switch fuse federal

advertisement

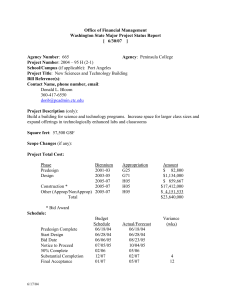

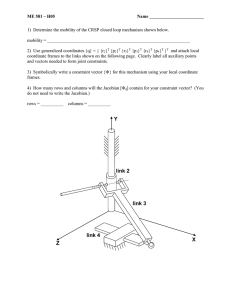

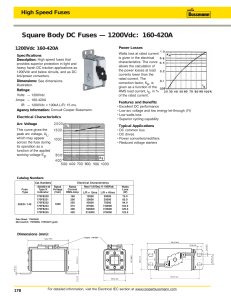

LOAD BREAK SWITCHES & SWITCH FUSES 3 Switch Fuses FSF 160 FSF 250 FSF 400 FSF 630 Load Break Switches FLS 160 FLS 250 FLS 400 FLS 630 CONTENTS General Information About Load Break Switches & Switch Fuses 2 Technical Characteristic and Pictures of Switch Fuses 4 Technical Characteristic and Pictures of Load Break Switches 5 Dimensions and Installation Diagram 6 -2006 3/1 GENERAL INFORMATION ABOUT LOAD BREAK SWITCHES & SWITCH FUSES General characteristics : The Federal Load Break Switches & Switch Fuses have been designed to provide a compact, instantly openingclosed with rolling or friction contact. They have a breaking feature from same phase and four different points and are high performance devices. Load break switches are manufactured with or without fuses according to the IECEN 60947-3 and VDE-0660 standards, CE certificate and AC 23 class. Due to this feature they are used at AC and DC systems and motor circuit. Various combinations and types with high amperes which are not shown in this catalogue are manufactured accordig to special orders. General features : • High breaking capacity, • High electrical and mechanical endurance, • Rolling contact system (except for 160 A) capable of selfcleaning, • Double breaking on each phase, • Modern technology and compact design, • Quick making and breaking operation independent of manuel operation, • Small dimension, •Case made of thermoset material, non absorbing and flame-heat resistant, • Capable of mounting to front or rear side of panel cover. 160A switches are manufactured with friction and high value switches are manufactured with using rolling contact. Friction and rolling contact systems provide clear and precise touching at every opening and closing of switch. Passing resistance and loss of energy among the contacts are limited to minimum with respect as a special spring. Current is broken from same phase and at four different points in the switch (except 160 A). This feature builds up current breaking capacity of switch and fuses separated from the circuit at two points. (Pic-1) Safety : - Off “0” position both fuse terminals will not be alive so the fuses can be changed, safely. - On “I” position the handle will be locked mechanically, so the panel cannot be opened while energized. - Off “0” position the handle can be blocked out with a padlock so that it may prevent any unauthorized personnel to energize the panel. - The isolation distance between the phases is rather wide to prevent arc jumping. - Additional fuse protection shields are used for better isolation and protection in the switch fuses. - Arc separators are used for arc extinguishing between contacts which occur during closing or breaking process. Locking with padlock “0” position Contacts : Load break switches & switch fuses consist of contact system with constant contact which placed moulded case. Breaking energy is divided between contacts with this system. Combustion in contact is kept minimum due to energy is dividing between contacts and arc extinguisher elements in the breaking chamber. Getting small combustion extends the life of contacts. Rolling contact system (250A, 400A, 630A) Pic-2 Opening-closing mechanism and control handle : Pic-1 3/2 Opening-closing mechanism has been provided to operate the poles altogether and very rapidly. Speed of opening and closing is independent from hand moving. Control handle is passing type. The handle extention is necessary for all cases supplied in the length, than it is cut by the customer at the desired length. The position of switch can be seen by means of indicating plate and control handle. Switching angle for ON/OFF operation is 90 degrees. -2006 GENERAL INFORMATION ABOUT THE LOAD BREAK SWITCHES & SWITCH FUSES Inside construction : Current is broken from the four separate points in a rolling contact system. This way the breaking capacity is increased and when the circuit breaker is in open position, fuses are seperated from the circuit completely. - Opening closing position are not depending on hand actuated. - High speed opening-closing can be done thanks to the springs in mechanism. Frictional system is applied at type of 160 A. In this way this system provides clear and precise touching at every opening and closed. Especially contact destruction is prevented by rolling contact system. Arc extinguishers are used for arc extinguishing between contacts which occur during making or breaking process. mechanical resistance in a compact design. Connection bars are plated with silver. Capable of mounting to front or rearside of panel cover. Operating principle : By means of a special sling rolling contact system, moving contacts are mechanically connected to the operating handle to ensure a positive ON/OFF action and a forced operation of contacts. Any damage to contact is prevented in the rolling contact. Accessories : Following accessories are available, -Cage type connection terminals - Terminal protective covers (Pic-4) - Neutral link available - Auxiliary conctact block 1NO + 1 NC for remote indication of switch status. - Special interlock and padlock system. Note: Terminal cover prevent to contact of switch fuse cable connection terminal with hand. This feature provides safe the insulation according to CE certificate. Switch fuse with terminal cover Pic-3 Frame and cover : Frame and cover are molded from glass-polyester material, BMC (Bulk Moulding Compound) in literature that combines ruggedness and high dieletric stength, as well as high Terminal covers Pic-4 Order Codes : Number of poles 3,4 3,4 Note : Type Order codes FSF 160 9BB-S110 -0160 FSF 250 9BC-S110 -0250 FSF 400 9BC-S110 -0400 FSF 630 9BD-S110 -0630 FLS 160 9BB-L110 -0160 FLS 250 9BC-L110 -0250 FLS 400 9BC-L110 -0400 FLS 630 9BD-L110 -0630 pole number is written (like 3 or 4) * Switch fuses can dispatch without NH fuse. Terminal Cover Order Codes : Upper Terminal Protection Cover Order Codes : Type Type FSF160 A 8BA-G0000-0000 FLS160 A 8BA-D0000-0000 FSF250-FSF400 A 8BB-G0000-0000 FLS250-FLS400 A 8BB-D0000-0000 FLS160 A 8BA-H0000-0000 FLS250-FLS400 A 8BB-H0000-0000 -2006 3/3 3 SWITCH FUSES Switch Fuses FSF 250 FSF 400 FSF 160 FSF 630 Technical Characteristics Type FSF 160 FSF 250 FSF 400 FSF 630 Number of pole 3,4 3,4 3,4 3,4 A 160 250 400 630 V 1000 1000 1000 1000 Rated thermal current (lth) Rated insulation voltage (Ui) Rated impulse withstand voltage - Uimp kV 8 8 8 8 Rated frequency Hz 40-60 40-60 40-60 40-60 Rated operating power 380V kW 75 132 200 320 AC23 500V kW 100 160 280 340 120 220 360 400 76 140 220 300 690V kW Reactive power 380V kVAr Rated breaking capacity AC 23 A 1280 2000 3200 5040 Rated closed capacity AC 23 A 1600 2500 4000 6300 kA 65 65 65 65 NH 00 1 2 3 Operation 10000 10000 10000 8000 Operation 1000 1000 1000 1000 kg. 2.7 4.7 4.8 8.7 mm2 70 120 240 2x185 Rated fuses short circuit breaking capacity Fuse type Mechanical life Electrical life Weight Min.connection conductor cross-section Dimensions Rear Connection 4. Pole (Mounting foot for FSF 630) Tip A B C D E F G H J K L M N P R FSF 160 185 142 123 105 37 43.5 15 32 28 3 20 13 160 12 152 15 220 20.5 197 83.5 220 14 222.5 FSF 250 FSF 400 FSF 630 3/4 255.5 163 138.5 127 43.5 65 15.5 33 32 4 317 202 50 89 16.5 54 37 6 243 164 25 30 40 S Ø 8 10-70 11 13 -2006 LOAD BREAK SWITCHES Load Break Switches 3 FLS 250 FLS 400 FLS 160 FLS 630 Technical Characteristics Type Number of pole Rated thermal current (lth) (Ui) Rated insulation voltage Rated impulse withstand voltage - Uimp Rated frequency FLS 160 FLS 250 FLS 400 FLS 630 Ad. 3,4 3,4 3,4 3,4 A 160 250 400 630 V 1000 1000 1000 1000 kV 8 8 8 8 Hz 40-60 40-60 40-60 40-60 380V kW 75 132 200 320 500V kW 100 160 280 340 690V kW 120 220 360 400 Reactive power 380V kVAr 76 140 220 300 Rated breaking capacity AC 23 A 1280 2000 3200 5040 Rated closed capacity AC 23 A 1600 2500 4000 6300 Rated operating power AC23 Rated fuses short circuit breaking capacity kA 65 65 65 65 Short-circuit making capacity kApeak 20 35 35 60 Short-time withstand current kA/1s 8 15 15 25 Mechanical life Operation 10000 10000 10000 8000 Electrical life Operation 1000 1000 1000 1000 kg. 2.6 4.4 4.5 8.5 mm2 70 120 240 2x185 Weight Min.connection conductor cross-section Dimensions Rear Connection 4. Pole Ø (Mounting foot for FLS 630) Tip A B C D E F G H J K L M N P R FLS 160 185 142 123 105 37 43.5 15 32 28 3 20 13 160 12 152 15 220 20.5 197 83.5 220 14 222.5 FLS 250 FLS 400 FLS 630 -2006 255.5 163 138.5 127 43.5 65 15.5 33 32 4 317 202 50 89 16.5 54 37 6 243 164 25 30 40 S Ø 8 10-70 11 13 3/5 DIMENSIONS AND INSTALLATION DIAGRAM Control handle Shaft extension Upper terminal protection cover : Door drilling template Right and left terminal protective cover : for FLS and FSF type for FSF type for FLS type 3/6 -2006