HVAC Ducts Handbook

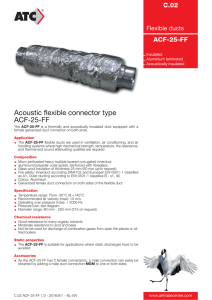

advertisement