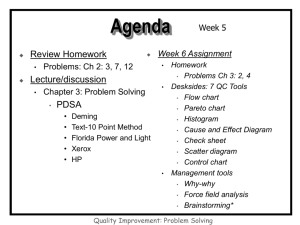

Quality Improvement Guide

advertisement