may/june 2015

January/February 2009

DEPARTMENTS

16

18

Vibrio Control In Shrimp Farming – Part I. Hatcheries

Stephen G. Newman, Ph.D.

Stress-Vibrio Dynamics During High-Density,

Zero-Exchange Production Of White Shrimp

Tzachi M. Samocha, Ph.D.; David I. Prangnell, Ph.D.;

Leandro F. Castro, M.S.; Susan Laramore, Ph.D.

22 The Bottom Line

Feed Trays – The Good, The Bad, The Ugly

Thomas R. Zeigler, Ph.D.; Scott E. Horton, M.S.

25 Sustainable Aquaculture Practices

Embodied Resource Use In Feed-Based Aquaculture

Claude E. Boyd, Ph.D.; Aaron McNevin, Ph.D.

28 Soy-Fed Fish News

Soybeans: Truly Sustainable Feed Ingredient?

Part II. Non-GMO Alternatives, Sustainability Certification

Kelly Coleman

30 Diets Affect Abalone Meat Quality, Shell Color

Zhi Yong Ju, Ph.D.; Cecilia Viljoen

32 Parasitism Enhances Tilapia Susceptibility

To Flavobacterium columnare

De-Hai Xu, Ph.D.; Craig Shoemaker, Ph.D.;

Benjamin LaFrentz, Ph.D.

Roger W. Doyle, Ph.D.; Cherdsak Virapat, Ph.D.;

Wongpathom Kamonrat, Ph.D.

da Silva Campos, Ítala Gabriela Sobral dos Santos,

Yllana Ferreira Marinho, Dr. Luis Vinatea, Luis Otavio Brito

Dr. Hugues Lemonnier, Pr. Yves Letourneur

From The President

From The Editor

GAA Activities

Industry News

GAA Calendar

Advocate Advertisers

34 National Broodstock Improvement Network –

Concept For Breaking Inbreeding/Disease Feedback Loop

36 Plankton Communities In Shrimp Monoculture,

Integrated Biofloc System

Dr. Alfredo Olivera Gálvez, Clarissa Vilela Figueiredo

2

3

6

76

78

80

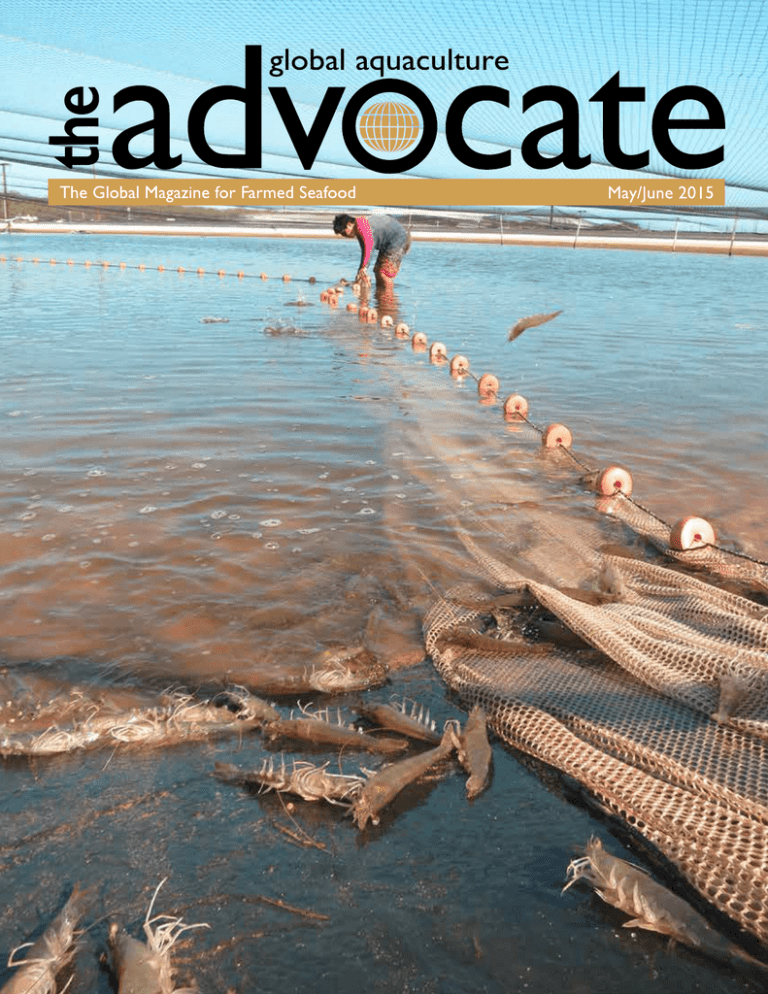

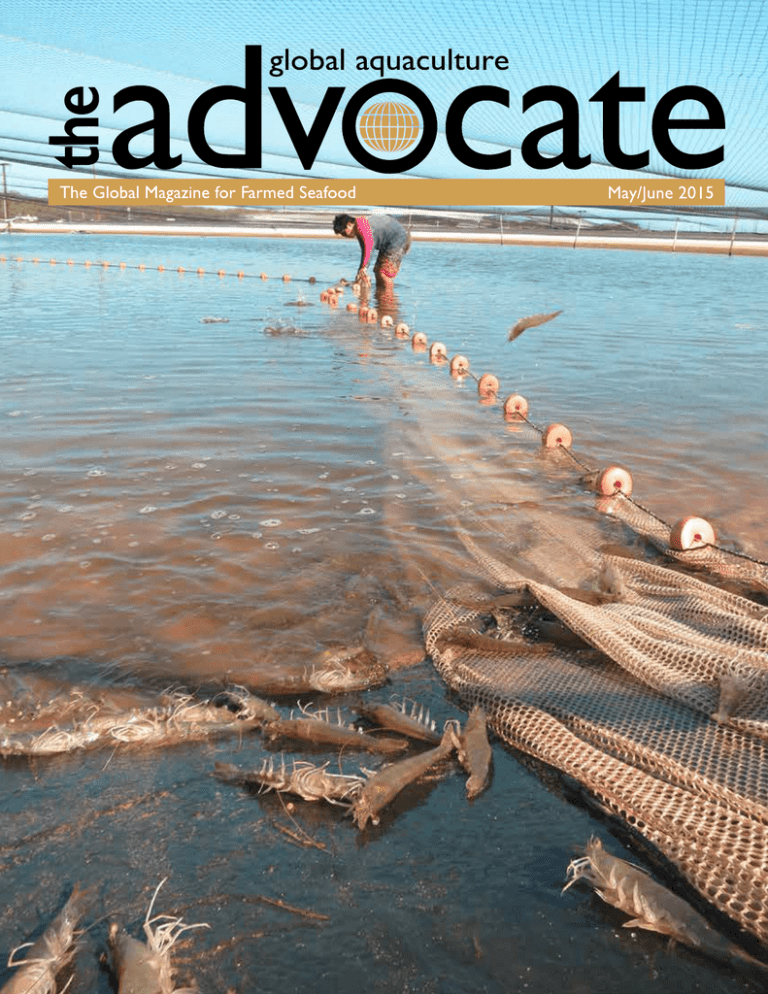

On the cover:

Kaui Shrimp. Photo by George Chamberlain.

Page 22

Feed Trays

Feed trays are credited with

reducing feed cost per unit

of production, but their

effects on optimizing overall

crop profitability are seldom

mentioned.

Page 58

PCR For AHPND

A new qPCR assay has high

sensitivity, delivers results

within half an hour and can

be used for quantification

of water and shrimp samples.

40 Study Seeks Candidates For Blue Shrimp Polyculture

In New Caledonia

Dr. Trung Cong Luong, Dr. Sébastien Hochard, Florence Royer,

42

44

Nesar Ahmed, Ph.D.

58 Real-Time PCR Offers Sensitivity, Specificity

In Detecting AHPND Plasmid

Jee Eun Han, DVM, Ph.D.; Kathy Tang, Ph.D.;

Michael Tlusty, Ph.D.; Øisten Thorsen, M.S.

62 Peracetic Acid Products Expand Sanitizing,

Organic Water Treatment Options

Coastal Aquaculture Must Adapt To Climate Change

In Bangladesh

Certified Clarity In Aquaculture – Defined Tiers

Could Provide Clearer Framework

46 FAO Fish Indices Enhance Global Seafood

Price Evaluations

50

52

54

ii

May/June 2015

global aquaculture advocate

Dr. Frank Asche, Dr. Sigbjørn L. Tveterås

Seafood and Health

Nutrition, Food Security Take Center Stage

Roy D. Palmer, FAICD

Food Safety And Technology

Human Enteric Viruses In Shellfish

Part I. Rotaviruses

George J. Flick, Jr., Ph.D.; David D. Kuhn, Ph.D.

U.S. Seafood Markets

Paul Brown, Jr.; Janice Schreiber; Angel Rubio

Carlos Pantoja, Ph.D.; Brenda White; Donald Lightner, Ph.D.

Lars-Flemming Pedersen, Ph.D.; Alfred Jokumsen; Villy Juul Larsen;

Niels Henrik Henriksen

Thomas M. Losordo, Ph.D.; Dennis P. DeLong, MSM;

Todd C. Guerdat, Ph.D.

Steven Summerfelt, Ph.D.; John Davidson, M.S.; Travis May;

Christopher Good, DVM, Ph.D.; Brian Vinci, Ph.D.

Matt Hawkyard, Ph.D. Candidate; Chris Landgon, Ph.D.;

Mark Drawbridge, M.S.; Kevin Stuart, M.S.

Jason Danaher, Ph.D.; Jeremy Pickens; Jeffrey Sibley, Ph.D.;

Jesse Chappell, Ph.D.; Terrill Hanson, Ph.D.

64 Aquaculture Engineering

TAN, Other Water Quality Factors Affect Nitrification

Rates In Biofilters

66 Emerging Trends In Salmoid RAS

Part II. System Enhancements

68 Liposomes Open New Doors In Larval Fish Nutrition

72 Aquaculture Effluent Partially Replaces Growing Mix

For Plant Production

global aquaculture advocate

May/June 2015

1

from the president

GLOBAL AQUACULTURE

ALLIANCE

The Global Aquaculture Al­li­ance is an international non-profit, non-gov­ernmental

association whose mission is to further en­vi­

ron­men­tally responsible aqua­culture to meet

world food needs. Our members are producers, pro­cessors, marketers and retailers of seafood prod­ucts worldwide. All aqua­­culturists

in all sectors are welcome in the organization.

OFFICERS

George Chamberlain, President

Bill Herzig, Vice President

Lee Bloom, Secretary

Jim Heerin, Treasurer

Iain Shone, Assistant Treasurer

Jeff Fort, Chief Financial Officer

Wally Stevens, Executive Director

BOARD OF DIRECTORS

Bert Bachmann

Mike Berthet

Lee Bloom

Rittirong Boonmechote

George Chamberlain

Shah Faiez

Robert Fields

Jeff Fort

John Galiher

Jim Heerin

Bill Herzig

Ray Jones

Alex Ko

Jordan Mazzetta

Robins McIntosh

Sergio Nates

John Peppel

César Real

John Schramm

Jeff Sedacca

Iain Shone

Wally Stevens

RELATIONSHIP MANAGER

Sally Krueger

sally.krueger@gaalliance.org

EDITOR

Darryl Jory

editorgaadvocate@aol.com

PRODUCTION STAFF

Assistant Editor

David Wolfe

david.wolfe@gaalliance.org

Graphic Designer

Lorraine Jennemann

lorraine.jennemann@gaalliance.org

HOME OFFICE

4111 Telegraph Road, Suite 302

St. Louis, Missouri 63129 USA

Telephone: +1-314-293-5500

FAX: +1-314-293-5525

E-mail: homeoffice@gaalliance.org

Website: http://www.gaalliance.org

All contents copyright © 2015

Global Aquaculture Alliance.

Global Aquaculture Advocate

is printed in the USA.

ISSN 1540-8906

2

May/June 2015

Learning From LEED

This issue marks 18 years since the Global

Aquaculture Alliance was founded. During this

time, GAA has contributed to major advances in

aquaculture sustainability by bringing together

stakeholders throughout the value chain to identify

issues and solutions at annual GOAL meetings, by

investigating improved practices such as mangrove

George

restoration and disease control and, perhaps most

Chamberlain, Ph.D.

importantly, by developing certification standards

for aquaculture.

President

GAA’s approach to certification has been to

Global Aquaculture Alliance

george.chamberlain@gaalliance.org

encourage the entire industry to move forward by

developing achievable standards that are continuously

improved over time. Since the Best Aquaculture

Practices program began in 2003, the annual seafood volume from BAP-certified facilities

has increased to 750,000 mt for farms and 1,400,000 mt for processing plants.

This is a remarkable achievement, but it has focused on high-value internationally

traded products like shrimp, salmon and tilapia, and amounts to only a small portion of

global aquaculture production. Going forward, aquaculture certification must also make

itself relevant to lower-value products and domestic markets.

How can a certification program diversify its programs? One way of surveying

options is to review parallel certification programs in more-advanced sectors, such as

energy and transportation. For example, a certification program for green buildings

called Leadership in Energy and Environmental Design (LEED) has experienced phenomenal growth in the last 15 years.

Both LEED and BAP began with one set of standards and expanded over time.

LEED now has nine products, including one for neighborhood development, which is

analogous to the developing BAP standards on zone management.

BAP has standards for aquaculture farms, hatcheries, feed mills and processing plants.

This is because to GAA, farm standards alone are not adequate to deal with the varied

range of labor, environmental and food safety issues impacting the aquaculture sector

today. Seafood retailers are increasingly embracing BAP’s four-level approach, known

as “four-star” certification.

A key to LEED’s success is the variety of incentives it offers. In addition to providing healthier living and working environments, LEED buildings have higher value and

lower operational costs, as well as tax and permitting advantages. BAP owes its growth

to strong support from major seafood buyers, due to its environmental, social and food

safety assurances. LEED reminds us to consider secondary benefits of certification,

such as risk reduction and traceability, that could lead to additional support from lenders, insurers and regulators.

In comparing BAP and LEED, a point of difference is that BAP offers only one

level of certification for a range of facilities. LEED offers four levels of excellence: certified, silver, gold and platinum, as determined by the number of points scored during

certification. Looking forward, the LEED model points to an opportunity to differentiate levels of excellence within BAP.

For example, it might be easier for small farms to clear the hurdle of certification if

there were a more achievable entry-level standard. On the other hand, some retailers are

calling for more rigorous food safety standards at processing plants. These different levels of excellence could be established within BAP or by aligning BAP with other standards programs to establish tiers using common criteria and metrics (see article by

Michael Tlusty and Øisten Thorsen on page 44 of this issue).

As BAP strives to move the aquaculture industry forward, it can take a lesson from

LEED and begin establishing secondary incentives and differentiating levels of excellence to provide a more comprehensive framework for the sustainability of aquaculture.

from the editor

Genetics Vital

For Aquaculture

Our aquaculture industry needs to significantly

expand its production to continue feeding the growing human population. Among the most important

tools at our disposal is genetic improvement of cultured stocks. Yet despite its potential to improve

Darryl E. Jory, Ph.D.

production efficiency, only an estimated 10 to 12%

of global aquaculture production is currently based

Editor, Development Manager

Global Aquaculture Advocate

on genetically enhanced stocks.

editorgaadvocate@aol.com

The plant and animal production industries have

been improved for many years through genetic intervention using a variety of technologies. The benefits

of these advances are well documented. For example, between 1957 and 1991, broiler

chickens achieved a 68% reduction in days to harvest, 66% improvement in feed-conversion efficiency, 30% reduction in carcass fat and 15% improvement in carcass yield.

Some 85 to 90% of these impressive figures were due to genetics.

The swine industry shows similar improvements. Between 1980 and 2001, it

achieved a 15% reduction in days to harvest and 45% improvement in lean gain efficiency – both due 50% to genetics. Further improvements have obviously continued

since then for both industries.

Historically, aquaculture genetics started over two millennia ago with the initiation

of aquaculture in China, Egypt and Rome when some fish were selected on cosmetic

traits like coloration and patterns. Genetic enhancement programs started in the 1960s.

Family-based breeding programs, which began for salmonids in Norway during the

1970s, have since been globally implemented for many important species.

Molecular-based technology arrived in the 1980s, and the use of traditional selective

breeding, biotechnology and molecular genetics is now well established. Various companies have emerged to produce improved stocks of salmonids, tilapia, marine shrimp,

catfish, cod, seabass, sea bream, shellfish and other species.

The further implementation of genetic improvement in the aquaculture industry

faces a number of challenges. One is the large number of farmed species – probably over

300 globally – which means extreme diversity regarding reproductive physiology and

capacities that affect the implementation of cost-efficient programs.

These programs are complex and very costly, and involve substantial financial risks.

Producers of many species often can access wild seedstock and broodstock, and will not

pay premium prices for improved animals. There is unauthorized reproduction of

improved animals for many species, with limited biological protection, mainly through

narrow genetic backgrounds, and relatively limited legal protection.

The pressure for the global aquaculture industry to produce more means there is everincreasing pressure to develop more efficient production technologies. Genetic improvement programs target several traits, the foremost of which is improved growth rate, which

results in shorter production cycles and improved risk management. Also targeted are

improved disease resistance, sexual maturation, carcass yield and salinity tolerance.

Genetic improvement is a common denominator among nutrition, health management and other major areas of production. At present, it is clearly a commercially viable

alternative for many species. The technology has unlimited potential to help the industry increase its output for the future.

As always, we encourage your suggestions for current topics you would like us to

cover, as well as contributions of short articles. Please contact me at your convenience

for our article guidelines. Your critical comments make our magazine better, and I urge

you to continue sending us your comments on how we can best represent and serve our

industry.

Sincerely,

Sincerely,

George Chamberlain

Darryl E. Jory

global aquaculture advocate

FOUNDING MEMBERS

Agribrands International Inc.

Agromarina de Panamá, S.A.

Aqualma – Unima Group

Aquatec/Camanor

Asociación Nacional de Acuicultores de Colombia

Asociación Nacional de Acuicultores de Honduras

Associação Brasileira de Criadores de Camarão

Bangladesh Chapter – Global Aquaculture Alliance

Belize Aquaculture, Ltd.

Bluepoints Co., Inc.

Cámara Nacional de Acuacultura

Camaronera de Coclé, S.A.

Cargill Animal Nutrition

Chicken of the Sea Frozen Foods

Continental Grain Co.

C.P. Aquaculture Business Group

Darden Restaurants

Deli Group, Ecuador

Deli Group, Honduras

Delta Blue Aquaculture

Diamante del Mar S.A.

Eastern Fish Co.

El Rosario, S.A.

Empacadora Nacional, C.A.

Expack Seafood, Inc.

Expalsa – Exportadora de Alimentos S.A.

FCE Agricultural Research and Management, Inc.

High Liner Foods

India Chapter – Global Aquaculture Alliance

Indian Ocean Aquaculture Group

INVE Aquaculture, N.V.

King & Prince Seafood Corp.

Long John Silver’s, Inc.

Lyons Seafoods Ltd.

Maritech S.A. de C.V.

Meridian Aquatic Technology Systems, LLC

Monsanto

Morrison International, S.A.

National Fish & Seafood Co./

Lu-Mar Lobster & Shrimp Co.

National Food Institute

National Prawn Co.

Ocean Garden Products, Inc.

Overseas Seafood Operations, SAM

Pescanova USA

Preferred Freezer Services

Productora Semillal, S.A.

Red Chamber Co.

Rich-SeaPak Corp.

Sahlman Seafoods of Nicaragua, S.A.

Sanders Brine Shrimp Co., L.C.

Sea Farms Group

Seprofin Mexico

Shrimp News International

Sociedad Nacional de Galápagos

Standard Seafood de Venezuela C.A.

Super Shrimp Group

Tampa Maid Foods, Inc.

U.S. Foodservice

Vitapro-Nicovita-Salmofood

Zeigler Brothers, Inc.

global aquaculture advocate

May/June 2015

3

Making the ordinary Pizza

Join the world’s leading

aquaculture organization

Aquaculture is the future of the world’s seafood supply.

Be part of it by joining the Global Aquaculture Alliance,

the leading standards-setting organization for farmed

seafood.

Access science-based information on efficient aquaculture management. Connect with other responsible

companies and reach your social responsibility goals.

Shrimp Extraordinary

Improve sales by adopting GAA’s Best Aquaculture

Practices certification for aquaculture facilities.

Annual dues start at U.S. $150 and include a subscription to the Global Aquaculture Advocate magazine,

GAA e-newsletters, event discounts and other benefits.

Visit www.gaalliance.org or contact the GAA office

for details.

Global Aquaculture Alliance

Feeding the World Through Responsible Aquaculture – www.gaalliance.org – +1-314-293-5500

GOVERNING MEMBERS

Alltech

Aqua Bounty Technologies, Inc.

Beaver Street Fisheries

Blue Archipelago Berhad

Capitol Risk Concepts, Ltd.

Cargill Animal Nutrition

Chang International, Inc.

Charoen Pokphand Foods PCL

Darden Restaurants

Dataj Aquafarm Inc.

Delta Blue Aquaculture LLC

Diversified Business Communications

Eastern Fish Co., Inc.

Ever Nexus Sdn. Bhd.

Grobest USA, Inc.

High Liner Foods

H.J. Baker & Brothers, Inc.

iAqua

International Associates Corp.

INVE B.V.

King & Prince Seafood Corp.

Lyons Seafoods Ltd.

Maloney Seafood Corp.

Marine Technologies

Mazzetta Co. LLC

Megasupply

Morey’s Seafood International

National Fish & Seafood Inc.

Pentair Aquatic Eco-Systems

Pescanova USA

Preferred Freezer Services

Red Chamber Co.

Rich Products Corp.

Sahlman Seafoods of Nicaragua, S.A.

Sea Port Products Corp.

Seafood Exchange of Florida

Seajoy

Seavina Joint Stock Co.

Sunnyvale Seafood Co., Inc.

Thai Union Group

Tropical Aquaculture Products, Inc.

Urner Barry Publications, Inc.

Vitapro-Nicovita-Salmofood

Wuhan Lanesync Supply Chain

Management Co., Ltd.

Zeigler Brothers, Inc.

4

May/June 2015

SUSTAINING MEMBERS

Akin Gump Strauss Hauer & Feld

Amanda Seafood

Ammon International, Inc.

Anova Food Inc.

Aqua Star

Aquatec Aquacultura Ltda.

A.Z. Gems Inc.

BioMar Group

Blue Ridge Aquaculture

BMR Seafood LLC

Camanchaca Inc.

Channel Fish Processing Co., Inc.

Direct Source Seafood

DNI Group, LLC

DSM Nutritional Products

Fega Marikultura P.T.

Fortune Fish Co.

Gorton’s Seafood

Great American Seafood Imports Co.

H & N Foods International, Inc./Expack

H & T Seafood, Inc.

Hai Yang International, LLC

Harbor Seafood, Inc.

Harvest Select

International Marketing Specialists

Ipswich Shellfish Co., Inc.

Long John Silver’s, LLC

Mahalo Seafood LLC

Maritime Products International

Merck Animal Health

Mirasco, Inc.

North Coast Seafoods

Odyssey Enterprises, Inc.

Orca Bay Seafoods

Ore-Cal Corp.

Pacific Supreme Co.

Quirch Foods

Rubicon Resources

Seacore Seafood, Inc.

Seafood Industry Development Corp.

Seattle Fish Co. of New Mexico

Seattle Shrimp & Seafood Co., Inc.

Skretting

Slade Gorton & Co., Inc.

Solae, LLC

Star Agro Marine Exports Ltd.

global aquaculture advocate

Tampa Bay Fisheries, Inc.

Tampa Maid Foods

The Fishin’ Co.

The Great Fish Co.

Trident Seafoods

United Seafood Enterprises, L.P.

ASSOCIATION MEMBERS

All China Federation of Industry

and Commerce Aquatic Production

Chamber of Commerce

American Feed Industry Association

Asociación Latino Americana

de Plantas de Rendimiento

Associação Brasileira de Criadores

de Camarão

Australian Prawn Farmers Association

Bangladesh Shrimp and Fish Foundation

China Aquatic Products Processing

and Marketing Alliance

Fats and Proteins Research

Foundation, Inc.

Indiana Soybean Alliance

Indonesian Aquaculture Society

IFFO – The Marine

Ingredients Organisation

Malaysian Shrimp

Industry Association

Marine Products Export

Development Authority

National Fisheries Institute

National Renderers Association

Oceanic Institute

Prince Edward Island Seafood

Processors Association

SalmonChile

Salmon of the Americas

Seafood Importers

and Processors Alliance

Soy Aquaculture Alliance

Thai Frozen Foods Association

Universidad Austral de Chile

U.S. Soybean Export Council

Washington Fish Growers Association

Washington State China Relations Council

World Aquaculture Society

World Renderers Organization

C

M

Y

CM

MY

CY

CMY

K

Premium Quality Shrimp at the Absolute Peak of Freshness

SAIL® Brand farm raised shrimp is produced under the highest standards of

sustainable aquaculture to ensure complete traceability from the hatchery through

the grow-out phase in aquaculture farms, to the facility where it is hand-processed

and then frozen for its final journey to the customer.

800-526-9066 easternfish.com

global aquaculture advocate

May/June 2015

5

gaa activities

GAA Recognizes Companies’ Commitment

To Excellence

The Global Aquaculture Alliance recognized nine companies with its “Commitment to Excellence” award at Seafood

Expo North America in Boston, Massachusetts, USA, in mid-March. The

awards reflect the companies’ recent

achievement of four-star Best Aquaculture Practices (BAP) certification.

The companies were Northern Harvest Sea Farms Group, Saota Foods JSC

(Fimex V.N.) Group, Trang Corp.

Group, C.P. Vietnam Corp. Group, Seafresh Industries Public Group, Pakfood

Group, Thai Union Frozen Group,

Marine Harvest Canada Group and

Cooke Aquaculture Group.

Carson Roper, international business

The awards recognized the achievement of BAP’s top level of facility certification.

development manager for BAP, presented

the awards during a brief ceremony at the

conclusion of the GAA membership and

Alliance Hosts

Retailer Tours

In Boston

On the eve of Seafood Expo North America, the Global

Aquaculture Alliance hosted two tours of retail outlets in the

Boston, Massachusetts, USA, area to give SENA exhibitors

from China and Vietnam the opportunity to view their seafood products on display at Wegmans, Stop & Shop and

B.J.’s Wholesale Club.

The Chinese delegation consisted of members of the

China Aquatic Products Processing and Marketing Alliance

(CAPPMA), led by Executive Deputy Secretary General Di

Gang. The Vietnamese delegation included members of the

Viet Nam Pangasius Association (VNPA), led by Chairman

Dr. Nguyen Viet Thang and Secretary General Dr. Vo Hung

Dung.

“The tour was a very beneficial experience,” CAPPMA’s

Di said. “It provided a great opportunity for our members to

further understand U.S. supermarket seafood merchandising

and U.S. consumers’ preferences.”

“We appreciated the chance to see how product is sold in

different types of U.S. retail stores,” VNPA said. “Our members benefited greatly from the tour.”

“This was a tremendous opportunity to view firsthand the

latest retail merchandising trends with respect to branding,

food safety, quality and sustainability,” said Carson Roper,

international business development manager for the Best

Aquaculture Practices certification program. “It was an educational experience for all of us.”

6

May/June 2015

global aquaculture advocate

update meeting in Boston.

Congratulations to the winners.

GAA-Fishin’ Co. Survey

Finds U.S. Views On

Aquaculture Mixed

In conjunction with the Global Aquaculture Alliance, The

Fishin’ Co. presented the preliminary results of a consumer survey at

the GAA membership meeting at Seafood Expo North America in

Boston, Massachusetts, USA, on March 16.

Administered by The Fishin’ Co. and fielded by Field Agent, the

survey asked questions on topics that included a general comparison

of farmed and wild seafood, country of origin and sustainability.

More than 500 U.S. seafood consumers were polled nationwide.

Nearly half (47%) of the survey respondents had a negative perception of farmed seafood due to product quality, food safety or environmental concerns. However, that perception of aquaculture did not necessarily translate to purchasing behavior, as a mere 5% of respondents

indicated they buy only wild seafood.

A higher-than-expected percentage of survey respondents understood the role of aquaculture in feeding the world’s growing population.

“Native fish populations are being overfished, and farming is

more sustainable,” one respondent said.

“In a controlled environment, food safety is more certain,” said

another respondent.

Ranging from 69 to 81%, the majority of respondents were unfamiliar with seafood ecolabels, including GAA’s Best Aquaculture

Practices (BAP) mark.

Robert Fields and Mike Berthet, the two newest members of

GAA’s board of directors, were on hand to share their thoughts on the

survey. Both agreed the perception of aquaculture is improving and

that a big opportunity exists to better educate consumers on responsible aquaculture practices.

The preliminary results of the survey were presented by Matt

Brooker, senior category manager with The Fishin’ Co. The full survey

results will be presented at GAA’s GOAL 2015 conference in October.

global aquaculture advocate

May/June 2015

7

Alliance Launches New GAA, BAP Websites

The Global Aquaculture Alliance

has strengthened its online presence by

relaunching its websites – www.gaalliance.org and bap.gaalliance.org – to

better communicate its mission of

advocating, educating and demonstrating responsible aquaculture practices to

feed and employ future generations.

Overall, the new BAP site is

designed to convey the scope and comprehensiveness of the BAP third-party

certification program.

A highlight of the site is search

functionality for the more than 700

BAP-certified farms, hatcheries, feed

mills, processing plants and repackaging plants. Users can refine their search

results using the facility type, species or

country filters, or use the search field

to search by any criteria, including

facility name, BAP certification number and country. Filtered results can be

copied, saved as a PDF, exported or

printed with ease.

Another helpful element of the

new BAP site is map functionality.

The new sites at www.gaalliance.org and bab.gaalliance.org provide more convenient access

Users can find BAP-certified facilities

to information on BAP facilities and other elements of GAA programming.

geographically by zooming in and out

on a map, similar to Google Maps.

A highlight of the new GAA site is

linked to the www.responsibleseafood.org URL found on the

the “Marketing Resources” page,

BAP retail marks. On these pages, the public can find informawhere retailers, foodservice operators, wholesalers and others can

tion on which retail and foodservice outlets sell seafood from

download and print consumer-friendly marketing materials

BAP-certified facilities, what species are covered by the BAP

designed to help them better communicate the benefits of

program and why it’s important to think BAP when purchasing

responsible aquaculture and the BAP program to their customseafood.

ers. Currently, there are six marketing pieces in the “tool kit,”

The new GAA and BAP sites were designed by Visible

and more will be added soon.

Logic

Inc. of Portland, Maine, USA.

Also on the GAA site is a consumer-friendly section that is

GAA Confirms Positions on Antibiotic Abuse,

Social Justice

The Global Aquaculture Alliance takes a proactive stance

against the abuse of antibiotics and social injustice in aquaculture, and its Best Aquaculture Practices (BAP) certification program provides a mechanism to follow up on alleged infractions.

Given the growing concern regarding antibiotic use, GAA is

developing a more rigorous risk-based testing methodology that

will require automatic heightened testing of processing plants

where antibiotic residues are detected.

Antibiotic Abuse

Social Justice

In the BAP standards for finfish and crustacean farms, use of

prohibited antibiotics, drugs and other chemicals is forbidden,

and farms are required to record any antibiotic use. If antibiotics

that are not prohibited for use in both the local and importing

countries are used for therapeutic purposes, residue tests are

required after the withdrawal period to ensure food safety regulations are met.

In the BAP processing plant standards, processors and thirdparty laboratories are required to collect random samples to test

for antibiotic residues, which is also part of the HACCP plan

requirements and supplier performance-monitoring requirements. Third-party auditors also collect random samples for

testing during the auditing process.

The BAP management team monitors the U.S. Food and

Drug Administration’s detention list regularly. If a BAP-certified facility lands on the list for a prohibited antibiotic, it is

required to take corrective action and must provide proof of such

before it can be certified or recertified. Facilities that fail to take

corrective action are decertified.

In light of media reports of worker abuse in the seafood supply chain, the Global Aquaculture Alliance has reiterated that

social justice is one of the pillars of its BAP certification standards.

BAP-certified processing plants, farms, hatcheries and feed

mills are required to provide adequate wages and a safe and

healthy working environment, and prevent child labor and

forced labor.

GAA is working collectively with IFFO and several international seafood suppliers and retailers to address social concerns

related to aquafeed production, agreeing to a position statement

last year. GAA is also working with the Aquaculture Stewardship Council and GlobalGAP on social concerns. The three certification organizations have been collaborating since signing a

memorandum of understanding in April 2013.

RAF, University Of New Hampshire Partner

To Deliver EMS Training

The Responsible Aquaculture Foundation (RAF), the charitable arm of the Global Aquaculture Alliance, is partnering with

the University of New Hampshire (UNH) to deliver online

learning on the prevention and management of early mortality

syndrome (EMS) in shrimp for farmers and other stakeholders

in Vietnam.

Developed by the UNH Cooperative Extension, UNH

School of Marine Science and Ocean Engineering, and New

Hampshire Sea Grant, and based on research conducted by

GAA and RAF, six learning modules will be delivered online in

a mobile-friendly format to Vietnamese farmers, processors, feed

manufacturers, extension educators, regulators and government

personnel. The modules will address diagnostics, breeding,

hatchery, farm, feed and zone management.

The training will be hosted on the RAF website using the

e-learning software SoftChalk to pilot the Cloud-based training.

8

May/June 2015

global aquaculture advocate

It is expected to be ready for delivery by the third quarter of 2015.

“The resources at UNH in the areas of aquaculture research,

training and education are perfect complements to the industry

relationships that RAF and GAA have developed over many

years,” said RAF Executive Director Wally Stevens. “We look

forward to the creation of this curriculum and delivery to interested parties.”

“This opportunity will allow us to develop a platform for disseminating best management practices to farmers in rural areas,”

UNH Aquaculture Specialist Michael Chambers said. “By making small, critical changes in the production chain, you can combat EMS and increase shrimp survival rates back to normal.”

Also known as acute hepatopancreatic necrosis, EMS affects

a shrimp’s digestive system, often causing death within 30 days.

The disease has resulted in billions of dollars of losses for the

global shrimp industry.

global aquaculture advocate

May/June 2015

9

October 26-29, 2015

GOAL 2015 Conference Program Takes Shape

four days of presentations and discussions, beginning with a

half-day seminar, followed by three half-day plenaries.

Vancouver, Canada

Consumer Education, Markets

In addition to updates on global farmed seafood supply and

demand, GOAL 2015 will include discussions on consumer

education, social responsibility and food safety.

Since their inception, GAA’s Global Outlook for Aquaculture

Leadership (GOAL) conferences have set out to move the dial on

matters that contribute to aquaculture’s long-term sustainability

and growth. Headline-grabbing issues such as antibiotics abuse,

social responsibility and consumer education will be on the agenda

at the Global Aquaculture Alliance’s GOAL 2015 conference.

From October 26 to 29 at the Four Seasons Hotel in Vancouver, British Columbia, Canada, GOAL 2015 will encompass

DEEPCHILL

TM

Does What Ice Doesn’t

.

Increased Yields

.

Customized to Your Needs

To discover how Sunwell’s Deepchill slurry ice

systems can help your company improve,

call us at +1-905-856-0400

or send an email to inquiries@sunwell.com

Sunwell Technologies Inc.

Woodbridge, Canada

www.sunwell.com

10

May/June 2015

global aquaculture advocate

Regi

strat

io

O

pen: n

www

.gaal

lia

goalnce.org/

Social Responsibility, Antibiotics

In light of recent media reports of worker abuse in the seafood supply chain, GAA is planning a session on social responsibility at GOAL 2015. Social issues are prominently addressed

within GAA’s Best Aquaculture Practices (BAP) third-party

certification program. A constructive discussion on the further

prevention of forced and child labor, and the assurance of safe

and healthy working environments at all levels of the seafood

chain will be had.

Likewise, GAA takes a proactive stance against antibiotic abuse

in aquaculture. As such, GOAL 2015 will provide an ideal opportunity to find practical solutions to the challenge of antibiotic abuse.

Zone management, which created a buzz at GOAL 2014,

will be another major topic on the GOAL 2015 program. Peter

Marshall of R.S. Standards, who chairs the BAP Zone Management Technical Committee, will lead a half day of presentations

and discussions on zone management – a key to effective disease

management – on October 26.

Seafood Production

Premium Product Quality

Four Seasons Hotel

Consumer education is shaping up to be a major topic of discussion at GOAL 2015. At GOAL 2014, GAA Executive

Director Wally Stevens identified consumer education as an

important challenge to aquaculture that ranks with such issues as

disease management, esnvironmental and social accountability,

investment and market support, and leadership.

In conjunction with GAA, The Fishin’ Co. will present the

full results of a consumer survey that consisted of more than 40

questions on topics related to aquaculture. More than 500 U.S.

seafood consumers were polled. “Influencers” such as celebrity

chefs, nutritionists/dieticians and food writers will be on stage to

share their thoughts on the survey results and consumer education

in general.

As always, Peter Redmond, GAA’s vice president of market

development for Best Aquaculture Practices, will lead a series of

roundtables with some of the world’s most influential retailers,

suppliers and non-governmental organizations. Among the companies represented on stage at GOAL 2014 were Walmart,

Wegmans Food Markets, Red Lobster Seafood Co., Long John

Silver’s, Compass Group, Tesco, Sainsbury’s, Morrisons, Marks

& Spencer, M & J Seafood/Brakes Group, Lyons Seafoods and

High Liner Foods.

In Vancouver, Drs. Jim Anderson of the World Bank and

Ragnar Tveteras of the University of Stavanger will once again

present the latest global production data on shrimp and finfish,

respectively. Exclusive to GOAL, the data is analyzed by Anderson and Tveteras, and collected by GAA Development Manager

Dr. Darryl Jory, who surveys dozens of producers worldwide

annually. Among the species included in the survey are shrimp,

tilapia, Pangasius, catfish, salmon, trout, barramundi, seabass and

sea bream.

For more information on GOAL 2015 or to register for the

conference and book your hotel room, visit www.gaalliance.org/

goal.

Make your mark on greater aquaculture production and sustainability

by joining the hundreds of seafood professionals and thought leaders

from around the world who attend the Global Aquaculture Alliance’s

annual GOAL (Global Outlook on Aquaculture Leadership) conference.

Why Attend GOAL 2015?

GOAL is a unique, opportunity to network, build relationships and

connect the supply side to the marketplace. Since its inception in 2001,

GOAL has evolved into a must-attend conference for the world’s top

seafood executives.

GOAL 2015 will feature four days of information and analysis on the

farmed seafood value chain, with sessions in the mornings and afternoon

breakouts. Topics such as animal welfare, environmental and social

responsibility, food safety, marketplace accessibility, leadership and

consumer education will be among the themes addressed.

Access the Marketplace

At GOAL, learn from – and network with – many of the world’s leading

retail and foodservice buyers representing hundreds of millions of dollars

in buying power. The GOAL schedule includes social events to bring

participants together for discussion and fun, too.

Be Part of the Solution

Help address aquaculture’s opportunities and challenges. Join GAA

in Vancouver, as GOAL returns to North America for 2015. For more

information, visit www.gaalliance.org/goal.

Reserve Your

Room Now!

GOAL 2015 will convene at

the luxurious Four Seasons

Hotel in Vancouver. Take

advantage of the special

conference room rate of

CAD $190 – book online

now before the room block

sells out.

global aquaculture advocate

May/June 2015

11

BAP Included

In GSSI Pilot Testing

Peru Trout Farmer

Enrolls In iBAP

Piscifactorías de los Andes, a trout-farming and -processing

operation located on Lake Titicaca in the Peruvian Andes,

recently became the first applicant to participate in the Global

Aquaculture Alliance’s new iBAP program.

The iBAP program – the “i” in iBAP represents “improver” –

is designed to provide assistance and encouragement to aquaculture facilities interested in pursuing Best Aquaculture Practices

(BAP) certification. Facilities that enroll in iBAP agree to a

step-by-step, deadline-driven improvement plan. iBAP incentivizes facilities to make the improvements necessary to apply for

BAP certification.

“Piscifactorías de los Andes’ enthusiasm to pursue BAP certification exemplifies the spirit and principles of the iBAP program,” said Marcos Moya, BAP facilities development manager.

“We look forward to working with the company.”

Founded in 1978, Piscifactorías de los Andes produces a

variety of trout products and smoked, breaded and canned trout.

Almost 70% of the company’s products are exported to South

America, North America and Europe.

For more information on iBAP, e-mail ibap@gaalliance.org.

The Global Aquaculture Alliance’s Best Aquaculture Practices (BAP) certification is among the third-party seafood certification programs about to undergo pilot testing against the

Global Sustainable Seafood Initiative’s (GSSI) updated Global

Benchmark Tool.

The common requirements established under the GSSI tool

are grounded in the Code of Conduct for Responsible Fisheries

(CCRF), Guidelines for the Ecolabelling of Fish and Fishery

Products from Marine Capture Fisheries, and Technical Guidelines on Aquaculture Certification of the Food and Agriculture

Organization (FAO) of the United Nations.

The tool defines indicators that allow certification programs

to show their diverse approaches and help stakeholders understand where differences exist. These are grounded in the CCRF

and related FAO documents, International Organization for

Standardization normative standards and ISEAL codes. The

pilot is co-funded by IDH, the Sustainable Trade Initiative.

“We are confident that GSSI will provide insight to retailers

and foodservice companies of what a truly robust third-party, FAObased certification program looks like,” said Peter Redmond, BAP

vice president of market development. “This will assist them tremendously as they perfect their sustainability programs.

“We have always believed the BAP program has a robust

environmental platform that fully embraces FAO guidelines, and

we believe the coming months will validate this through the

pilot process.”

GSSI is a global platform and partnership of seafood companies, non-governmental organizations, governmental agencies

and experts whose mission is to ensure confidence in the supply

and promotion of certified seafood as well as promote improvement in seafood certification schemes.

New International Companies Join GAA

Sunnyvale Seafood Co., Inc. recently

joined the Global Aquaculture Alliance as

a Governing Member. The seafood distributor is the United States sales arm of

Zhanjiang Guolian Aquatic Products Co.,

Ltd., a large-scale, fully integrated aquaculture producer of shrimp and tilapia.

Based in China, Guolian operates facilities for breeding, feed

manufacturing, farming and processing. It has achieved four-star

status for shrimp in the Best Aquaculture Practices program.

With offices in Union City, California, USA, Sunnyvale

Seafood has been supplying the San Francisco Bay area and

beyond with fine seafood for over 25 years. It supplies a variety

of raw and cooked white and black tiger shrimp products under

the O’Good brand. It also provides multiple species of fresh and

frozen fish, scallops and cephalopods.

With a capacity of over 1,360 m3 of freezer space, Sunnyvale

can accommodate an impressive variety of daily fresh catches. It

provides customers with products only from suppliers that have

met or exceeded all HACCP standards and requirements. Its

modern distribution system is both accessible and reliable.

Skretting is the latest Sustaining Member of GAA. With a

sales volume totalling 2 mmt, Skretting is the world’s leading

12

May/June 2015

global aquaculture advocate

supplier of fish and shrimp

feeds. It has operations on five

continents, producing feeds in

16 countries with sales in more

than 40 countries. It produces

high-quality sustainable diets – from hatchery to harvest – for

more than 60 aquaculture species.

As an essential link in the feed-to-food chain, Skretting

applies its knowledge of ingredients and the nutritional needs of

fish and shrimp to help producers optimize their aquaculture

systems. It is supported in this aim by world-class innovation

and technical capabilities. New concepts are driven by the Skretting Aquaculture Research Centre, while its Sustainable Economic Aquafeeds program guides its strong sustainability focus.

Safety and quality are ensured through the companywide

Nutrace management system.

Skretting’s overriding ambition is to contribute to meeting

the food needs of a fast-growing population in a sustainable

manner. It endeavors to do this by seeking innovative ways to

raise the efficiency and nutritional value of its products, improve

the productivity of its activities and those of its customers, and

reduce the environmental impact of its value chains.

GAA Joins

Clinton Global

Initiative

The Global Aquaculture Alliance is

proud to announce that it has become a

member of the Clinton Global Initiative

(CGI).

Established in 2005 by U.S. President

Bill Clinton, CGI is an initiative of the

Clinton Foundation. It convenes global

leaders to create and implement innovative

solutions to the world’s most pressing

challenges.

GAA received an invitation to join

CGI in late 2014.

“We are intrigued with the opportunities within CGI to address economic

development for startup operations in the

aquaculture community,” GAA Executive Director Wally Stevens said. “The

work of GAA and the Responsible

Aquaculture Foundation is a good fit

with the work being undertaken by the

other members of the CGI community.”

The Clinton Foundation convenes

businesses, governments, non-governmental organizations and individuals to

improve global health and wellness,

increase opportunity for women and girls,

reduce childhood obesity, create economic opportunity and growth, and help

communities address the effects of climate change.

The Clinton Global Initiative is dedicated to turning ideas into action. CGI

members share best practices, forge partnerships and leverage resources to affect

measurable change. To date, members of

the CGI community have made more

than 3,100 Commitments to Action,

which have improved the lives of over 430

million people in more than 180 countries.

CGI Annual Meetings have brought

together more than 180 heads of state, 20

Nobel Prize laureates and hundreds of

leading CEOs, heads of foundations and

NGOs, major philanthropists and members of the media.

In addition to its annual meetings,

CGI convenes CGI America, which is

focused on collaborative solutions to economic recovery in the United States, and

CGI University, which brings together

undergraduate and graduate students to

address pressing challenges in their communities or around the world.

More information on the Clinton

Global Initiative is available at www.

clintonglobalinitiative.org.

global aquaculture advocate

May/June 2015

13

Penver First Four-Star BAP Group In India

Penver Products Ltd., in conjunction with National Fish &

Seafood (NFS), has become India’s first group to reach four-star

Best Aquaculture Practices (BAP) status. It is the highest level

of achievement in the BAP program.

The four-star BAP status was achieved when Avanti Feeds

Ltd.’s feed mill recently earned BAP certification. Also certified

are the Ocean Edibles International Ltd. processing plant, which

is leased to Penver Products; its shrimp farm, which consists of

one five-farm integrated operating module (IOM); and BMR

Industries Pvt. Ltd.’s shrimp hatchery.

The effort was coordinated by U.S.-based NFS, a division of

Pacific Andes International Holdings Ltd., which sources

shrimp from Penver. In February, NFS and Penver held a joint

training seminar to educate farmers on responsible aquaculture

practices and the BAP farm standards.

“We want to thank Avanti Feeds, Penver Products and the

BAP staff for their efforts to advance responsible aquaculture in

India,” said Jeff Sedacca, president of the shrimp division at

NFS. “This achievement is the result of the cooperation of Philips Thomas, Madhu and our farmers associated with this project

in Andhra Pradesh.

“Together we share a commitment to drive aquaculture

improvements in India. We will continue our work to help farmers, small and large alike, to meet the BAP standards, and expect

to add significant quantities of four-star BAP shrimp over the

next 12 months.”

In addition to the recent certification of a five-farm IOM,

NFS and Penver are grouping together small-scale, single-pond

farms for certification under the new BAP group program. This

program, which is in its pilot phase, will provide family farms

with a more cost-effective option to participate in the internationally accredited certification scheme.

BAP Gains Four-Star Salmon,

More Farms

The Best Aquaculture Practices (BAP) program continues to

expand with new certifications around the world. The list now

includes salmon operations with four-star status, new feed mills in

China and farms in Ecuador, Peru, Chile, Vietnam and Indonesia.

Earlier this year, Marine Harvest Canada (MHC) became

the first salmon company in British Columbia – and the second

in the world – to achieve four-star BAP certification. The status

reflects certification of the company’s salmon-processing plants,

farm sites, hatcheries and feed mills.

MHC’s Dalrymple freshwater hatchery in Campbell River,

British Columbia, was the world’s second salmon hatchery to

earn BAP certification since BAP’s multispecies hatchery standards were completed in September 2014.

“Our four-star certification shows our commitment to providing customers the highest-quality salmon,” said Katherine

Dolmage, MHC’s certification manager. “We expect this fourstar product to be available in the market in 2016.”

In 2013, Marine Harvest was British Columbia’s first salmon

company to achieve three-star BAP status.

Cooke Aquaculture Inc., North America’s largest vertically

integrated, independent salmon-farming company, has also

reached four BAP stars. Its products are marketed under the

True North Salmon and other brands.

The four-star BAP status was achieved when Cooke’s Bingham, Gardner Lake and Oquossoc salmon hatcheries recently

earned BAP certification. Cooke is the world’s first salmon company to have more than one BAP-certified hatchery.

Cooke was the second salmon company in Atlantic Canada

to achieve four-star BAP status. In February 2014, it reached

three-star status for its processing plants, several salmon farm

sites and Northeast Nutrition Inc. feed mill.

“This was always our goal, and our team is proud of this

accomplishment,” Cooke CEO Glenn Cooke said. “Certifications like BAP are an excellent measure and learning tool. The

entire process helps us identify areas for improvement that never

ends. Part of maintaining this certification is to keep improving

and to continue delivering a great product with minimal environmental impact.”

14

May/June 2015

global aquaculture advocate

Recent BAP certifications around the world.

Facility

Country

Species

Alquimia Marina Golfo Mar,

Colas de Oro

Ecuador

Shrimp

Cermaq Canada – McIntyre Lake

Farm

Canada

Salmon

Cermaq Canada – Westside Farm

Farms

Canada

Salmon

Cultivos Yadran S.A. – Simpson

Farm

Chile

Salmon

Ecoacuicola SAC

Peru

Shrimp

Huong Vuong – Ban Island Farm

Vietnam

Pangasius

Huong Vuong – Cai Ga Island Farm

Vietnam

Pangasius

Kampe Mandiri – P.T. Panca Mitra

Indonesia

Shrimp

P.T. Surya Windu Kartika

Indonesia

Shrimp

Vinh Thuan

Vietnam

Shrimp

Vietnam

Shrimp

Binh Minh Fish Corp.

Vietnam

Pangasius

Castlerock Fisheries

India

Shrimp

IFB Agro Industries

India

Shrimp

Hatcheries

Bein Dong Hatchery

Processing Plants

Chile

Salmon

P.T. Wirontono Baru

Procesadora y Comercial Rapco

Indonesia

Shrimp

S.A. Exports Kolkata

India

Shrimp

Vietnam

Shrimp

Vietnam Clean Seafood

Feed Mills

Guangdong Shuanghu Feed

China

Hainan Branch of Tongwei

China

global aquaculture advocate

May/June 2015

15

production

Vibrio Control In Shrimp Farming

Part I. Hatcheries

Stephen G. Newman, Ph.D.

President and CEO

AquaInTech Inc.

6722 162nd Place Southwest

Lynnwood, Washington

98037-2716 USA

sgnewm@aqua-in-tech.com

Production Stages Connected

Artemia culture systems can be significant sources of bacterial contamination.

Mitigants range from bacterial amendments to disinfection to kill surface-attached

Vibrios.

Summary:

Various Vibrio bacteria have been

associated with high mortality in

shrimp larval culture. Control of

Vibrios should focus on minimizing overall bacterial loads and the

potential for horizontal transmission. Females should be rinsed

with a surface disinfectant before

placement in spawning tanks, then

quickly removed after spawning.

Eggs should be washed with clean

water between surface disinfection

protocols. Healthy nauplii should

be washed in a similar manner. To

avoid contamination from Artemia

and algae feeds, use amendments

and/or surface disinfection.

Perhaps the single greatest problem

affecting shrimp hatcheries is high mortality in the early stages of larval culture.

The term “zoeae syndrome” was coined

to describe the affected stage. Typically,

the animals do not molt from Z1 to Z2,

and very high levels of mortality ensue.

Various strains of Vibrio bacteria have

been implicated in this process.

The challenge for hatchery managers

is to identify gaps in biosecurity and how

16

May/June 2015

to plug them without creating a production environment that has been manipulated to the point where other problems

can readily present themselves. The idea

is to control the bacteria without creating

niches for other potential pathogens.

Ubiquitous Bacteria

It is important to appreciate that bacteria are everywhere. Life depends on

them. They are critical for ecological stability and recycling of nutrients, and play

a myriad of other roles that we are just

beginning to appreciate.

Most bacteria are benign, while some

can negatively impact animals that have

been made susceptible to them for various

reasons, of which the presence of stressors

is usually a critical element. A very few are

obligate pathogens that kill animals merely

by being present. Most of the problems in

hatcheries arise from bacterial species that

are not obligate pathogens.

It is also important to realize there

has been an inordinate focus on Vibrios

when many other species of bacteria

could (and do) cause problems. Control

efforts should not be focused on total

elimination of all bacteria, but instead

should target those production areas

where it is possible to minimize the overall bacterial loads.

global aquaculture advocate

As with any agricultural process,

aquaculture production stages are linked

and overlap others. Broodstock sold in

huge numbers commercially become the

sources of eggs and nauplii that, in turn,

are sold to become the source of postlarval shrimp stocked in production systems

for growout to commercial sizes.

Broodstock come from a variety of

sources. Most – especially for Pacific

white shrimp, Litopenaeus vannamei – are

from commercial operations that sell

genetically selected animals that are usually also specific-pathogen-free (SPF),

typically for pathogens the World Organization for Animal Health dictates

should not be present.

Black tiger shrimp, Penaeus monodon,

are available from similar sources,

although there is still significant use of

wild broodstock at black tiger farms.

Routine Procedures

For Maturation Facilities

The use of SPF animals has had a

dramatic impact on shrimp farming globally, although it has not always proven to

be the salvation that many envisioned it

could be. There are many reasons for this.

Suffice it to say that regardless of the

source of the animals, maturation facilities should all be doing certain things

routinely.

Aside from efforts to minimize the

levels of bacteria entering maturation systems, the focus should be on controlling

the potential for horizontal transmission

throughout the production process.

While mass spawning is the norm, for

example, individual spawning offers

greater control.

When females spawn, bacteria present

on them and in their ovarian fluids and

feces can readily attach to the surfaces of

eggs. Females should be rinsed with a

surface disinfectant such as formalin for a

short period before being placed in

spawning tanks to lessen the external

loads of bacteria.

Females should be removed from

spawning tanks as soon as possible after

spawning – easier when animals are

spawned individually. The eggs should be

collected and washed with copious

amounts of clean water between surface

disinfection protocols using formalin,

iodophors or other compounds that have

been shown effective in reducing the levels of attached bacteria.

After the eggs hatch into nauplii,

healthy nauplii are collected by their

attraction to light and seeded into hatchery tanks. Prior to their addition to the

tanks, they should be washed in a manner

similar to that used to surface disinfect

the eggs.

These procedures are aimed at significantly reducing the levels of bacteria on

external surfaces. Bacteria present in eggs

cannot be eliminated in this manner. If

tests determine this is a problem, the

broodstock need to be treated with

appropriate antibiotics in a clean production system and given feeds that are not

carrying potential pathogens.

Contamination

Assuming the water in production

systems is properly treated and that an

effective tool for managing microbial

loads in production tanks is used, perhaps

the greatest sources of contamination

from bacteria in the early life stages are

Artemia and algal culture systems.

There are many ways to mitigate

these contaminants, ranging from the use

of bacterial amendments to the use of

chemicals such as formalin or chloramine-T to kill any surface-attached

Vibrios and airborne contaminants that

occur as a result of where and how the

Artemia are produced. Alternatively, Artemia nauplii can be collected and surface

disinfected as with shrimp. The use of

copious amounts of clean water is essential to dislodge weakened and weakly

attached bacteria.

Algae are often heavily contaminated

with bacteria, as well. This can be mitigated by the use of closed production systems. Where this is not feasible, microbial amendments can lower overall nonbenign bacterial loads.

Perspectives

It is critical to examine all inputs into

maturation and the early stages of larval

culture to ensure levels of potential

pathogens are controlled. As the animals

molt and various feeds are added to the

production tanks, bacteria will grow.

Again, the use of a bacterial bioremediation amendment can help control the levels of Vibrios throughout this process.

The last link in this process is the

stocking of postlarvae into ponds. Some

of the same tools used in disinfection of

eggs and nauplii can be employed to

lessen the levels of attached bacteria.

The Pillars of Sustainability

Best Aquaculture

Practices is the world’s

most comprehensive

third-party aquaculture

certification program,

addressing all of the

components necessary

to conduct aquaculture

operations in a responsible and sustainable

manner.

global aquaculture advocate

May/June 2015

17

production

Stress-Vibrio Dynamics During High-Density,

Zero-Exchange Production Of White Shrimp

Tzachi M. Samocha, Ph.D.

Texas A & M AgriLife Research Mariculture Lab

at Flour Bluff

4301 Waldron Road

Corpus Christi, Texas 78418 USA

t-samocha@tamu.edu

David I. Prangnell, Ph.D.

Table 1. L. vannamei performance

in a 62-day nursery trial.

Average weight (g)

Maximum weight (g)

Minimum weight (g)

Coefficient of variation

Yield (kg/m3)

Feed-conversion ratio

Survival (%)

Yellow (x 1,000)

Green (x 1,000)

Texas A & M AgriLife Research Mariculture Lab

at Flour Bluff

Total (x 1,000)

Leandro F. Castro, M.S.

Green (%)

Summary:

Vibrio infections are an increasingly common problem

in intensive shrimp culture. As evidenced by study

results, weekly Vibrio monitoring can be a useful tool

for predicting bacterial disease outbreaks. Nurseryphase shrimp appeared healthy, and GCFU Vibrio

numbers were very low. However, the stress of harvest

and restocking, combined with water quality stressors, likely depressed the shrimp immune systems and

resulted in increased vulnerability to Vibrio infection.

Concurrently, disruption of the established bacterial

community may have caused a shift in the balance of

non-pathogenic and pathogenic Vibrio populations.

Vibrio infections are an increasingly common problem in

intensive shrimp culture. Recent outbreaks around the world in

both traditional and biofloc systems are significantly reducing

production and proving to be a limiting factor in the further

development of recirculating aquaculture and super-intensive,

biofloc-dominated shrimp culture systems.

Many Vibrio species are ubiquitous in shrimp culture water,

but do not negatively impact shrimp unless a stressor is present.

To better understand Vibrio dynamics during a shrimp production cycle, the authors monitored Vibrio populations during

nursery and growout phases in super-intensive, zero-exchange,

biofloc-dominated raceways.

Trial Setup

Nursery and growout trials were conducted in two, 100-m3

greenhouse-enclosed raceways with 1.1 m mean water depth.

Each raceway was equipped with two optical dissolved-oxygen

probes and an in-line D.O.-monitoring system. Aeration, mixing and circulation were generated by 14 high-pressure injectors

driven by up to two, 2-hp pumps per raceway. Solids concentra-

18

May/June 2015

global aquaculture advocate

tions were maintained within the desired range using a settling

tank and foam fractionator for each raceway.

For the nursery phase, raceways were stocked with 5- to

10-day-old Litopenaeus vannamei postlarvae weighing 0.93 ± 0.56

mg from specific pathogen-free, Taura-resistant and fast-growth

hybrid broodstock. Two days prior to stocking, the raceways were

filled with 90% 10-ppm chlorinated natural water and 10% aged

seawater at a salinity of 30 ppt. In addition to manually mixing

every second day for the first three weeks, injectors were operated

in the raceways at full flow for five minutes twice daily. Water

flow to these injectors was gradually increased over time.

The postlarvae were fed a combination of a commercial

microencapsulated Artemia replacement and dry postlarvae feed

for the first eight days post-stocking, and then appropriately

sized particles with an immune booster and nutritional supplement for the remainder of the nursery phase. A commercial

nitrifying bacteria product and white sugar were used to enhance

nitrifying and heterotrophic bacterial activities to control nitrogen species. At the conclusion of the 62-day nursery phase,

shrimp were harvested, weighed and held for restocking.

For the growout phase, biofloc-rich water from the nursery

phase was reused to make up 87.5% of the raceway volume and supplemented with 12.5% disinfected seawater. Shrimp harvested from

the nursery phase at about 6.45-g weight were restocked into the

two raceways at a density of 458/m3. No water exchange was conducted during either phase. Municipal freshwater was used to compensate for water losses due to evaporation and biofloc control.

The shrimp were fed a 40%-protein commercial feed and harvested after 38 days. Feed was supplied continuously by belt feeders.

Feed particle sizes and rates were adjusted on an ongoing basis

according to twice-weekly growth sampling and weekly checks of

shrimp size variation, assumed growth, feed conversion and survival.

A commercial probiotic was added every third day during the

nursery phase and daily during the growout phase. Vibrio concentrations in the culture water were monitored twice weekly

using thiosulfate citrate bile salts sucrose (TCBS) agar plates

6.43

10.50

0.50

31.0

3.28

0.81

94.6

Mean

Range

Mean

Range

Mean

Range

Mean

Range

Nursery

Growout

3.89

0.09-12.20

0.005

0-0.10

3.89

0.09-12.20

0.21

0-1.77

7.85

3.45-17.70

5.860

0-14.30

13.70

5.30-27.75

38.74

0-72.00

Table 3. L. vannamei performance

in a 38-day growout trial.

Susan Laramore, Ph.D.

Harbor Branch Oceanographic Institute

Florida Atlantic University

Fort Pierce, Florida, USA

Raceway 2

6.49

11.90

0.60

35.6

3.43

0.81

97.8

Table 2. Vibrio colonies (CFU/mL) expressed on agar

plates from nursery and growout culture water.

Florida Organic Aquaculture

Fellsmere, Florida, USA

Shrimp mortalities and exuviae recovered during a growout

outbreak of Vibrio caused by multiple culture-related stressors.

Raceway 1

Survival (%)

Final weight (g)

Growth (g/week)

Yield (kg/m3)

Feed-conversion ratio

Raceway 1

Raceway 2

79.5

18.37

2.20

6.02

2.07

71.6

19.01

2.31

6.92

1.61

throughout both phases and Vibrio chromogenic agar plates late

in the growout. Vibrio from the hemolymph and hepatopancreas

of moribund shrimp was also cultured using these methods.

Results

At the conclusion of the nursery trial, survival was high at 95

to 98%, and the 0.81 average feed-conversion ratio was low

(Table 1). Water quality variables were all within the range suitable for L. vannamei culture. Mean temperature, salinity, D.O.

concentration and pH were 26.6° C, 30.4 ppt, 6.7 mg/L and 8.1,

respectively. Mean total ammonia nitrogen (TAN) and nitrite

nitrogen (NO2-N) values were 0.76-0.80 and 1.60-2.27 mg/L,

respectively. Total suspended solids (TSS) remained below 511

mg/L for the duration of the trial.

Non-sucrose-fermenting (green colony-forming units, GCFU)

Vibrio concentrations remained below 50 CFU/mL – less than 9.1%

of the total colony concentration throughout the trial – and were

only observed on 12.1% of plates (Figure 1). Sucrose-fermenting

(yellow colony-forming units, YCFU) Vibrio concentrations were

variable throughout the nursery trial, reaching concentrations as

high as 12,200 CFU/mL (Table 2). There was no evidence of Vibriosis or chitinoclastic bacterial infections in either raceway.

During the nursery harvest and subsequent 24-hour holding

period, the shrimp (particularly those from raceway 1) were subject to multiple stressors, including overcrowding, physical handling, low dissolved-oxygen levels, and high water temperature

and suspended solids levels. The shrimp experienced approximately 20% mortality prior to restocking. Seven days into the

growout phase, a new wave of shrimp mortalities commenced in

raceway 1 and quickly spread to raceway 2.

Subsequent mortalities in both raceways resulted in early termination of the growout trial. At its conclusion, survival was

71.6 and 79.5% in the two raceways, with final shrimp weights

of 18.37 and 19.01 g. Shrimp grew an average 2.2 and 2.3 g

eMail: sales@seajoy.com

Tel: (877) 537-1717 • Fax: (262) 375-9028

To Learn More, Visit Us Online: www.seajoy.com

global aquaculture advocate

May/June 2015

19

Perspectives

This study demonstrated the roles that multiple environmental

and handling stressors play in triggering Vibrio outbreaks during

transfers of shrimp from one production phase to the next, underscoring the importance of weekly Vibrio monitoring in predicting

bacterial disease outbreaks. It further demonstrated how quickly

bacterial diversity can change in a biofloc system. Even with additions of probiotics, environmental stresses can cause a shift to

more pathogenic species.

These observations underscore the complexity of bacterial

interactions within a biofloc system and warrant further investigation into avoiding and controlling detrimental Vibrio outbreaks

in super-intensive, zero-exchange biofloc systems.

20

May/June 2015

global aquaculture advocate

Concentration (CFU/mL)

Nursery

Concentration (CFU/mL)

weekly, although feed-conversion ratios were relatively poor:

1.61 to 2.07 (Table 3).

Water quality parameters were within the ranges suitable for

L. vannamei culture. Mean temperature, salinity, D.O. and pH

were 30.3° C, 30.4 ppt, 6.1 mg/L and 7.6, respectively. Mean total

ammonia nitrogen and nitrite nitrogen values were 1.09-1.32

mg/L and 0.15-0.21 mg/L, respectively. Nitrate levels increased

over time, reaching as high as 187 mg/L. TSS remained below

600 mg/L during the trial. GCFU Vibrio concentrations started

increasing in both raceways after day 4 and were generally similar

in concentration to YCFU, reaching 14,300 CFU/mL.

The total Vibrio concentration increased as the trial progressed, reaching 27,750 CFU/mL. Results suggested the presence of Vibrio parahaemolyticus, V. vulnificus and V. alginolyticus

in the culture water and the hemolymph and hepatopancreas tissues of moribund shrimp. 16S rRNA sequencing confirmed the

presence of these three species, along with V. harveyi and V. mytili in moribund shrimp hemolymph.

12,000

Yellow Colonies

Green Colonies

9,000

6,000

3,000

0

1 14 2431 4556

Day

15,000

Growout

Yellow Colonies

Green Colonies

10,000

5,000

0

3 1525 36

Day

Figure 1. Sucrose-fermenting (yellow) and non-sucrose-fermenting

(green) Vibrio concentrations as expressed on agar plates over the

course of the nursery and growout phases.

global aquaculture advocate

May/June 2015

21

production

the bottom line

Feed Trays – The Good, The Bad, The Ugly

Thomas R. Zeigler, Ph.D.

Senior Technical Advisor

Past President and Chairman

Zeigler Bros., Inc.

400 Gardners Station Road

Gardners, Pennsylvania 17324 USA

tom.zeigler@zeiglerfeed.com

Scott E. Horton, M.S.

Nutrition Marina S.A. de C.V.

Sinaloa, Mexico

Information gleaned from the use of feed trays can be both helpful and misleading.

The authors encourage the verification of primary assumptions to reality.

Shrimp Feed Trays

Summary:

Feed trays are typically used to

avoid overfeeding in aquaculture

production systems. They are

sometimes used to deliver 100%

of the feed that is fed, and other

times a small number of trays are

used as a guide to evaluate broadcast feeding techniques. They are

credited with reducing feed cost

per unit of production, but there

is seldom mention of their effects

on optimizing overall crop profitability.

Industries evolve because of change.

The shrimp industry is experiencing significant change in numerous areas,

including intensification, markets, economics, regulation, genetics, feeds and

nutrition. In spite of such changes, it is

frequently human nature to continue to

use traditional production methods that

have worked satisfactorily in the past,

although they may not be as effective in

optimizing profits under present and

future conditions.

22

May/June 2015

The use of feeding trays addresses the

need to reduce overfeeding and related

feed costs, and improve shrimp pond bottoms, water quality and associated water

discharges. It is based on the critical

assumptions that all feed leaving the trays

is carried off by shrimp, and that all the

feed that leaves the trays is consumed and

digested by the shrimp.

Feeding shrimp using feed trays

involves placing a quantity of feed on a

properly designed feed tray, placing the

feed and tray in the water at the pond

bottom and observing the rate of feed

disappearance from the tray over time.

The rate of disappearance of the feed is

used to determine the amount of feed

that should be fed each day.

Rapid feed disappearance suggests

that more feed should be fed, and slow

feed disappearance suggests that less feed

should be given to culture animals. In

some cases, all of the feed offered to the

shrimp in a pond is placed on trays for

feeding. In other cases, a small number of

trays are used as a sample measurement,

while most of the feed is applied by

broadcast feeding.

Feeding trays evolved in Taiwan to

global aquaculture advocate

feed shrimp in ponds with highly

degraded bottoms. In the 1980s, the

Peruvian industry adopted the technology

to control the application of medicated

feeds and estimate mortality. Feed tray

use also spread to Brazil and Guatemala.

Their use in Guatemala went beyond the

monitoring of feed consumption to a tool

for monitoring the health of the shrimp.

The Good (Strengths)

Feed consumption varies because of

the genetic capacity of the shrimp, as well

as temperature and other physical conditions in the pond. Additionally, feeding

varies daily due to shrimp molting states.

When used correctly for 100% of the feed,

trays provide much greater control over

consumption rates and other benefits.

• Feed-conversion ratios are reduced.

• Per-unit feed costs are reduced.

• Growth is frequently improved.

• Culture conditions are improved.

• Improved water quality supports

increased stocking density, greater yield

and reduced environmental pollution.

• Information can be provided on size

class distribution.

• The presence of predators and competitors can be established.

• Trays can determine uninhabited

areas of ponds where animals are not

feeding.

global aquaculture advocate

May/June 2015

23

• Regular feed tray use causes more

frequent observation of the animals,

which contributes to more rapid

management decisions concerning

feed rates, health management and

harvesting times.

• Shrimp feeding on dead animals

transport the dead ones to trays in

the process of searching for fresh

feed. This provides a method for

observing even minor mortalities.

• It is believed that shrimp contract