Gas Measuring Sensor GMF 4.E.NO2.03

advertisement

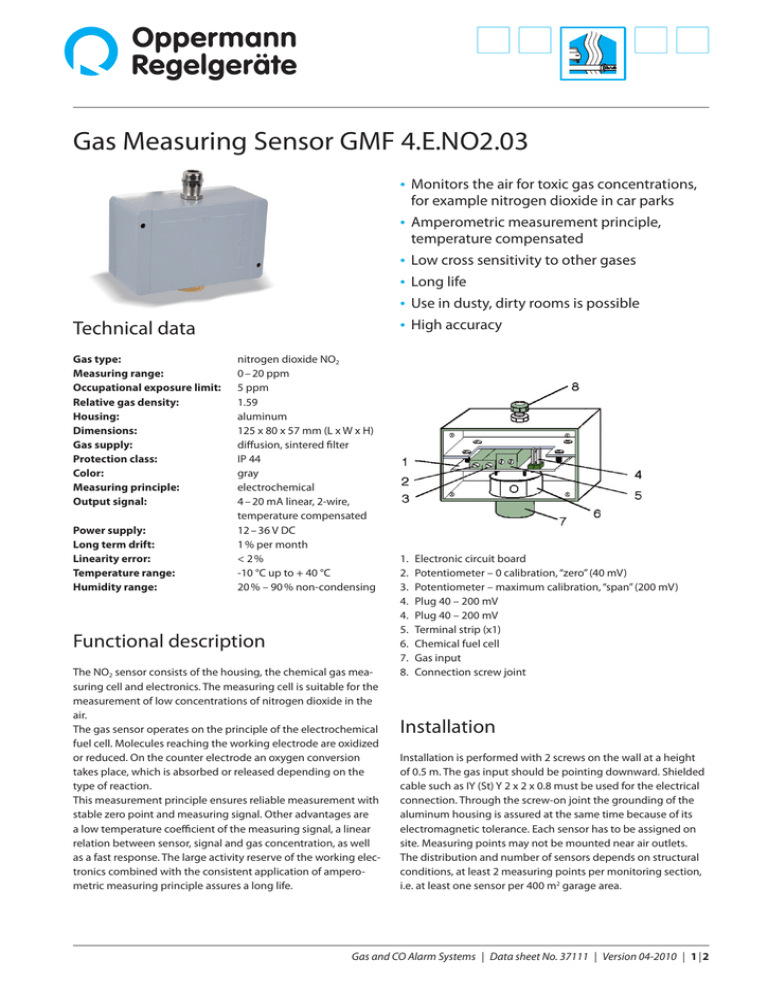

Gas Measuring Sensor GMF 4.E.NO2.03 • Monitors the air for toxic gas concentrations, for example nitrogen dioxide in car parks • Amperometric measurement principle, temperature compensated • Low cross sensitivity to other gases • Long life • Use in dusty, dirty rooms is possible • High accuracy Technical data Gas type: Measuring range: Occupational exposure limit: Relative gas density: Housing: Dimensions: Gas supply: Protection class: Color: Measuring principle: Output signal: Power supply: Long term drift: Linearity error: Temperature range: Humidity range: nitrogen dioxide NO2 0 – 20 ppm 5 ppm 1.59 aluminum 125 x 80 x 57 mm (L x W x H) diffusion, sintered filter IP 44 gray electrochemical 4 – 20 mA linear, 2-wire, temperature compensated 12 – 36 V DC 1 % per month < 2 % -10 °C up to + 40 °C 20 % – 90 % non-condensing Functional description The NO2 sensor consists of the housing, the chemical gas measuring cell and electronics. The measuring cell is suitable for the measurement of low concentrations of nitrogen dioxide in the air. The gas sensor operates on the principle of the electrochemical fuel cell. Molecules reaching the working electrode are oxidized or reduced. On the counter electrode an oxygen conversion takes place, which is absorbed or released depending on the type of reaction. This measurement principle ensures reliable measurement with stable zero point and measuring signal. Other advantages are a low temperature coefficient of the measuring signal, a linear relation between sensor, signal and gas concentration, as well as a fast response. The large activity reserve of the working electronics combined with the consistent application of ampero­ metric measuring principle assures a long life. 1. 2. 3. 4. 4. 5. 6. 7. 8. Electronic circuit board Potentiometer – 0 calibration, “zero” (40 mV) Potentiometer – maximum calibration, “span” (200 mV) Plug 40 – 200 mV Plug 40 – 200 mV Terminal strip (x1) Chemical fuel cell Gas input Connection screw joint Installation Installation is performed with 2 screws on the wall at a height of 0.5 m. The gas input should be pointing downward. Shielded cable such as IY (St) Y 2 x 2 x 0.8 must be used for the electrical connection. Through the screw-on joint the grounding of the aluminum housing is assured at the same time because of its electromagnetic tolerance. Each sensor has to be assigned on site. Measuring points may not be mounted near air outlets. The distribution and number of sensors depends on structural conditions, at least 2 measuring points per monitoring section, i.e. at least one sensor per 400 m2 garage area. Gas and CO Alarm Systems | Data sheet No. 37111 | Version 04-2010 | 1 | 2 Gas Measuring Sensor GMF 4.E.NO2.03 Calibration The sensors are delivered factory calibrated. In case of assembly times beyond 3 months calibration before start-up is imperative. A breaking-in time of 1 hour must be observed. Procedure: remove cover from the housing and plug voltmeter into measuring socket at point X2. Zero calibration: Use testing gas with synthetic air; adjust pressure valve and flow meter so that approximately 30 l/h flow into the gas inlet. After about 3 – 5 minutes a stable signal appears; then adjust potentiometer “zero” to 40 mV. Calibration for increased levels: Use testing gas with 20 ppm of NO2. Apply to sensor with the same fittings and the same flow rate. Set the potentiometer “span” to 200 mV. The calibration is now complete. If the value 200mV cannot be reached, the fuel cell is used up and must be replaced with a new one. Attention, under no circumstances should excess pressure be applied to the sensor; this would inevitably destroy the fuel cell. A recalibration of the system must be performed once a year. +24 B TGÜ 04-08 control unit M 1 2 3 Pressure bottle Pressure regulating valve Flow meter Gas inlet cap Measuring head Output in mA 4 8 12 16 20 Output in Voltage 40 80 120 160 200 Circuit board dimensions 4 Operating side view 50 Ω only with additional board Sensor 1. 2. 3. 4. 5. Concentration ppm 0 5 10 15 20 Electrical connection TGÜ 06-28 control unit Test setup for calibration of the NO2 sensor Sensor side view Sensor Cable connection exchangeable Oppermann Regelgeräte GmbH | Im Spitzhau 1 | 70771 Leinfelden-Echterdingen, Germany Phone +49 711 72 72 35 60 | Fax +49 711 72 80 52 7 | info@oppermann-regelgeraete.de | www.oppermann-regelgeraete.de 2 | 2 | Gas and CO Alarm Systems | Data sheet No. 37111 | Version 04-2010 Specifications subject to change.