June/July/August 1998

1

2

CERAMICS MONTHLY

JunelJuly! August 1998

Volume 46

Number 6

Hirotsune Tashima

at the Clay Studio

in Philadelphia.

FEATURES

54

38 A Look at Glaze Calculation Software

with Using Glaze Programs by Rick Malmgren

Easier, faster and more informative computer aids

46 Norman Schulman by David JP Hooker

Monolithic sculpture with painterly imagery

47 The Potters of Kwarn Ar-Marn by Mick Shippen

A Thai village faces market changes

51 The Totemic Sculptures of Ted Vogel

by Kate Bonansinga

Symbolic work from the Pacific Northwest

Jars, to approximately

15 inches in height, deco­

rated with black pigment on

white slip, by Carmel Lewis

Haskaya; from “The Legacy

of Generations.”

62

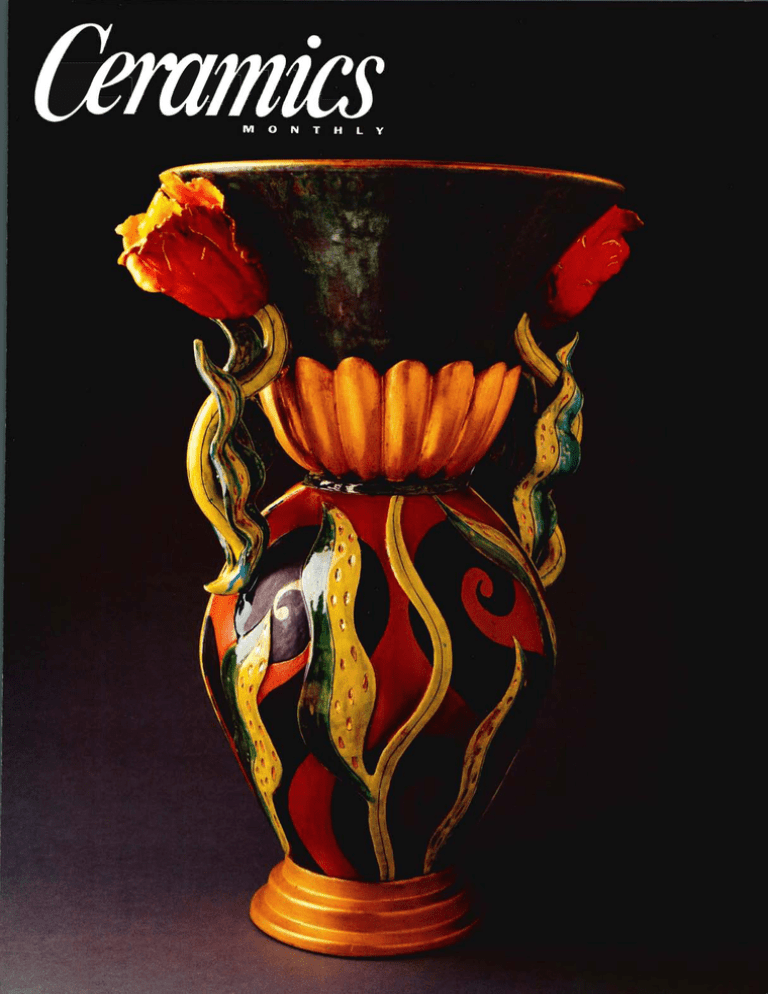

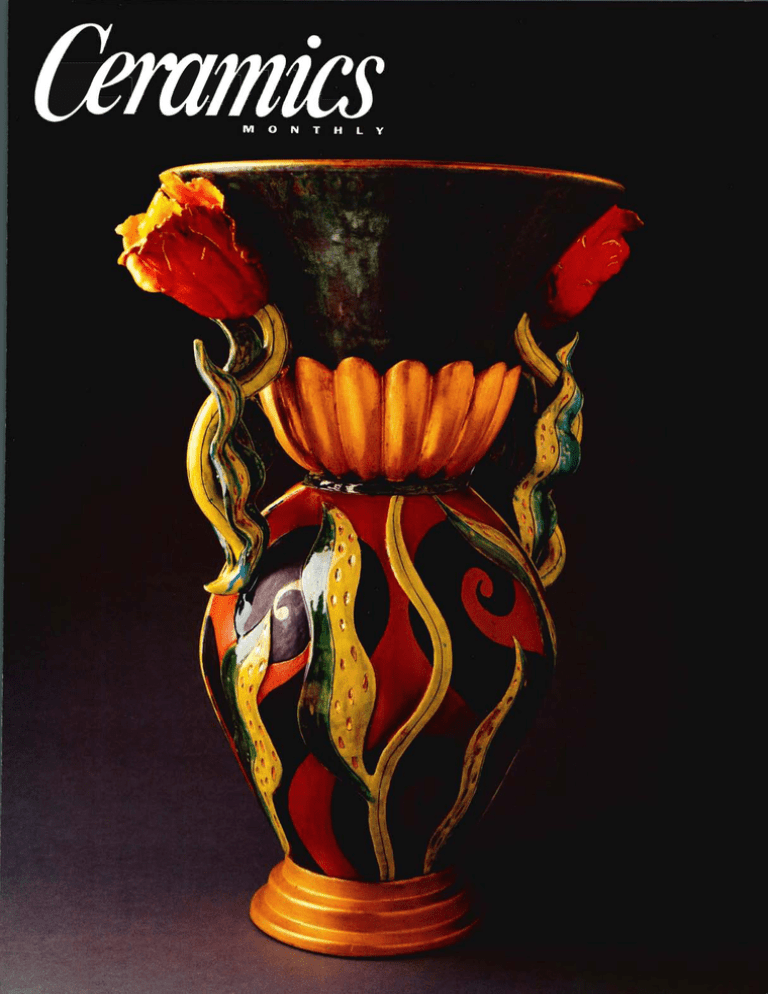

The cover: “Tulip Vase,”

22 inches in height, thrown,

cast and handbuilt terra

cotta with underglazes,

glazes and lusters, by Carol

Gouthro; see page 68.

Photo: Roger Schreiber.

June/July/August 1998

54 Hirotsune Tashima by Louana M. Lackey

Self-portraits with a sense of humor

“Balancing Point,” 46 inches

57 Consuming Pots

in height, earthenware with

Listening to Mark Hewitt’s Customers by Charles Zug

terra sigillata and gold

leaf, by Ted Vogel,

62 The Legacy of Generations

Portland, Oregon.

Pottery by American Indian Women by Susan Peterson

51

68 Carol Gouthro by Nan Krutchkoff

Vibrantly glazed dinnerware and one-of-a-kind works

73 Gerstley Borate and Colemanite by JeffZamek

Properties of and substitutes for these troublesome materials

75 To Have and to Hold

Exhibition featuring vessels by 65 artists working in Texas

76 Nicholas Wood by Glen R. Brown

Exploring minute distinctions in texture and color

79 Pioneer Pottery by Lyn Kidder

The challenge of building a business in rural Montana

83 Confessions of a Closet Beautician

by Geoffrey Wheeler

Playful, seductive pots that ask to be touched

116

Niche Marketing for Beginners by Ivor Lewis

Guidelines for exploring sales opportunities

Julie Dickinson and Janet

Hero Dodge in their rural

Montana studio.

79

3

UP FRONT

14 Ceramics Annual at Scripps College

Invitational featuring work by ten artists

14 Magdalene Anyango N Odundo

Cleveland Museum of Ait acquires its first contemporary African art object

14 Juried National in Connecticut

Over 200 craftworks at Silvermine Guild Galleries

16 Visiting Potters in Nicaragua by Beverly T. Fillers

Reflections on Potters for Peace tour

18 Erna Aaltonen

Vessels on view at the Hameenlinna Art Museum in Finland

20 American Craft Council Update

Sales records broken at Baltimore show

20 Mother’s Day Sale

Annual open studio at Appalachian Center for Crafts in Tennessee

20 Aaron Lee Benson by Christopher Nadaskay

Sculpture series portraying victims of the Nazi regime

22 Dick Lehman

Wood-fired pots at Cedar Valley College Ceramics Gallery in Texas

22 Tamara Laird

Slab-built ware at Kline Campus Center Art Gallery at Bridgewater College

24 Broadway, Here We Come

Throwing advice for the latest production of The Sound of Music

24 Not Your Usual Faculty Show by Claudia Giannini

West Virginia art faculty collaborates on earthenware plates

26 Seven Points of View by Julie Miracle

Invitational exhibition at Urban Artifacts Gallery in Houston

26 Randy Brodnax and Michael Obranovich

Wheel-thrown and handbuilt vessels at Dallas Visual Arts Center

28 Sally Brogden

Abstract sculpture at Gallery One in Smithville, Tennessee

28 Scott R. Jones

Decorative pottery at the Washington County Museum of Fine Arts

28 Dong-Hun Chung

Residency show at Towson University Asian Arts Gallery

30 Exhibition of Danish Ceramics

Second triennial at the Trapholt Museum, Kolding, Denmark

30 David Stuempfle Receives Japan Fellowship

Six-month residency to allow study of contemporary and traditional work

30 Bennett Welsh, 1922-1998

30 Robert Sperry, 1927-1998

DEPARTMENTS

8 Letters

32 New Books

86 Call For Entries

86 International Exhibitions

86 United States Exhibitions

88 Fairs, Festivals and Sales

90 Video

92 Suggestions

94 Calendar

94 Conferences

94 Solo Exhibitions

94 Group Ceramics Exhibitions

96 Ceramics in Multimedia Exhibitions

99 Fairs, Festivals and Sales

100 Workshops

104 International Events

110 Questions

123 Classified Advertising

126 Comment: Flying Blind with Clay on My Glasses by Delia Robinson

128 Index to Advertisers

4

Editor Ruth C. Butler

Associate Editor Kim

Nagorski

Assistant Editor Connie Belcher

Assistant Editor H. Anderson Turner III

Editorial Assistant Elaine Jebsen

Production Specialist Robin Chukes

Advertising Manager Steve Hecker

Circulation Administrator Mary R. Hopkins

Circulation Administrator Mary E. May

Publisher Mark Mecklenborg

Editorial, Advertising and Circulation Offices

735 Ceramic Place

Post Office Box 6102

Westerville, Ohio 43086-6102

Telephone: (614) 523-1660

Fax: (614) 891-8960

E-mail: editorial@ceramicsmonthly.org

advertising@ceramicsmonthly.org

classifieds@ceramicsmonthly.org

circulation@ceramicsmonthly.org

Website: www.ceramicsmonthly.org

Ceramics Monthly (ISSN 0009-0328) is published monthly,

except July and August, by The American Ceramic Society, 735

Ceramic Place, Westerville, Ohio 43081. Periodicals postage

paid at Westerville, Ohio, and additional mailing offices.

Opinions expressed are those of the contributors and do not

necessarily represent those of the editors or The American

Ceramic Society.

Subscription Rates: One year $26, two years $49, three years

$70. Add $ 12 per year for subscriptions outside North America.

In Canada, add GST (registration number R123994618).

Change of Address: Please give us four weeks advance notice.

Send the magazine address label as well as your new address to:

Ceramics Monthly, Circulation Department, PO Box 6102,

Westerville, OH 43086-6102.

Contributors: Writing and photographic guidelines are avail­

able on request. Mail manuscripts and visual support (photo­

graphs, slides, transparencies, drawings, etc.) to Ceramics Monthly,

735 Ceramic PL, PO Box 6102, Westerville, OH 43086-6102.

We also accept unillustrated texts faxed to (614) 891-8960, or

e-mailed to editorial@ceramicsmonthly.org

Indexing: An index of each year’s feature articles appears in

the December issue. Feature articles are also indexed in the

Art Index and daai (design and applied arts index), available

through public and university libraries.

Copies and Reprints: Searchable databases and document

delivery are available through Information Access Company,

362 Lakeside Dr., Foster City, CA 94404; and through Univer­

sity Microfilms, 300 N. Zeeb Rd., Ann Arbor, MI 48106.

Authorization to photocopy items for internal or personal

use, or the internal or personal use of specific clients, is granted

by The American Ceramic Society, provided the base fee of

$5.00 per copy, plus $0.50 per page, is paid directly to the

Copyright Clearance Center, 222 Rosewood Dr., Danvers, MA

01923. Prior to copying items for classroom use, please contact

the Copyright Clearance Center, 222 Rosewood Dr., Danvers,

MA 01923; (508) 750-8400. The code for users of the Trans­

actional Reporting Service is 0009-0328/97 US$5.00 + $0.50.

Back Issues: When available, back issues are $7 each, includes

shipping and handling; $10 each outside North America.

Postmaster: Send address changes to Ceramics Monthly, PO Box

6102, Westerville, OH 43086-6102. Form 3579 requested.

Copyright © 1998

The American Ceramic Society

All rights reserved

CERAMICS MONTHLY

June/July/August 1998

5

Letters

ten what it takes to be a potter of competence

in this age. So thanks, Brad!

Paula Collins, Lakewood, Colo.

With Tongue Firmly in Cheek

Stanko Responses

I must assume that Mel Jacobson is smil­

ing ear to ear over Gary Stanko’s comment

(Letters, April 1998 CM) that his work is

“drab and formless...similar to Warren

MacKenzie...somewhat amateurish.” We

should all live to be so “amateurish.” Indeed,

I long for the day when someone condemns

me as having no better an idea of lyrical form

than Steven Hill, glazes as ordinary as Val

Cushing, as little idea underlying my work as

Stephen DeStaebler.

Dannon Rhudy, Paris, Tex.

In response to Gary Stanko’s letter about

Mel Jacobson’s pots: it takes many, many

years to get one’s work to look so effortless.

Mel has been potting for 40 years, quietly

doing his work and helping others. There are

hundreds of people who are working today

because Mel has helped or taught or picked

them up when they were ready to quit. I am

one of those people, and I stand in his very

large shadow.

My wish for you, Mr. Stanko, is that

someday you can stand in his shadow too.

Kevin Caufield, St. Paul, Minn.

I am writing this letter to express how

much my wife and I enjoy receiving Ceramics

Monthly. You see, both my wife and I are

potters. She does mostly jack-o-lanterns but

has also a pretty mean Indian head—spitting

image of Mel Brooks. She insists that this is

art, but I say I am not so sure and why don’t

you do one of them funky teapots. She says

she would but CM don’t never include the

template. So what I am saying, if the maga­

zine could include the template once in a

while, along with the formulas, firing cycle

and the little tricks I know the editors often

leave out, she would be much appreciative.

As for myself, I have noticed that there is

a lot of bickering about whether the cover

should include a picture of the potter or only

the work. I, personally, have often wondered

what potters look like in the nude. Would it

be possible, once in a while, to feature a nude

potter? I, personally, being a professional

potter, would be interested in an up-andcoming young Norwegian pottress with say, a

butter plate and a fish platter. Or no, better

yet, a jug. No, a set of jugs. That’s it! A

young Norwegian pottress with a possible set

of jugs.

One final note. I would like to put this

“art versus craft” thing to rest once and for

all. It’s really very simple. Let’s say you have a

pig. Now if you draw a picture of that pig

and nail it to your parlor wall, you might

think that that is art but it is not—it’s merely

a decorative accessory. If, however, you take

and nail the pig to the wall, well then, that

there is art. Now, if at a later date you can

take the pig off the wall and play “Scotland

the Brave” with it, well, then, that is craft.

Stu Gray, Birmingham, Mich.

I concur with Gary Stanko’s use of the

words “virtue, balance and beauty” in regards

to Brad Schwieger’s teapot sculptures in

February’s issue. However, I’m sure I’ve

misunderstood the context. I mean, we can

see that in fact, Brad’s works are quite origi­

nal. I spent a good deal of time studying the

movement, flow and glazes of his work. It

seemed as if the pots were moving to the beat

of a funky masculine rhythmic dance. Fun,

delightful, inspirational. His expression and

placement struck a chord in my heart and

Pro Gender Specific

sent me back to the studio with a refreshed

Yes, indeed, Laura Waters (Letters, May

awareness of my own love-labors.

1998). We do still need women-only art

Speaking of heart, is it really necessary to

shows—until that glorious future date (we

condemn something that you simply do not

used to say the millennium, but that’s upon

understand? Is it actually meaningful to

us) when exhibitions in museums and galler­

dictate and intellectualize a work based on

ies will become truly gender blind.

superior pretense?

Helene Bernardo, Bronx, N.Y.

What is next—politically correct pottery?

I would like to think we are seeking the

“loftier and higher” ground of mutual respect Broad-Based Information

Jeff7Zamek began his article “Is Barium

and acceptance. Or maybe Stanko has forgotCarbonate Safe?” in the September 1997

In keeping with our commitment to provide

issue of CM with the line: “Yes, provided you

an open forum for the exchange of ideas

don’t go into your studio and eat or directly

and opinions, the editors welcome letters

inhale barium carbonate.” He went on to

from all readers. All letters must be signed,

state that “knowledge of a material, especially

but names will be withheld on request. Mail

in the raw form, is vital to a potter’s health

to Ceramics Monthly, PO Box 6102,

and safety.” The body of the article is then a

Westerville, OH 43086-6102, e-mail to

comprehensive discussion of uses, alternatives

editorial@ceramicsmonthly.org or fax to

and other facts, including toxic aspects of

(614) 891-8960.

barium and safe handling in the studio.

8

What then is my point? Over the years, I

have read incomplete and alarmist reports

about dangers involved in the use of various

ceramic materials, which often are quite

irrelevant to the way potters use materials.

Some reports select limited information or

extrapolate data in an unrealistic (for potters)

way and thereby exaggerate potentially harm­

ful effects. For example, I was once errone­

ously challenged relative to the dust

generated when mixing clay. The challenge

statistics used were based on a commercial

operation in an eight-hour day, then applied

to a periodic studio-mixing operation of no

more than one hour.

Later, following publication of my article,

“Using Soluble Salts at Stoneware Tempera­

tures,” in the September 1996 CM, I was

questioned by a well-known college ceramics

instructor and told (in no uncertain terms)

that soluble chromium, copper and cobalt

compounds were hazardous materials and

produced hazardous wastes. In a related

telephone conversation with that same per­

son, after I had had discussions with a haz­

ardous-waste consultant and checked

Wisconsin DNR regulations, there was no

willingness to discuss degree, only an outand-out adamant declaration that they were

hazardous materials and should not be used.

In my mind, a closed-minded approach to

the situation. My inquiries had indicated

permissible exposure levels existed in the

concentrations I used, and the dilutions

occurring when I rinsed brushes and contain­

ers were of a safe level. My CM article had

also noted: “Basic safety precautions should

be taken whenever using soluble materials.”

Zamek warned against alarmist views and

decision making “based on incomplete facts,”

“unchallenged claims” and “generalizations”

that have more to do with “drama than

documented fact.” His article is an excellent

example of the kind of comprehensive infor­

mation upon which we should be making

our decisions in order to protect our students’

and our own health.

I recently heard someone suggest that one

should not allow children to catch snowflakes

on their tongues because of the pollutants in

the air. How many of you would immedi­

ately accept that advice? Let’s not do the

same when it comes to warnings about ce­

ramic materials. Let’s look to more broadbased information.

Zamek should also be applauded for his

fine article “The Perfect Clay Body?” that

appeared in the March 1998 issue of CM. It

was, indeed, my pleasure to read an under­

standable, thorough and convincing, as well

as reasonably technical, article by someone

who appears not to be stuck in the depths of

his own expertise. Over the years, I have read

articles that were either overly complex in the

chemistry and physics of ceramic materials,

and others with just enough ego-propelled or

CERAMICS MONTHLY

June/July/August 1998

9

Letters

incomplete information to be dangerous or

confusing to the less knowledgeable clay

enthusiast. CM should continue to print

more articles of this caliber by this knowl­

edgeable and articulate individual.

Kurt Wild, River Falls, Wis.

What a Ride

I am an architectural ceramist and a

member of the Clayart online discussion

group. I just attended my second NCECA

[National Council on Education for the

Ceramic Arts] conference, and thanks to Mel

Jacobson who rented a room for us to meet, I

met even more Clayart people than I did the

year it was held in Rochester. I believe that

one of the greatest strengths of this group is

the way it has brought people who work in

near isolation in their studios into this larger

community that is perhaps dominated more

by those with an academic affiliation. Because

I am self-taught, I do not have this affiliation.

I would have never thought of NCECA as

something to attend if it hadn’t been for

Clayart.

I had a very interesting evening on Friday

night when I went with a group of others to

Billy Bob’s Texas, the world’s largest honkytonk. It even has live bull rides. Near the bull

pen was a stuffed bull used as a photographic

prop by people willing to wear chaps for a

few minutes. Earlier in the evening, Mel

Jacobson dragged me to the dance floor with

a dance that could only be intended to get us

both tarred and feathered out of Texas. The

formalized Texas two-step was all around us

and Mel paid it no mind. That was the

leverage I needed to get him and the others

on the stuffed bull. That’s how I ended up

with this great photo of (from the left) Kevin

Caufield, Vince Pitelka, Mel Jacobson, Mark

Issenberg and David McBeth on this bull,

looking their Texas-best in hats and chaps. I

thought I would send it to CM to show

people what really goes on at NCECA.

Linda Blossom, Ithaca, N.Y.

The Name Game

I’d like to challenge all those clay educa­

tors out there to let us know those great

10

CERAMICS MONTHLY

June/July/August 1998

11

Letters

“clay” names of students in their classes. I’m

sure we have all had Potters, Wares, Glazers

and Clays, but I recently had a student I’m

sure will beat them all—a promising young

potter named Ana Gama.

Tim Ludwig, Port Orange, Fla.

Potter of the Century?

It seems like the perfect time for CM to

think about naming a Potter of the Century.

Who was the most influential studio potter

of the 20th century? Who did the most to

move the field ahead? Leach and Hamada

were certainly big influences, but very conser­

vative. My vote goes to George Ohr, who was

one of the most innovative artists this field

has ever seen.

Name withheld by request

Overreaction?

I am motivated to write regarding an

experience I had recently at a local nonjuried

exhibition that included work of various

visual artists and interior designers. Because

most of the sculptural work I did toward my

master’s degree was in clay, I’m always most

attracted to displays of ceramic work.

It was one artist’s ceramic work in an

interior designer’s display that caught my eye

and caused me disappointment. Each vessel

was accompanied by a brightly lettered card

with the word raku. This is a technique in

which I am well versed, having spent many

years producing raku vessels and sculpture,

helping to design and build raku kilns, and

even arranging to live in an isolated farmland

area that would allow me to fire outdoors

without restriction.

This person’s work was not raku. It ap­

peared to be made of porcelain or a tightbodied white clay and had never seen smoke.

The stoppers in some of the small-mouthed

vessels were a pale gray in their unglazed

areas, but not of an intensity that would

suggest heavy reduction. The copy on the

attached cards claimed these pieces had been

placed glowing into an airtight smoke cham­

ber. Any crazing of the glazes looked more

like a bad fit with the clay body, and the

cracks were all as clean as a whistle. The cards

also described raku as a glazing technique. I

wonder how many raku artists would agree

with that description.

I asked the exhibitors some questions and

pointed out some inconsistencies. They

seemed unconcerned, but did mention that I

was not the first person to complain. There

were some good examples of raku work in

their display, and they admitted that the two

artists who had produced them became angry

about the pieces I have described. But then

one of them was careful to put me in my

place by stating coldly that this was the way

the artist presented them and that was that.

In the past few years, I have seen more

and more manufacturers (I hesitate to say

artists) of raku-style work get away with poor

misrepresentations of the art. At juried

events, I have listened to exhibitors describe

work as raku that obviously was not. I was

unable to raise questions to the jurors since

the pieces were not entered as such. I think

what bothered me most about the incident

this time is that there were fine examples that

met both the technical and spiritual aspects

of raku in the same display with what I

consider frauds—overdone, predictable

(marketable) forms that obviously never

experienced the risk inherent in the firing

process and the value of their survival.

My purpose in contacting CM is to

discover others’ opinions. Should this kind of

activity be expected and ignored? Am I over­

reacting? It bugs me to think people who hire

this interior designer will display this kind of

work as raku.

Name withheld by request

Addendum

The color images of “Formation,” the tile

mural by Daleene Menning featured in the

April 1998 CM (see pages 49-51) were taken

by photographer Dan Watts.

12

CERAMICS MONTHLY

Up Front

Ceramics Annual at Scripps College

Ten clay artists—Marek Cecula, New York City; Lazio Fekete,

Budapest, Hungary; Arthur Gonzalez, Alameda, California;

Phyllis Green, Leslie Rosdol, Los Angeles; Sergei Isupov, Louis-

work in the 54th “Ceramics Annual” at Scripps College in

Claremont, California.

“The art in this exhibition embodies conflicts of the psyche,

dramas that normally play out away from view, in people’s

emotional lives,” Kolodziejski stated. “The artists’ emotive issues

and technical approaches range from intensely heated to clini­

cally cool, from twisted illustration to biting social satire.

“Much of this work breeds questions: Whose psyche are we

viewing? Are the artists exorcising their own demons in making

these works? Is their art psychologically irritating like a grain of

sand in an oyster? Psychological drama is manifested in three

ways by the artists in this exhibition. Some depict interior states

with imagery and/or words; others have made works that

provoke the viewers’ unresolved conflicts; and some create

hybrids of these two approaches.”

Magdalene Anyango N Odundo

The Cleveland Museum of Art recently acquired a ceramic

vessel by Kenya native Magdalene Anyango N Odundo. Like all

her works, this piece was coil built from terra cotta, then bur­

nished. It was fired twice, first in an oxidized atmosphere then

Leslie Rosdol’s “Untitled Clown Teapot,” 8 inches

in height, porcelain; at Ruth Chandler Williamson

Gallery, Scripps College, Claremont, California.

Sergei Isupov’s “Whirlwind of Unguarded Love,”

13½ inches in height.

ville, Kentucky; Anne Kraus, Boulder, Colorado; Jean-Pierre

Larocque, Long Beach, California; Keisuke Mizuno, Tempe,

Arizona; M. Elisabeth Higgins O’Connor, San Pedro, Califor­

nia—were invited by curator Cindy Kolodziejski to exhibit

Magdalene Anyango N Odundo “Untitled,” approximately

17½ inches in height, coil-built terra cotta with burnished

slips; at the Cleveland Museum of Art.

in reduction. This is the first contemporary African object to be

added to the museum’s collection.

Juried National in Connecticut

Submissions are welcome. We would be pleased to consider

press releases, artists' statements and photoslslides in con­

junction with exhibitions or other events of interest for publi­

cation in this column. Mail to Ceramics Monthly, Post Office

Box 6102, Westerville, Ohio 43086-6102.

14

“USA Craft Today,” a juried exhibition of 207 works by 149

artists, was presented recently at Silvermine Guild Galleries in

New Canaan, Connecticut. From 739 entries, juror Kenneth

Botnick, director of the Penland School of Crafts in North

Carolina, selected works in clay, fiber, glass, jewelry, metal,

CERAMICS MONTHLY

June/July/August 1998

15

Up Front

There are many potters in Nicaragua. As they live without

electricity or running water, their lifestyle has changed little

from that of their ancestors. Since the burden of putting food

on the table leaves little time for experimentation, and most are

unwilling to risk a bad kiln load, techniques have not changed

much over time.

We traveled with two Nica potters, Valentin Lopez and Paula

Rodgriquez, who assisted Rivera in translating. Our journey

began in Calle Real de Tolepa, a small village where generations

of women have produced pottery, all making basically the same

style of pots and competing for sales in the same marketplace.

We were there to help Emisela Rivera build a 5-foot-tall,

beehive-shaped kiln from castable material. Emisela had been

firing at a neighbor s kiln for some time and had finally saved up

enough money to build one of her own. She had hired a local

Laura J. McLaughlin’s “Columbus Landing,” 18 inches

wide, white stoneware with slips, carved; at Silvermine

Guild Galleries, New Canaan, Connecticut.

mixed media, paper, wood and basketry. Among the ceramic

works on view were “Trois Boites” by Connecticut potter Karen

Ford and “Columbus Landing” by Pennsylvania artist Laura

Jean McLaughlin, who received the Juror s Choice award.

“The imagery that appears on my work represents the

psychological struggle, chaos and violence that occur in many of

Oval serving dish, 12 inches in length, handbuilt from

local clay, with terra sigillata, burnished, fired to

earthenware temperature, by members of the Ducuale

Women’s Cooperative in Condega, Nicaragua.

Karen Ford’s “Trois Boites,” to 4 inches in height,

wood-fired stoneware.

our lives,” McLaughlin noted. “Much of my work is very busy

with a closely packed composition. These chaotic compositions

represent the constant bombardment of information from

structures such as family, government and religion, as well as the

media. These structures influence and often form our percep­

tions of ourselves and others.”

Visiting Potters in Nicaragua

by Beverly T. Pillers

Last year, I—along with three others from the United States and

Canada—joined a group of potters traveling to Nicaragua with

Ron Rivera of Potters for Peace (PFP). Originally organized

during the Nicaraguan civil war to provide pottery cooperatives

with technical support, PFP now concentrates on helping to

make these potteries self-sufficient and to expand their markets.

16

man to build the framework, which was then covered with

straw. Stomping with our feet, we mixed a slurry (from clay

mined from a nearby mountain and horse manure). It took a

day to mix and then apply several coats of this slurry over the

straw. Holes were left for burner ports, and the exterior was

reinforced by placing large pottery shards on top. We planned

to come back a week later to see if the kiln was dry enough to

check the draft with a test fire.

We then traveled to Condega, about 1 ½ hours from the

Honduran border, to visit the Ducuale Women’s Cooperative.

The facility consists of a throwing area with four wheels, a

handbuilding board, drying room and display area, and is built

around a courtyard that includes the kiln and clay-processing

area. They are fortunate to have a small building in which to

store their freshly dug clay, unlike most Nicaraguan potters who

must leave their clay in the open, which causes its own set of

problems during the rainy season.

Dug nearby, the clay is dried, then broken up and slaked in a

small brick trough. After a day or two, it is sieved to remove

debris, then dried on briclcs in the courtyard. When the clay is

nearly dry enough for use, it is brought inside and slapped

against the brick wall to pull out a little more water until it is

just right for throwing or handbuilding.

After introductions were made, one of the local potters

demonstrated handbuilding a 12-inch round vessel, using only a

corn cob, a piece of gourd and a table knife as tools. She began

CERAMICS MONTHLY

June/July/August 1998

17

Up Front

with a thick, round tortilla-shaped slab that was draped inside

an old pot shard. She then attached a large coil, pinching with

her fingers. As she added more coils, she thinned the wall with

pressure from her hand and the corn cob.

She was incredibly fast, and worked sequentially on several

vessels, setting each aside to stiffen while going back to complete

another. After slowly necking in the opening at the top, she

would tear the rim perfectly straight with her fingers, then

smooth it with a piece of wet cloth. The completed pots ap­

peared perfectly symmetrical and could easily be mistaken for

wheel-thrown.

When the shaping was finished, she applied tawe (terra

sigillata made from a local clay and iron oxide), and put the pot

aside to slowly dry until it was strong enough to burnish. A

group of women and young girls spent their days burnishing the

pieces produced by the five or six women who form the pots.

(Young girls start their training by burnishing at the age of nine

or ten, and will probably make pottery into their seventies and

beyond.) The burnishers worked steadily, using smooth riverworn stones handed down through generations, chatting quietly

while small children ran around.

After the demonstration, we went to work ourselves. Most of

us had to make a big adjustment to the working conditions,

using unfamiliar kick wheels, and continuously reaching for

tools that weren’t there. The workshop, like most we saw, had

no electricity; the small amount of daylight that crept in under

the extended roof made it impossible to see inside the pot we

were making, limiting us strictly to touch. Soon we were busy

making our pots and trying theirs, attempting to communicate

in two different languages when our translator wasn’t around. I

learned that laughter is universal, though, when I sat at a kick

wheel that was too short for me, and my legs wouldn’t fit in the

kick space. At the end of the day, we covered our wares with

terra sigillata and lined them up to dry.

The burnished ware was low fired, then decorated with a

simple slip that would act as a resist during the smoldng process.

They were placed in a small kiln along with wood and dried

coffee husks, and smoked for about 20 minutes until chocolate

brown. After they had been pulled from the kiln and cooled, we

washed off the dried slip. The result was two-toned ware with

reduced chocolate-brown backgrounds and oxidized bright

orange designs where the slip had been.

While we were there, the women were given the news that

they had just received an order from Pier 1 Imports in the

United States for 18,000 pieces. They immediately began to

consider ways of drying clay faster during the rainy season to

meet the store’s deadline. Since arriving home, I have heard

from Rivera that, in order to fill this order, the cooperative

doubled the size of its wortapace and now employs 37 people.

The impact of this one order will change the lives of many

Nicaraguan families, perhaps allowing their children to go to

school, provide health care, or even make it possible to install

electricity in their homes.

Over the next two weeks, we bumped over remote country

roads and forded a bridgeless stream in a small pickup truck,

visiting potteries around the country. After hiking up a

mountainside, we spent one day working alongside the women

of Loma Ponda in their workshop. They had a kick wheel—

which is just being introduced in the countryside—that was

brought in on the back of a donkey A high point of our stay

18

there was hiking to see an undocumented ancient petroglyph on

an isolated mountainside. We quickly decided to leave our mark

by appropriating the petroglyph’s design for a mural on the kiln

when we returned to Calle Real de Tolapa.

On our final day out in the country, we gathered along with

many of the potters we had met over the last two weeks for a

multicultural festival at the Art and History Museum in

Condega. We demonstrated throwing techniques, decorating

and raku firing. Many potters brought their work into town in

large baskets balanced on their heads to sell at the festival.

The trip has given me a fresh perspective on pottery from the

view of these courageous and dignified people—wonderful

artists who allowed us a glimpse into their lives.

Erna Aaltonen

Stoneware vessels by Finland potter Erna Aaltonen were exhib­

ited recently at the Hameenlinna Art Museum in Hameenlinna,

Finland. “Pottery is one of the oldest technical skills of man-

Erna Aaltonen’s “Knight,” approximately 38 inches in

height, stoneware lidded jar; at the Hameenlinna Art

Museum, Hameenlinna, Finland.

CERAMICS MONTHLY

June/July/August 1998

19

Up Front

kind. Being part of and continuing this tradition is a way to

express myself,” Aaltonen remarked.

Whether handbuilding, throwing or casting her forms,

Aaltonen “focuses on glazing and the effects on the surface.”

American Craft Council Update

The American Craft Council (ACC) has reported that sales for

the “1998 ACC Craft Show Baltimore,” held February 17-22 at

the Baltimore Convention Center, were at an all-time high.

Projected totals showed an increase of over $4 million from

1997. On a per-exhibitor basis, wholesale sales were up by 17%

and retail sales by 11%. Attendance by wholesale buyers in­

creased 6% over 1997, while attendance by retail buyers re­

mained the same.

The ACC also introduced a new program at the Baltimore

show. Designed to recognize excellence in the work of exhibitors,

“The American Craft Council Award of Excellence” was (will be)

given to artists “who, in their work, display an extraordinary

vision or idea in concert with a superb competence and mastery

of a craft medium,” stated Michael Monroe, executive director of

ACC. Each recipient received a cash award of $500 and is

automatically accepted into next year’s Baltimore show. Plans are

underway to extend the program to other shows.

Mothers Day Sale

The Appalachian Center for Crafts in Smithville, Tennessee, held

its annual “Mother’s Day Open Studio” on May 9. Among the

Vince Pitelka’s “Industrial Ruin Vessel #2,” 22 inches

in height, colored-clay marquetry, $850.

clay artists featured were Clive Clintonson, Sean Gouge,

Kathleen Guss, Jeff Lee, Kirke Martin, Chris Mosey, Vince

Pitelka and Stephen Robison.

Along with the sale of work, several artists gave demonstra­

tions, including Guss, who fired a wood kiln, and Robison, who

threw pottery on the wheel.

Aaron Lee Benson

Jeff Lee bottles, to 12 inches in height, salt-fired

stoneware, $45-$50; at the Appalachian Center

for Crafts, Smithville, Tennessee.

20

by Christopher Nadaskay

“Imitators of God,” a series of sculptures by Tennessee artist

Aaron Lee Benson, portrays individuals who fell victim to the

Nazi regime during the Holocaust. Shown recently at Mary

Adams Gallery at Wheaton College in Norton, Massachusetts,

the forms are both architectural and figurative.

Benson has long been creating large-scale clay sculpture with

an architectural theme (see the March 1997 issue of CM). His

recent research into martyrs, the reason they chose to die and

why they were killed, led him to the Holocaust and the discov­

ery of hundreds of cases where individuals died because they

had chosen to defend Jews.

The sculpture “Janusz Korczak” (shown on page 22) depicts

a man who ran an orphanage for Jewish children. When the

Nazis forced the children to go to a concentration camp,

Korczak did not have to go because he was Protestant. Ignoring

CERAMICS MONTHLY

Up Front

his own fate, he chose to accompany the children, even to the

gas chambers at Treblinka.

Each of Benson’s works takes on the likeness of the indi­

vidual it portrays, combines it with a symbol and imagery

relating to his or her life, and juxtaposes them against the

architectural framework of the traditional Christian cathedral.

The symmetry of the forms gives them an archetypal presence

that is only enhanced by Benson’s surface treatment.

He does not use traditional glaze techniques. Instead, each

piece is painted with transparent layers of varying media,

ranging from inks, paint and shoe polish to tea, coffee, mud

Dick Lehman’s “Ash-Awash,” approximately 10 inches in

height, porcelaneous stoneware with feldspathic

contaminants, ash glazed, fired for nine days with pine; at

Cedar Valley College Ceramics Gallery, Lancaster, Texas.

ing fuel consumption), length of firing and clay body choices,

and their effects upon natural-ash accumulation.”

Tamara Laird

Functional ware by Takoma Park, Maryland, potter Tamara

Laird was exhibited through April 8 at the Kline Campus

Center Art Gallery at Bridgewater College in Bridgewater,

Aaron Lee Benson’s “Janusz Korczak,” 22 inches in

height; at Mary Adams Gallery, Wheaton College in

Norton, Massachusetts.

and berry juices. He often uses as many as 30 layers to achieve

the surface effects he wants.

Dick Lehman

“Collaborative Accommodations,” an exhibition of wood-fired

ceramics by Goshen, Indiana, potter Dick Lehman, was pre­

sented recently at the Cedar Valley College Ceramics Gallery in

Lancaster, Texas. The works on view were the culmination of

experiments with eight different clay bodies fired in five woodburning lnlns.

They were “all fired in anagama-style kilns,” Lehman ex­

plained, “ranging from massive-fireboxed ‘minigamas’ to more

traditional large-scale anagamas. I am especially interested in

exploring the relationships between firebox size (and the result-

22

Tamara Laird teapot, 18 inches in height, red earthen­

ware, slab built, fired to Cone 04; at the Kline Campus

Center Art Gallery, Bridgewater (Virginia) College.

Virginia. Slab built from red earthenware, Laird’s pots are

decorated with vitreous slips, dry colorants and translucent

glazes. “Meant to be friendly, inviting and capable of producing

a smile,” her worlds “consist of a number of separate pieces

CERAMICS MONTHLY

June I July I August 1998

23

Up Front

joined together to create playful combinations of color, form

and balance,” Laird notes.

Broadway, Here We Come

When the new Broadway production of The Sound of Music

opened in March, it had a new prop—clay. Director Susan

viewed simultaneously as an everyday household item and as a

precious art object.

Their worl<s ran the gamut from decorative through func­

tional to installation art. Each one made a personal statement in

clay, and it was the individuality, and in some cases intimacy, of

these statements that made the results exciting. For instance,

Eve Faulkes, professor of art in graphic design, manipulated

still-soft plates to reflect the forms of the dried leaves, ferns and

seed pods that she attached to the finished piece. Through the

use of scratching, shaping and glazing, she achieved an exquisite

concurrence between the decoration and natural forms.

With the wide range of interpretations, it was interesting to

note that the only plates with a functional aesthetic were made

by Bob Anderson. His majolica-glazed plates brought to mind a

combination of two traditions worlds apart: the majolica ware

of the Mediterranean and the boldly painted ceramic ware of

Japan in the custom of Sotatsu and Korin.

Anderson’s were the only plates in “Division of Art Faculty:

The Plate Show” that one could actually eat from. There is

Connecticut potter Kristin Muller instructs actress Jeanne

Lehman on proper throwing techniques in preparation for

the Broadway musical The Sound of Music.

Schulman, who had researched the historical aspects of the

abbey in which Maria Von Trapp was a nun, discovered that the

nuns had produced wheel-thrown and handbuilt daywork.

For the latest production, she hired Kristin Muller, director

of ceramics at Brookfield Craft Center in Connecticut, to teach

actress Jeanne Lehman, the choreographer and the property/set

manager the process of throwing and other aspects of working

with clay that “would be dramatic on stage.” One of the earlier

scenes depicts the nuns making pottery during the musical

number “How Do You Solve a Problem Like Maria?”

“Throwing clay on the wheel relates to dancing very closely,

because there is a repetition and rhythm,” Muller noted. “You

do it over and over, yet each time is a little different because of

the human element.”

Bob Anderson plate, earthenware with majolica

and overglazes; at Paul Mesaros Gallery, West

Virginia University, Morgantown.

Not Your Usual Faculty Show

by Claudia Giannini

To celebrate the 100th anniversary of the Division of Art at

West Virginia University (WVU) in Morgantown, the art faculty

collaborated with faculty artist Bob Anderson, coordinator of

the ceramics department, to create unique artistic statements

using earthenware plates as their point of departure. In the

world of academic ceramics, the university is one of only a few

that focuses on production processes and explores creative

decorating techniques, training students to be self-sufficient

potters upon graduation. The program’s emphasis on functional

ware provided the basis for the collaboration.

When artists have the opportunity to work in a medium

with which they have little experience, they are not bound by

preconceptions, and interesting things are allowed to happen.

The faculty artists visiting the ceramics department approached

this project through the rich associations brought to something

24

Eve Faulkes earthenware plate, 12½ inches in

diameter, with white slip, oxides and clear glaze,

and natural objects.

CERAMICS MONTHLY

June/July/August 1998

25

Up Front

something refreshing and direct in the idea of making objects

that are both useful and beautiful.

Seven Points of View

by Julie Miracle

Seven ceramists revealed seven points of view in an invitational

exhibition featured at Urban Artifacts Gallery in Houston. “I

really wanted an eclectic show to illustrate the diversity and

breadth of the medium,” commented curator Barbara

Chadwick, an artist and adjunct professor of art at North

Harris College in Houston. Along with her own work,

Chadwick selected ceramics by Margaret Bohls, Huntsville,

Texas; Nick de Vries, Houston; Kate Inskeep, Boulder, Colo­

rado; Phyllis Kloda, Athens, Ohio; Paul McCoy, Waco, Texas;

and Matt Wilt, Philadelphia.

Together, Chadwick’s selections convey a message of the

potential of clay. The art illustrates expansive, individual po­

tential guided by, and dependent upon, the medium.

Nick de Vries’ highly structured forms depict sobering

themes. Having recently returned from symposia in the

Czech Republic and Poland, his work transports us to an

Eastern Europe still scarred by war. Almost like artifacts from

a bombed-out building, his slab-built stoneware sculptures

suggest visual paradox: structure in distortion, beauty amidst

ugliness, hope despite despair.

De Vries describes his work as metaphorical—“relating

selected themes of the human condition. My fascination with

structures, be it physical or behavioral, has always been an area

of intrigue,” he explains. “I have used forms that are predictable

and not-so-predictable. Today, I am noticing the two forms

blurring at the edges and fading into each other.”

Margaret Bohls’ condiment trays interpret traditional forms;

the forms of the ewers, jars and shakers interact and contrast.

Nick J. de Vries’ “Na Hrebienka 35, No. 1,” 23 inches

in height, handbuilt stoneware; at Urban Artifacts

Gallery, Houston, Texas.

Margaret Bohls’ “Celadon Condiment Tray,” to 10 inches

in height, handbuilt porcelain.

“Besides their actual function, these forms function visually like

three-dimensional still lives,” notes Bohls. “The visual interac­

tion of each individual form against the others in the set is of

great interest to me.”

Randy Brodnax and Michael Obranovich

Barbara Chadwick’s “Allegro,” 8¾ inches in height,

porcelain, thrown and handbuilt.

26

“Two Peas Outta the Pod,” an exhibition of wheel-thrown and

handbuilt vessels by Texas artists Randy Brodnax and Michael

Obranovich, was presented through May 2 at the Dallas Visual

Arts Center. Preferring to produce pottery for everyday use,

Obranovich concentrates on forms that are “simple and comple­

mented with glazes that enhance the utility of the piece,” he

explains. “Some are used to serve food; some are a celebration of

the elements.”

For Brodnax, clay provides an “opportunity to be provoca­

tive and earthbound, yet at the same time strong and highly

CERAMICS MONTHLY

June/July/August 1998

27

Up Front

untitled to allow viewers to make their own assessments,

Brogden explains that she is “fascinated by the associations

made as we interpret the world around us. The objects that I

build reflect this fascination. It is my hope to create forms with

a broad and often ambiguous reference; forms that are perplex­

ing due to their many allusions.”

Scott R. Jones

“Many Styles,” an exhibition of ceramic wall platters, decorative

pottery and drawings by New Cumberland, Pennsylvania, artist

Scott R. Jones, was presented at the Washington County

Museum of Fine Arts in Hagerstown, Maryland. “My work is

the culmination of many styles and media,” Jones commented.

“And this exhibit represents my desire to never stick to one

Michael Obranovich teapot, 10 inches in height, slabbuilt stoneware with copper glaze; at the Dallas Visual

Arts Center, Texas.

individual. It pulls you inward to become one with this incred­

ible, plastic material. Clay is always a bodacious experience.”

Sally Brogden

Ceramic sculpture by Knoxville, Tennessee, artist Sally Brogden

was exhibited recently at Gallery One at the Appalachian

Center for Crafts in Smithville, Tennessee. Leaving her works

Scott R. Jones’ “Three Styles in One Plate,” 17 inches in

diameter, glazed terra cotta; at the Washington County

Museum of Fine Arts, Hagerstown, Maryland.

medium or one way of working within a medium. It features

multiple ways to express the same subject.

“Collectibles, old magazine ads and pop art directly influ­

ence my work, as do artists such as Stuart Davis, Marsden

Hartley, Charles Burchfield and Edward Hopper. Their art, like

mine, reminds me of an expression I once read: ‘The delinea­

tion of essence.’

“I approach an object by first discerning its simplicity,” he

continued. “Pottery, my favorite medium of expression, is

unforgiving. The many unexpected things that can happen—

and inevitably do—make creating the perfect piece extremely

difficult. As much as 40% of what I produced for this show is

not represented for reasons as varied as craclcs, warping, bubbles

and bad batches of clay.

“The constant two-steps-forward-one-step-back nature of

creating pottery requires the stubborn streak seen in so many

potters,” Jones concluded. “Without the willpower to persevere

in the face of these setbacks, many artists turn to another

medium. I prefer to figure out what went wrong and to try

different approaches until I get it right.”

Dong-Hun Chung

Sally Brogden “Untitled,” 24 inches in height; at Gallery

One, Appalachian Center for Crafts, Smithville, Tennessee.

28

Clayworlcs created during a one-year residency by Korean artist

Dong-Hun Chung were exhibited recently at the Towson

University Asian Arts Gallery in Towson, Maryland. Combining

CERAMICS MONTHLY

Up Front

asserts that ceramics will never rise in popularity or respectabil­

ity, because it is too decorative, beautiful and sensuous. These

qualities, he maintains, are not taken seriously.

David Stuempfle Receives Japan Fellowship

Dong-Hun Chung sculpture, approximately 3 feet in

height, handbuilt, multifired; at Towson University Asian

Arts Gallery, Towson, Maryland.

size and simplicity in his sculpture, Chung creates human-size

urns, vases and figurative pieces based on the Chinese philoso­

phy of yin-yang.

“My works are quite the same as marriage,“ Chung observes.

“Two people living together, separate people, unified into one. I

create separate forms, but adjust them, bring them together to

make one art form.

“I am really representing Korea through my work,” he

concludes. “It reflects a desire to unify Korea, two separate

entities uniting into one country.”

Exhibition of Danish Ceramics

For the “Second Danish Ceramics Triennial” at the Trapholt

Museum in Kolding, Denmark, jurors Soren Thygesen and

Gunhild Aaberg (both ceramists), and Sven Jorn Andersen,

Trapholt director, chose 20 artists to present 6—8 examples of

their most recent work.

In an essay published in the accompanying catalog, Peder

Rasmussen (one of the selected artists) writes about his career as

a ceramist and the current state of ceramic arts in Denmark. He

Installation view of the “Second Danish Ceramics Triennial”; in the

foreground are two modeled stoneware sculptures by Martin Bodilsen

Kaldahl, to approximately 11 inches in height, approximately US$1065

and US$1220 (left to right); at the Trapholt Museum, Kolding, Denmark.

30

Seagrove, North Carolina, potter David Stuempfle was awarded

one of three 1998 United States/Japan Creative Artists Fellow­

ships. The program sends American artists to Japan for a sixmonth residency.

During their stay, the

fellowship artists are

encouraged to consider

how exposure to

Japan’s contemporary

or traditional cultures

can influence their

studio work.

While in Japan,

Stuempfle hopes “not

only to improve myself

as a potter by experi­

encing life and art in

Japan, but to open

communications

between Seagrove and

David Stuempfle stoneware

other pottery commubottles, 17 inches in height,

sa^ 9lazed and wood fired.

nities in Japan.”

Bennett Welsh, 1922-1998

Gresham, Oregon, potter Bennett Welsh died on April 2. One

of the first potters in the Northwest to work with high-fired

stoneware, Welsh founded and built the equipment for the

ceramics department at the Portland Art Museums school (now

called the Oregon Art Institute). He later went on to work in

the ceramics department at Tektronix, a high-tech computer

and oscilliscope company, but soon quit to buy Pacific Stone­

ware, a production company with several retail shops. In the

1970s, he sold the company and began working in a smaller

studio with just a few employees. After officially retiring from

production potting in 1984, he had concentrated on making

large sculptural pieces.

Robert Sperry, 1927-1998

Seatde, Washington, artist Robert Sperry died on April 14.

Recognized as an influential force on the development of ceramic

art in the Pacific Northwest, Sperry was known for his work with

crackled slips on large plates and wall forms (see “Abstractions in

Black and White” in the June/July/August 1990 CM). He liked

the idea of art “as an event, rather than a description.”

In fact, he credited “the accidental happenings of

which life is full” for some of his best ideas.

Although Sperry initially studied painting (at the

University of Saskatchewan and the Chicago Art

Institute), he became interested in ceramics after

meeting Peter Voulkos and Rudy Autio at the Archie

Bray Foundation. Sperry then went on to earn an

M.F.A. at the University of Washington, after which

he joined the staff as a ceramics teacher.

Early in his ceramics career, he was influenced by

the Scandinavian aesthetic; he also explored salt

glazing and metallic lusters before focusing on

recording the interaction of white slip brushed,

poured or troweled over fired black glaze.

CERAMICS MONTHLY

June/July/August 1998

31

New Books

ues. “He demonstrated a wish not just to de­

velop a glaze or even a group of glazes, [but] to

develop an integrated body of work with a

unique personality. He learned to throw on the

potter’s wheel;...he found a clay body that fit

Charles Fergus Binns

his needs, and he found glazes that fit the

The Father of American Studio Ceramics

body. He did all this with a consciousness that

by Margaret Carney

every aspect of the work had to mesh with every

other aspect, for only then would it convey a

with essays by Paul Evans, Susan Strong and

sense of rightness.”

Richard Zakin

The final section of the book describes the

Published in conjunction with the exhibi­

tion of the same name, this catalog/book lookscareers of 11 of his most accomplished students,

at the life and work of potter/educator/scholarincluding Arthur Baggs, Paul Cox, Maija

Charles Fergus Binns. Included are essays fo­ Grotell, Mary Chase Perry Stratton and Adelaide

cusing on Binns’ life and career before Alfred Alsop Robineau. 254 pages, including bibliog­

University, his work at Alfred, his designation raphy and index. $50; American Ceramic Soci­

as the father of Ameri­ ety member, $45. Hudson Hills Press, Inc., 122

can studio ceramics, the East 25th Street, Floor 5, New York, New York

technical aspects of and 10010-2936. Also available from The American

the Oriental influences Ceramic Society, Post Office Box 6 136, Westerville,

Ohio 43086-6136; telephone (614) 794-5890

on his work.

or

fax (614) 794-5892.

Born in 1857 in

Worcester, England,

Binns apprenticed at Handbuilt Ceramics

the Royal Worcester by Kathy Triplett

“Today, when a potter with a wheel can turn

Porcelain Works when

he was 14; he contin­ out 50 cups in an hour and when industry can

ued to work there for 25 years, primarily as headreproduce endless, inexpensive, fiber-glass ar­

chitectural details, hand sculpting clay seems

of the sales office, but also as a lecturer. In 1897,

he resigned from the factory and moved to especially slow and laborious. Yet people con­

America. As he lectured and wrote about pot­ tinue to shape clay by hand because doing so

tery, Binns’ reputation grew, and in 1899, he provides something beyond utility or expedi­

was asked to be 1 of 25 founding members of ence,” observes the author of this nicely illus­

trated “how-to” guide. “Working with clay

the American Ceramic Society.

A year later, Binns became the director (andoffers, as do very few activities in our mechanis­

teacher) of the newly founded New York State tic world, the opportunity to participate fully in

an act of creation—to

School of Clay-Working and Ceramics (now

known as the New York State College of Ce­

simultaneously express

and fulfill a wide range

ramics at Alfred University), the first school to

of human needs.”

combine ceramic an and technology. “Its course

After an explana­

was set by the artistic and educational philoso­

tion of the tools and

phies of its first director, Charles Fergus Binns,”

equipment needed, as

notes Strong in her essay on Binns at Alfred.

well as a look at clay

It was clear to Binns, she adds, “that crafts­

and its properties,

men were not undertaking sufficiently lengthy

Triplett describes sev­

or rigorous training to produce fine wares and

eral handbuilding tech­

that the public was not sufficiently educated to

appreciate or buy them. Alfred became a leaderniques, including pinching, coiling and slab

in American ceramics because of Binns’ power­building, illustrated by “how-to” photos and

ful influence as a teacher and because he unitedexamples of works by various artists.

Surface decoration—materials used, testing

art with technology.”

When Binns began his career at Alfred in glazes and underglazes, preparing glazes from

1900, he was well respected in the ceramic powdered ingredients, techniques, application

industry, but was not yet a potter. In the next of glazes, etc.—is discussed next. “The word

few years, though, he began experimenting ‘decoration’ in a discussion of surface treat­

with stoneware clay bodies and glazes. “By ments for clay is somewhat deceptive,” notes

1905, his career as an artist-potter was begin­ Triplett. “It suggests, among other things, that

ning to gel,” states Zakin in his essay on the surface treatments are afterthoughts—colorful

technical aspects of Binns’ work. “He not only veneers applied after the fact. They shouldn’t

was thinking about the artist-potter and about be. A glaze applied with no forethought can

stoneware, he was becoming an artist-potter. overwhelm rather than complement the form

He was throwing sectioned formed pieces on of a piece. Contemplating a finish while you

the potter’s wheel, and he was beginning to design and make a piece is critical.”

After discussing kilns and firing techniques,

make his own stoneware.

“Binns adopted a wide-ranging approach to she provides step-by-step instructions for eight

the way he developed his work,” Zakin contin­ projects (stiff-slab windowsill planter, coiled

32

CERAMICS MONTHLY

June/July/August 1998

33

New Books

ter and water ratios; underglaze, engobe, kiln craftworks,” states the author of this compila­

wash, casting slip, glaze, terra-sigillataandcrack- tion of 23 tear-out business and legal forms

repair recipes; glossary; list of contributing art­ (contract of sale, invoice, commission contract,

and extruded planter, extended pinch pitcher, ists; metric conversions; list of resources; bibli­ distribution contract, rental contract, copy­

etc.); each includes a list of tools needed, de­ ography; and index. 458 color photographs. right application, etc.) for individual use. Ex­

tailed instructions, tips and variations. “These $24.95, plus $3.95 shipping and handling. planations and detailed instructions on how to

Lark Books, 50 College Street, Asheville, North use each one are pro­

projects will show you how particular tech­

vided as well.

niques can be used, and by making each one, Carolina 28801; telephone (800) 284-3388.

Crawford also ex­

you’ll learn valuable handbuilding methods.

Every one of these projects, however, could be Business and Legal Forms for Crafts plains standard provi­

sions to contracts, such

by Tad Crawford

made by using a different technique.”

as arbitration, death or

“Attaining

the

knowledge

of

good

business

The final chapters cover acquiring and work­

ing on commissions, plus various sources of practices and implementing their use is an disability, force mainspiration. 160 pages, including appendixes important step toward success for any profes­ jeure, etc.: “Under­

on safety precautions; cone-firing ranges; plas­ sional, including the professional artist creating standing the business

concepts behind the

forms is as important as using them. By know­

ing why a certain provision has been included

and what it accomplishes, the artist is able to

negotiate when faced with someone else’s busi­

ness form.” 176 pages, including index.

Softcover, $19.95 (includes a CD-ROM with

forms, for Windows or Macintosh). Allworth

Press, 10 East 23rd Street, Suite 400, New York,

New York 10010; or telephone (800) 491-2808.

The Complete Potter’s Companion

by Tony Birks

First published in 1972, this revised and

updated edition is designed to “encourage pot­

ters to experiment more widely and aim high,

not to be satisfied with adequate results, but to

relate to the increasing throng of creative artists

worldwide who make scintillating work and for

whom pottery is central to their lives.”

The processes of throwing (centering; open­

ing to a cylinder; making lids, lips, handles,

spouts; trimming; etc.) are detailed in the first

section. Here and throughout the book, “how­

to” photos and ex­

amples of works by

individual artists ac­

company the text.

The second section

looks at handbuilding

techniques. “As a tech­

nical device, the wheel

may give speed and pre­

cision while imposing

discipline, but there is no question of its elbow­

ing handmade ceramics into second place as far

as worth and beauty are concerned,” maintains

Birks. “The would-be potter without a wheel

must never for a moment feel he or she lacks the

facilities to make pots. Some trepidation is

justified, however, since, armed with a simple

technique and the simplest of tools, the begin­

ner is entering the arena from which have

emerged many of the world’s greatest pots, and

much of the best modern work.”

Glazes—their ingredients; application; reci­

pes, results, faults and remedies—are consid­

ered next, then Birks discusses the decoration of

raw, bisqued and glazed pottery, plus multicol­

ored clays. The final section describes kilns and

various firing processes, as well as the space and

34

CERAMICS MONTHLY

June/July/August 1998

35

New Books

192 pages, including glossary, list of suppli­ guide (first published in 1972) to creating

ers and publications, index, and index of pinched pottery. “Pinching has invited me to

potters’ work. 450 color photographs; 21 slow down into time, way down into the plea­

equipment needed for making pots. “There are sketches. $26.95, softcover. Bulfinch Press/Little, sure and sensuality of first a pinch, now a stroke,

hundreds of studios and cooperatives world­ Brown and Company, 1271 Avenue of the Ameri­ then another pinch and this one herelhear; one

pinch at a time.”

wide, and it is not too difficult to make contact cas, New York, New York 10020.

Of all the forming methods, pinching pots,

with the potters who run them,” he notes.

he says, is “most often given the least emphasis,

Emphasis is “either on the functionalism Finding One’s Way with Clay

despite the fact that it

and good design of a medium that started, by Paulus Berensohn

“As soon as I learned how to pinch clay, I is generally the first

and continues, to serve the table, or on the

aesthetic and emotional potential of the me­ wanted to share this process of pinching with method we are taught

dium, clay, as a means of communication. It is others. I am less passionate these days about or teach. It is difficult

only this schism that is artificial. Good pots willthe pots we make as pots than I am in the meansto make a controlled

continue to communicate their quality and whereby...we experience forming them,” com­ form by this method.

beauty when the talking is over and done.” ments Berensohn in this revised and updated The pots look crude,

they crack in our hands

and collapse.”

Yet, through pinch­

ing, Berensohn has

found a “new respect and interest...for the

touch and the color of clay, for its perishability

and its strength. I am taking more care in my

selection and making of clay bodies: allowing

them their own time to age. This lesson, that

time is needed for both clay and potter to ripen,

is a nourishing and supportive one.”

Providing detailed instructions and “how­

to” photos, the book begins with the simple

exercise of creating a small, thin-walled, sym­

metrical pinch pot; then goes on to asymmetri­

cal pots; closed, near-closed and necked forms;

and large forms. Putting pieces together, add­

ing clay to a shape, texturing and surface enrich­

ment are covered next.

“It is very easy for surface enrichment and

design to be just that: a decoration and on the

surface,” Berensohn notes. “What I try to

evolve in my work is a reason for the designs

I’m using that will deepen the surface and

enliven the form with signs of my person, my

interests, my life.”

The second section deals with colored clays—

wedging various clays together, adding oxides

to clay, etc., plus detailed information on four

clay bodies that Berensohn uses in combination

with oxides.

Information on sawdust kilns and firing is

also included. “Sawdust firing is the gentlest of

fires: a flameless fire. Pottery fired in sawdust is

extremely low-fired, just past the point where

the pot would not dissolve back into workable

clay if it were soaked. It will not hold water, nor

can it be glazed. The limitation (I should say

‘privilege’) of this palette is blackness. And yet

within this limitation is a gentle and soft range

of possibility.”

The final section includes notes, quotes and

stories from Berensohn’s journal. 165 pages,

including appendix noted “to the experienced,”

“on wedging in additives to your clay” and

“Twenty-five Years Later: Wilder ClaylSlower

Hands”; glossary and bibliography. 41 color

and 334 black-and-white photographs; 45

sketches. $26.50, plus $3.50 shipping. Trinity

Ceramic Supply, 9016 Diplomacy Row, Dallas,

Texas 75247; or telephone (214) 631-0540.

36

CERAMICS MONTHLY

June/July/August 1998

37

A Look at Glaze Calculation Software

by Rick Malmgren

asier, faster, more powerful—the last

few years have seen significant

changes in the arena of computer glaze

calculation programs (see the October

1995 CM). The earliest programs were

essentially just quick unity formula cal­

culators, but theyve come a long way

since then. All (old and new alike) are

smoother, more intuitive and filled with

many useful features. More than simply

keeping pace, some of the newer pro­

grams have raised the standards and

expectations several notches, and low­

ered prices.

Computers will never replace glaze

testing. If anything, they encourage

more testing. As the materials that make

up the glazes are better understood, the

direction for improvement becomes

clearer, and the power more enticing.

Ultimately, it comes down to your own

understanding of the materials, appli­

cation methods and firing.

All of the features of these glaze cal­

culation programs fall into three basic

categories: electronic notebook, recipe

analysis and predicting fired results. Each

of the programs discussed here offers

something in every category, but only a

few excel in all three.

Electronic notebook: First, and most

familiar to everyone, is the glaze note­

book. We have all used some system of

storing glaze recipes and tips on how to

apply and fire our glazes. For many of

us, a spiral notebook or three-ring binder

works fine. As our careers advance, we

tend to collect new recipes and new

ideas, and do some testing. Here is where

the computer programs become help­

ful—they provide an order to the mess

that most glaze notebooks become.

Computer programs are great at

searching and sorting. With an elec­

tronic notebook, you can also instantly

calculate how much of each ingredient

you would need to achieve a batch of

any given size, then print out the recipe

to use as a checklist for mixing. Prob­

ably the most common glaze-mixing

errors are miscalculating an ingredient

amount or skipping one altogether. A

checklist solves both problems.

E

38

GlazeChem 1.2 blends calculation and database functions.

Using the electronic notebook doesn’t

require any special skill or understand­

ing. It just takes an afternoon or so to

type your recipes in, and an occasional

20 minutes to update notes.

Recipe analysis: At the next level of

complexity, the programs will calculate

the precise amount of each oxide in the

finished, fired glaze. Each material brings

its own collection of chemical elements

to the glaze. In order to fully under­

stand what the glaze is, we need to get

down to this basic chemical level.

It is also at this level that we can

work backward from a target formula

to a batch recipe. This reverse calcula­

tion is essential if we want to substitute

new materials or to reformulate a glaze

recipe to solve a problem.

Predictingfired results: At the top level

of complexity is the shakiest feature—a

prediction of how the glaze will look or

react after being fired. All of the pro­

grams reviewed offer a theoretical mea­

sure of how much a given recipe will

contract on cooling. This is a useful

measurement for predicting whether a

glaze will craze or shiver. One program

even goes so far as to predict whether a

glaze will crawl.

Several of the programs also attempt

to estimate the optimal firing tempera­

ture of the glaze by comparing the analy­

sis with standard ranges for glazes at any

given temperature.

This review divides the programs into

three major groups: those that run un­

der Windows, those that have separate

versions that run under Windows or

the Macintosh, and those that run only

on a Macintosh.

Each of these programs was written

by a potter with years and, in some

cases, several decades of personal expe­

rience in the studio. Naturally, their ap­

proaches and emphases differ. The

happiest option obviously would be to

try each one out yourself—and now,

through the magic of electronic com­

munication, you can! Most can be

downloaded from Internet websites, so

that you can try them out on your own

computer and decide before you buy

whether one is right for you.

GlazeChem 1.2 (Windows)

GlazeChem 1.2 is a bright new pro­

gram, and one that I recommend highly

and without reservation. It is simple,

intuitive, flexible and powerful—a per-

CERAMICS MONTHLY

feet blend of glaze calculation and glaze one to another. These links help solve graph shows how nearly the analysis of

recipe database. Drop-down pick lists the problem of having multiple names, the recipe matches common limit for­

make glaze descriptions and recording or generic and specific names for the mulas, so it is possible to guess the likely

firing range and surface quality. To­

notes a snap. Recipes are easily entered same material.

by selecting materials from lists or typ­

It is shareware, so you can download gether, the graphs present a quick “pic­

ing in part of the materials name. You a copy of GlazeChem to try (http:// ture” of the recipe. The question with

can easily find a single recipe buried in a www.tiac.net/users/rjw/), but if you all such projections is how accurate the

pile of hundreds of tests by searching would like to use it on a regular basis, coefficients are for the qualities they

for any of a variety of criteria. All the remember to support the work in the purport to describe. Fraser Forsythe, the

standard calculations are instantaneous. program and its continued development programs author, acknowledges this in

Percent analysis, unity formula, cost per by sending the purchase price to: Rob­ his help file, but it would have been

kilogram, cost per batch, expansion and ert J. Wilt, 92 Bay State Avenue, #2, really valuable if he had gone a step

Si/Al ratios are presented on easy-to-use Somerville, Massachusetts 02144; the further to describe the process he used

tabbed cards. Calculating back from a price is US$25 when downloaded, in selecting the actual numbers in the

target formula to a recipe is greatly sim­ US$30 when shipped in the United program. Surface tension, for example,

plified, as GlazeChem makes recom­

States, or US$33 shipped overseas. For appears to be a simple rank of the ce­

mendations for the materials to use and further information, e-mail rjw@tiac.net ramic oxides and not more narrowly

focused on the precise differences among

the precise amounts to add.

Glaze Simulator (Windows)

elements. Viscosity, which is a measure

Anyone who has studied the chem­

Glaze Simulator is a program that of melting power, is cleverly structured

istry of glazes knows how useful it is to

takes the ambitious tack of projecting to recognize that different oxides have

compare one particular recipe to an­

other similar recipe. The standard ranges the final appearance of the glaze based different melting powers at different

for any given firing temperature are on the recipe. Similar to Richard Zakins temperatures. Again, one may disagree

called limit formulas. Each of the ox­ Ceramic Utilities program reviewed in with the numbers Forsythe has selected.

ides has a defined high and low limit,

and the recipe under examination can

be compared to those values. With

GlazeChem, you can compare to stan­