MODELS

JX6H-NL50

JX6H-NL60

JX6H-NL70

JX6H-NL30

JX6H-NL40

FIRE PUMP DRIVERS

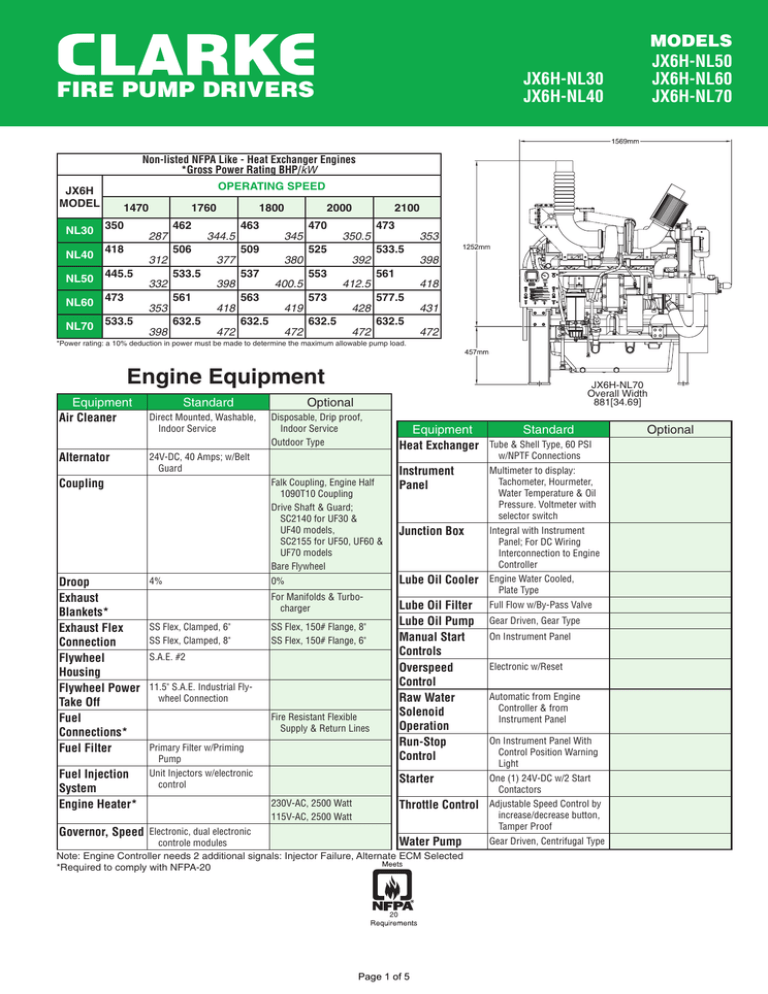

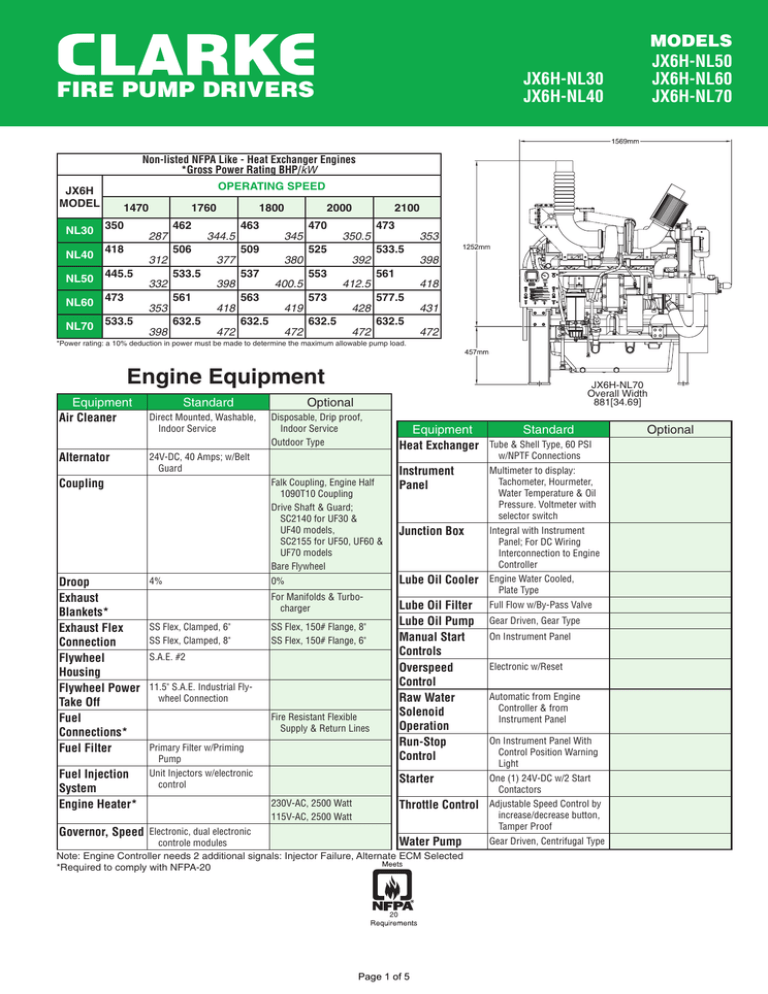

Non-listed NFPA Like - Heat Exchanger Engines

*Gross Power Rating BHP/kW

OPERATING SPEED

JX6H

MODEL

1470

NL30

350

NL40

418

NL50

445.5

NL60

473

NL70

533.5

1760

287

312

332

353

398

462

506

533.5

561

632.5

344.5

377

398

418

472

1800

463

509

537

563

632.5

345

380

400.5

419

472

2000

470

525

553

573

632.5

2100

350.5

392

412.5

428

472

473

353

533.5

561

398

418

577.5

632.5

431

472

*Power rating: a 10% deduction in power must be made to determine the maximum allowable pump load.

Engine Equipment

Equipment

Air Cleaner

Alternator

Standard

Direct Mounted, Washable,

Indoor Service

JX6H-NL70

Overall Width

881[34.69]

Optional

Disposable, Drip proof,

Indoor Service

Outdoor Type

24V-DC, 40 Amps; w/Belt

Guard

Coupling

Falk Coupling, Engine Half

1090T10 Coupling

Drive Shaft & Guard;

SC2140 for UF30 &

UF40 models,

SC2155 for UF50, UF60 &

UF70 models

Bare Flywheel

Equipment

Heat Exchanger

Standard

Tube & Shell Type, 60 PSI w/NPTF Connections

Instrument

Panel

Multimeter to display:

Tachometer, Hourmeter,

Water Temperature & Oil

Pressure. Voltmeter with

selector switch

Junction Box

Integral with Instrument

Panel; For DC Wiring

Interconnection to Engine

Controller

Lube Oil Cooler

Engine Water Cooled,

Plate Type

Full Flow w/By-Pass Valve

Droop

Exhaust

Blankets*

Exhaust Flex

Connection

Flywheel

Housing

Flywheel Power

Take Off

Fuel

Connections*

Fuel Filter

4%

Primary Filter w/Priming

Pump

Lube Oil Filter

Lube Oil Pump

Manual Start

Controls

Overspeed

Control

Raw Water

Solenoid

Operation

Run-Stop

Control

Fuel Injection

System

Engine Heater*

Unit Injectors w/electronic

control

Starter

One (1) 24V-DC w/2 Start

Contactors

Throttle Control

Adjustable Speed Control by

increase/decrease button,

Tamper Proof

0%

For Manifolds & Turbocharger

SS Flex, Clamped, 6"

SS Flex, Clamped, 8"

SS Flex, 150# Flange, 8"

SS Flex, 150# Flange, 6"

S.A.E. #2

11.5" S.A.E. Industrial Flywheel Connection

Fire Resistant Flexible

Supply & Return Lines

230V-AC, 2500 Watt

115V-AC, 2500 Watt

Governor, Speed

Electronic, dual electronic

Water Pump

controle modules

Note: Engine Controller needs 2 additional signals: Injector Failure, Alternate ECM Selected

*Required to comply with NFPA-20

Page 1 of 5

Gear Driven, Gear Type

On Instrument Panel

Electronic w/Reset

Automatic from Engine

Controller & from

Instrument Panel

On Instrument Panel With

Control Position Warning

Light

Gear Driven, Centrifugal Type

Optional

JX6H-NL30

JX6H-NL40

FIRE PUMP DRIVERS

MODELS

JX6H-NL50

JX6H-NL60

JX6H-NL70

Specifications

JX6H Models

Item

NL30

NL40

NL50

Number of Cylinders

NL60

NL70

6

Aspiration

TJWA

Rotation*

TRWA

CounterClockwise (CCW)

Weight - kg (lb)

1429 (3150)

1474 (3250)

Compression Ratio

16:1

Displacement - l (cu. in.)

12.5 (766)

Engine Type

4 Cycle - Inline

Bore & Stroke - mm (in.)

127 (5.00) x 165 (6.5)

Installation Drawing

D - 546

Wiring Diagram

C07957

Engine Series

John Deere 6125 Series

Abbreviations: CCW – CounterClockwise TJWA – Turbocharged with Jacket Water Aftercooling

TRWA – Turbocharged with Raw Water Aftercooling *Rotation viewed from Flywheel CW Rotation is not available.

Engine intended for Indoor use or inside weatherproof enclosure only

†

ENGINE RATINGS BASELINES

Engines are rated at standard SAE conditions of 29.61 in. (7521 mm) Hg barometer and 77˚F (25˚C) inlet air temperature [approximates 300 ft. (91.4

m) above sea level] by the testing laboratory (see SAE Standard J 1349).

A deduction of 3 percent from engine horsepower rating at standard SAE conditions shall be made for diesel engines for each 1000 ft. (305 m) altitude

above 300 ft. (91.4 m).

A deduction of 1 percent from engine horsepower rating as corrected to standard SAE conditions shall be made for diesel engines for every 10˚F

(5.6˚C) above 77˚F (25˚C) ambient temperature.

GUARANTEED POWER AT ANY SPEED

Although Guaranteed BHP ratings are shown at specific speeds, Clarke engines can be applied at any

intermediate speed, but must be factory set for final desired speed. To determine the intermediate certified power, make a linear interpolation from the Clarke Guaranteed power curve. Contact Clarke or your

Pump OEM representative to obtain details.

Fire Protection Products

www.clarkefire.com

CLARKE Fire Protection Products, Inc.

CLARKE UK, Ltd.

3133 E. Kemper Rd.

Cincinnati, Ohio 45241

United States of America

Tel +1-513-771-2200 Fax +1-513-771-0726

C132546 2/08

Grange Works, Lomond Rd.

Coatbridge, ML5-2NN

United Kingdom

Tel +44-1236-429946 Fax +44-1236-427274

Specifications and information contained in this brochure subject to change without notice.

Page 2 of 5

Printed in U.S.A.

FIRE PUMP MODEL: JX6H-NL30

Heat Exchanger Cooled

Turbocharged

6.8L 6 Cylinder

380

360

353

344.5

340

320

300

287

280

260

1000

1250

1500

RESTRICTED:

1750

2000

ENGINE SPEED - RPM

2250

2500

USE ONLY FOR STAND-BY FIRE PUMP APPLICATIONS

GROSS kW

ENGINE PERFORMANCE:

STANDARD CONDITIONS: (SAE J1349, ISO 3046)

77°F (25°C) AIR INLET TEMPERATURE

29.61 IN. (751.1MM) HG BAROMETRIC PRESSURE

#2 DIESEL FUEL (SEE C13940)

KEN WAULIGMAN 25JAN08

Reduce published Gross kW’s by 10% to determine

maximum pump load.

THIS DRAWING AND THE INFORMATION HEREIN ARE OUR

PROPERTY AND MAY BE USED BY

OTHER ONLY AS AUTHORIZED BY

US. UNPUBLISHED -- ALL RIGHTS

RESERVED UNDER THE

COPYRIGHT LAWS.

Page 3 of 5

CREATED

DATE CREATED

01/25/08

ENGINE MODEL JX6H-NL30

DRAWING NO.

C131209

REV

B

CLARKE

Fire Protection Products

JX6H-NL30

INSTALLATION & OPERATION DATA

UK Production

Basic Engine Description

Engine Manufacturer………………………………………………………………. John Deere Co.

Ignition Type……….……..……….……..……….……..……….……..……….……Compression (Diesel)

Number of Cylinders………….……….……..……….……..……….……..……… 6

Bore and Stroke - mm (in)…………..……….……..……….……..……….…….. 127 (5.00) x 165 (6.50)

Displacement - L (in.3 )………...…………….……..……….……..……….……..…12.5 (763)

Compression Ratio…………….……….……..……….……..……….……..………16:1

Valves per cylinder - Intake……..……….……..……….……..……….……..……

2

Exhaust…..……….……..……….……..……….……..……2

Combustion System………….……….……..……….……..……….……..……… Unit Injection

Engine Type……………..……….……..……….……..……….……..……….…… In-Line, 4 Stroke Cycle

Aspiration…………….……….……..……….……..……….……..……….……..…Turbocharged

Firing Order (CW Rotation)………..……….……..……….……..……….……..…1-5-3-6-2-4

Charge Air Cooling Type………….……….……..……….……..……….……..… Raw Water Cooled

Rotation (Viewed from Front) - Clockwise……….……..……….……..……….…Standard

Not Available

Counter-Clockwise….……….……..……….……

Engine Crankcase Vent System..………………….……..……….……..……….…

Open

Installation Drawing…………………….……..……….……..……….……..………UD-146

Cooling System

1470

Engine H2O Heat - kW (Btu/sec)…………..……….……..……….……..……….. 100 (95)

Engine Radiated Heat (With Blanket) - kW (Btu/sec)…………………….…...… 39 (37)

Engine Radiated Heat (Without Blanket) - kW (Btu/sec)…………………….…. 84 (80)

Heat Exchanger Minimium Flow

15°C (60°F) Raw H2O - L/min. (gal/min.)………….……….……..………. 38 (10)

35°C (95°F) Raw H2O - L/min. (gal/min.)………….……….……..………. 57 (15)

1760

106 (101)

47 (45)

100 (95)

2100

114 (108)

48 (46)

103 (98)

45 (12)

61 (16)

57 (15)

63 (17)

Heat Exchanger Maximum Cooling H2O

Inlet Pressure - bar (kPa) (lb./in.2).……..……….……..……….……..…… 4 (60) (400)

Flow - L/min. (gal./min).………….……….……..……….……..……….……302 (80)

Thermostat, Start to Open - °C (°F)…………………….……..……….……..……82 (180)

Fully Opened - °C (°F)………………..……….……..……….……. 94 (202)

Engine Coolant Capacity - L (qt.)………..……….……..……….……..……….…29.6 (28)

2

Coolant Pressure Cap - kPa (lb./in. )…………………..……….……..……….…. 69 (10)

Maximum Engine H20 Temperature - °C (°F)………..……….……..……….……100 (212)

71 (160)

Minimum Engine H20 Temperature - °C (°F)………………..……….……..………

Electric System - DC

System Voltage (Nominal)…………………..……..……….……..……….……..…24

Battery Capacity for Ambients Above 0°C (32°F)

Voltage (Nominal)………..……..……….……..……….……..……….……. 12

Qty. per Battery Bank…………..……….……..……….……..……….……. 2

SAE size per J537………..……..……….……..……….……..……….…… 8D-900

CCA @ -18°C (0°C)………..……..……….……..……….……..……….……900

Reserve Capacity - Minutes…………..………..……..……….……..………430

Battery Cable Circuit*, Max Resistance - ohm…...….…..……..……….……..…0.0012

Battery Cable Minimum Size

0 -120 in. Circuit* Length………………..……….……..……….……..………. 00

121 - 160 in. Circuit* Length……….……..……….……..……….……..……….…000

161 - 200 in. Circuit* Length……….……..……….……..……….……..……….…0000

Charging Alternator Output - Amp…………….…………...……..……….……..…40

Starter Cranking Amps - @ 15°C (60°F)…...………………..……….……..…… 600

*Positive and Negative Cables Combined Length

NOTE: This engine is Intendend For Indoor Installation Or In A Weatherproof Enclosure.

Page 4 of 5

(Continued)

CLARKE

Fire Protection Products

JX6H-NL30

INSTALLATION & OPERATION DATA (Continued)

UK Production

Exhaust System

1470

Exhaust Flow - m 3/min. (ft. 3/min.)………….……….……..……….……..……….…45 (1599)

Exhaust Temperature - °C (°F)……………..……….……..……….……..……….…533 (992)

Maximum Allowable Back Pressure - kPa (in. H 20)…………………….……..…… 7.5 (30)

Minimum Exhaust Pipe Dia. - mm (in.)**…………..……….……..……….……..… 127 (5.0)

1760

58 (2064)

486 (907)

2100

65 (2280)

455 (851)

Fuel System

Fuel Consumption - L/hr. (gal./hr.)………………….……..……….……..……….…68.1 (18.0) 83.3 (22.0) 90.8 (24.0)

246.1 (65.0) 242.3 (64.0) 238.5 (63.0)

Fuel Return - L/hr. (gal./hr.)…………………….……..……….……..……….………

Total Supply Fuel Flow - L/hr (gal./hr.)……….……..……….……..……….………314.2 (83.0) 325.6 (86.0) 329.3 (87.0)

2

483-620 (70-90)

Fuel Pressure - kPa (lb./in. )………..…..…….….……...……….……..………..

Minimum Line Size - Supply - (in.)……..……….….………….………………….… .75 Schedule 40 Steel Pipe

Pipe Outer Diameter mm (in.)……..…………..……..…………..………..… .041 (1.05)

Minimum Line Size - Return - (in.)……….……….……..……….……..….……… .50 Schedule 40 Steel Pipe

Pipe Outer Diameter mm (in.)……..…………..……..…………..………..… .033 (.848)

Maximum Allowable Fuel Pump Suction

With Clean Filter - m H 20 (in. H 20)……….……..……….……..……….…… 2.5 (100)

Maximum Allowable Fuel Head above Fuel pump, Supply or Return - m (ft.)... 2.7 (9)

2

Fuel Filter Micron Size……………….……..……….……..……….……..……….…

Heater System

Jacket Water Heater……..……….……..……….……..……….……..……….…… Standard

2500

Wattage (Nominal)……..……..……….……..……….……..……….……..…

Voltage - AC, 1P……..……..……….……..……….……..……….……..……230 (+5%, -10%)

Optional Voltage - AC, 1P…………..……..……….……..……….……..……115 (+5%, -10%)

Lube Oil Heater Wattage

(Required Option When Ambient is Below 40°F (4°C)……………………… 150

Induction Air System

Air Cleaner Type…………………….……….……….……..……….……..……… Indoors Service Only - Washable

Air Intake Restriction Maximum Limit

Dirty Air Cleaner - kPa (in. H 20)…..……….……..……….……..……….……4.0 (16)

Clean Air Cleaner - kPa (in. H 20)………….……..……….……..……….……2.0 (8)

Engine Air Flow - m 3/min. (ft. 3/min.)……………..……….……..……….……..……16.8 (592)

Maximum Allowable Temperature (Air To Engine Inlet) - °C (°F)***……….…… 54 (130)

Lubrication System

Oil Pressure - normal - kPa (lb./in. 2)…………………………….…...…..………

In Pan Oil Temperature - °C (°F)…………..………………...……..………….…

Total Oil Capacity with Filter - L (qt.)………………….…….……………………

23.0 (811)

26.5 (934)

310 (45)

115 (239)

40 (42)

Performance

2

2

BMEP - kg/cm (lb./in. )……...………………….……..……….……..……….…… 1972 (286) 1972 (286) 1738 (252)

Piston Speed - m/min. (ft./min.)………………….……..……….……..……….……485 (1593) 581 (1907) 693 (2275)

Mechanical Noise - dB(A) @ 1m…....…….……..……….……..……………….…

Consult Factory

Power Curve…………………….……..……….……..……….……..…..…….…….

C131970

** Based On Nominal System. Flow Analysis Must Be Done To Assure Adherance To System Limitations.

(Minimum Exhaust pipe Diameter is based on 15 feet of pipe, one elbow, and a silencer

pressure drop no greter than one half the max. allowable back pressure.)

*** Review For Power Deration If Air Entering Engine Exceeds °77F (25°C)

C132548 revF

RJT 14JAN10

Page 5 of 5