UTI evaluation kit with RS232 or USB output

advertisement

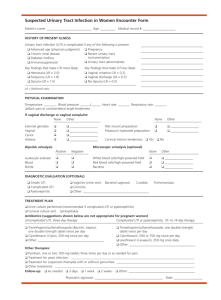

last update February 7, 2011 MANUAL UTI Evaluation board reference uti toolkitn.doc page 1/8 Universal Transducer Interface (UTI) Evaluation Board 1. Introduction page 2 2. Operating the UTI evaluation board page 4 3. Connections and connectors page 4 4. Running the UTI interfacing software page 6 5. OnOn-board reprogramming page 7 6. Multiple Multiplele -capacitance measurement page 8 last update February 7, 2011 UTI Evaluation board reference uti toolkitn.doc page 2/8 1. Introduction This Application Note describes an evaluation board for the UTI. The UTI is a complete front-end interface for many types of passive sensors, such as resistive, resistive-bridge and capacitive sensors. The UTI converts low-level sensor signals to a period-modulated microcontroller-compatible signal. By the application of continuous auto-calibration a high accuracy, of up to 13 bits, is obtained. Full data of the UTI is available in the UTI specification sheet and should be consulted in conjunction with this Application Note when using the Evaluation Board. The evaluation board is equipped with a microcontroller (Microchip PIC16C73A). An RS232 interfacing chip offers serial communication between the microcontroller and, for instance, a personal computer. A 20 MHz crystal completes the on-chip oscillator of the microcontroller. Two voltage regulators (78L05) provide the 5 V, DC supply voltages for the UTI, and the microcontroller and the RS232 interfacing, respectively. The evaluation-board block diagram is shown in Figure 1, while a full circuit diagram and a photograph of the evaluation board are shown in Figure 2 and Figure 3, respectively. J4 ICD J3 VDD Voltage regulator +5V A A′ F UTI E B C D J2 P8 Voltage regulator A µC RS232 CLR SCK DATA P7 J1 Figure 1 Functional block diagram. 9-way D-type connector J5 last update February 7, 2011 UTI Evaluation board reference uti toolkitn.doc page 3/8 PIC16C73 U2 C7 10 4.7p OSC2/CLKOUT 9 OSC1/CLKIN RA1/AN1 U3 4 5 SEL1 9 3 2 D 1 E 15 F 14 A SEL2 B C SEL3 SEL4 6 7 RC0/T1OSO/T1CKI 13 RC2/CCP1 RC3/SCK/SCL SYNC 14 15 16 TxD RxD 17 RB5 RB4 RA5 RB1 11 12 RC1/T10SI/CCP2 18 RB0/INT RB1 RB2 RC4/SDI/SDA RC5/SDO RB3 RB4 RC6/TX/CK RC7/RX/DT RB5 RB6 D E TEST F OUT PD 13 12 SF RA3 11 OUT RB2 10 RB0 1 C1+ V+ 21 RB0 22 RB1 RB2 24 25 RB3 26 RB5 RB6 1.0 3 C1- V- 4 C2+ 5 C2- 11 T1IN T1OUT 14 6 10 T2IN T2OUT 7 2 7 12 R1OUT R2OUT 13 3 8 8 C20 P7 TxD RxD 9 RB7 RB7 RB6 6 VCC 5 4 ICD 3 2 BNC Sync Pulse VCC GND CON6 OUT Output VCC J2 VDD D C B E F A1 U5 5 7 6 8 9 10 GND GND GND 11 13 15 12 14 16 1 C11 100.0 C10 D2 C13 P8 Vin 8 IN 0.1 G N D C1 0.1 100.0 POWER 2 VCC GND GND VDD CON16A J1 VDD 78L05 VDD SCK GND U4 D 1 3 2 4 GND C B 5 6 F A1 11 13 8 10 12 C B E 7 9 A1 15 D 1 C9 C8 78L05 VDD C16 IN R1 R C12 8 D1 LED G N D E 14 F A1 16 A 4 9 5 DB9 SYNC RB3 MCLR 1 DATA R1IN R2IN J4 R2 J3 2 4 1.0 1 MAX232 10K 1 3 6 RB4 27 28 UTI CLR VCC C18 1.0 MCLR/VPP MCLR A SCK CLR DATA 23 RB7 1.0 2 1 C19 RA3 2 RA0/AN0 OUT OUT B C 5 4 3 RA2/AN2 C4 RA5 RA4 6 RA3/AN3/VR 4.7p A U1 7 RA5/AN4/SS RA4/TOCI Q1 20M C17 2 10.0 0.1 0.1 0.1 CON16A Figure 2 Circuit diagram of the UTI evaluation board. 6-point solder pads (J4) 16-point solder pads (J1) D-type connector (P7) 16-point solder pad array (J2) 1 5-point solder pads (J3) Power supply connector (P8) 1 3-pin header (J5) Figure 3 A photograph of the UTI evaluation board. last update February 7, 2011 UTI Evaluation board reference uti toolkitn.doc page 4/8 2. Operating the UTI evaluation board Functions The evaluation board can be used for all functions of the UTI. The setting of the operating mode is performed by the microcontroller. Moreover, the microcontroller also measures the output signal from UTI and communicates with the outside digital world. Power supply Two on-board voltage regulators (78L05) provide the internal supply voltages of 5 V. The board requires an external DC supply voltage in the range of 7 V to 15 V. 3. Connections to the board Evaluation board interfacing Connection to the UTI evaluation board is implemented with six connectors/connecting pads: J2 16-point solder pad array for connection of the sensing, reference and biasing elements J3 5-point solder pads for connection of capacitive sensing elements J4 6-point solder pads for connection to the ICD reprogramming module J5 3-pin header to monitor UTI with an oscilloscope P7 9-way D-type connector for communication with a PC (standard serial cable) P8 Socket for connection of power supply Figures 4, 5, 6, 7 & 8 show the pin/pad connections. The soldering-pad arrays, J2 and J3, are used for mounting flat cable wires, sockets, or external components. This enables the connection of to connect external sensing, reference and biasing elements. In the CMUX mode of the UTI, the on-board microcontroller provides the control signals (CLR, DATA and SCK) for an optional, external multiplexer, via the soldering pad J2. For detailed information about the CMUX mode, please consult the UTI specification sheet. In the capacitive modes of the UTI the measurement system is very sensitive to signals that are capacitively coupled with the input A, including capacitive-coupled interference signals. To provide selective detection of the desired signals only, for the connection to input A, a shielded or coaxial cable wire must be used. For this purpose pad J3 provides a connection for a coaxial plug. In other UTI modes, it is allowed to connect input node A using unshielded wire. In these modes, a wired connection is made between the soldering pads A′ and A′′ (Figure 1). For the connections of various sensors, it is advised to consult the UTI specification sheet. The order of the J2 soldering pad array is shown in Figure 4. The output signal of the UTI can be monitored, using an oscilloscope, connected via header J5 (Figure 6). Besides the output signal this header also provides a trigger signal for the oscilloscope. The soldering pads are also used to mount the required external reference and biasing components. These components are chosen in accordance with the UTI mode. For instance, in the Pt100 mode of the UTI, the user has to connect a current-limiting resistor RBIAS and a reference resistor Rref, using last update February 7, 2011 UTI Evaluation board reference uti toolkitn.doc page 5/8 soldering pad J2. For the other modes, please consult the UTI specification sheet. WhenJ3 is not used, pads A to A’ of pad array J2 have to be connected by wire. 1 16 2 15 3 14 4 13 5 12 6 11 7 10 8 9 1 to 6 7 8 9 10 11 12 13 14 15 16 GND SCK DATA CLR VDD D C B E F A’ Evaluation-board ground For MUX use For MUX use For MUX use Power supply Sensors connection of UTI Sensors connection of UTI Sensors connection of UTI Sensors connection of UTI Sensors connection of UTI Sensors connection of UTI Figure 4 J2 pad configuration. 1 1 2 3 4 5 6 2 3 4 5 Evaluation-board ground +5 V Power supply output MCLR RB3 RB6 RB7 6 J4 Figure 5 J4 pin configuration. 1 2 3 1 2 Evaluation-board ground Trigger signal Output signal of UTI 3 J5 Figure 6 J5 pin configuration. 5 9 4 8 3 7 2 6 1 2 3 4 5 6 7 8 9 1 Figure 7 P7 pin configuration. NC T1OUT R1IN NC GND NC NC NC NC Not connected Serial data input Serial data output Not connected Evaluation-board ground Not connected Not connected Not connected Not connected last update February 7, 2011 UTI Evaluation board reference uti toolkitn.doc page 6/8 1 2 1 Power supply 2 Evaluation-board ground P8 Figure 8 P8 pin configuration. 4. Running the UTI interfacing software There are many ways to display evaluated results, such as the terminal program under Windows and the LabView program. The following shows two of them. 4.1 Executable LabView Included in the UTI development kit is a PC-compatible disk, which contains the software for controlling and evaluating the performance of the UTI using the serial port of a PC. There are three files, named: EVAL-UTI.arj, ARJ.exe and SERPDRV, respectively, on the contribution disk. The file SERPDRV is a serial-port-driver file. The file EVAL-UTI.arj is a freshened file of EVAL-UTI.exe, and ARJ.exe is a file manager. To use the software, the user must have an IBM-compatible PC, with Windows 95 or later installed. These three files on the contribution disk have to be copied to a subdirectory, for instance, EVALUTI, in the hard disk of your PC. After that, the EVAL-UTI.arj should be extracted by running ARJ.exe under DOS or Windows. This can be performed by running arj e evaleval -uti.arj. Then, the file EVALUTI.exe is extracted. When working under Windows and using the FILE MANAGER you can simply double click on EVALUTI.EXE to start the evaluation program. When the program starts up a front panel window appears. There exist five control items: MODE, Serial port No., Reference, SPEED and Average Index . Further, there are a few indication items: RealReal- time value and Graphic chart of the measured results, Std Deviation, Average value and Meas. time. The UTI evaluation software allows the user to program and gather samples from the UTI evaluation board via the serial port of the PC. The port number they wish to use is selected by using the item, Serial port No .. The item MODE is used to select the mode of the UTI and SPEED to set the UTI in a slow or a fast mode. The item Reference is used to set the reference signal value corresponding to the value of a reference capacitance or a reference resistance. For example, when the evaluation board is used to measure the signal from a Pt100 and a reference resistor of 100.00 Ω is used, the item Reference should be set to 100.00. The item Average Index is used to set the number of measurements to be averaged. A large number of measurements results in lower noise, but also increases the measurement time. last update February 7, 2011 UTI Evaluation board reference uti toolkitn.doc page 7/8 The output information RealReal- time value digitally displays the measurement result. For instance, for the measurement of a Pt100, the measured resistor value of the Pt100 is displayed, and for the measurement of the potentiometer, the relative value is displayed. Meanwhile, a graphic chart displays the real-time value by a red line. The item Average Value indicates the average value of a variable number of measurements indicated by the Average Index. The item Std Deviation indicates the standard deviation of the evaluation board for a variable (by Average Index) number of the measurements. Table 1 lists the displayed measurement results for each UTI mode. The item Meas. time indicates the measurement time for one complete measurement. F or instance, to measure a capacitance by using mode C23 of UTI, the Meas. time is the total time to measure the three periods, Toff, Tx and Tref (see UTI specification sheet). To Start Measurement Double clicking the button ⇒ at the top-left corner of the front-panel window will start the measurement. After a few seconds the results are displayed at the monitor. 4.2 Terminal under Windows The program Terminal (or Hyper terminal) terminal under Windows can easily display the measurement results via the serial port of the PC. The configuration of Terminal (or Hyper terminal) terminal is: 8 data bit, 1 stop bit and No parity error check. The microcontroller will automatically select the baudrate by sending a @ sign to the evaluation board. So, in order to have a communication between the microcontroller and the PC, first the sign @ is send to the microcontroller. Once the communication between the microcontroller and the PC is actuated, by typing “H”, “h” or “?”, you can get on-line help. With this on-line help, it is easy to manage the evaluation board and to display the result. The displayed data under the Terminal (or Hyper terminal) terminal is Hexadecimal. The data, which corresponds to the time interval of each phase of the UTI output signal. Using the counting function of the microcontroller, with a counting frequency of 5 MHz, the time intervals are measured accurately. 5. OnOn- board reprogramming the microcontroller with the ICD Together with the evaluation board also the microcontroller software is supplied. This software enables the evaluation of the sixteen basic modes of the UTI. Yet, for specific applications, it is possible that it is needed to modify the software. This is the case, for instance, when the UTI is used in combination with an external multiplexer, to perform multiple-capacitance measurements (see section 6). For easy on-board reprogramming of the microcontroller, the evaluation board provides a 6-pad soldering array (J4 see Figure 5) to mount a six-pole connector for the ICD module (In Circuit Debugger). This module is available from Microchip and can be ordered with Smartec. In order to use the ICD, the microcontroller should have the ICD capability. For this option, for instance, the PIC16F873 or PIC16F876 can be used. last update February 7, 2011 UTI Evaluation board reference uti toolkitn.doc page 8/8 6. MultipleMultiple- capacitance capacitance measurement A large number of capacitances can be measured using the CMUX mode of the UTI together with an external multiplexer, such as Smartec’s MUX03. The number of measured capacitances is not limited. For detailed information on the MUX03, please consult the MUX03 specification sheet. With a single external MUX03 the evaluation board provides the possibility to measure up to nine capacitances. The evaluation board generates the three control signals (CLR, DATA and SCK) for the external multiplexer. When the program Terminal (or Hyper terminal) terminal under Windows is used to display the measurement results, after sending the character ‘3’ for selection of the CMUX mode, a character between ‘1’ and ‘9’ (HEX 31 to 39) should be sent to specify the number of capacitances to be measured. When this character is ignored, the system will use the default value (‘9’), which means that nine capacitors are measured. Attention: Do not forget to switch on the power supply of the evaluation board before starting the measurement. Mode Result 1 Result 2 Result 3 0 (CDA-CBA)/(CCA-CBA)Cref (CEA-CBA)/(CCA-CBA)Cref (CFA-CBA)/(CCA-CBA)Cref 1 (CDA-CBA)/(CCA-CBA)Cref × × 2 (CDA-CBA)/(CCA-CBA)Cref (CEA-CBA)/(CCA-CBA)Cref (CFA-CBA)/(CCA-CBA)Cref 3 See section 6 4 (CDA-CBA)/(CCA-CBA)Cref × × 5 RCD/RABRref RBC/RABRref × 6 RCD/RABRref RBC/RABRref × 7 RCD/RABRref RBC/RABRref RDF/RABRref 8 RCD/RABRref RBC/RABRref RDF/RABRref 9 VCD/VAB × × 10 VCD/VAB × × 11 VCD/VAB × × 12 VCD/VAB × × 13 VCD/VEA RAB/RBFRref × 14 VCD/VEA RAB/RBFRref × 15 VBF/VEF VCF/VEF VDF/VEF Note: ×: No measurement. Table 1. The displayed measurement results for various modes._