Jacket . ....................................................................167 Color Code Chart . ........................................................................................................168 Specifications subject to change. For complete specifications and availability visit www.lapptannehill.com 150 Tray Cables 800.633.6339 • www.lapptannehill.com Tray Cables ÖLFLEX® TRAY II/II CY, Flexible & Oil Resistant Tray Cable with both UL & CSA TC Approval for Industrial Applications ÖLFEX® TRAY II -(UL) TYPE TC-ER OR DP-I 90ºC 600V---c(UL) TC/CIC FT4--CSA AWM FT4 RoHS Construction: Finely stranded bare copper conductors; Insulation: Specially blended PVC/nylon insulation; Jacket: Specially formulated oil resistant black PVC jacket. ÖLFEX® TRAY II CY-(UL) TYPE TC-ER OR DP-I 90ºC 600V---c(UL) TC/CIC FT4--CSA AWM FT4 RoHS MSHA Construction: Finely stranded bare copper conductors; Insulation: Specially blended PVC/nylon insulation. 100% shielding with foil tape and tinned copper braid (70% coverage); Jacket: Specially formulated oil resistant black PVC jacket. Features: ÖLFLEX® TRAY II/II CY is an industrial grade tray cable with superior oil performance for long cable life. It has a pressure extruded jacket and fine copper stranding for excellent flexibility making it much easier to pull through tray. With UL TC-ER approval, no conduit is needed so you can reduce material costs along with saving on labor. Applications: Industrial plant expansions, Automotive plants, Tray wiring, anywhere that VNTC® cables are used. ÖLFLEX® TRAY II: Flexible and Oil Resistant Tray Cable Technical Data: Minimum Bending Radius for installation: < 1 AWG: 5 x cable diameter. > 1 AWG: 7.5 x cable diameter. Please note that VNTC® is a trademark for General Cable Technologies Corporation. Temperature: •< -40ºC to +90ºC UL/CSA TC. • -40ºC to +105ºC UL AWM Rated Voltage: • 600V - TC • 1000V - AWM • 1000V - TC Wind Turbine (WTTC) Color Code: • Black with white numbers plus green/yellow ground ÖLFLEX® TRAY II CY: Shielded Flexible and Oil Resistant Tray Cable Tray Cables 800.633.6339 • www.lapptannehill.com Approvals: UL: • Type TC-ER (Exposed Run) or DR-1 • UL AWM, Oil Res I, Wet Rating 75ºC UL 83 • UL MTW, NFPA 79 2007 • Class 1, Div. 2 per NEC Art. 336, 392, 501 • Submersible pump (14 AWG & Larger: 2 to 7 conductors) CSA: • c(UL) Type TC and CIC FT4 • CSA-AWM I/II A/B FT4 Additional: • MSHA-P-07-KA050016-MSHA (Shielded Only). • Torsion tested for wind market (+/- 150º/m) 151 Tray Cables ÖLFLEX® FORTIS, Flexible & Oil Resistant Tray Cable with UL/CSA and Excellent Cold Temperature Flexibility LAPP KABEL STUTTGART ÖLFLEX® FORTIS P/N 331404- 14 AWG (2.50MM2)/4C (UL)TYPE TC-ER THHN/THWN 90ºC DRY 75ºC WET 600V, SUN RES, OIL RES I/II E171371 or MTW “FLEXING” or WTTC 1000V 90ºC DRY, or c(UL) CONTROL CIC/TC PVC/N -40ºC OUTDOOR FT4 -- CSA AWM II A/B 90ºC 600V FT4 CE ROHS Construction: Finely stranded bare copper conductors; Insulation: Specially blended PVC/nylon; Jacket: Formulated oil resistant and elastomeric polymer alloy black jacket. Features: ÖLFLEX® FORTIS is named after the Latin Word meaning “strength”. It offers outstanding mechanical performance, particularly at low temperatures. The specially formulated elastomeric jacket passes UL’s -40ºC cold impact test. ÖLFLEX® FORTIS also offers outstanding oil resistance (UL OIL RES I & II) and meets all Tray Cable (UL-1277) and Wind Turbine Tray Cable (UL-2277) requirements. Applications: Wind energy, Machine tool, Forestry equipment, Oil & petrochem equipment, Cold temperature storage & packaging facilities. Technical Data: Minimum Bend Radius for installation: 5 x cable diameter. Temperature: •F or stationary use: -55ºC to +105ºC (UL 90ºC) • For flexible use: -40ºC to +105ºC (UL 90ºC). 152 Rated Voltage: • 600V - TC • 1000V - TC Wind Turbine (WTTC) Color Code: • Black with white numbers plus grn/yel ground. Approvals: UL: CSA: • • • • • • ype TC-ER (Exposed Run), UL WTTC T Type MTW or UL AWM, NFPA 79 2007 Oil Res I/II Class 1, Div.2 per NEC Art. 336, 392, 501 c(UL) Type TC and CIC FT4 -40ºC CSA-AWM I/II A/B FT4 -40ºC. Tray Cables 800.633.6339 • www.lapptannehill.com Tray Cables ÖLFLEX® CONTROL TM/TM CY, Flexible & Oil Resistant Tray and Machine Cable with UL/CSA MTW + UL TC-ER/CSA CIC/TC Approval ÖLFLEX® CONTROL TM-(UL)TYPE TC-ER or MTW 90ºC 600V---CSA AWM FT4 RoHS Construction: Finely stranded bare copper conductors; Insulation: Specially blended PVC/nylon insulation; Jacket: Specially formulated PVC jacket. OLFLEX® CONTROL TM CY-(UL) TYPE TC-ER or MTW 90ºC 600V---CSA AWM FT4 RoHS Construction: Finely stranded bare copper conductors; Insulation: Specially blended PVC/nylon insulation, overall foil and tinned copper braid (85% coverage); Jacket: Specially formulated PVC jacket. Features: ÖLFLEX® CONTROL TM is a multi-conductor cable designed for use on machine tool equipment and other industrial machinery conforming to NFPA 79 2007 wiring norms. ÖLFLEX® CONTROL TM is also UL TC-ER + CSA CIC/TC approved so it can be routed in tray as well. Applications: Machine tool machinery, Food & beverage, Processing equipment, Machine wiring for conformance to NFPA 79 2007. Technical Data: Minimum bend radius for installation: 6 x cable diameter. Temperature: •< -40ºC to +90ºC Rated Voltage: • 600V - TC • 1000V - TC Wind Turbine (WTTC) Color Code: • Conductors are black printed with white numbers plus green/yellow ground. Approvals: UL: • • • • • CSA: • • Additional:• U L Type TC-ER (Exposed Run) AWM, UL Wet Approval 75ºC Type MTW, NFPA 79 2007 Class 1, Div.2 per NEC Art. 336, 392, 501 UL Bus Drop-14 AWG & Larger 3c & 4c only** C(UL) CIC/TC FT4 AWM I/II A/B FT4 Torsion tested for wind market (+/- 150º/m) ÖLFLEX® CONTROL TM: Flexible and Oil Resistant Tray & Machine Cable ÖLFLEX® CONTROL TM CY: Shielded Flexible and Oil Resistant Tray & Machine Cable Tray Cables 800.633.6339 • www.lapptannehill.com 153 Tray Cables Instrumentation Cable, 300 Volt UL Type PLTC & ITC, 105ºC Single Pair or Triad, Non-Shielded Construction: 7-strand soft bare annealed copper per ASTM B-3, Class B stranding per ASTM B-8; Insulation: Flame-retardant PVC; Jacket: Sunlight-resistant PVC. A ripcord is applied longitudinally under the jacket to facilitate stripping. Applications: For use in instrumentation and process control applications where protection from electrostatic interference is not required. UL listed as Type PLTC and ITC and approved for installation indoors or outdoors, aerially, in conduits, ducts and cable trays in circuits not exceeding 300 volts. May be used in NEC Class 1, Division 2 hazardous locations. Catalog Size Pair of No. AWG Triad LTC300-18/1P-7N P PLTC300-16/1P-7N PLTC300-18/1T-7N PLTC300-16/1T-7N 18 16 18 16 1 Pair 1 Pair 1 Triad 1 Triad Insulation Thickness Mils Jacket Thickness Mils Overall Diameter Inch Net Weight Lbs/Mft 15 15 15 15 35 35 35 35 .25 .27 .26 .29 33 42 41 54 Technical Data: Flame Tests: • UL 1581 70,000 BTU/hr flame test. • CSA FT4 rated. Temperature: •1 05ºC Rated Voltage: • 300V Color Code: • ICEA Method 9: black and white for pairs. • ICEA Method 1: black, white and red for triads. Approvals: •U L Standard 13 • UL Standard 2250 • NEC Type ITC per Articles 501, 502, 503, and 504 • Approved for Class 2 and Class 3 circuits per Article 725 of the NEC Instrumentation Cable, 300 Volt UL Type PLTC & ITC, 105ºC Single Pair or Triad, Shielded Construction: 7-strand soft bare annealed copper per ASTM B-3, Class B stranding per ASTM B-8; Insulation: Flame-retardant PVC; Jacket: Sunlight-resistant PVC. A ripcord is applied longitudinally under the jacket to facilitate strippping. Features: Aluminum-polyemer tape providing 100% coverage with a flexible 7-strand tinned copper drain wire. Applications: For use in instrumentation and process control applications where protection from electrostatic interference is required. UL listed as Type PLTC and ITC and approved for installation indoors or outdoors, aerially, in conduits, ducts and cable trays in circuits not exceeding 300 volts. May be used in NEC Class 1, Division 2 hazardous locations. Technical Catalog Size Pair of No. AWG Triad LTC300-20/1P-7S P PLTC300-18/1P-7S PLTC300-16/1P-7S PLTC300-20/1T-7S PLTC300-18/1T-7S PLTC300-16/1T-7S 20 18 16 20 18 16 1 Pair 1 Pair 1 Pair 1 Triad 1 Triad 1 Triad Insulation Thickness Mils Jacket Thickness Mils Overall Diameter Inch Net Weight Lbs/Mft 15 15 15 15 15 15 35 35 35 35 35 35 .24 .26 .28 .25 .28 .30 30 37 46 36 46 62 Temperature: •1 05ºC Rated Voltage: • 300V Color Code: • ICEA Method 9: black and white for pairs. • ICEA Method 1: black, white and red for triads. Approvals: •U L Standard 13 • UL Standard 2250 • NEC Type ITC per Articles 501, 502, 503, and 504 • Approved for Class 2 and Class 3 circuits per Article 725 of the NEC Not finding what you are looking for? Please contact us at sales@lapptannehill.com, or visit our website at: www.lapptannehill.com 154 Data: Flame Tests: • UL 1581 70,000 BTU/hr flame test. • CSA FT4 rated. Tray Cables 800.633.6339 • www.lapptannehill.com Tray Cables Instrumentation Cable, 300 Volt UL Type PLTC & ITC, 105ºC Multiple Pairs, Overall Shield Construction: 7-strand soft bare annealed copper per ASTM B-3, Class B stranding per ASTM B-8; Insulation: Flame-retardant PVC; Jacket: Sunlight-resistant PVC. A ripcord is applied longitudinally under the jacket to facilitate stripping. Features: Aluminum-polyemer tape providing 100% coverage with a flexible 7-strand tinned copper drain wire. Applications: For use in instrumentation and process control applications where protection from electrostatic interference is required. UL listed as Type PLTC and ITC and approved for installation indoors or outdoors, aerially, in conduits, ducts and cable trays in circuits not exceeding 300 volts. May be used in NEC Class 2, Division 2 hazardous locations. Catalog Size No. AWG PLTC300-20/2P-7S PLTC300-20/4P-7S PLTC300-20/8P-7S PLTC300-20/12P-7S PLTC300-20/16P-7S PLTC300-20/24P-7S PLTC300-20/36-7S PLTC300-20/50P-7S PLTC300-18/2P-7S PLTC300-18/4P-7S PLTC300-18/8P-7S PLTC300-18/12P-7S PLTC300-18/16P-7S PLTC300-18/24P-7S PLTC300-18/36P-7S PLTC300-18/50P-7S PLTC300-16/2P-7S PLTC300-16/4-7S PLTC300-16/8P-7S PLTC300-16/12P-7S PLTC300-16/16-7S PLTC300-16/24P-7S PLTC300-16/36P-7S PLTC300-16/50P-7S Number of Pairs Insulation Thickness Mils 20 2 20 4 20 8 20 12 20 16 20 24 20 36 20 50 18 2 18 4 18 8 18 12 18 16 18 24 18 36 18 50 16 2 16 4 16 8 16 12 16 16 16 24 16 36 16 50 15 15 15 15 15 15 15 15 15 15 15 15 15 15 15 15 15 15 15 15 15 15 15 15 Jacket Thickness Mils Overall Diameter Inch Net Weight Lbs/Mft 40 .34 52 40 .40 78 50 .52 143 50 .61 195 60 .74 261 60 .82 356 70 .95 513 70 1.17 692 40 .37 64 50 .47 113 50 .58 187 60 .69 271 60 .81 341 60 .90 479 70 1.06 695 70 1.29 930 50 .44 94 50 .52 148 60 .66 264 60 .77 367 70 1.01 503 70 1.04 683 70 1.19 970 80 1.60 1378 Technical Data: Flame Tests: • UL 1581 70,000 BTU/hr flame test. • CSA FT4 rated. Temperature: •1 05ºC Rated Voltage: • 300V Color Code: • ICEA Method 9: black and white pairs with printed number. Approvals: •U L Standard 13 • UL Standard 2250 • NEC Type ITC per Articles 501, 502, 503, and 504 • Approved for Class 2 and Class 3 circuits per Article 725 of the NEC Specifications subject to change. For complete specifications and availability visit www.lapptannehill.com Tray Cables 800.633.6339 • www.lapptannehill.com 155 Tray Cables Instrumentation Cable, 300 Volt UL Type PLTC & ITC, 105ºC Multiple Pairs, Individual and Overall Shield Construction: 7-strand soft bare annealed copper per ASTM B-3, Class B stranding per ASTM B-8; Insulation: Flame-retardant PVC; Jacket: Sunlight-resistant PVC. A ripcord is applied longitudinally under the jacket to facilitate stripping. Features: Individual Shield: Aluminum-polymer tape providing 100% coverage with a flexible 7-strand tinned copper drain wire. Overall Shield: Aluminum-polyemer tape providing 100% coverage with a flexible 7-strand tinned copper drain wire. Applications: For use in instrumentation and process control applications where superior protection from electrostatic interference is required. UL listed as Type PLTC and ITC and approved for installation indoors or outdoors, aerially, in conduits, ducts and cable trays in circuits not exceeding 300 volts. May be used in NEC Class 1, Divison 2 hazardous locations. Catalog Size No. AWG PLTC300-20/2P-7SPOS PLTC300-20/4P-7SPOS PLTC300-20/8P-7SPOS PLTC300-20/12P-7SPOS PLTC300-20/16P-7SPOS PLTC300-20/24P-7SPOS PLTC300-20/36P-7SPOS PLTC300-20/50P-7SPOS PLTC300-18/2P-7SPOS PLTC300-18/4P-7SPOS PLTC300-18/8P-7SPOS PLTC300-18/12P-7SPOS PLTC300-18/16P-7SPOS PLTC300-18/24P-7SPOS PLTC300-18/36P-7SPOS PLTC300-18/50P-7SPOS Number of Pairs 20 2 20 4 20 8 20 12 20 16 20 24 20 36 20 50 18 2 18 4 18 8 18 12 18 16 18 24 18 36 18 50 Insulation Thickness Mils 15 15 15 15 15 15 15 15 15 15 15 15 15 15 15 15 Jacket Thickness Mils Overall Diameter Inch Net Weight Lbs/Mft 40 .36 61 50 .46 110 50 .58 182 60 .71 267 60 .81 315 70 .97 492 70 1.11 685 70 1.33 768 40 .40 76 50 .50 134 50 .63 226 60 .78 332 60 .89 374 70 1.08 619 70 1.23 869 80 1.49 1047 Technical Data: Flame Tests: • UL 1581 70,000 BTU/hr flame test. • CSA FT4 rated. Temperature: •1 05ºC Rated Voltage: • 300V Color Code: • ICEA Method 9: black and white pairs with printed number. Approvals: •U L Standard 13 • UL Standard 2250 • NEC Type ITC per Articles 501, 502, 503, and 504 • Approved for Class 2 and Class 3 circuits per Article 725 of the NEC Check out our complete inventory of products at www.lapptannehill.com 156 Tray Cables 800.633.6339 • www.lapptannehill.com Tray Cables Instrumentation Cable, 300 Volt UL Type PLTC & ITC, 105ºC Multiple Pairs, Individual and Overall Shield Construction: 7-strand soft bare annealed copper per ASTM B-3, Class B stranding per ASTM B-8; Insulation: Flame-retardant PVC; Jacket: Sunlight-resistant PVC. A ripcord is applied longitudinally under the jacket to facilitate stripping. Features: Individual Shield: Aluminum-polymer tape providing 100% coverage with a flexible 7-strand tinned copper drain wire. Overall Shield: Aluminum-polyemer tape providing 100% coverage with a flexible 7-strand tinned copper drain wire. Applications: For use in instrumentation and process control applications where superior protection from electrostatic interference is required. UL listed as Type PLTC and ITC and approved for installation indoors or outdoors, aerially, in conduits, ducts and cable trays in circuits not exceeding 300 volts. May be used in NEC Class 1, Divison 2 hazardous locations. Catalog Size No. AWG PLTC300-16/2P-7SPOS PLTC300-16/4P-7SPOS PLTC300-16/8P-7SPOS PLTC300-16/12P-7SPOS PLTC300-16/16P-7SPOS PLTC300-16/24P-7SPOS PLTC300-16/36P-7SPOS PLTC300-16/50P-7SPOS Number of Pairs 16 2 16 4 16 8 16 12 16 16 16 24 16 36 16 50 Insulation Thickness Mils 15 15 15 15 15 15 15 15 Jacket Thickness Mils Overall Diameter Inch Net Weight Lbs/Mft 50 .47 107 50 .55 178 60 .73 323 60 .87 456 70 1.02 529 70 1.21 860 80 1.40 1250 80 1.68 1453 Technical Data: Flame Tests: • UL 1581 70,000 BTU/hr flame test. • CSA FT4 rated. Temperature: •1 05ºC Rated Voltage: • 300V Color Code: • ICEA Method 9: black and white pairs with printed number. Approvals: •U L Standard 13 • UL Standard 2250 • NEC Type ITC per Articles 501, 502, 503, and 504 • Approved for Class 2 and Class 3 circuits per Article 725 of the NEC Specifications subject to change. For complete specifications and availability visit www.lapptannehill.com Tray Cables 800.633.6339 • www.lapptannehill.com 157 Tray Cables Instrumentation Cable, 300 Volt UL Type PLTC & ITC, 105ºC Multiple Triads, Individual and Overall Shield Construction: 7-strand soft bare annealed copper per ASTM B-3, Class B stranding per ASTM B-8; Insulation: Flame-retardant PVC; Jacket: Sunlight-resistant PVC. A ripcord is applied longitudinally under the jacket to facilitate stripping. Features: Individual Shield: Aluminum-polymer tape providing 100% coverage with a flexible 7-strand tinned copper drain wire. Overall Shield: Aluminum-polymer tape providing 100% coverage with a flexible 70 strand tinned copper drain wire. Applications: For use in instrumentation and process control applications where superior protection from electrostatic interference is required. UL listed as Type PLTC and ITC and approved for installation indoors or outdoors, aerially, in conduits, ducts and cable trays in circuits not exceeding 300 volts. May be used in NEC Class 1, Division 2 hazardous locations. Catalog Size No. AWG PLTC300-20/4T-7STOS PLTC300-20/8T-7STOS PLTC300-20/12T-7STOS PLTC300-20/16T-7STOS PLTC300-20/24T-7STOS PLTC300-20/36T-7STOS PLTC300-18/4T-7STOS PLTC300-18/8T-7STOS PLTC300-18/12-7STOS PLTC300-18/16T-7STOS PLTC300-18/24T-7STOS PLTC300-16/4T-7STOS PLTC300-16/8T-7STOS PLTC300-16/12T-7STOS PLTC300-16/16T-7STOS PLTC300-16/24T-7STOS Number of Triads 20 4 20 8 20 12 20 16 20 24 20 36 18 4 18 8 18 12 18 16 18 24 16 4 16 8 16 12 16 16 16 24 Insulation Thickness Mils 15 15 15 15 15 15 15 15 15 15 15 15 15 15 15 15 Jacket Thickness Mils Overall Diameter Inch Net Weight Lbs/Mft 50 .50 136 50 .65 214 60 .78 338 60 .86 428 70 1.10 591 70 1.22 887 50 .54 134 60 .74 293 60 .86 332 70 .97 420 70 1.21 768 50 .61 229 60 .82 395 70 .98 621 70 1.09 794 80 1.39 1085 Technical Data: Flame Tests: • UL 1581 70,000 BTU/hr flame test. • CSA FT4 rated. Temperature: •1 05ºC Rated Voltage: • 300V Color Code: • ICEA Method 9: black and white pairs with printed number. Approvals: •U L Standard 13 • UL Standard 2250 • NEC Type ITC per Articles 501, 502, 503, and 504 • Approved for Class 2 and Class 3 circuits per Article 725 of the NEC Not finding what you are looking for? Please contact us at sales@lapptannehill.com, or visit our website at: www.lapptannehill.com 158 Tray Cables 800.633.6339 • www.lapptannehill.com Tray Cables Instrumentation Cable, 600 Volt UL Type TC-ER, 90ºC Multiple Pairs, Overall Shield Construction: 7-strand soft bare annealed copper per ASTM B-3, Class B stranding per ASTM B-8; Insulation: Flame-retardant PVC per UL Standard 62 for Type TFN wire. Insulation Jacket: Clear nylon per UL Standard 62 for Type TFN wire; Jacket: Sunlight-resistant PVC per UL Standard 1277. A ripcord is applied longitudinally under the jacket to facilitate stripping. Clear nylon per UL Standard 62 for Type TFN wire. Features: Overall Shield: Aluminum-polymer tape providing 100% coverage with a flexible 7-strand tinned copper drain wire. Applications: For use in instrumentation and process control applications where superior protection from electrostatic interference is required. UL listed as Type PLTC and ITC and approved for installation indoors or outdoors, aerially, in conduits, ducts and cable trays in circuits not exceeding 300 volts. May be used in NEC Class 1, Divison 2 hazardous locations. Number Catalog Size of No. AWG Pairs TRAY600-18/2P-7S TRAY600-18/4P-7S TRAY600-18/8P-7S TRAY600-18/12P-7S TRAY600-18/16P-7S TRAY600-18/24P-7S TRAY600-18/36P-7S TRAY600-18/50P-7S TRAY600-16/2P-7S TRAY600-16/3P-7S TRAY600-16/4P-7S TRAY600-16/8P-7S TRAY600-16/12P-7S TRAY600-16/16P-7S TRAY600-16/24P-7S TRAY600-16/36P-7S TRAY600-16/50P-7S 18 2 18 4 18 8 18 12 18 16 18 24 18 36 18 50 16 2 16 3 16 4 16 8 16 12 16 16 16 24 16 36 16 50 PVC Insulation Thickness Mils Nylon Jacket Thickness Mils 15 15 15 15 15 15 15 15 15 15 15 15 15 15 15 15 15 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 Overall Jacket Overall Thickness Diameter Mils Inch Net Weight Lbs/Mft 45 .41 70 45 .49 118 60 .65 212 60 .76 302 80 .89 374 80 1.03 572 80 1.18 796 80 1.44 1046 45 .45 89 45 .52 121 45 .57 150 60 .75 283 60 .88 389 80 1.03 540 80 1.21 742 80 1.40 1038 80 1.61 1436 Technical Data: Flame Tests: • UL 1581 70,000 BTU/hr flame test. Temperature: •9 0ºC Rated Voltage: • 600V Color Code: • ICEA Method 9: black and white pairs with printed number. Approvals: •N EC Type TC for Class I Division 2 areas per Articles 336, 392, and 501, and for Class 1 circuits per NEC Article 725 • NEC Type NPFL for Non Power Limited Fire Please contact your sales representative for detailed information at sales@lapptannehill.com Tray Cables 800.633.6339 • www.lapptannehill.com 159 Tray Cables Instrumentation Cable, 600 Volt UL Type TC-ER, 90ºC Multiple Pairs, Individual and Overall Shield Construction: 7-strand soft bare annealed copper per ASTM B-3, Class B stranding per ASTM B-8; Insulation: Flame-retardant PVC per UL Standard 62 for Type TFN wire. Clear nylon per UL Standard 62 for Type TFN wire; Jacket: Sunlight-resistant PVC per UL Standard 1277. A ripcord is applied longitudinally under the jacket to facilitate stripping. Features: Individual Shield: Aluminum-polymer tape providing 100% coverage with a flexible 7-strand tinned copper drain wire. Overall Shield: Aluminum-polymer tape providing 100% coverage with a flexible 7-strand tinned copper drain wire. Applications: For use in instrumentation and process control applications where superior protection from electrostatic inteference is required. UL listed as Type TC and approved for installation indoors or outdoors, aerially, in conduits, ducts, cable trays and direct burial in circuits not exceeding 600 volts. Maybe used in NEC Class1, Division 2 hazardous locations. Number Catalog Size of No. AWG Pairs TRAY600-18/2P-7SPOS TRAY600-18/4P-7SPOS TRAY600-18/8P-7SPOS TRAY600-18/12P-7SPOS TRAY600-18/16P-7SPOS TRAY600-18/24P-7SPOS TRAY600-18/36P-7SPOS TRAY600-18/50P-7SPOS TRAY600-16/2P-7SPOS TRAY600-16/3P-7SPOS TRAY600-16/4P-7SPOS TRAY600-16/6P-7SPOS TRAY600-16/8P-7SPOS TRAY600-16/12P-7SPOS TRAY600-16/16P-7SPOS TRAY600-16/24P-7SPOS TRAY600-16/36P-7SPOS TRAY600-16/50P-7SPOS 18 2 18 4 18 8 18 12 18 16 18 24 18 36 18 50 16 2 16 3 16 4 16 6 16 8 16 12 16 16 16 24 16 36 16 50 PVC Insulation Thickness Mils 15 15 15 15 15 15 15 15 15 15 15 15 15 15 15 15 15 15 Nylon Jacket Thickness Mils Overall Jacket Overall Thickness Diameter Mils Inch Technical Data: Flame Tests: • UL 1581 70,000 BTU/hr flame test. Net Weight Lbs/Mft 4 45 .44 82 4 45 .52 146 4 60 .71 279 4 60 .85 391 4 80 1.05 494 4 80 1.20 752 4 80 1.37 1053 4 80 1.71 1300 4 45 .48 105 4 45 .56 136 4 60 .63 207 4 60 .77 257 4 60 .81 349 4 80 1.11 528 4 80 1.56 623 4 80 1.39 944 4 80 1.59 1331 4 110 1.96 1731 Temperature: •9 0ºC Rated Voltage: • 600V Color Code: • ICEA Method 9: black and white pairs with printed number. Approvals: •N EC Type TC for Class I NEC Type TC for Class I Division 2 areas per Articles 336, 392 and 501, and for Class 1 circuits per NEC Article 725 • NEC Type NPFL for Non Power Limited Fire Protective Signaling circuits per NEC Article 760 Not finding what you are looking for? Please contact us at sales@lapptannehill.com, or visit our website at: www.lapptannehill.com 160 Tray Cables 800.633.6339 • www.lapptannehill.com Tray Cables Instrumentation Cable, 600 Volt UL Type TC-ER, 90ºC Multiple Pairs, Individual and Overall Shield Construction: 7-strand soft bare annealed copper per ASTM B-3, Class B stranding per ASTM B-8; Insulation: Flame-retardant PVC per UL Standard 83 for Type THHN or THWN-2 wire. Insulation jacket: Clear nylon per UL Standard 83 for Type THHN or THWN-2 wire; Jacket: Sunlight-resistant PVC per UL Standard 1277. A ripcord is applied longitudinally under the jacket to facilitate stripping. Features: Individual Shield: Aluminum-polymer tape providing 100% coverage with a flexible 7-strand tinned copper drain wire. Overall Shield: Aluminum-polymer tape providing 100% coverage with a flexible 7-strand tinned copper drain wire. Applications: For use in instrumentation and process control applications where superior protection from electrostatic interference is required. UL listed as Type TC and approved for installation indoors or outdoors, aerially, in conduits, ducts, cable trays and direct burial in circuits not exceeding 600 volts. May be used in NEC Class 1, Division 2 hazardous locations. UL approved for NEC continuous operation at 75ºC in wet locations, 90ºC in dry locations, 130ºC for emergency overload conditions, and 250ºC for short circuit conditions. Number Catalog Size of No. AWG Pairs TRAY600-14/2P-7SPOS TRAY600-14/4P-7SPOS TRAY600-14/8P-7SPOS TRAY600-14/12P-7SPOS TRAY600-14/24P-7SPOS 14 2 14 4 14 8 14 12 14 24 PVC Insulation Thickness Mils Nylon Jacket Thickness Mils 15 15 15 15 15 4 4 4 4 4 Overall Jacket Overall Thickness Diameter Mils Inch Net Weight Lbs/Mft 45 .57 156 60 .73 285 60 .93 520 80 1.16 788 80 1.58 1445 Technical Data: Flame Tests: • UL 1581 70,000 BTU/hr flame test. Temperature: •9 0ºC Rated Voltage: • 600V Color Code: • ICEA Method 9: black and white pairs with printed number. Approvals: •N EC Type TC for Class I Division 2 areas per Articles 336, 392 and 501, and for Class 1 circuits per NEC Article 725 • NEC Type NPFL for Non Power Limited Fire Protective Signaling circuits per NEC Article 760.0 Check out our complete inventory of products at www.lapptannehill.com Tray Cables 800.633.6339 • www.lapptannehill.com 161 Tray Cables Instrumentation Cable, 600 Volt UL Type TC-ER, 90ºC Multiple Triads, Individual and Overall Shield Construction: 7-strand soft bare annealed copper per ASTM B-3, Class B stranding per ASTM B-8; Insulation: Flame-retardant PVC per UL Standard 62 for Type TFN wire. Insulation jacket: Clear nylon per UL Standard 62 for Type TFN wire; Jacket: Sunlight-resistant PVC per UL Standard 1277. A ripcord is applied longitudinally under the jacket to facilitate stripping. Features: Individual Shield: Aluminum-polymer tape providing 100% coverage with a flexible 7-strand tinned copper drain wire. Overall Shield: Aluminum-polymer tape providing 100% coverage with a flexible 7-strand tinned copper drain wire. Applications: For use in instrumentation and process control applications where superior protection from electrostatic interference is required. UL listed as Type TC and approved for installation indoors or outdoors, aerially, in conduits, ducts, cable trays and direct burial in circuits not exceeding 600 volts. May be used in NEC Class 1, Divison 2 hazardous locations. UL approved for NEC continuous operations at 75ºC in wet locations, 90ºC in dry locations, 130ºC for emergency overload conditions, and 250ºC for short circuit conditions. Number Catalog Size of No. AWG Triads TRAY600-18/4T-7STOS TRAY600-18/8T-7STOS TRAY600-18/12T-7STOS TRAY600-18/24T-7STOS TRAY600-16/4T-7STOS TRAY600-16/8T-7STOS TRAY600-16/12T-7STOS TRAY600-16/16T-7STOS TRAY600-16/24T-7STOS 18 4 18 8 18 12 18 24 16 4 16 8 16 12 16 16 16 24 PVC Insulation Thickness Mils Nylon Jacket Thickness Mils 15 15 15 15 15 15 15 15 15 4 4 4 4 4 4 4 4 4 Overall Jacket Overall Thickness Diameter Mils Inch Technical Data: Flame Tests: • UL 1581 70,000 BTU/hr flame test. Temperature: •9 0ºC Net Weight Lbs/Mft 60 .61 207 60 .78 355 80 .98 538 80 1.33 971 60 .67 233 60 .90 401 80 1.08 607 80 1.27 838 80 1.48 1100 Rated Voltage: • 600V Color Code: • ICEA Method 1: black, white and red triads with printed number. Approvals: •N EC Type TC for Class 1 Division 2 areas per Articles 336,392 and 501, and for Class 1 circuits per NEC Article 725 • NEC Type NPFL for Non Power Limited Fire Protective Signaling circuits per NEC Article 760 Specifications subject to change. For complete specifications and availability visit www.lapptannehill.com 162 Tray Cables 800.633.6339 • www.lapptannehill.com Tray Cables Tray Cable-Control Cable, 600 Volt UL Type TC-ER, TFN Insulation PVC Jacket, Copper Conductors Construction: Soft bare annealed copper per ASTM B-3, Class B stranding per ASTM B-8; Insulation: Flame-retardant PVC per UL Standard 62 for Type TFN wire. Insulation jacket: clear nylon per UL Standard 62 for Type TFN wire; Jacket: Sunlight-resistant PVC per UL Standard 1277. Features: 600 Volt UL Type TC, TFN Insulation, PVC Jacket, Copper Conductors Applications: General purpose cable for use in power, control and lighting circuits in a broad range of commercial and industrial applications. Approved for continuous operation at 90ºC in dry locations, installation indoors or outdoors, aerially, in conduits, ducts, cable trays or direct burial in circuits not exceeding 600 volts. May be used in NEC Class I and II, Divison 2 hazardous locations. Number Number Insulation Catalog Size of of Thickness No. AWG Conductors Strands Mils TRAY600-18/2-7N* TRAY600-18/3-7N TRAY600-18/4-7N TRAY600-18/5-7N TRAY600-18/6-7N TRAY600-18/7-7N TRAY600-18/8-7N TRAY600-18/9-7N TRAY600-18/10-7N TRAY600-18/12-7N TRAY600-18/15-7N TRAY600-18/19-7N TRAY600-18/25-7N TRAY600-18/30-7N TRAY600-18/37-7N *Flat construction 18 2 18 3 18 4 18 5 18 6 18 7 18 8 18 9 18 10 18 12 18 15 18 19 18 25 18 30 18 37 7 7 7 7 7 7 7 7 7 7 7 7 7 7 7 15 15 15 15 15 15 15 15 15 15 15 15 15 15 15 Number Number Insulation Catalog Size of of Thickness No. AWG Conductors Strands Mils TRAY600-16/2-7N* TRAY600-16/3-7N TRAY600-16/4-7N TRAY600-16/5-7N TRAY600-16/6-7N TRAY600-16/7-7N TRAY600-16/8-7N TRAY600-16/9-7N TRAY600-16/10-7N TRAY600-16/12-7N TRAY600-16/15-7N TRAY600-16/16-7N TRAY600-16/19-7N TRAY600-16/20-7N TRAY600-16/25-7N TRAY600-16/37-7N TRAY600-16/50-7N *Flat construction 16 2 16 3 16 4 16 5 16 6 16 7 16 8 16 9 16 10 16 12 16 15 16 16 16 19 16 20 16 25 16 37 16 50 7 7 7 7 7 7 7 7 7 7 7 7 7 7 7 7 7 15 15 15 15 15 15 15 15 15 15 15 15 15 15 15 15 15 Nylon Jacket Thickness Mils 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 Nylon Jacket Thickness Mils 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 Overall Jacket Overall Thickness Diameter Mils Inch 45 45 45 45 45 45 45 45 45 45 45 60 60 60 60 .19 x .28 33 .28 43 .31 52 .33 62 .36 72 .37 79 .38 89 .41 104 .45 111 .46 127 .51 157 .57 202 .65 258 .69 300 .74 360 Overall Jacket Overall Thickness Diameter Mils Inch 45 45 45 45 45 45 45 45 45 45 60 60 60 60 60 80 80 Net Weight Lbs/Mft Technical Data: Flame Tests: • IEEE 383 70,000 BTU/hr flame test. • ICEA 210,000 BTU/hr flame test. Temperature: •9 0ºC Rated Voltage: • 600V Color Code: • ICEA Method 1, Table K-2 Approvals: •U L Type TC per Article 336 of the NEC • Approved for Class 1 remotecontrol and signaling circuits per Article 725 of the NEC Net Weight Lbs/Mft .20 x .30 42 .31 55 .34 69 .36 83 .39 96 .39 106 .39 122 .43 138 .46 149 .51 174 .60 229 .60 241 .63 275 .66 291 .72 355 .82 498 1.01 703 Tray Cables 800.633.6339 • www.lapptannehill.com 163 Tray Cables Tray Cable-Control Cable, 600 Volt UL Type TC-ER, THHN or THWN Insulation PVC Jacket Construction: Soft bare annealed copper per ASTM B-3, Class B stranding per ASTM B-8; Insulation: Flame-retardant PVC per UL Standard 83 for Type THHN or THWN wire. Insulation jacket: clear nylon per UL Standard 83 for Type THHN or THWN wire; Jacket: Sunlight-resistant PVC per UL Standard 1277. Features: 600 Volt UL Type TC, THHN or THWN Insulation, PVC Jacket, Copper Conductors Applications: General purpose cable for use in power, control and lighting circuits in a broad range of commercial and industrial applications. Approved for continuous operation at 90ºC in dry locations, installation indoors or outdoors, aerially, in conduits, ducts, cable trays or direct burial in circuits not exceeding 600 volts. May be used in NEC Class I and II, Divison 2 hazardous locations. Number Number Insulation Catalog Size of of Thickness No. AWG Conductors Strands Mils TRAY600-14/2-7N* TRAY600-14/3-7N TRAY600-14/4-7N TRAY600-14/5-7N TRAY600-14/6-7N TRAY600-14/7-7N TRAY600-14/9-7N TRAY600-14/10-7N TRAY600-14/12-7N TRAY600-14/16-7N TRAY600-14/19-7N TRAY600-14/20-7N TRAY600-14/25-7N TRAY600-14/30-7N TRAY600-14/37-7N TRAY600-14/40-7N TRAY600-14/50-7N TRAY600-14/60-7N *Flat construction 14 2 14 3 14 4 14 5 14 6 14 7 14 9 14 10 14 12 14 16 14 19 14 20 14 25 14 30 14 37 14 40 14 50 14 60 7 7 7 7 7 7 7 7 7 7 7 7 7 7 7 7 7 7 15 15 15 15 15 15 15 15 15 15 15 15 15 15 15 15 15 15 Nylon Jacket Thickness Mils 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 Overall Jacket Overall Thickness Diameter Mils Inch 45 45 45 45 45 45 45 60 60 60 60 60 80 80 80 80 80 80 Net Weight Lbs/Mft .22 x .33 62 .35 80 .38 99 .41 118 .45 140 .45 153 .52 196 .60 230 .61 267 .68 343 .71 396 .75 423 .83 511 .93 636 .98 766 1.01 840 1.17 1043 1.21 1200 Technical Data: Flame Tests: • IEEE 383 70,000 BTU/hr flame test. • ICEA 210,000 BTU/hr flame test. Temperature: •9 0ºC Rated Voltage: • 600V Color Code: • ICEA Method 1, Table K-2. Approvals: •U L Type TC per Article 336 of the NEC • Approved for Class 1 remotecontrol and signaling circuits per Article 725 of the NEC. Please contact your sales representative for detailed information at sales@lapptannehill.com 164 Tray Cables 800.633.6339 • www.lapptannehill.com Tray Cables Tray Cable-Control Cable, 600 Volt UL Type TC-ER, THHN or THWN Insulation PVC Jacket Construction: Soft bare annealed copper per ASTM B-3, Class B stranding per ASTM B-8; Insulation: Flame-retardant PVC per UL Standard 83 for Type THHN or THWN wire. Insulation jacket: Clear nylon per UL Standard 83 for Type THHN or THWN wire; Jacket: Sunlight-resistant PVC per UL Standard 1277. Features: 600 Volt UL Type TC, TFN Insulation, PVC Jacket, Copper Conductors Applications: General purpose cable for use in power, control and lighting circuits in a broad range of commercial and industrial applications. Approved for installation indoors or outdoors, aerially, in conduits, ducts, cable trays or direct burial in circuits not exceeding 600 volts. May be used in NEC Class I and II, Divison 2 hazardous locations. UL approved for use in continuous operation at 75ºC in wet locations, 90ºC in dry locations, 130ºC for emergency overload conditions, and 250ºC for short circuit conditions. Number Number Insulation Catalog Size of of Thickness No. AWG Conductors Strands Mils TRAY600-12/2-7N* TRAY600-12/3-7N TRAY600-12/4-7N TRAY600-12/5-7N TRAY600-12/7-7N TRAY600-12/9-7N TRAY600-12/10-7N TRAY600-12/12-7N TRAY600-12/15-7N TRAY600-12/16-7N TRAY600-12/19-7N TRAY600-12/20-7N TRAY600-12/25-7N TRAY600-12/30-7N TRAY600-12/37-7N *Flat construction 12 2 12 3 12 4 12 5 12 7 12 9 12 10 12 12 12 15 12 16 12 19 12 20 12 25 12 30 12 37 7 7 7 7 7 7 7 7 7 7 7 7 7 7 7 15 15 15 15 15 15 15 15 15 15 15 15 15 15 15 Number Number Insulation Catalog Size of of Thickness No. AWG Conductors Strands Mils TRAY600-10/2-7N* TRAY600-10/3-7N TRAY600-10/4-7N TRAY600-10/5-7N TRAY600-10/6-7N TRAY600-10/7-7N TRAY600-10/9-7N TRAY600-10/12-7N TRAY600-10/16-7N TRAY600-10/19-7N *Flat construction 10 2 10 3 10 4 10 5 10 6 10 7 10 9 10 12 10 16 10 19 7 7 7 7 7 7 7 7 7 7 20 20 20 20 20 20 20 20 20 20 Nylon Jacket Thickness Mils 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 Nylon Jacket Thickness Mils 4 4 4 4 4 4 4 4 4 4 Overall Jacket Overall Thickness Diameter Mils Inch 45 45 45 45 45 60 60 60 60 60 60 80 80 80 80 .24 x .37 77 .39 110 .42 138 .46 165 .50 216 .62 297 .67 324 .69 378 .76 468 .76 488 .80 568 .89 642 .99 775 1.03 910 1.14 1105 Overall Jacket Overall Thickness Diameter Mils Inch 45 45 60 60 60 60 60 80 80 80 Net Weight Lbs/Mft .27 x .44 .45 .50 .58 .63 .63 .73 .86 .97 1.02 Technical Data: Flame Tests: • IEEE 383 70,000 BTU/hr flame test. • ICEA 210,000 BTU/hr flame test. Temperature: •9 0ºC Rated Voltage: • 600V Color Code: • ICEA Method 1, Table K-2 Approvals: •U L Type TC per Article 336 of the NEC • Approved for Class 1 remotecontrol and signaling circuits per Article 725 of the NEC Net Weight Lbs/Mft 131 169 231 276 329 361 465 647 817 920 Not finding what you are looking for? Please contact us at sales@lapptannehill.com, or visit our website at: www.lapptannehill.com Tray Cables 800.633.6339 • www.lapptannehill.com 165 Tray Cables Tray Cable-Control Cable, 600 Volt UL Type TC-ER, THHN or THWN Insulation PVC Jacket Construction: Soft bare annealed copper per ASTM B-3, Class B stranding per ASTM B-8; Insulation: Flame-retardant PVC per UL Standard 83 for Type THHN or THWN wire. Jacket: Sunlight-resistant PVC per UL Standard 1277. Features: Insulation jacket: clear nylon per UL Standard 83 for Type THHN or THWN wire Grounding Conductor: soft bare annealed copper per ASTM B-3, Class B stranding per ASTM B-8 sized in accordance with UL Standard 1277. 600 Volt, UL Type TC, THHN or THWN Insulation, PVC Jacket, Copper Conductors. Applications: General purpose cable for use in primary power and feeder circuits in a broad range of commercial and industrial applications. Approved for installation indoors or outdoors, aerially, in conduits, ducts, cable trays or direct burial in circuits not exceeding 600 volts. May be used in NEC Class I and II, Divison 2 hazardous locations. UL approved for use in continuous operation at 75ºC in wet locations, 90ºC in dry locations, 130ºC for emergency overload conditions, and 250ºC for short circuit conditions. Number Number Insulation Catalog Size of of Thickness No. AWG Conductors Strands Mils TRAY600-8/3-7N TRAY600-8/4-7N TRAY600-6/3-7N TRAY600-6/4-7N TRAY600-4/3-7N TRAY600-4/4-7N TRAY600-2/3-7N TRAY600-2/4-7N TRAY600-1/3-19N 8 8 6 6 4 4 2 2 1 3 7 4 7 3 7 4 7 3 7 4 7 3 7 4 7 3 19 Nylon Jacket Thickness Mils 30 30 30 30 40 40 40 40 50 5 5 5 5 6 6 6 6 7 Size Number Number Insulation Catalog AWG/ of of Thickness No. kcmil Conductors Strands Mils TRAY600-1/0-3-19N TRAY600-1/0-4-19N TRAY600-2/0-3-19N TRAY600-2/0-4-19N TRAY600-3/0-3-19N TRAY600-3/0-4-19N TRAY600-4/0-3-19N TRAY600-4/0-4-19N TRAY600-250/3-37N TRAY600-250/4-37N TRAY600-350/3-37N TRAY600-350/4-37N TRAY600-500/3-37N TRAY600-500/4-37N TRAY600-750/3-37N 166 1/0 1/0 2/0 2/0 3/0 3/0 4/0 4/0 250 250 350 350 500 500 750 3 4 3 4 3 4 3 4 3 4 3 4 3 4 3 19 19 19 19 19 19 19 19 37 37 37 37 37 37 37 50 50 50 50 50 50 50 50 60 60 60 60 60 60 60 Overall Jacket Overall Thickness Diameter Mils Inch Technical Data: Flame tests: • IEEE 383 70,000 BTU/hr flame test. • ICEA 210,000 BRU/hr flame test. Temperature: •9 0ºC Net Weight Lbs/Mft Rated Voltage: • 600V 60 .58 220 60 .61 286 60 .69 386 60 .76 505 60 .89 630 80 .97 828 80 1.03 930 80 1.13 1213 80 1.15 1252 Nylon Jacket Thickness Mils 7 7 7 7 7 7 7 7 8 8 8 8 8 8 9 Ground Wire Size AWG Overall Jacket Thickness Mils 6 80 6 80 6 80 6 80 4 80 4 80 4 80 4 80 3 110 3 110 3 110 3 110 2 110 1 110 1 110 Color Code: • ICEA Method 4 Approvals: •U L Type TC per Article 336 of the NEC Overall Diameter Inch Net Weight Lbs/Mft 1.22 1.34 1.32 1.45 1.42 1.58 1.54 1.77 1.75 1.94 1.97 2.18 2.26 2.49 2.82 1423 1832 1718 2223 2131 2756 2592 3457 3123 4046 4204 5469 5792 7556 9060 Tray Cables 800.633.6339 • www.lapptannehill.com Tray Cables Tray Cable-Shielded Control Cable, 600 Volt UL Type TC-ER, TFN Insulation PVC Jacket Construction: Soft bare annealed copper per ASTM B-3, Class B stranding per ASTM B-8; Insulation: Flame-retardant PVC per UL Standard 62 for Type TFN wire; Jacket: Sunlight-resistant PVC per UL Standard 1277. Features: Insulation jacket: clear nylon per UL Standard 62 for Type TFN wire. Overall Shield: Aluminum-polymer tape providing 100% coverage with a flexible 7-strand tinned copper drain wire. Applications: General purpose cable for use where shielding from electrostatic interference is required in power, control and lighting circuits in a broad range of commercial and industrial applications. Approved for continuous operation at 90ºC in dry locations, installation indoors or outdoors, aerially, in conduits, ducts, cable trays or direct burial in circuits not exceeding 600 volts. May be used in NEC Class I and II, Division 2 hazardous locations. Number Number Insulation Catalog Size of of Thickness No. AWG Conductors Strands Mils TRAY600-18/2-7S TRAY600-18/3-7S TRAY600-18/4-7S TRAY600-18/5-7S TRAY600-18/6-7S TRAY600-18/7-7S TRAY600-18/8-7S TRAY600-18/12-7S TRAY600-18/19-7S TRAY600-18/37-7S 18 2 18 3 18 4 18 5 18 6 18 7 18 8 18 12 18 19 18 37 7 7 7 7 7 7 7 7 7 7 15 15 15 15 15 15 15 15 15 15 Number Number Insulation Catalog Size of of Thickness No. AWG Conductros Strands Mils TRAY600-16/2-7S TRAY600-16/3-7S TRAY600-16/4-7S TRAY600-16/5-7S TRAY600-16/6-7S TRAY600-16/7-7S TRAY600-16/8-7S TRAY600-16/9-7S TRAY600-16/10-7S TRAY600-16/12-7S TRAY600-16/19-7S TRAY600-16/25-7S TRAY600-16/37-7S 16 2 16 3 16 4 16 5 16 6 16 7 16 8 16 9 16 10 16 12 16 19 16 25 16 37 7 7 7 7 7 7 7 7 7 7 7 7 7 15 15 15 15 15 15 15 15 15 15 15 15 15 Nylon Jacket Thickness Mils 4 4 4 4 4 4 4 4 4 4 Nylon Jacket Thickness Mils 4 4 4 4 4 4 4 4 4 4 4 4 4 Overall Jacket Overall Thickness Diameter Mils Inch 45 45 45 45 45 45 45 45 60 60 .27 34 .28 43 .31 52 .33 62 .36 72 .36 79 .38 89 .46 127 .57 202 .74 360 Overall Jacket Overall Thickness Diameter Mils Inch 45 45 45 45 45 45 45 45 45 45 60 60 80 Net Weight Lbs/Mft Technical Data: Flame Tests: • IEEE 383 70,000 BTU/hr flame test. • ICEA 210,000 BTU/hr flame test. Temperature: •9 0ºC Rated Voltage: • 600V Color Code: • ICEA Method 1, Table K-2 Approvals: •U L Type TC per Article 336 of the NEC • Approved for Class 1 remotecontrol and signaling circuits per Article 725 of the NEC Net Weight Lbs/Mft .29 43 .31 55 .34 69 .36 83 .39 96 .39 106 .43 122 .46 138 .49 149 .51 174 .63 275 .72 355 .82 498 Specifications subject to change. For complete specifications and availability visit www.lapptannehill.com Tray Cables 800.633.6339 • www.lapptannehill.com 167 Tray Cables Color Code Charts ICEA/NEMA Method 1 - Colored insulation with contrasting ink tracers as required. Six different insulation colors and four different colored ink tracers are used to provide positive identification through 21 conductors. The same identification sequence may be repeated for cables containing more than 21 conductors. ICEA/NEMA Method 4 - A neutral- or single-colored insulation compound is surface ink printed with conductor number to provide positive conductor identification through 21 conductors. The identification sequence is repeated for cables containing more than 21 conductors. Color Code Charts ICEA METHOD 1, Table K-2 Conductor No. Base Color Spiral Stripe Conductor No. 1 Black --- 19 Orange Blue 2 Red --- 20 Yellow Blue 3 Blue --- 21 Brown Blue 4 Orange --- 22 Black Orange 5 Yellow --- 23 Red Orange 6 Brown --- 24 Blue Orange 7 Red Black 25 Yellow Orange 8 Blue Black 26 Brown Orange 9 Orange Black 27 Black Yellow 10 Yellow Black 28 Red Yellow 11 Brown Black 29 Blue Yellow 12 Black Red 30 Orange Yellow Blue Red 31 Brown Yellow 14 Orange Red 32 Black Brown 15 Yellow Red 33 Red Brown 16 Brown Red 34 Blue Brown 17 Black Blue 35 Orange Brown 18 Red Blue 36 Yellow Brown 13 Base Color Spiral Stripe NOTE: Color code repeats after 36 conductors. No green or white conductors/stripes. For different colors, please call 800.633.6339 for information. 168 Tray Cables 800.633.6339 • www.lapptannehill.com Not finding what you are looking for? Please contact us at sales@lapptannehill.com, or visit our website at: www.lapptannehill.com Tray Cables 800.633.6339 • www.lapptannehill.com 169 170 Tray Cables 800.633.6339 • www.lapptannehill.com