High signal integrity speeds up µTCA systems

advertisement

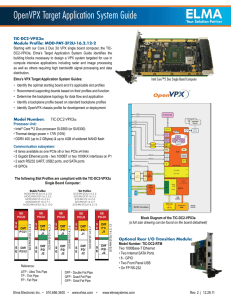

Issue June 2007 Backplane: Look into its eyes! High signal integrity speeds up µTCA systems The blu!box by Elma is a new MicroTCA shelf with optimised backplane for demanding practical tests. The implementation of real-time applications requires a powerful infrastructure for the data transfer which has to distinguish itself by large transmission bandwidths at least possible delays and minimum risks of loss. High data transfer rates are required mainly by modern telecommunication applications. This field extends increasingly towards sophisticated multimedia applications and demanding industrial fields of application, such as machine and process control. In particular the MicroTCA standard contributes decisively towards this development, thanks to its high degree of modularity. In this connection, signal integrity is of great importance. As we will see in the following, certain reflections on 3 GHz systems have to be made that take into consideration the signal behavior of up to 15 GHz! The following contribution is meant to specify the “natural enemies“ of signal integrity and to sensitise to the fact that with parsimony, you easily back the wrong horse in this particular field. Or, put into positive words: It’s worth the effort to look for the right partner. After all, the complete information chain that even includes peripherals is decisive for the quality and immunity to interferences and fault tolerance. Our considerations are based on serial data transmission. The standardisation committees at PICMG and VITA realised at an early stage that for high-speed applications, you have to dismiss classical bus structures and switch over to point-to-point connections with differential pairs. To avoid the formation of long sequences of logical zeros and ones on serially transmitted data packets – which complicate clocking and data regeneration – the 8B/10B encoding is successful in such applications. 8B/10B encoding When using 8-bit words, you will get 256 (28) possible bit combinations, 10-bit sequences however, result in 1024 possible bit combinations. For the formation of 8-bit words, the 8B/10B code only uses such bit combinations that provide multiple state changes. These are words which contain a maximum sequence of 5 zeros or 5 ones in a row. Thus it is possible to safely generate a clock signal that is required for synchronisation from a coded signal with an adequate number of state changes. Thanks to these advantages, the 8B/10B encoding is used in the Gigabit Ethernet, the 10-GigabitEthernet, with Fibre-Channel, StarFabric and generally with ATM (Asynchronous Transfer Mode) interfaces. Issue June 2007 MicroTCA, the latest development of the AdvancedTCA standards which promises particular success, offers the possibility to transmit data by Gigabit Ethernet, PCI-Express, Serial Rapid I/O, Serial Attached SCSI or Advanced Switching. At first, the question arises why to make highly crucial reflections on signal integrity. After all, it’s a XAUI transmission by means of an NRZ signal with a data rate of „only“ 3.125 Gbps (XAUI = X Attachment Unit Interface, an interface used in the 10-Gigabit-Ethernet; NRZ = “Non-Return-to-Zero” signal, a signal that does not return to zero at regular intervals). It is a fact, however, that the edge steepness of the signals determines the bandwitdth. Thus, at a basic frequency of 3.125 GHz, the signal integrity for a bandwidth of at least 15.625 GHz has to be guaranteed. This is due to the high-frequency, low-level harmonic waves, strictly speaking to the 5th harmonic wave according to Fourier. With MicroTCA, Advanced Mezzanine Cards (AMC) are defined as smallest modular assembly. For cost reduction reasons, this technology uses contacting via connectors on the backplane and gold pads directly on the AMC board. Due to their small mechanical shape, 170 contacts have to be realized via these connectors on a width of only 73.5 mm. To investigate the performance of different printed conductor geometries, Elma Trenew Electronic GmbH, as an experienced specialist in the field of backplane and basic systems, carried out fundamental metrological examinations. For this purpose, a MicroTCA test backplane with appropriate high-quality test boards was developped. It served to measure the physical properties by means of a TDR (Time Domain Reflector) and VNA (Vector Network Analyzer). These measurements assisted in deriving decisive findings on important influencing quantities that affect signal integrity. The ISI effect: Maximum influence on signal integrity The measurements showed that the Inter Symbol Interference (ISI) effect decisively influences signal integrity. The ISI effect describes how pulse-shaped signals are broadened compared to the output signal through dispersion, skin effect, dielectric losses and reflections. In addition, the inductive stub effects (with THT connectors) or bone effects of up to 1.2 nH (that occur when connecting SMT connectors to the inner layers of the backplane) contribute to the ISI effect. Since the pulses can be broadened through Inter Symbol Interference over several periods, this effect limits the transmission bandwith that can be used actually. Issue June 2007 Each conductor made of copper has different line capacities and inductivities – depending on the layout geometry, dielectrical insulation and frequency. Because of this, pulse-shaped signals are broadened. Such broadening increases with the physical length of the transmission line. This results in different propagation rates and thus in transit-time distortions for each individual contactor which can be seen in the eye diagram as jitter. For each differential pair, they have to be adjusted to each other to few picoseconds (which corresponds to less than 1 mm of physical path). Especially for broad-band signals, an optimisation has to be obtained by correctly selecting the basic material to be used and by adopting a clever layout strategy. This happens in several iterative steps since the individual parameters have an influence on each other. This requires the backplane design engineer to have well-founded experience so that he is able to find a carefully selected compromise for which all factors of influence are valued, and to minimize them altogether. Data transmission happens in the electric field! With increasing frequency, the importance of the DC conductor decreases, while the effects taking place in the electric field become more and more dominant. In the case in hand, the measurements also showed that the data transmission does not take place in the conductor, but mainly in the field. Thus, we do not have to observe the conductors and connector pins, but the field in which the data transmission takes place as a whole. In addition to this, it is necessary to reduce the influencing quantities of dispersion, skin effect, dielectrical losses, stub and bone effects by means of appropriate connector and layout geometries and thus to positively influence signal integrity, always while taking into consideration economic solutions using the least expensive basic material. But it’s not only one interference factor. Beside the factors described above, another important item has to be mentioned: cross-talking between differential pairs. Ideally, neighbored pairs are separated from each other and shielded by ground planes in which case only few “aggressors“ could influence the individual pair. In practical operation, the high number of layers of the board necessary for doing so, and thus the high costs involved and the manufacturing difficulties speak against it. Plus, the stub effect becomes more and more important with an increasing board thickness. Issue June 2007 The experiments also showed that in the backplane, the signal is considerably invalidated due to attenuation and losses. X-talk (crosstalk) on the other hand dominates in the connector. For this reason, the relevant parameter for x-talk measurements is the NEXT (Near Ended Crosstalk) parameter. Oddly enough, FEXT (Far Ended Crosstalk) benefits from the attenuation on the board and can be neglected provided that this influence now is known. What does this mean in practice? To sum up, the following can be said: Thanks to the detailed experiments carried out by ELMA regarding the signal behavior on the transmission path it was possible to optimise the layout strategy for MicroTCA backplanes. That way the number of layers in the board can be reduced and in spite of that, all requirements of the X-talk limits according to the MicroTCA specification can at least be satisfied or even surpassed. (Thus, ELMA succeeded for example in transmitting 6.25 Gigabits via one of their AdvancedTCA backplanes in cooperation with their partner Enigma, using an ingenious encoding. There still were sufficient safe capacities so that an even higher data transfer rate is realistic). The measured parameters not only serve to determine once the optimal layout strategy from an economic and technical point of view. They rather can contribute to simulation programs. Thus, it will be possible in future to investigate the complete package of connectors plus board in HSPICE simulations regarding its requirements on signal integrity (HSPICE® is an industrial standard for the high-precision simulation of systems by a complex analysis algorithm). This decisively reduces the development process and supports users in reducing the timeto-market. To avoid that this is all mere theory for potential users of the promising MicroTCA technology, ELMA has supported this market segment from the very beginning. With their blu!box by Elma, the specialists situated in the town of Pforzheim, Germany, provide an innovative, but most of all complete, ready-to-run MicroTCA shelf for form factor testing and intense board tests. The fully enclosed 19” subrack is 5 U high and 200 mm deep. The tested basic system is fully redundant thanks to 2 x MCH (MicroTCA Carrier Hub), two power modules for – 48 V / – 60 V and two cooling units. The speed of their high performance-fans is PWM controlled. Issue June 2007 For this purpose, and for the exact detection of the thermic situation in the test structure, up to 20 temperature sensors can be positioned in the shelf. The system can be enlarged with maximally 12 AMC, 8 “full height” and 4 “half height” in accordance with the form factor. All modules are Hot Swap components and IPMI-controlled. The inserted backplane benefits already from the results of the detailed series of measurements described above. It has a 20 layer structure and guarantees optimum signal integrity. Plus, it supports all FRU (Field Replaceable Unit) functions. High speed routing is effected via DualStar technology, the FCI connectors used are developed especially for high-speed data transfer. Two options are available for telecommunication and non-telecommunication applications. The reference signal: the eye diagram at the feeding point. Eye diagram of the signal at a 15 mm slot distance. Eye diagram of the signal deformed through the ISI efect after 396 mm. Due to the suboptimal layout strategy, there are 173 mask violations. Compared to the eye diagram at 396 mm and optimum layout strategy: no mask violations. For further information concerning our products, please contact our regional offices: Germany info@elma.de Phone: +49 7231 97 34 0 Fax: +49 7231 97 34 97 Stuttgarter Strasse 11, D-75179 Pforzheim Switzerland sales@elma.ch Phone: +41 44 933 41 11 Fax: +41 44 933 42 15 Hofstrasse 93, Postfach, CH-8620 Wetzikon France sales@elma-electronic.fr Phone: +33 4 37 06 21 10 Fax: +33 4 37 06 21 19 ZA du Buisson Rond, F-38460 Villemoirieu Romania info@elma.ro Phone: +40 21 3 10 79 98 Fax: +40 21 3 10 79 92 Str. Maltopol 16, RO-011048 Bucuresti United Kingdom info@elma-mektron.co.uk Phone: +44 1 234 272 677 Fax: +44 1 234 761 335 Elma-Mektron, Unit 8 Bedford Business Centre, Mile Road, Bedford MK42 9TW Other Countries Backplanes and System Platforms info@elma.de Phone: +49 7231 97 34 0 Fax: +49 7231 97 34 97 Stuttgarter Strasse 11, D-75179 Pforzheim Enclosures & Components, Switches, Knobs & LEDs sales@elma.ch Phone: +41 44 933 41 11 Fax: +41 44 933 42 15 Hofstrasse 93, Postfach, CH-8620 Wetzikon ELMA Electronic is a global manufacturer of products for housing electronic systems. The company provides everything from components such as modular enclosures, cabinets and backplanes, up to complete standard or custom system platforms. ELMA also manufactures precision rotary switches. The company offers a fast, flexible response to customer needs and extensive practical knowledge in tailoring solutions to specific applications.