AL3 and AL6 Airflow Measuring Stationary

advertisement

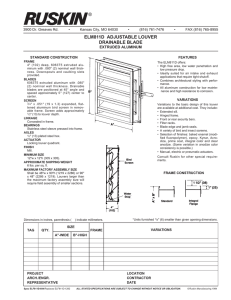

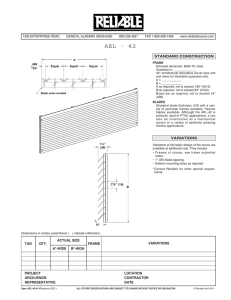

Code No. LIT-1900821 Issued July 15, 2013 AL3 and AL6 Airflow Measuring Stationary Louvers Description Since 1905, Johnson Controls has developed and refined air control products by providing the highest quality control dampers that fit your application and size requirements. Now we are including airflow measuring louvers in our product offering: • AL3 airflow measuring louvers feature stationary aluminum blades with aluminum sensor blades in a 3 in. (7.5 cm) deep aluminum frame. • AL6 airflow measuring louvers feature stationary aluminum blades with aluminum sensor blades in a 6 in. (15 cm) deep aluminum frame. Refer to the AL3 and AL6 Airflow Measuring Stationary Louvers Product Bulletin (LIT-12011834) for important product information. Features and Benefits • • • • • Three-year warranty on materials and workmanship provides confidence in product and reliability. Extruded 60635 T5 aluminum construction offers the optimal balance of strength, durability and cost-effectiveness; resists corrosion while requiring little maintenance. Pressure transducer provided (shipped loose) matches components for effective application. Excellent pressure drop performance allows maximum air penetration while keeping water out. Closely spaced vertical blades prevent the penetration of winddriven rain, reducing damage and additional operating expenses. AML3 Airflow Measuring Louver Transducer shall be capable of using field-selectable pressure ranges of 0 to 0.1, 0 to 0.25, 0 to 0 0.50, 0 to 1, and 0 to 2.5 in. W.C. with accuracy within ± 0.5 in. W.C. (±12.5 Pa) and shall handle up to 10 PSID overpressure without zero shift. Transducer output to be field-selectable: 4 to 20 mA 2-wire, 0 to 5 VDC, or 0 to 10 VDC. Transducer shall incorporate glass-on-silicone (Gi-Si) capacitance sensor and shall be housed in a NEMA 4 enclosure. Application The patented AL3 airflow measuring louver combines the functions of an outside air intake louver and an airflow measuring station in one assembly. Its 4 in. (102 mm) nominal depth requires less installation space than separate louvers and air measurement devices. The AL3 features a wind-driven-rain-resistant louver that allows high airflow with minimal water penetration and pressure drop. It is particularly well suited for applications in air handling units as well as air plenum wall installations. The AL6 airflow measuring louver combines the functions of an outside air intake louver and an airflow measuring station in one assembly. Its 7 in. (178 mm) nominal depth requires less installation space than separate louvers and air measurement devices. The AL6 features a wind-driven-rain-resistant louver that allows high airflow with minimal water penetration and pressure drop. It is particularly well suited for applications in air handling units as well as air plenum wall installations. The AL6 has been tested to Air Movement and Control Association International, Inc. (AMCA) Standard 611-95. Louver sizes too large for shipping shall be built up by the contractor from factory-assembled louver sections to provide overall sizes required. Louver design shall limit sizes of shipped single sections to 48 x 96 in. (1,219 x 2,438 mm) and shall withstand a wind load of 20 lb per sq. ft. (0.96 kPa) (equivalent of a 90 mph [145 kph] wind - specifier may substitute any loading required). Louver shall have extruded 6063T5 aluminum alloy construction. Construction Part AL3 AL6 Frame1 0.062 in. (1.6 mm) wall thickness 0.125 in. (3.2 mm) wall thickness Blade 0.040 in. (1 mm) wall thickness, installed vertically on approximately 0.75 in. (19 mm) centers 0.081 in. (2.1 mm) wall thickness, installed vertically on approximately 1.5 in. (38 mm) centers 1. Caulking surfaces provided Sample Specifications (AL3 Louver) Furnish and install louvers as hereinafter specified where shown on plans or as described in schedules. Louvers shall possess stationary vertical blades designed to prevent the penetration of wind-driven rain. Louver blades shall be contained within a 3 in. (76 mm) or 6 in. (152 mm) frame. Louver components (heads, jambs, sill and blades) shall be factory assembled by the louver manufacturer. Louvers shall be provided with a pressure transducer conforming to Electromagnetic Compatibility (EMC) standards EN50082-1/EN5014/ EN60730-1. The performance specifications are nominal and conform to acceptable industry standards. For applications at conditions beyond these specifications, consult the local Johnson Controls office. www.johnsoncontrols.com Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2013 Johnson Controls, Inc. 1 AL3 and AL6 Airflow Measuring Stationary Louvers (Continued) Technical Specifications Specification AL3 AL6 Frame 3 in. (76 mm) deep, 6063T5 extruded aluminum with 0.062 in. (1.6 mm) nominal wall thickness 6 in. (152 mm) deep, 6063T5 extruded aluminum with 0.125 in. (3.2 mm) nominal wall thickness Airflow Measurement Pickups adds 1 in. (25.4 mm) depth to the louver’s frame Blades1 6063T5 extruded aluminum with 0.040 in. (1 mm) nominal wall thickness. 6063T5 extruded aluminum with 0.081 in. (2.1 mm) nominal wall thickness. Sensor Blade 6063T5 extruded aluminum, clear anodized finish Sensor Port Fittings brass Pressure Transducer DMPR-RA001, 4 to 20 mA 2-wire, 0 to 5 VDC, or 0 to 10 VDC output (field selectable). Output signal is proportional to CFM. Extended Sill 0.081 in. (2.1 mm) formed aluminum with end dams Finish Mill Minimum Size 12 in. w x 12 in. h (305 mm x 305 mm). Maximum Size 48 in. w x 72 in. h (1,219 mm x 1,829 mm). Maximum ship section size is 48 in. w x 96 in. h (1,219 mm X 2,438 mm). Lifting lugs provided on louvers 48 in. x 72 in. and larger. Louvers larger than the maximum factory assembly size require field assembly of smaller sections. 48 in. w x 72 in. h (1,219 mm X 1,829 mm). Maximum ship section size is 72 in. w x 72 in. h (1,829 mm X 1,829 mm). Lifting lugs provided on louvers 48 in. x 72 in. and larger. Louvers larger than the maximum factory assembly size require field assembly of smaller sections. Free Area Velocity Requirements Minimum 275 FPM (1.4 m/s) Maximum 2,024 FPM (10.28 m/s) Minimum 345 FPM (1.8 m/s) Maximum 2,175 FPM (11.05 m/s) Approximate Shipping Weight 5 lb/sq. ft. (24 kg/m2) 12 lb/sq. ft. (58.6 kg/m2). Operating Temperature -22 to 150ºF (-30 to 60ºC) -22 to 150ºF (-30 to 60ºC) 1. Blades are mounted vertically and spaced approximately 1-1/2 in. (38 mm) center to center. Selection Airflow Measuring Louver Ordering Information Product Description AFEDN AL3 Louver AFEFN AL6 Louver Repair Information If an AL3 or AL6 airflow measuring louver fails to operate within its specifications, replace the unit. For a replacement AL3 or AL6 airflow measuring louver, contact the nearest Johnson Controls® representative. All Johnson Controls® AL3 or AL6 airflow measuring louvers are built to order and cannot be returned due to ordering errors. All AL3 or AL6 airflow measuring louvers are backed by a 3-year warranty, which covers defects in materials or workmanship. Refer to terms and conditions of sale for specifics. The performance specifications are nominal and conform to acceptable industry standards. For applications at conditions beyond these specifications, consult the local Johnson Controls office. www.johnsoncontrols.com Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2013 Johnson Controls, Inc. 2