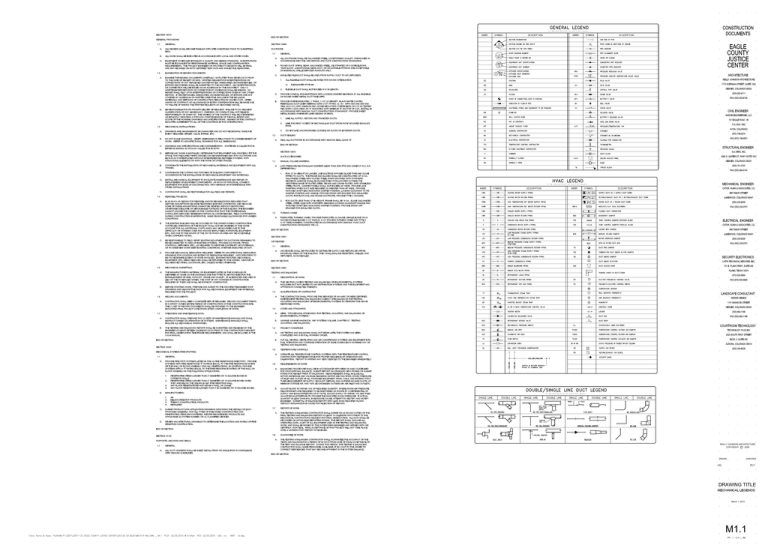

drawing title - Eagle County

advertisement

REILLY JOHNSON ARCHITECTURE COPYRIGHT C 2008 DRAWN CHECKED LKL DLY DRAWING TITLE March 1, 2010 M1.1 REILLY JOHNSON ARCHITECTURE COPYRIGHT C 2008 DRAWN CHECKED LKL DLY DRAWING TITLE March 1, 2010 M4.10 LUMINAIRE SCHEDULE TYPE DESCRIPTION LAMPS VOLT AMPS MANUFACTURER CATALOG NO. VOLTAGE FINISH MOUNTING RECESS (1) 42W TRT LITHONIA (GOTHAM) AF1/42TRT-6AR-LD-120 6" DIA RECESSED FLUORESCENT DOWNLIGHT, SEMI DIFFUSE ALZAK REFLECTOR, WHITE TRIM AND ELECTRONIC 3500K DF6 42 PORTFOLIO 120/277 STANDARD RECESS 7-3/4" BALLAST. 85 CRI HUBBELL GENERAL NOTES: 1. CATALOG NUMBER REFERS TO FIRST NAME LISTED UNDER MANUFACTURER 5. ALL DIMMING BALLASTS SHALL BE LUTRON. PER LUMINAIRE TYPE. REMAINING MANUFACTURERS LISTED ARE CONSIDERED EQUIVALENT PRODUCTS FOR THIS PROJECT AND SHALL MEET ALL CRITERIA 6. ALL FLUORESCENT BALLAST SHALL BE PROGRAMMED RAPID START. LISTED INCLUDING THAT CALLED FOR BY THE SPECIFIC LUMINAIRE CATALOG 7. WHERE EMI/RFI SHIELDING IS IDENTIFIED IN A LUMINAIRE DESCRIPTION OR MODEL NUMBER, PROVIDE NUMBER. CATALOG NUMBERS DO NOT NECESSARILY REPRESENT COMPLETE CATALOG NUMBERS. ALL ITEMS LISTED IN THE DESCRIPTION SHALL BE PROVIDED. LUMINAIRE ASSEMBLY LISTED AND LABELED AS COMPLYING WITH MIL STD. 461 C/D/E. 2. ALL LIGHTING REQUIRING A BALLAST SHALL BE PROVIDED WITH AN ELECTRONIC HIGH POWER FACTOR BALLAST WITH LESS THAN 10% THD. 8. PROVIDE FACTORY INSTALLED BALLAST DISCONNECT SWITCH FOR FLUORESCENT LUMINAIRES PER NEC 410. 3. ALL LENSES LISTED AS .125" MINIMUM SHALL BE 9.1 oz/sq ft. 9. PROVIDE MINIMUM 0.88 BALLAST FACTOR ( 0.71-0.78 FOR SUPER T-8 LAMPS). 4. PROVIDE QUANTITY OF BALLASTS FOR INDIVIDUAL LUMINAIRES AS REQUIRED TO ACCOMMODATE SWITCHING ARRANGEMENTS AS SHOWN ON THE DRAWINGS. * PROVIDE UNIT PRICING FOR ALL LUMINAIRES BY TYPE AND SUBMIT WITH BID FORM FOR ALL LUMINAIRES IN THIS SECTION. EXISTING 100 A 100 A TYPE : MTG. : NOTE M.L.O. BUS SQUARE D SURFACE RECEPT NEC CALCULATED PHASE AMPACITY PHASE BALANCE OTHER GENERAL TOTAL 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 VICTIM WIT. SW. SIDE ATTOR. WEST, SW SIDE LIGHTING RECEPTACLES MOTORS OTHER GENERAL TOTAL (VA) MOTORS PH A 0.0 0.0 0.0 0.0 0.0 0.0 PH B 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0 100.0 A-B 0% B-C 0% PH C LOAD TYPE 0.0 0.0 0.0 LIGHTING 0.0 RECEPTACLES 0.0 FIRST 10 KVA 0.0 REMAINDER MOTORS LARGEST 0.0 REMAINDER OTHER GENERAL C-A 0% TOTAL "B" Panel Notes: 1. NEW LOAD ON EXISTING CIRCUIT BREAKER. 2. PROVIDE NEW CIRCUIT BREAKER IN SPACE TO MATCH EXISTING. 3. REPLACE EXISTING CIRCUIT BREAKER WITH NEW CIRCUIT BREAKER AS SHOWN. 4. EXISTING LOAD ON NEW CIRCUIT BREAKER. EXISTING LOAD IS ESTIMATED. 5. EXISTING LOAD REMOVED. 6. NEW LOAD. BREAKER CCT AMP / P TOTAL GENERAL OTHER MOTORS RECEPT LTG 20 / 1 0 2 20 / 1 0 4 6 20 / 1 0 8 20 / 1 0 10 20 / 1 0 20 / 1 0 12 20 / 1 0 14 16 20 / 1 0 18 20 / 1 0 20 20 / 1 0 22 20 / 1 0 20 / 1 0 24 26 / 0 28 0 / 30 0 / V 10,000 AMPERE SHORT CIRCUIT RATING (FULLY RATED) DESCRIPTION LTG ASSIT DA SW. SIDE ADMIN TECH SW. SIDE ATTOR. EAST, SW. SIDE CONF. RM SW SIDE COMM SERV. NE SIDE COMM SERV. NE SIDE OFFICER NE SIDE OFFICER NE SIDE OFFICER NE SIDE CONF. RM NE SIDE SPACE SPACE SPACE PHASE LOADING SUMMARY LOAD TYPE (VA) 120 / 208 3 PH 4 W VOLTAGE PHASE WIRE PANEL BREAKER AMP / P CCT PH 20 / 1 1 A 20 / 1 3 B 5 20 / 1 C 20 / 1 7 A 20 / 1 9 B 20 / 1 11 C 20 / 1 13 A 20 / 1 15 B 20 / 1 17 C 20 / 1 19 A 20 / 1 21 B 20 / 1 23 C / 25 A / 27 B 29 / C PANEL LOADING SUMMARY NEC CALCULATED CONNECTED DEMAND LOAD LOAD KVA POWER FACTOR DEMAND LOAD KW 0.0 KVA x 125% = 0.0 KVA x 95% = 0.0 KW 0.0 0.0 KVA KVA x 100% = x 50% = 0.0 KVA 0.0 KVA x 100% = x 100% = 0.0 KW 0.0 KW 0.0 0.0 0.0 0.0 KVA KVA KVA KVA x 125% = x 100% = x 125% = x 100% = 0.0 KVA 0.0 KVA 0.0 KVA 0.0 KVA x 90% = x 90% = x 100% = x 100% = 0.0 KW 0.0 KW 0.0 KW 0.0 KW 0.0 KVA GENERAL NOTES: ' PROVIDE NEW UPDATED PANEL DIRECTORIES FOR PANELS THAT ARE INCLUDED IN THIS PROJECT. ' PROVIDE TYPED DESCRIPTIONS OF NEW CIRCUITS BEING INSTALLED. INDICATE NEW SPARES IN PENCIL. 0.0 KVA DESCRIPTION NOTE ADMIN TECH SE SIDE RECEPTION SE SIDE ADMIN TECH SE SIDE SUPERVISOR SE SIDE VOLUNTEER SE SIDE RECEPTION NW SIDE RECEPTION NW SIDE ADMIN TECH NW SIDE ADMIN TECH NW SIDE JD OFFICER NW SIDE ADMIN TECH NW SIDE INVESTIGATOR NW SIDE SPACE SPACE SPACE PANEL CONNECTED PF= 0% CONNECTED AMPACITY = 0.0 NEC DEMAND AMPACITY = 0.0 REILLY JOHNSON ARCHITECTURE COPYRIGHT C 2008 DRAWN CHECKED JAH JAH 0.0 KW BREAKER ACCESSORIES * = GFCI ** = SHUNT TRIP DRAWING TITLE March 1, 2010 E0.1 SECTION 16010 GENERAL PROVISIONS 1.1 GENERAL: A. DESCRIPTION: PROVIDE ALL LABOR, EQUIPMENT, SUPPLIES, MATERIALS, DELIVERY, STORAGE, INSURANCE, PERMITS AND TAXES UNLESS OTHERWISE SPECIFIED, NECESSARY FOR THE INSTALLATION OF COMPLETE ELECTRICAL SYSTEMS AS REQUIRED BY THE SPECIFICATIONS AND AS SHOWN ON THE DRAWINGS, SUBJECT TO THE TERMS AND CONDITIONS OF THE CONTRACT. 1.2 DRAWINGS AND SPECIFICATIONS: A. DRAWINGS AND SPECIFICATIONS ARE PART OF THE CONTRACT DOCUMENTS FOR THIS PROJECT. B. THE DRAWINGS INDICATE THE GENERAL ARRANGEMENT OF CIRCUITS AND OUTLETS, LOCATIONS OF SWITCHES, PANELBOARDS AND OTHER WORK. INFORMATION SHOWN ON THE DRAWINGS IS DIAGRAMMATIC, HOWEVER DO NOT REVISE THE CIRCUITING SHOWN WITHOUT SPECIFIC APPROVAL OF THE ENGINEER. DRAWINGS AND SPECIFICATIONS ARE COMPLEMENTARY TO EACH OTHER; WORK REQUIRED BY EITHER SHALL BE AS BINDING AS IF REQUIRED FOR BY BOTH. THE DRAWINGS AND SPECIFICATIONS ARE AS ACCURATE AS PLANNING CAN DETERMINE. CONTRACTOR’S FIELD VERIFICATION OF ALL DIMENSIONS, LOCATIONS, LEVELS, ETC., TO SUIT FILED CONDITIONS IS REQUIRED. REVIEW ALL ARCHITECTURAL, STRUCTURAL AND MECHANICAL DRAWINGS AND SPECIFICATIONS; ADJUST WORK TO CONFORM TO ALL CONDITIONS SHOWN THEREIN. THE ARCHITECTURAL DRAWINGS AND SPECIFICATIONS SHALL TAKE PRECEDENCE OVER ALL OTHER DRAWINGS AND SPECIFICATIONS. DO NOT SCALE DISTANCES OFF THE ELECTRICAL DRAWINGS. USE ACTUAL BUILDING DIMENSIONS. C. PRIOR TO SUBMITTING A COST PROPOSAL, VISIT THE JOB SITE AND ASCERTAIN ALL FIELD CONDITIONS AFFECTING THE PROPOSED INSTALLATION. INCLUDE IN THE PROPOSAL COST AND SCHEDULE IMPACTS ARISING FROM FIELD CONDITIONS. NO ADDITIONAL COMPENSATION WILL BE PROVIDED AS A RESULT OF FIELD CONDITIONS. D. DISCREPANCIES BETWEEN DIFFERENT PLANS, BETWEEN PLANS AND SPECIFICATIONS, BETWEEN SPECIFICATIONS, OR REGULATIONS AND CODES GOVERNING THIS INSTALLATION SHALL BE BROUGHT TO THE ATTENTION OF THE ARCHITECT/ENGINEER IN WRITING A MINIMUM OF TWO (2) DAYS PRIOR TO BID SUBMITTAL DUE DATE. IN THE EVENT SUCH DISCREPANCIES EXIST AND THE ARCHITECT/ENGINEER IS NOT SO NOTIFIED, RESOLUTION INCLUDING ASSOCIATED CONSTRUCTION COST SHALL BE THE SOLE RESPONSIBILITY OF THE CONTRACTOR. E. PROVIDE PRODUCTS AS SPECIFIED. EQUAL PRODUCTS WILL BE CONSIDERED FOR SUBSTITUTION ONLY IF SUBMITTED TO THE ARCHITECT/ENGINEER FOR REVIEW 3 DAYS PRIOR TO BID SUBMITTAL DUE DATE. 1.3 A. B. C. 1.4 A. B. 1.5 A. SUBMITTALS: PRIOR TO ORDERING PURCHASING, STORING OR INSTALLING MATERIALS, SUBMIT (3) COPIES OF SHOP DRAWINGS AND PRODUCT DATA FOR THE FOLLOWING ITEMS: WIRING DEVICES, OVERCURRENT PROTECTIVE DEVICES, FIRE ALARM SYSTEM COMPONENTS AND LUMINAIRES. SUBMIT ONLY FOR PRODUCTS WHERE REQUIRED BY THESE SPECIFICATION SECTIONS. CLEARLY INDICATE THE EQUIPMENT AND MATERIAL PROPOSED FOR APPLICATION AND BE THE PROPOSED FABRICATION AND INSTALLATION METHODS. CONTINUE TO SUBMIT THREE (3) SETS, AFTER EACH ARCHITECT/ENGINEER’S ACTION, UNIT A “NO EXCEPTION TAKEN” OR “MAKE CORRECTION NOTE” ACTION IS RECEIVED WITH THE EXCEPTION OF FIRE ALARM SUBMITTALS WHICH MUST BE SUBMITTED UNTIL A “NO EXCEPTION TAKEN” ACTION IS RECEIVED. SUBMITTALS NOT REQUIRED WILL BE RETURNED WITHOUT ACTION. SUBMITTAL SHALL BE REVIEWED BY THE ARCHITECT/ENGINEER FOR GENERAL CONFORMANCE WITH CONTRACT REQUIREMENTS. SUBMITTALS PROCESSED BY THE ARCHITECT/ENGINEER SHALL NOT BE CONSIDERED CHANGE ORDERS. THE CONTRACTOR SHALL REVIEW AND STAMP, EACH SUBMITTAL FOR CONFORMANCE WITH THE DRAWINGS AND SPECIFICATIONS PRIOR TO SUBMITTAL TO THE ARCHITECT/ENGINEER. DATA SUBMITTED FROM SUB-CONTRACTORS AND MATERIAL SUPPLIERS DIRECTLY TO THE ARCHITECT/ENGINEER WILL NOT BE PROCESSED. THE CONTRACTOR IS RESPONSIBLE FOR DIMENSIONS, FABRICATION PROCESSES, TECHNIQUES OF CONSTRUCTION AND COORDINATION OF HIS WORK WITH THAT OF ALL OTHER TRADES. VERIFY ALL MEASUREMENTS AND REVIEW SHOP DRAWINGS BEFORE SUBMITTING THEM. IF ANY DEVIATIONS FROM THE SPECIFIED REQUIREMENTS FOR ANY ITEM OF MATERIAL OR EQUIPMENT EXIST, SUCH DEVIATION SHALL BE EXPRESSLY STATED IN WRITING AND INCORPORATED AS PART OF THE SUBMITTAL. RECORD DRAWINGS: APPLICATIONS OF ELECTRICAL POWER CONNECTIONS SPECIFIED IN THIS SECTION INCLUDE THE FOLLOWING: 1. TO LIGHTING EQUIPMENT. 2. TO MISCELLANEOUS EQUIPMENT NOTED. 3. OTHER CONNECTIONS AS SHOWN. MAINTAIN AN UP TO DATE CONTRACT SET OF ELECTRICAL DRAWINGS AND SPECIFICATIONS AT THE SITE, INCLUDING ALL ADDENDUMS, CHANGE ORDERS, FIELD CHANGES, FEEDER CONDUIT ROUTING AND CHANGES BASED ON SHOP DRAWING REVIEW. NEATLY MARK ALL CHANGES AND DEVIATIONS FROM THE ORIGINAL DRAWINGS AND SPECIFICATIONS. USE RED FOR ADDITIONAL ITEMS AND GREEN FOR REMOVED ITEMS. THIS SHALL BE A SEPARATE SET OF DRAWINGS, NOT USED FOR CONSTRUCTION PURPOSES AND SHALL BE MADE AVAILABLE FOR REVIEW BY THE ARCHITECT/ENGINEER AT ALL TIMES. UPON COMPLETION OF THE CONTRACT, THIS SET OF RECORD DRAWINGS SHALL BE DELIVERED TO THE [OWNER] OR [ARCHITECT/ENGINEER]. REGULATORY REQUIREMENTS: 1.10 A. B. C. D. E. F. G. A. B. C. ALL ELECTRICAL MATERIALS SHALL BE ACCEPTABLE FOR INSTALLATION ONLY IF LABELED OR LISTED BY A NATIONALLY RECOGNIZED TESTING LABORATORY AND ACCEPTED BY LOCAL AUTHORITY HAVING JURISDICTION. F. HORIZONTALLY ALIGN ADJACENT WALL MOUNTED OUTLET BOXES AND MUD RING FOR SWITCHES, THERMOSTATS AND SIMILAR DEVICES. L. DO NOT USE POWDER ACTUATED ANCHORS. O. INSTALL RACEWAY SEALING FITTING WHERE CONDUITS ENTER OR LEAVE A HAZARDOUS LOCATION, WHERE CONDUITS PASS FROM A WARM TO COLD LOCATION AND WHERE CONDUITS ENTER THROUGH A FOUNDATION OR THROUGH SLAB ON GRADE. M. G. USE FLUSH MOUNTING OUTLET BOX IN FINISHED AREAS. USE #9 CEILING WIRE TO SUPPORT INDIVIDUAL CONDUITS UP TO ¾” WITH SPRING STEEL FASTENERS. H. DO NOT INSTALL FLUSH MOUNTED BOXES BACK-TO-BACK IN WALLS; PROVIDE MINIMUM 6 INCHES SEPARATION. PROVIDE MINIMUM 24 INCHES SEPARATION IN ACOUSTIC OR FIRE RATED WALLS. N. CONDUITS SHALL NOT BE SUPPORTED FROM THE SUPPORT WIRES OF SUSPENDED CEILING SYSTEMS. O. ELECTRICAL DEVICES OR EQUIPMENT SHALL NOT BE HUNG FROM THE ROOF DECK. P. INSTALL SURFACE-MOUNTED CABINETS AND PANELBOARDS WITH MINIMUM OF FOUR ANCHORS. PROVIDE STEEL CHANNEL SUPPORTS TO STAND CABINET ONE INCH OFF WALL. Q. CUT OFF UNUSED LENGTHS THREADED ROD SUPPORTS. R. BRIDGE STUDS TOP AND BOTTOM WITH CHANNELS TO SUPPORT FLUSH-MOUNTED CABINETS AND PANELBOARDS IN STUD WALLS. S. PROVIDE CONCRETE EQUIPMENT BASES FOR ALL FLOOR MOUNTED ELECTRICAL EQUIPMENT. DIMENSIONS SHALL BE 4 INCHES HEIGHT WITH WIDTH AND LENGTH PROJECTION OF BASE BEYOND OUTLINE DIMENSION EQUIPMENT. DEMO DRAWINGS ARE BASED ON LIMITED FIELD OBSERVATION AND/OR EXISTING RECORD DOCUMENTS. REPORT DISCREPANCIES TO ARCHITECT/ENGINEER BEFORE DISTURBING EXISTING INSTALLATION. VISIT THE SITE PRIOR TO BIDDING TO UNDERSTAND EXISTING CONDITIONS AND INCLUDE IN THE BID DEMO AND RELOCATION OF EXISTING CONDUITS, WIRES DEVICES, FIXTURES OR OTHER EQUIPMENT AS INDICATED ON THE PLANS OR AS REQUIRED TO COORDINATE AND ADAPT NEW AND EXISTING ELECTRICAL SYSTEMS TO THE WORK OF ALL OTHER TRADES REQUIRED ON THIS PROJECT. MAINTAIN EXISTING ELECTRICAL SERVICE TO EQUIPMENT, FIRE ALARM SYSTEM AND TELEPHONE SYSTEMS SERVING OCCUPIED AREAS IN SERVICE UNTIL NEW SYSTEMS ARE FULLY OPERATIONAL OR AS OTHERWISE INDICATED. PROVIDE TEMPORARY WIRING AND CONNECTIONS TO MAINTAIN EXISTING SYSTEMS IN SERVICE DURING CONSTRUCTION. DISABLE SYSTEMS ONLY TO MAKE SWITCHOVERS AND CONNECTIONS. SCHEDULE ANY OUTAGES WITH THE OWNER AT LEAST 72 HOURS BEFORE PARTIALLY OR COMPLETELY DISABLING SYSTEM. MINIMIZE OUTAGE DURATION. MAKE TEMPORARY CONNECTIONS TO MAINTAIN SERVICE IN AREAS ADJACENT TO WORK AREA. CONTRACTOR SHALL NOT LEAVE THE SITE WITHOUT RESTORING THE OPERATION OF ALL SYSTEMS. PROVIDE ALL SHUT DOWN WORK DURING OWNER’S OFF HOURS. REMOVE EXPOSED ABANDONED CONDUIT, INCLUDING ABANDONED CONDUIT ABOVE ACCESSIBLE CEILINGS. CUT CONDUIT FLUSH WITH WALLS AND FLOORS. REMOVE ABANDONED WIRING TO SOURCE OF SUPPLY. DISCONNECT ABANDONED OUTLETS AND REMOVE DEVICES. REMOVE ABANDONED OUTLET BOXES IF CONDUIT SERVING THEM IS ABANDONED AND REMOVED. UNLESS NOTED OTHERWISE, PROVIDE BLANK COVER FOR ABANDONED OUTLET BOXES THAT ARE NOT REMOVED. DISCONNECT AND REMOVE ELECTRICAL DEVICES AND EQUIPMENT SERVING UTILIZATION EQUIPMENT THAT HAS BEEN REMOVED, ABANDONED LUMINAIRES, BRACKETS, STEMS, HANGERS, ETC. A. J. A. K. EXISTING CONDUITS, WIRE, DEVICES, FIXTURES, ETC WHICH SHALL BE REMOVED SHALL BECOME THE PROPERTY OF THE CONTRACTOR UNLESS OTHERWISE NOTED. L. IF HAZARD MATERIALS ARE ENCOUNTERED THE CONTRACTOR SHALL REPORT FINDINGS TO THE ARCHITECT/ENGINEER. 1.11 A. B. C. 1.12 A. B. C. 1.9 A. B. C. D. ALL ERRORS IN INSTALLATION SHALL BE CORRECTED AT THE EXPENSE OF THE CONTRACTOR. WHERE DETAILS OR SPECIFIC INSTALLATION REQUIREMENTS ARE NOT PROVIDED, FOLLOW MANUFACTURER’S RECOMMENDATIONS. 1.13 DELIVER THREE COMPLETE OPERATING AND MAINTENANCE MANUALS PARTS LISTS AND WARRANTY INFORMATION TO THE OWNER AT THE TIME OF THE ABOVE REQUIRED TRAINING. FULLY EXPLAIN THE CONTENTS OF THE MANUALS AS PART OF TRAINING AND INSTRUCT THE OWNERS PERSONNEL IN THE CORRECT PROCEDURE FOR OBTAINING SERVICE, BOTH DURING AND AFTER THE WARRANTY PERIOD. INCLUDE ADDRESSES AND PHONE NUMBERS FOR THE OWNER TO CONTACT FOR WARRANTY, SERVICE AND PARTS. FINAL ACCEPTANCE BY THE OWNER WILL NOT OCCUR UNTIL ALL OPERATING AND MAINTENANCE MANUALS ARE RECEIVED AND OWNER’S PERSONNEL HAVE BEEN THOROUGHLY INDOCTRINATED IN THE MAINTENANCE AND OPERATION OF ALL EQUIPMENT. THE ELECTRICAL SYSTEM INSTALLED UNDER THIS CONTRACT SHALL BE LEFT IN PROPER WORKING ORDER. REPLACE, AT NO ADDITIONAL COST TO THE OWNER, ANY WORK, MATERIALS, OR EQUIPMENT WHICH EXHIBIT DEFECTS IN DESIGN, CONSTRUCTION OR WORKMANSHIP WITHIN ONE YEAR, OR AS SPECIFICALLY NOTED ELSEWHERE IN THESE SPECIFICATIONS, FROM DATE OF FINAL OWNER ACCEPTANCE. ALL OPENINGS MADE IN FIRE-RATED WALLS, FLOORS OR CEILINGS SHALL BE PATCHED AND MADE TIGHT IN A MANNER TO CONFORM TO THE FIRE RATING FOR THE UL RATED ASSEMBLY. ALL PENETRATIONS REQUIRED THROUGH EXISTING MASONRY OR CONCRETE CONSTRUCTION SHALL BE CORE DRILLED AT MINIMUM SIZE REQUIRED. PRECAUTIONS SHALL BE TAKEN WHEN DRILLING TO PREVENT DAMAGE TO STRUCTURAL CONCRETE. THE CONTRACTOR SHALL OBTAIN PERMISSION FROM THE OWNER/ARCHITECT/ ENGINEER BEFORE PROCEEDING WITH CUTTING OR DRILLING. FOR ALL CORE DRILLING, PROVIDE AN X-RAY OF THE AREA PRIOR TO DRILLING. COORDINATE WITH ALL TENANTS AFFECTED BY X-RAYING AS WELL AS CORE DRILLING. PROVIDE SLEEVE SEALS FOR PENETRATIONS LOCATED IN FOUNDATION WALLS BELOW GRADE, OR IN EXTERIOR WALLS. SEALS SHALL BE MODULAR MECHANICAL TYPE AS MANUFACTURED BY LINK SEAL CORP. CONSISTING OF INTERLOCKING SYNTHETIC RUBBER LINKS SHAPED TO CONTINUOUSLY FILL ANNULAR SPACE BETWEEN RACEWAY AND SLEEVE, CONNECTED WITH BOLTS AND PRESSURE PLATES WHICH CAUSE RUBBER SEALING ELEMENTS TO EXPAND WHEN TIGHTENED, PROVIDING WATERTIGHT SEAL. D. 1.3 A. PROVIDE WIRE AND CABLE SUITABLE FOR THE TEMPERATURE, CONDITIONS, AND LOCATION WHERE INSTALLED. 1. COMPLETELY AND THOROUGHLY SWAB RACEWAY BEFORE INSTALLING WIRE. 2. METAL CLAD CABLE MAY BE USED ONLY FOR: CONNECTION OF LUMINAIRES IN ACCESSIBLE CEILINGS (MAX. 6 FOOT LENGTHS). B. C. 1.2 A. 1. B. C. A. CONDUIT REQUIREMENTS B. C. MINIMUM SIZE: ½ INCH EXCEPT BRANCH CIRCUIT HOME RUNS TO PANELBOARD SHALL NOT BE LESS THAN ¾ INCH. F. USE 10 AWG CONDUCTORS FOR 20 AMPERE, 277 VOLT BRANCH CIRCUITS LONGER THAN 100 FEET TO THE FIRST FIXTURE OR DEVICE. G. PULL ALL CONDUCTORS INTO RACEWAY AT SAME TIME. DO NOT EXCEED THE MAXIMUM TENSILE STRENGTH OF THE CABLE BEING PULLED AS ALLOWED BY NEC AND/OR THE CABLE MANUFACTURER. PULLING COMPOUND SHALL BE NON-CONDUCTIVE AND SHALL DRY TO A FINE LUBRICATING POWDER. WHERE A BRANCH CIRCUIT EXTENDS THROUGH A RECEPTACLE OUTLET, ALL CONNECTING CONDUCTORS SHALL BE PIGTAILED SO AS TO PREVENT DOWNSTREAM LOADS FOR BEING CONDUCTED THROUGH RECEPTACLE. I. USE SUITABLE WIRE PULLING LUBRICANT FOR BUILDING WIRE 4AWG AND LARGER. J. SUPPORT CABLES ABOVE ACCESSIBLE CEILING, USING SPRING METAL CLIPS OR METAL CABLE TIES TO SUPPORT CABLES FROM STRUCTURE. CEILING SUSPENSION SYSTEM OR SUSPENDED GRID SYSTEMS SHALL NOT BE ALLOWED TO PROVIDE SUPPORT FOR CABLE WIRING SYSTEMS. DO NOT ALLOW CABLE TO REST ON CEILING PANELS. DRY LOCATIONS: 1. CONCEALED: ELECTRICAL METALLIC TUBING. 2. EXPOSED: RIGID STEEL CONDUIT, OR INTERMEDIATE METAL CONDUIT UP TO 8’-0” ABOVE FINISHED FLOOR AND ELECTRICAL METALLIC TUBING ABOVE 8’-0”. MOTOR AND EQUIPMENT CONNECTIONS: FLEXIBLE METAL CONDUIT OR PVC JACKETED LIQUID-TIGHT FLEXIBLE METALLIC CONDUIT WITH LIQUID TIGHT CONNECTORS FOR DAMP, WET OR EXTERIOR LOCATIONS. USE INSULATED SPRING WIRE CONNECTORS WITH PLASTIC CAPS FOR COPPER CONDUCTOR SPLICES AND TAPS, 10 AWG AND SMALLER WIRE AND CABLE COLOR CODING: WIRE NO. 6 AWG AND SMALLER SHALL BE FACTORY COLOR-CODED. WIRE NO. 4 AWG AND LARGER MAY BE COLOR-CODED BY FIELD PAINTING OR COLOR TAPING OF 6-INCH LENGTH OF EXPOSED ENDS. CONDUCTORS HAVING WHITE, GRAY, WHITE WITH COLORED STRIPE, GREEN OR GREEN WITH COLORED STRIPE SHALL NOT BE USED TO INDICATE OTHER THAN NEUTRAL OR GROUNDING. D. CONCEAL ALL CONDUIT UNLESS INDICATED OTHERWISE, WITHIN FINISHED WALLS AND CEILINGS. E. PUSH-ON, DIE, OR PRESSURE CAST ZINC ALLOY, WHITE METAL OR POT METAL FITTINGS SHALL NOT BE USED. F. EMT CONNECTIONS IN DRY LOCATIONS SHALL BE STEEL SETSCREW. G. CONDUIT SHALL NOT BE MOUNTED ON DUCTWORK OR OTHER MECHANICAL EQUIPMENT EXCEPT WHERE NECESSARY TO MAKE CONNECTIONS TO ELECTRICAL DEVICES THAT ARE PART OF OR MOUNTED ON SUCH EQUIPMENT. WHERE CONDUIT MUST BE INSTALLED ON EQUIPMENT, DO NOT COVER ACCESS DOORS, CONTROLS, REMOVABLE PANELS, OR OTHERWISE HINDER NORMAL MAINTENANCE AND REPAIR OF THE EQUIPMENT. WHERE IT IS NECESSARY TO MAKE CONDUIT CONNECTIONS TO EQUIPMENT MOUNTED ON VIBRATION MOUNTS, FLEXIBLE CONNECTION SHALL BE USED. SECTION 16135 CABINETS, OUTLET/DEVICE BOXES AND FITTINGS 1.2 A. A. H. DO NOT SUPPORT CONDUIT WITH WIRE OR PERFORATED PIPE STRAPS. I. DO NOT ATTACH CONDUIT TO CEILING SUPPORT WIRES. SUSPENDED CONDUIT INDEPENDENT OF CEILING GRID SUPPORTING WIRING SYSTEMS. J. ROUTE CONDUIT PARALLEL AND PERPENDICULAR TO BUILDING WALLS. K. INSTALL NO MORE THAN EQUIVALENT OF THREE 90-DEGREE BENDS BETWEEN BOXES. USE CONDUIT BODIES TO MAKE SHARP CHANGES IN DIRECTION. USE FACTORY ELBOWS FOR BENDS IN METAL CONDUIT LARGER THAN 2-INCH SIZE. L. AVOID MOISTURE TRAPS; PROVIDE JUNCTION BOX WITH DRAIN FITTING AT LOW POINTS IN CONDUIT SYSTEM. GENERAL: THIS SECTION INCLUDES CABINETS, BOXES, AND FITTINGS FOR ELECTRICAL INSTALLATIONS AND CERTAIN TYPES OF ELECTRICAL FITTINGS NOT COVERED IN OTHER SECTIONS. TYPES OF PRODUCTS SPECIFIED IN THIS SECTION INCLUDE: ELECTRICAL CABINETS, BOXES, AND FITTINGS: OF INDICATED TYPES, SIZES, AND NEMA ENCLOSURE CLASSES. WHERE NOT INDICATED, PROVIDE UNITS OF TYPES, SIZES, AND CLASSES APPROPRIATE FOR THE USE AND LOCATION. PROVIDE ALL ITEMS COMPLETE WITH COVERS AND ACCESSORIES REQUIRED FOR THE INTENDED USE. PROVIDE GASKETS FOR UNITS IN DAMP OR WET LOCATIONS. E. FLUORESCENT LAMP DIMMERS: PROVIDE SINGLE POLE, FULL WAVE SEMI CONDUCTOR MODULAR TYPE AC DIMMERS FOR FLUORESCENT LAMPS; WATTAGE AND VOLTAGE AS INDICATED, AND WITH ELECTROMAGNETIC FILTERS TO REDUCE NOISE, RF AND TV INTERFERENCE TO MINIMUM. CONSTRUCT WITH CONTINUOUSLY ADJUSTABLE TRIM POTENTIOMETER FOR ADJUSTMENT OF LOW DIMMING; AND WITH ANODIZED HEAT SINKS. PROVIDE 5 INCH WIRE CONNECTING LEADS. DIMMERS SHALL BE LUTRON NOVA "T" STAR. 1.3 A. PROVIDE EXTENSION RINGS TO BRING OUTLET BOXES FLUSH WITH FINISHED SURFACE. B. CLEAN DEBRIS FROM OUTLET BOXES. C. INSTALL DEVICES PLUMB AND LEVEL. D. INSTALL SWITCHES WITH OFF POSITION DOWN. E. CONNECT WIRING DEVICE GROUNDING TERMINAL TO BRANCH CIRCUIT EQUIPMENT GROUNDING CONNECTOR. F. CONNECT WIRING DEVICES BY WRAPPING CONDUCTOR AROUND SCREW TERMINAL. G. INSTALL RECEPTACLES WITH EITHER GROUND OR NEUTRAL UP. H. PROVIDE GFCI TYPE OUTLETS FOR EACH ABOVE COUNTER DUPLEX RECEPTACLE SHOWN WITHIN 6 FEET-0 INCHES OF SINKS/LAVATORIES. FOR ABOVE COUNTER MULTI-OUTLET ASSEMBLIES WHICH DO NOT CONTAIN DUPLEX RECEPTACLES THAT CAN BE REPLACED WITH GFCI DEVICES, PROVIDE GFI CIRCUIT BREAKERS ON THE BRANCH CIRCUIT(S) FEEDING THE ASSEMBLY. I. EACH BRANCH CIRCUIT SERVING DEDICATED, ISOLATED OR EMERGENCY RECEPTACLES, MULTI-OUTLET ASSEMBLIES OR EQUIPMENT CONNECTIONS SHALL BE FURNISHED WITH A DEDICATED NEUTRAL CONDUCTOR. NEUTRALS COMMON TO MORE THAN ONE CIRCUIT SHALL ONLY BE PERMITTED WHERE SPECIFICALLY NOTED. END OF SECTION 2. FIXTURE OUTLETS BOXES IN FINISHED CEILINGS SHALL BE FITTED WITH OPEN COVERS, SET TO COME FLUSH WITH THE FINISHED SURFACE. 3. SWITCHES, RECEPTACLES AND SPECIAL ELECTRICAL SYSTEM DEVICES SHALL BE MOUNTED IN 4” SQUARE BOXES OF 25 CUBIC INCH MINIMUM CAPACITY, SUITABLY FITTED WITH APPROPRIATE MUD RING WHERE NECESSARY TO SET FLUSH WITH THE FINISHED SURFACE. B. INSTALL PULL BOXES AND JUNCTION BOXES ABOVE ACCESSIBLE CEILINGS AND IN UNFINISHED AREAS ONLY. C. INACCESSIBLE CEILING AREAS: PROVIDE ACCESS PANEL AS REQUIRED. INSTALL OUTLET AND JUNCTION BOXES NO MORE THAN 6 INCHES FROM CEILING ACCESS PANEL OR FROM REMOVABLE RECESSED LUMINAIRE. D. A. COORDINATE MOUNTING HEIGHTS AND LOCATIONS OF OUTLETS MOUNTED ABOVE COUNTERS, BENCHES AND BACKSPLASHES WITH ARCHITECTURAL PLANS AND ELEVATIONS. DESCRIPTION: PROVIDE COLORED ADHESIVE MARKING TAPE FOR BANDING WIRES AND CABLES. B. IDENTIFY JUNCTION, PULL AND CONNECTION BOXES: IDENTIFICATION OF SYSTEMS AND CIRCUITS SHALL INDICATE SYSTEM VOLTAGE AND IDENTIFY OF CONTAINED CIRCUITS ON OUTSIDE OF BOX COVER. COLOR CODE SHALL BE SAME AS CONDUITS FOR PRESSURE SENSITIVE LABELS. USE SELF ADHESIVE MARKING TAPE LABELS AT EXPOSED LOCATIONS AND INDELIBLE BLACK MARKER AT CONCEALED BOXES. ALL FIRE ALARM BOXES SHALL HAVE COVERS PAINTED RED. ALL TEMPERATURE CONTROL BOXES SHALL HAVE COVERS PAINTED BLUE. C. A. 1.2 D. MATCH IDENTIFICATION MARKINGS WITH DESIGNATIONS USED IN PANELBOARDS SHOP DRAWINGS, CONTRACT DOCUMENTS AND SIMILAR PREVIOUSLY ESTABLISHED IDENTIFICATION SCHEMES FOR THE FACILITY’S ELECTRICAL INSTALLATIONS. E. DEVICE PLATES: WHERE MORE THAN TWO WALL SWITCHES OR WALL DIMMERS ARE INSTALLED IN GANGED OUTLET ASSEMBLIES: 1/8 INCH; IDENTIFY TYPE OF LIGHTING CONTROLLED. USE KROY OR BROTHER TYPE LABELS ON THE EXTERIOR OF EACH WALL PLATE TO IDENTIFY THE CIRCUIT SERVING THE DEVICE. . FABRICATE SUPPORTS FROM STRUCTURAL STEEL OR STEEL CHANNEL, RIGIDLY WELDED OR BOLTED TO PRESENT A NEAT APPEARANCE. USE HEXAGON HEAD BOLTS WITH SPRING LOCK WASHERS UNDER ALL NUTS. 1.3 A. B. C. D. 1.2 THIS SECTION INCLUDES OVERCURRENT PROTECTIVE DEVICES (OCPD’S) RATED 600 V AND BELOW AND SWITCHING DEVICES COMMONLY USED WITH THEM IN PANELBOARDS AND SWITCHBOARDS. PROVIDE COORDINATION STUDY PERFORMED BY A REGISTERED PROFESSIONAL ENGINEER IN ACCORDANCE WITH ANSI/IEEE STANDARD 242 1986, "RECOMMENDED PRACTICE FOR PROTECTION AND COORDINATION OF INDUSTRIAL AND COMMERCIAL POWER SYSTEMS," WHERE OCPD MANUFACTURERS OTHER THAN THOSE DESIGNATED FIRST IN SCHEDULES OR PRODUCT LISTINGS OF OVERCURRENT PROTECTIVE DEVICES ARE PROPOSED FOR USE. SUBMIT A FULL COORDINATION STUDY SHOWING GRAPHICALLY THAT THE SUBSTITUTE OCPD’S COORDINATE SELECTIVELY WITH BOTH UPSTREAM AND DOWNSTREAM COMPONENTS. INCLUDE SINGLE LINE DIAGRAM, COORDINATED TIME CURRENT CHARACTERISTICS, DEVICE PERFORMANCE CURVES, AND FAULT CURRENT CALCULATIONS ADEQUATE TO DEMONSTRATE SATISFACTORY COMPONENT PROTECTION AND SELECTIVE COORDINATION OF PROTECTIVE DEVICES. STUDY SHALL BE COMMISSIONED AND PAID FOR BY THE CONTRACTOR. SUBMIT STUDY WITH SWITCHBOARD AND PANELBOARD SUBMITTALS. EACH TYPE OF OCPD SHALL BE THE PRODUCT OF A SINGLE MANUFACTURER TO MATCH THE PANELBOARD OR SWITCHBOARD MANUFACTURER. WHERE OCPD'S ARE TO BE INSTALLED IN EXISTING PANELBOARDS, SWITCHBOARDS THEY SHALL BE OF THE SAME MANUFACTURE AND TYPE AS THOSE EXISTING IN THE EQUIPMENT. IF THIS IS NOT POSSIBLE, PROVIDE DEVICES WHICH ARE COMPATIBLE WITH THE EXISTING EQUIPMENT AND WHEN INSTALLED WILL NOT VOID THE U.L. LABEL OR REDUCE THE SHORT CIRCUIT RATING OF THE EQUIPMENT. PROVIDE OCPDS IN INDICATED TYPES, AS INTEGRAL COMPONENTS OF PANELBOARDS, SWITCHBOARDS, AND OTHER RELATED EQUIPMENT; AND ALSO AS INDIVIDUALLY ENCLOSED AND MOUNTED SINGLE UNITS. MATERIALS: SUBJECT TO COMPLIANCE WITH REQUIREMENTS, PROVIDE PRODUCTS BY THE FOLLOWING MANUFACTURER: 1. PROVIDE 100 PERCENT RATED EQUIPMENT AND FEEDER BREAKERS UNLESS OTHERWISE NOTED. PROVIDE STANDARD 80 PERCENT RATED BRANCH CIRCUIT BREAKERS UNLESS OTHERWISE NOTED. 2. ALL OVERCURRENT DEVICES SHALL BE INDIVIDUALLY RATED FOR THE AVAILABLE FAULT CURRENT UNLESS OTHERWISE NOTED. SERIES RATINGS OF EQUIPMENT WILL ONLY BE ALLOWED WHERE SPECIFICALLY IDENTIFIED. 3. MOLDED CASE CIRCUIT BREAKERS: INSTALLATION: A. INSTALL SUPPORTING DEVICES TO FASTEN ELECTRICAL COMPONENTS SECURELY AND PERMANENTLY IN ACCORDANCE WITH NEC REQUIREMENTS. B. STRENGTH OF EACH SUPPORT SHALL BE ADEQUATE TO CARRY PRESENT AND FUTURE PROPOSED LOAD MULTIPLIED BY A SAFETY FACTOR OF LEAST FOUR. WHERE THIS DETERMINATION RESULTS IN A SAFETY ALLOWANCE OF LESS THAN 200LBS, PROVIDE ADDITIONAL STRENGTH UNTIL THERE IS A MINIMUM OF 200 LBS SAFETY ALLOWANCE IN THE STRENGTH OF EACH SUPPORT. C. INSTALL INDIVIDUAL AND MULTIPLE (TRAPEZE) RACEWAY HANGERS AND RISER CLAMPS AS NECESSARY TO SUPPORT RACEWAYS. PROVIDE U-BOLTS, CLAMPS, ATTACHMENTS AND OTHER HARDWARE NECESSARY FOR HANGER ASSEMBLY AND FOR SECURING HANGER RODS AND CONDUITS. D. SUPPORT PARALLEL RUNS OF HORIZONTAL RACEWAYS TOGETHER ON TRAPEZE-TYPE HANGERS. USE 3/8” DIAMETER OR LARGER THREADED STEEL RODS FOR SUPPORT. E. SUPPORT INDIVIDUAL HORIZONTAL RACEWAYS BY SEPARATE PIPE HANGERS. SPRING STEEL FASTENERS MAY BE USED IN LIEU OF HANGERS ONLY FOR 1-1/2 INCH AND SMALLER RACEWAYS SERVING LIGHTING AND RECEPTACLE BRANCH CIRCUITS ABOVE SUSPENDED CEILINGS ONLY. FOR HANGER RODS WITH SPRING STEEL FASTENERS, USE ¼” DIAMETER OR LARGER THREADED STEEL. USE SPRING STEEL FASTENERS THAT ARE SPECIFICALLY DESIGNED FOR SUPPORTING SINGLE CONDUITS OR TUBING. FOR HANGER RODS SUPPORTING 1-1/2 INCH OR LARGER CONDUITS PROVIDE 3/8 INCH MINIMUM THREADED STEEL RODS WITH PIPE HANGERS. F. SPACE SUPPORTS FOR RACEWAYS IN ACCORDANCE WITH NEC. WHEN THERE ARE 4 OR MORE 2” CONDUITS IN A TRAPEZE, SUPPORTS SHALL BE SPACED 5 FEET O.C. G. IN ALL RUNS, ARRANGE SUPPORT SO THE LOAD PRODUCED BY THE WEIGHT OF THE RACEWAY AND THE ENCLOSED CONDUCTORS IS CARRIED ENTIRELY BY THE CONDUIT SUPPORTS WITH NO WEIGHT LOAD ON RACEWAY TERMINALS. H. I. J. IN OPEN OVERHEAD SPACES, SUPPORT METAL BOXES DIRECTLY FROM THE BUILDING STRUCTURE VIA ¼” MINIMUM ALL-THREAD OR BY BAR HANGERS. WHERE BAR HANGERS ARE USED, ATTACHÉ THE BAR TO RACEWAYS ON OPPOSITE SIDES OF THE BOX AND SUPPORT THE RACEWAY WITH AN APPROVED TYPE OF FASTENER NOT MORE THAN 24 INCHES FROM THE BOX. SUPPORTING METAL BOXES UTILIZING CEILING WIRE IS NOT ACCEPTABLE. FASTEN HANGER RODS, CONDUIT CLAMPS AND OUTLET AND JUNCTION BOXES TO BUILDING STRUCTURE USING PRECAST INSERT SYSTEM, EXPANSION ANCHORS, BEAM CLAMPS, OR SPRING STEEL CLIPS. USE TOGGLE BOLTS OR HOLLOW WALL FASTENERS IN HOLLOW MASONRY, PLASTER OR GYPSUM BOARD PARTITIONS AND WALLS; SELF-DRILLING ANCHORS OR EXPANSION ANCHORS OR PRESET INSERTS IN SOLID MASONRY WALLS; SELF-DRILLING ANCHORS OR EXPANSION ANCHOR ON CONCRETE SURFACES; SHEET METAL SCREWS IN SHEET METAL STUDS; AND WOOD SCREWS IN WOOD CONSTRUCTION. A. LUMINAIRE MANUFACTURERS: SUBJECT TO COMPLIANCE WITH REQUIREMENTS, PROVIDE LUMINAIRES AS LISTED IN THE LUMINAIRE SCHEDULE OR ELSEWHERE ON THE DRAWINGS OR SPECIFICATION. B. LAMP MANUFACTURERS: C. D. 1. FLUORESCENT: PROVIDE FLUORESCENT LAMP TYPES AS SPECIFIED IN THE LUMINAIRE SCHEDULE AND TYPES COMPATIBLE WITH LUMINAIRES. LAMPS SHALL BE LOW MERCURY TYPE. PROVIDE 3500°K COLOR TEMPERATURE LAMPS UNLESS OTHERWISE NOTED IN SCHEDULES OR ON DRAWINGS. 2. INCANDESCENT: PROVIDE INCANDESCENT LAMP TYPES AS SPECIFIED IN THE LUMINAIRE SCHEDULE AND TYPES COMPATIBLE WITH LUMINAIRES. PROVIDE FROSTED LAMPS UNLESS OTHERWISE NOTED. 3. HIGH INTENSITY DISCHARGE: PROVIDE METAL HALIDE OF HIGH PRESSURE SODIUM LAMP TYPES AS SPECIFIED IN THE LUMINAIRE SCHEDULE AND TYPES COMPATIBLE WITH LUMINAIRES. LAMPS SHALL HAVE BURNING POSITION COMPATIBLE WITH LUMINAIRE. FLUORESCENT BALLAST MANUFACTURERS: 1. 2. 3. E. 1.3 A. B. C. D. E. F. G. H. I. J. a. GENERAL: UL 489, "MOLDED CASE CIRCUIT BREAKERS AND CIRCUIT BREAKER ENCLOSURES," AND NEMA AB 1, "MOLDED CASE CIRCUIT BREAKERS." b. CONSTRUCTION: PROVIDE BOLT IN TYPE, EXCEPT BREAKERS 225 AMPERE FRAME SIZE AND LARGER WHICH MAY BE PLUG IN TYPE IF HELD IN PLACE BY POSITIVE LOCKING DEVICE REQUIRING MECHANICAL RELEASE FOR REMOVAL. c. CHARACTERISTICS: INDICATED FRAME SIZE, TRIP RATING, NUMBER OF POLES, AND A SHORT-CIRCUIT INTERRUPTING CAPACITY RATING AS INDICATED OR REQUIRED TO MATCH EXISTING DEVICES OR EQUIPMENT. d. TRIPPING DEVICE: QUICK MAKE, QUICK BREAK TOGGLE MECHANISM WITH INVERSE TIME DELAY AND INSTANTANEOUS OVERCURRENT TRIP PROTECTION FOR EACH POLE. TRIP UNIT TO BE INTERCHANGEABLE WITHIN FRAME SIZES FOR BREAKERS 200 AMPERES OR LARGER. BREAKERS 150 AMPERES AND ABOVE SHALL HAVE ADJUSTABLE TRIP SELECTION FOR TRIP UNITS. ALL 120/208 VOLT RATED BREAKERS SHALL BE RATED AND LABELED "HIGH MAGNETIC". INSTALLATION: INDEPENDENTLY MOUNTED OCPDS: LOCATE AS INDICATED AND INSTALL IN ACCORDANCE WITH MANUFACTURER'S WRITTEN INSTALLATION INSTRUCTIONS. INSTALL OCPDS LEVEL AND PLUMB. OCPDS IN NEW DISTRIBUTION AND BRANCH CIRCUIT EQUIPMENT SHALL BE FACTORY INSTALLED. ARRANGE FUSES SO THAT FUSE RATINGS ARE READABLE WITHOUT REMOVING FUSE. ALL FUSES FOR NEW DISCONNECT SWITCHES OR MCC’S FEEDING MOTORS OR MOTOR STARTERS SHALL BE PROVIDED WITH CLASS J FUSES. IDENTIFY COMPONENTS IN ACCORDANCE WITH DIVISION 16 SECTION ON ELECTRICAL IDENTIFICATION. INSTALL WIRING BETWEEN OCPDS AND CONTROL/INDICATION DEVICES. CHECK CONNECTORS, TERMINALS, BUS JOINTS, AND MOUNTINGS FOR TIGHTNESS. TIGHTEN FIELD CONNECTED CONNECTORS AND TERMINALS, INCLUDING SCREWS AND BOLTS, IN ACCORDANCE WITH EQUIPMENT MANUFACTURER'S PUBLISHED TORQUE TIGHTENING VALUES. WHERE MANUFACTURER'S TORQUING REQUIREMENTS ARE NOT INDICATED, TIGHTEN CONNECTORS AND TERMINALS TO COMPLY WITH TIGHTENING TORQUES SPECIFIED IN UL 486A AND UL 486B. PROVIDE EQUIPMENT GROUNDING CONNECTIONS FOR INDIVIDUALLY MOUNTED OCPD UNITS AS REQUIRED BY NEC. REPORTS: PREPARE WRITTEN REPORTS ON TESTS AND OBSERVATIONS. REPORT DEFECTIVE MATERIALS AND WORKMANSHIP AND UNSATISFACTORY TEST RESULTS. INCLUDE COMPLETE RECORDS OF REPAIRS AND ADJUSTMENTS MADE. TESTS SHALL BE MADE ON ALL NEW AND EXISTING OCPD'S PROVIDED AND/OR CONNECTED UNDER THIS PROJECT IN ACCORDANCE WITH THIS SECTION. 1. LABELING: UPON SATISFACTORY COMPLETION OF TESTS AND RELATED EFFORT, APPLY A LABEL TO TESTED COMPONENTS INDICATING TEST RESULTS, DATE, AND RESPONSIBLE ORGANIZATION AND PERSON. UPON COMPLETING INSTALLATION OF THE SYSTEM, PERFORM THE FOLLOWING TESTS: 1. OVERCURRENT PROTECTIVE DEVICE RATINGS AND SETTINGS: VERIFY INDICATED RATINGS AND SETTINGS TO BE APPROPRIATE FOR FINAL SYSTEM ARRANGEMENT AND PARAMETERS. F. 1.3 INTERIOR FLUORESCENT BALLASTS: 1. PROVIDE HIGH FREQUENCY PROGRAMMED RAPID START ELECTRONIC BALLASTS FOR ALL FLUORESCENT LAMPS WITH VOLTAGE AS INDICATED ON THE PLANS AND LUMINAIRE SCHEDULE. THE BALLAST SHALL DELIVER NORMAL LAMP LIFE AND MUST BE INTERCHANGEABLE WITH ELECTROMAGNETIC BALLASTS. THE LIGHT OUTPUT SHALL NOT VARY IN RESPONSE TO AN INPUT VOLTAGE VARIANCE OF LESS THAN 10% RATED VOLTAGE. DRIVE OUTPUT SHALL BE GREATER THAN 42 KHZ WITH LAMP FLICKER LESS THAN 2%. 2. TOTAL HARMONIC DISTORTION SHALL BE LESS THAN 10% WITH THE NUMBER OF LAMPS AS IDENTIFIED PER LUMINAIRE TYPE OR AS INDICATED IN THE LUMINAIRE SCHEDULE. CREST FACTOR OF LESS THAN 1.5 AND SHALL HAVE TRANSIENT PROTECTION WHICH MEETS IEEE 587, CATEGORY A (ANSI C62.41) REQUIREMENTS. POWER FACTOR OF 0.98 OR HIGHER, AND SHALL HAVE A BALLAST EFFICIENCY OF 90% OR HIGHER. UL LISTED CLASS P AND SHALL HAVE A SOUND RATING BETTER THAN A. THE BALLAST ELECTROMAGNETIC INTERFERENCE AND RADIO FREQUENCY INTERFERENCE SHALL COMPLY WITH FCC CFR 4, PART 18 REQUIREMENTS FOR BOTH CONDUCTED AND RADIATED EMI/RFI. MINIMUM LAMP STARTING TEMPERATURE OF 0 DEGREES F. PROVIDE BALLAST WITH COLOR CODED INTEGRAL LEADS PER ANSI C82.11 FLUORESCENT DIMMING BALLASTS: SOLID STATE TYPE FOR SMOOTH DIMMING OVER A RANGE FROM 100% TO 1%, 5% OR 10% LIGHT OUTPUT AND LISTED FOR USE WITH THE SPECIFIC FLUORESCENT DIMMERS OR DIMMING SYSTEM. DIMMING BALLASTS SHALL BE LUTRON HI-LUME FOR 1%, LUTRON HI-LUME COMPACT OR TU-WIRE FOR 5%, AND LUTRON ECO-10 FOR 10% DIMMING. A. INSTALL LIGHTING AT LOCATIONS AND HEIGHTS AS INDICATED, IN ACCORDANCE WITH MANUFACTURER'S WRITTEN INSTRUCTIONS, APPLICABLE REQUIREMENTS OF NEC, NECA'S "STANDARD OF INSTALLATION", NEMA STANDARDS, AND WITH RECOGNIZED INDUSTRY PRACTICES TO ENSURE THAT LIGHTING FULFILLS REQUIREMENTS. B. PROVIDE LUMINAIRES AND/OR OUTLET BOXES WITH HANGERS TO PROPERLY SUPPORT LUMINAIRE WEIGHT. SUBMIT DESIGN OF HANGERS, METHOD OF FASTENING, OTHER THAN INDICATED OR SPECIFIED HEREIN, FOR REVIEW BY ARCHITECT. 1. LUMINAIRES SHALL BE POSITIVELY ATTACHED TO THE SUSPENDED CEILING SYSTEM. THE ATTACHMENT DEVICE SHALL HAVE A CAPACITY OF 100% OF THE LUMINAIRE WEIGHT ACTING IN ANY DIRECTION. 2. LUMINAIRES WEIGHING LESS THAN 56 POUNDS SHALL HAVE, IN ADDITION TO THE REQUIREMENTS ABOVE, TWO NO. 12 GAUGE HANGERS CONNECTED FROM THE LUMINAIRE HOUSING TO THE STRUCTURE ABOVE. THESE WIRES MAY BE SLACK. LUMINAIRES WEIGHING 56 POUNDS OR MORE SHALL BE SUPPORTED DIRECTLY FROM THE STRUCTURE ABOVE BY FOUR NO. 12 GAUGE HANGERS CONNECTED FROM THE LUMINAIRE HOUSING TO THE STRUCTURE ABOVE. C. FASTEN LUMINAIRES SECURELY TO STRUCTURAL SUPPORTS; AND ENSURE THAT PENDANT LUMINAIRES ARE PLUMB AND LEVEL. PROVIDE INDIVIDUALLY MOUNTED PENDANT LUMINAIRES LONGER THAN 2 FEET WITH TWIN STEM HANGERS. PROVIDE STEM HANGER WITH BALL ALIGNERS AND PROVISIONS FOR MINIMUM ONE INCH VERTICAL ADJUSTMENT. MOUNT CONTINUOUS ROWS OF LUMINAIRES WITH AN ADDITIONAL STEM HANGER GREATER THAN NUMBER OF LUMINAIRES IN THE ROW. PENDANT HUNG LUMINAIRES SHALL BE SUPPORTED DIRECTLY FROM THE STRUCTURE ABOVE WITH NO. 9 GAUGE WIRE OR APPROVED ALTERNATE SUPPORT WITHOUT USING THE CEILING SUSPENSION SYSTEM FOR DIRECT SUPPORT. D. SUPPORT SURFACE MOUNTED LUMINAIRES GREATER THAN 2 FEET IN LENGTH AT LEAST ONE POINT IN ADDITION TO THE OUTLET BOX STUD. E. REPLACE DEFECTIVE AND BURNED OUT LAMPS AND DEFECTIVE BALLASTS FOR A PERIOD OF ONE YEAR FOLLOWING THE DATE OF SUBSTANTIAL COMPLETION. END OF SECTION SECTION 16535 EMERGENCY LIGHTING 2. GENERAL: A. B. 1.2 A. B. 2.3 A. B. INSPECT FOR DEFECTS AND PHYSICAL DAMAGE, NRTL LABELING, AND NAMEPLATE COMPLIANCE WITH CURRENT SINGLE LINE DIAGRAM. C. 3. EXERCISE AND PERFORM OPERATIONAL TESTS OF ALL MECHANICAL COMPONENTS AND OTHER OPERABLE DEVICES IN ACCORDANCE WITH MANUFACTURER'S INSTRUCTION MANUAL. D. VERIFY INSTALLATION OF PROPER FUSE TYPES AND RATINGS IN FUSIBLE OCPD’S TO MATCH EQUIPMENT PROTECTED. OSRAM SYLVANIA ADVANCE ALL OTHER MANUFACTURERS SHALL REQUEST PRIOR APPROVAL AND SUPPLY TEST DATA FROM AN INDEPENDENT TESTING LABORATORY AND COMPARISON REPORT TO SUBSTANTIATE COMPLIANCE WITH SPECIFICATIONS AND SPECIFIED EQUIPMENT. INSTALLATION: 2. 4. G E LIGHTING OSRAM SYLVANIA PHILIPS LIGHTING COMPANY LAMPS: SECTION 16475 OVERCURRENT PROTECTIVE DEVICES 1.1 GENERAL: MATERIALS: B. MATERIALS: END OF SECTION THIS SECTION INCLUDES SECURE SUPPORT FROM THE BUILDING STRUCTURE FOR ELECTRICAL ITEMS BY MEANS OF HANGERS, SUPPORTS, ANCHORS, SLEEVES, INSERTS, SEALS, AND ASSOCIATED FASTENINGS. ALL HANGERS, SUPPORTS, STRAPS, ETC. SHALL BE CORROSION RESISTANT OR GALVANIZED WHERE EXPOSED TO MOISTURE. EXTENT, LOCATION, AND DETAILS OF LIGHTING WORK ARE INDICATED ON DRAWINGS AND IN SCHEDULES. 1. 2. 3. PROVIDE TAPE LABELS FOR IDENTIFICATION OF INDIVIDUAL RECEPTACLE AND LIGHT SWITCH WALL PLATES. LOCATE TAPE ON FRONT OF PLATE AND IDENTIFY BRANCH CIRCUIT SERVING THE RECEPTACLE. PROVIDE TAPE LABELS FOR IDENTIFICATION OF INDIVIDUAL SWITCHES OR THERMAL OVERLOAD SWITCHES WHICH SERVE AS EQUIPMENT DISCONNECTS. LOCATE THE TAPE ON THE FRONT OF THE COVER PLATE AND IDENTIFY THE BRANCH CIRCUIT SERVING THE EQUIPMENT. GENERAL: A. 1.2 WIRE MARKERS: A. SUPPORTING DEVICES INSTALLATION: ELECTRICAL BOXES ARE SHOWN ON DRAWINGS IN APPROXIMATE LOCATIONS UNLESS DIMENSIONED. VERIFY LOCATIONS OF FLOOR BOXES AND OUTLETS WITH ARCHITECTURAL DOCUMENTS PRIOR TO ROUGH-IN. EMBOSSED TAPE OR SELF-STICKING ADHESIVE BACKED NAMEPLATES WILL NOT BE PERMITTED FOR ANY APPLICATION. SECTION 16190 SHEET METAL OUTLET BOXES: NEMA OS 1, GALVANIZED STEEL LUMINAIRE AND EQUIPMENT SUPPORTING BOXES: RATED FOR WEIGHT OF EQUIPMENT SUPPORTED; INCLUDE ½ INCH MALE FIXTURE STUDS WHERE REQUIRED. BOXES SHALL HAVE 4” X 2-1/8” DEEP SQUARE BOXES AS A MINIMUM. SUPPORT BOXES FROM BUILDING STRUCTURE. C. INSTALLATION: MATERIALS: 1. 1.3 SPECIFICATION GRADE, TYPE NEMA 5-20R DUPLEX UNLESS NOTED OTHERWISE. DEVICE COVER PLATES: SMOOTH NYLON FOR FINISHED AREAS, MATCH EXISTING FACEPLATE COLOR. 120/208 VOLTS A=BLACK; B=RED; C=BLUE; NEUTRAL=WHITE; GROUND=GREEN B. 1. D. 1.1 A. RECEPTACLES: USES NOT PERMITTED INCLUDE BRANCH CIRCUIT HOME RUNS, EQUIPMENT OR MOTOR FEEDERS, EXPOSED INSTALLATIONS OR EMERGENCY SYSTEMS. USE 10 AWG CONDUCTORS FOR 20 AMPERE, 120 VOLT BRANCH CIRCUITS LONGER THAN 50 FEET TO THE FIRST FIXTURE OR DEVICE. 1.1 HANDLE: MATCH EXISTING COLOR. e. END OF SECTION INSTALLATION: 2. WEATHERPROOF COVER PLATE: HUBBELL #WP26MH NEMA 3R FOR “IN USE” PROTECTION. N. 1.3 NEMA WD 1, SPECIFICATION GRADE FS W-S-896E, 20 AMP 4. RACEWAYS SURFACE METAL RACEWAYS: WIREMOLD CO., AIREY, THOMPSON CO., B-LINE SYSTEMS, INC., ISODUCT ENERGY SYSTEMS, SQUARE D. CO., MONO-SYSTEMS, INC. 1. FOR BRANCH CIRCUIT DROPS FROM A LOCAL JUNCTION BOX ABOVE THE CEILING INTO A STUD WALL AND CASEWORK. E. INSTALL NAMEPLATES AND TAPE LABELS PARALLEL TO EQUIPMENT LINES. SECURE NAMEPLATES TO EQUIPMENT WITH SCREWS OR RIVETS FOR A PERMANENT INSTALLATION. WALL SWITCHES: d. USE CONDUCTOR NOT SMALLER THAN 12 AWG FOR POWER AND LIGHTING CIRCUITS. SUBJECT TO COMPLIANCE WITH REQUIREMENTS, PROVIDE PRODUCTS BY THE FOLLOWING MANUFACTURERS: 1. RIGID METAL CONDUIT: ALLIED, WHEATLAND, TRIANGLE, WESTERN TUBE & CONDUIT 2. STEEL FITTINGS AND CONDUIT BODIES: O/Z GEDNEY, RACO, APPLETON, EPT, STEEL CITY MANUFACTURERS: HUBBELL, LEVITON, PASS & SEYMOUR, COOPER WIRING DEVICES AND BRYANT. MATCH EXISTING FACE PLATE COLOR, STYLE AND MATERIAL. D. B. 1.2 GENERAL: GENERAL: DEGREASE AND CLEAN SURFACES TO RECEIVE NAMEPLATES AND TAPE LABELS. MANUFACTURERS-WALL SWITCHES AND RECEPTACLES: 3. USE STRANDED CONDUCTORS FOR CONTROL CIRCUITS. MATERIALS: 1.1 A. MATERIALS: FOR OUTLET-TO-OUTLET BRANCH CIRCUIT WIRING IN STUD PARTITIONS OR CASEWORK. C. A. WIRING DEVICES FOR OWNER FURNISHED EQUIPMENT: MATCH DEVICES TO PLUG CONNECTORS FOR OWNER-FURNISHED EQUIPMENT. CORD AND PLUG SETS: WHERE INDICATED, CONTRACTORS SHALL PROVIDE A LENGTH OF SO CORD COMPLETE WITH A STRAIGHT BLADE OR TWIST-LOCK RECEPTACLE FOR CONNECTION OF EQUIPMENT. CORD AND PLUG RATING SHALL BE SUITABLE FOR THE CONNECTED EQUIPMENT LOAD AND RATING OF THE BRANCH CIRCUIT OVERCURRENT PROTECTIVE DEVICE. PLUG SHALL MATCH RECEPTACLE CONFIGURATION INCLUDED ON THE PLANS AND CORD LENGTH SHALL BE AS REQUIRED. CONTRACTOR SHALL CONNECT CORD TO EQUIPMENT. c. USE SOLID CONDUCTOR FOR FEEDERS AND BRANCH CIRCUITS 10 AWG AND SMALLER. 1.4 THE EXTENT OF WIRING DEVICE WORK IS INDICATED BY DRAWINGS AND SCHEDULES. WIRING DEVICES ARE DEFINED AS SINGLE DISCRETE UNITS OF ELECTRICAL DISTRIBUTION SYSTEMS WHICH ARE INTENDED TO CARRY BUT NOT UTILIZE ELECTRIC ENERGY. GROUND FAULT RECEPTACLES SHALL BE SPECIFICATION GRADE, “FEED-THROUGH” TYPE NEMA 5-20R CONFIGURATION WITH 5 MILLIAMP TRIP. END OF SECTION SECTION 16110 A. A. 2. B. H. SECTION 16515 LIGHTING GENERAL: CONNECTIONS TO LUMINAIRES ON NON-ACCESSIBLE CEILINGS (MAX. 3 FOOT LENGTHS). USE SOLDERLESS PRESSURE CONNECTORS WITH INSULATING COVERS FOR COPPER CONDUCTOR SPLICES AND TAPS, 8 AWG AND SMALLER. 1.2 USE GANG BOX WHERE MORE THAN ONE DEVICE IS MOUNTED TOGETHER. DO NOT USE SECTIONAL BOX. USE GANG BOX WITH PLASTER RING FOR SINGLE DEVICE OUTLETS. b. M. EXTENT OF RACEWAY WORK IS INDICATED BY DRAWINGS AND SCHEDULES. PROVIDE COMPLETE CONDUIT SYSTEMS FOR ALL CONDUCTORS UNLESS OTHERWISE SPECIFIED. M. INSTALLATION: USE UL LISTED INSULATED CONNECTORS FOR COPPER CONDUCTOR SPLICES AND TAPS, 6 AWG AND LARGER. TAPE UNINSULATED CONDUCTORS AND CONNECTOR WITH ELECTRICAL TAPE TO 150 PERCENT OF INSULATION RATING OF CONDUCTOR. A. SUPPORT BOXES INDEPENDENTLY OF CONDUIT. 1.1 L. GENERAL: L. 1.1 NEATLY TRAIN AND LACE WIRING INSIDE BOXES, EQUIPMENT AND PANELBOARDS. 1.1 DO NOT FASTEN BOXES TO CEILING SUPPORT WIRES. PERFORM THE FOLLOWING TESTS IN ACCORDANCE WITH MANUFACTURER'S INSTRUCTIONS: a. INSULATION RESISTANCE TEST OF MOLDED CASE CIRCUIT BREAKERS, 600 AMPERE FRAME SIZE AND OVER AT 1000 DEGREE V D.C. FOR ONE MINUTE FROM POLE TO POLE AND FROM EACH POLE TO GROUND WITH BREAKER CLOSED AND ACROSS OPEN CONTACTS OF EACH PHASE. INSULATION RESISTANCE LESS THAN 100 MEGOHMS IS NOT ACCEPTABLE. b. MAKE INSULATION RESISTANCE TESTS OF OCPD BUSES, COMPONENTS, AND CONNECTING SUPPLY, FEEDER, AND CONTROL CIRCUITS. c. MAKE CONTINUITY TESTS OF CIRCUITS. d. VERIFY RELAY OPERATION BY INTRODUCTION OF ACCURATELY METERED CURRENTS INTO OVERCURRENT/GROUND FAULT/ AND OTHER CIRCUITRY AT VALUES WHICH WILL ENABLE ACCURATE DETERMINATION OF THE TRIPPING OR ACTIVATION VALUES. K. RETEST: CORRECT DEFICIENCIES IDENTIFIED BY TESTS AND OBSERVATIONS AND PROVIDE RETESTING OF OCPDS BY TESTING ORGANIZATION. VERIFY BY THE SYSTEM TESTS THAT SPECIFIED REQUIREMENTS ARE MET. L. UPON COMPLETION OF INSTALLATION, INSPECT OCPD’S. REMOVE PAINT SPLATTERS AND OTHER SPOTS, DIRT, AND DEBRIS. TOUCH UP SCRATCHES AND MARS OF FINISH TO MATCH ORIGINAL FINISH. M. CONDUCT A MINIMUM OF ONE DAY OF TRAINING IN OPERATION AND MAINTENANCE AS SPECIFIED UNDER IN THE PROJECT CLOSEOUT SECTION OF THESE SPECIFICATIONS. SCHEDULE TRAINING WITH AT LEAST SEVEN DAYS' ADVANCE NOTIFICATION. END OF SECTION WIRING DEVICES CONNECTORS: O Z/GEDNEY CO., AMP, INC., BURNDY CORPORATION, IDEAL INDUSTRIES, INC.3M COMPANY, THOMAS AND BETTS CORP. a. WARRANTY: THE ELECTRICAL SYSTEM INSTALLED UNDER THIS CONTRACT SHALL BE LEFT IN PROPER WORKING ORDER. REPLACE AT NO ADDITIONAL COST TO THE OWNER, ANY WORK, MATERIALS, OR EQUIPMENT WHICH EXHIBIT DEFECTS IN DESIGN, CONSTRUCTION OR WORKMANSHIP WITHIN ONE YEAR, OR AS SPECIFICALLY NOTED ELSEWHERE IN THESE SPECIFICATIONS, FROM DATE OF FINAL OWNER ACCEPTANCE. K. MATERIALS: TRAINING OF OWNER’S OPERATING AND MAINTENANCE PERSONNEL: PROVIDE TRAINING WHEN THE INSTALLATION IS COMPLETE AND AT TIMES COORDINATED WITH THE OWNER A MINIMUM OF 14-DAYS IN ADVANCE. A REPRESENTATIVE OF THE CONTRACTOR SHALL BE PRESENT FOR ALL TRAINING. USE ADJUSTABLE STEEL CHANNEL FASTENERS FOR HUNG CEILING OUTLET BOX. 5. ELECTRICAL IDENTIFICATION K. A. CHASES, OPENINGS, CUTTING AND PATCHING: CAREFULLY LAY OUT ALL WORK IN ADVANCE SO AS TO ELIMINATE WHERE POSSIBLE, CUTTING, CHANNELING, CHASING OR DRILLING OF FLOORS, WALL, PARTITIONS, CEILINGS AND ROOFS. ANY DAMAGE TO THE BUILDING, STRUCTURE, PIPING, DUCTS, EQUIPMENT OR ANY DEFACED FINISH SHALL BE REPAIRED BY SKILLED MECHANICS OF THE TRADES INVOLVED AT NO ADDITIONAL COST TO THE OWNER AND TO THE SATISFACTION OF THE ARCHITECT/ENGINEER. ANY NECESSARY CUTTING, CHANNELING, DRILLING OR WELDING AS REQUIRED FOR THE PROPER SUPPORT, CONCEALMENT, INSTALLATION OR ANCHORING OF RACEWAYS, OUTLETS, OR OTHER ELECTRICAL EQUIPMENT SHALL BE PERFORMED IN A WORKMAN LIKE MANNER AND AS PER THE DRAWINGS AND SPECIFICATIONS. 1.2 PROJECT CLOSEOUT: 2. J. SECTION 16143 THIS SECTION INCLUDES WIRES, CABLES AND CONNECTORS FOR POWER, LIGHTING, SIGNAL, CONTROL AND RELATED SYSTEMS RATED 600 VOLTS AND LESS. REMOVE ALL MATERIALS, SCRAP AND DEBRIS RELATIVE TO THE ELECTRICAL INSTALLATION AND LEAVE THE PREMISES AND ALL EQUIPMENT, LAMPS, FIXTURES, ETC. IN A CLEAN AND ORDERLY CONDITION. ANY COSTS TO THE OWNER FOR CLEAN-UP OF THE SITE NOT PROVIDED BY THE CONTRACTOR AS DEFINED IN THE DRAWINGS OR SPECIFICATIONS WILL BE CHARGED TO THE CONTRACTOR. PROVIDE A QUALIFIED REPRESENTATIVE OF THE SUPPLIER OF EACH ITEM OR SYSTEM FOR WHICH TRAINING IS SPECIFIED OR REQUIRED, FOR THE PURPOSE OF INSTRUCTING SPECIFIC PERSONNEL, AS DESIGNATED BY THE OWNER, IN THE OPERATION AND MAINTENANCE OF SUCH ITEMS OR SYSTEMS. PROVIDE STUD TO STUD SUPPORT FOR MOUNTING OUTLET BOX BETWEEN STUDS. SECTION 16195 GENERAL: CLEAN EXPOSED PANELBOARDS SURFACES AND CHECK TIGHTNESS OF ELECTRICAL CONNECTIONS. REPLACE DAMAGED CIRCUIT BREAKERS AND PROVIDE CLOSURE PLATES FOR VACANT POSITIONS. PROVIDE TYPED CIRCUIT DIRECTORY SHOWING REVISED CIRCUITING ARRANGEMENT. WORKMANSHIP: WORKMANSHIP SHALL CONFORM TO INDUSTRY STANDARDS. CONTRACTOR’S PERSONNEL AND SUB-CONTRACTOR SELECTED TO PERFORM THE WORK SHALL BE WELL VERSED AND SKILLED IN THE TRADES INVOLVED. A. CLEAN AND REPAIR EXISTING MATERIALS AND EQUIPMENT THAT REMAIN OR ARE TO BE REUSED. 1. I. END OF SECTION WIRES AND CABLE 1.1 FIRE RATED WALLS: IF ACCEPTABLE TO THE LOCAL AUTHORITY, BOXES MAY BE SPACED A MINIMUM OF 6 INCHES APART IF WRAPPED WITH UL CATEGORY CLIV PUTTY PADS TO PROVIDE A 1 OR 2 HOUR RATED FIRE STOP. END OF SECTION SECTION 16120 CLEANING AND REPAIR: STORAGE AND PROTECTION: INSTALLER'S QUALIFICATIONS: FIRMS WITH AT LEAST 2 YEARS OF SUCCESSFUL INSTALLATION EXPERIENCE WITH PROJECTS UTILIZING ELECTRICAL CONNECTIONS FOR EQUIPMENT SIMILAR TO THAT REQUIRED FOR THIS PROJECT. SURFACE RACEWAYS ARE ACCEPTABLE ONLY WHERE SPECIFICALLY INDICATED ON THE DRAWINGS. THE PROPOSED USE OF SURFACE RACEWAYS SHALL BE SUBMITTED FOR REVIEW BY THE ARCHITECT/ENGINEER PRIOR TO INSTALLATION. 1. END OF SECTION CONNECT NEW WORK TO EXISTING WORK IN A MANNER THAT WILL ASSURE PROPER RACEWAY GROUNDING THROUGHOUT IN CONFORMANCE WITH THE NATIONAL ELECTRICAL CODE. 1. 1.8 S. PAINT NEW EXPOSED SURFACE METAL RACEWAY TO MATCH ADJACENT SURFACES WHERE RACEWAY IS INSTALLED IN FINISHED AREAS SUCH AS LOBBIES, CORRIDORS AND NORMALLY OCCUPIED SPACES. WIRE AND CABLE MANUFACTURERS: AMERICAN INSULATED WIRE, ANACONDA ERICSSON INC; WIRE AND CABLE DIV., BELDEN DIV; COOPER INDUSTRIES., BRAND REX DIV; PYLE NATIONAL CO., GENERAL CABLE CORPORATION, HITEMP WIRES, INC. PHELPS DODGE CABLE AND WIRE CO., ROME CABLE CORP., SOUTHWIRE COMPANY, SUPERIOR ESSEX: TRIANGLE, EXCEL, ROYAL ALL EQUIPMENT COMPONENTS SHALL HAVE THE MANUFACTURER’S NAME, ADDRESS, MODEL NUMBER AND SERIAL NUMBER PERMANENTLY ATTACHED IN A CONSPICUOUS LOCATION. STORE PRODUCTS IN ACCORDANCE WITH MANUFACTURER’S INSTRUCTIONS, WITH SEALS AND LABELS INTACT AND LEGIBLE. STORE SENSITIVE PRODUCTS IN WEATHER-TIGHT ENCLOSURES; MAINTAIN WITHIN TEMPERATURE AND HUMIDITY RANGES REQUIRED BY MANUFACTURER’S INSTRUCTIONS. R. WHERE INDIVIDUAL CONDUITS PENETRATE EXISTING FIRE-RATED WALL AND FLOORS, PACK VOID AROUND CONDUIT WITH FIRE RATED INSULATION AND SEAL OPENING AROUND CONDUIT WITH UL LISTED FOAM SILICONE ELASTOMER COMPOUND. C. 3. 1.7 Q. FLEXIBLE CONNECTIONS: USE SHORT LENGTH (MAXIMUM OF 6 FEET) OF FLEXIBLE CONDUIT FOR RECESSED AND SEMI-RECESSED LUMINAIRES, FOR EQUIPMENT SUBJECT TO VIBRATION NOISE TRANSMISSION OR MOVEMENT; AND FOR ALL MOTORS. USE LIQUID-TIGHT FLEXIBLE CONDUIT IN WET LOCATIONS. METAL CLAD CABLE: COPPER 600 VOLT THERMOPLASTIC INSULATION RATED 90 DEGREES C, STEEL INTERLOCKED METAL TYPE ARMOR. PROVIDE MATERIALS AND EQUIPMENT ACCEPTABLE TO THE AUTHORITY HAVING JURISDICTION AND AS SUITABLE FOR THE USE INTENDED, EXCEPT WHERE MORE STRINGENT REQUIREMENTS ARE INDICATED BY THE CONTRACT DOCUMENTS. E. F. B. MATERIALS AND EQUIPMENT: DEFECTIVE OR DAMAGED MATERIALS SHALL BE REPLACED OR REPAIRED, PRIOR TO FINAL ACCEPTANCE, IN A MANNER ACCEPTABLE TO THE ARCHITECT/ENGINEER OR OWNER AND AT NO ADDITIONAL COST TO THE OWNER. PROVIDE PULL STRING IN EACH EMPTY CONDUIT. CIRCUITS OR SYSTEMS WIRING SHALL NOT PASS THOUGH OUTLET OR JUNCTION BOXES THAT MAY BE RENDERED INACCESSIBLE BY CHANGES MADE TO THE BUILDING. MAINTAIN ACCESS TO EXISTING ELECTRICAL INSTALLATIONS THAT ARE TO REMAIN ACTIVE. MODIFY INSTALLATION OR PROVIDE ACCESS PANEL AS APPROPRIATE. PAY FOR ALL FEES AND ELECTRICAL PERMITS, PLAN REVIEW AND INSPECTIONS FROM AUTHORITY HAVING JURISDICTION. PROVIDE ALL NOTICES NECESSARY IN CONNECTION THEREWITH. WORK SHALL NOT BE COVERED BEFORE INSPECTIONS BY THE JURISDICTIONAL AUTHORITIES AND OBSERVATION BY THE OWNER/ENGINEER. D. N. I. COMPLY WITH REQUIREMENTS OF THE UTILITY, (POWER, TELEPHONE AND COMMUNICATIONS) COMPANIES FURNISHING SERVICE TO THIS INSTALLATION. ALL EQUIPMENT AND MATERIALS INSTALLED SHALL BE NEW AND COMPLETE, THOROUGHLY CLEANED, CHECKED, CORRECTLY ADJUSTED AND LEFT READY FOR INTENDED USE OR OPERATION. EXTERIOR SURFACES OF ALL MATERIAL AND EQUIPMENT SHALL BE PROVIDED IN UNBLEMISHED CONDITION UNLESS OTHERWISE SPECIFIED. MANUFACTURED PRODUCTS SHALL BE STANDARD CATALOGED ITEMS WHICH HAVE BEEN IN PRODUCTION FOR A PERIOD NOT LESS THAN FIVE (5) YEARS PRIOR TO DATE FOR RECEIPT OF BIDS OR PROPOSALS. DO NOT FASTEN SUPPORTS TO PIPING, DUCTWORK, MECHANICAL EQUIPMENT OR CONDUIT. BUILDING WIRE: COPPER 600 VOLT THERMOPLASTIC INSULATION RATED 90 DEGREES C, TYPE THHN/THWN. INTERNATIONAL BUILDING CODE (IBC) INCLUDING LOCAL AMENDMENTS AND APPLICABLE REQUIREMENTS OF THE LOCAL FIRE DEPARTMENT, PREVENTION BUREAU OR FIRE MARSHAL. EQUIPMENT LAYOUTS ARE BASED ON USE OF EQUIPMENT AS SPECIFIED. IF THE CONTRACTOR CHOOSES EQUIPMENT FROM ANOTHER LISTED MANUFACTURER, THE CONTACTOR SHALL BE SOLELY RESPONSIBLE FOR FIRST ASCERTAINING THAT THE PROPOSED EQUIPMENT CAN BE INSTALLED IN THE SPACE AVAILABLE WITH CODE AND MAINTENANCE CLEARANCE. K. A. D. 1.6 LOCATE OUTLET BOXES TO ALLOW LUMINAIRES POSITIONED AS SHOWN ON REFLECTED CEILING PLAN. REPAIR TO ORIGINAL CONDITION ADJACENT CONSTRUCTION AND FINISHES DAMAGED DURING DEMOLITION AND EXTENSION WORK. C. B. E. PRIOR TO DEMOLITION, VERIFY CIRCUITING AND VERIFY THAT ABANDONED WIRING AND EQUIPMENT SERVE ONLY ABANDONED FACILITIES. MAINTAIN ELECTRICAL CONTINUITY TO REMAINING WIRING AND EQUIPMENT. PROVIDE LISTED FITTINGS TO ACCOMMODATE EXPANSION AND DEFLECTION WHERE CONDUIT CROSSES SEISMIC, CONTROL AND EXPANSION JOINTS. H. B. 3. M. P. THE DRAWINGS AND SPECIFICATIONS TAKE PRECEDENCE WHEN THEY ARE MORE STRINGENT THAN ADOPTED CODES, AMENDMENTS OR STATUTES. ALL WORK SHALL BE EXECUTED IN ACCORDANCE WITH THOSE EDITIONS OF THE FOLLOWING AS CURRENTLY ADOPTED BY THE LOCAL AND STATE AUTHORITY HAVING JURISDICTION: 1. NFPA, ADA, UL, IEEEE, NEMA, CBM, ANSI, NECA, ICEA AND NETA. 2. REMODELING PROVISIONS: EXTENT OF EMERGENCY EGRESS AND EXIT SIGNAGE IS INDICATED BY DRAWINGS AND SPECIFICATIONS. TYPES OF EMERGENCY LUMINAIRES IN THIS SECTION INCLUDE THE FOLLOWING: 1. EXIT LIGHTS 2. EMERGENCY FLUORESCENT LAMP POWER SUPPLY. MATERIALS: ACCEPTABLE MANUFACTURERS FOR EMERGENCY FLUORESCENT LAMP POWER SUPPLIES: a. BODINE b. DUAL LITE INC. c. LITHONIA LIGHTING INC. d. SILTRON ILLUMINATION INC. GENERAL: PROVIDE SELF CONTAINED BATTERY POWERED INVERTOR UNIT FOR DIRECT MOUNTING IN DESIGNATED FLUORESCENT LUMINAIRES. PROVIDE UNIT WITH FULLY AUTOMATIC TWO RATE CHARGER, NICKEL CADMIUM BATTERY, AC "ON" PILOT LIGHT, AND TEST SWITCH. UNIT SHALL AUTOMATICALLY TRANSFER TO BATTERY SUPPLY ON LOSS OF NORMAL AC POWER AND SHALL OPERATE ONE OR TWO RAPID START F32 FLUORESCENT LAMPS WITH MINIMUM OUTPUT OF 1350 LUMENS. UNIT SHALL HAVE MINIMUM OUTPUT OF 3000 LUMENS FOR SINGLE HIGH OUTPUT LAMP APPLICATIONS. UNIT SHALL BE RATED FOR THE ANTICIPATED MINIMUM AMBIENT TEMPERATURE FOR THE INTENDED INSTALLATION LOCATION. INSTALLATION: INSTALL EMERGENCY LIGHTING UNITS AT LOCATIONS AND HEIGHTS AS INDICATED, IN ACCORDANCE WITH MANUFACTURER'S WRITTEN INSTRUCTIONS, APPLICABLE REQUIREMENTS OF NEC, NECA'S "STANDARD OF INSTALLATION", NEMA STANDARDS, AND WITH RECOGNIZED INDUSTRY PRACTICES TO ENSURE THAT LIGHTING FULFILLS REQUIREMENTS. COORDINATE MOUNTING OF TEST SWITCH INDICATOR LIGHT AND BALLAST PRIOR TO INSTALLATION. PROVIDE REMOTE BATTERY POWERED UNITS WHERE MINIMUM AMBIENT TEMPERATURES ARE BELOW OPERATING TEMPERATURE OF THE UNIT. PROVIDE WIRING AS SHORT AND DIRECT AS POSSIBLE BETWEEN BATTERY UNIT AND LAMPS SERVED AND WITHIN MANUFACTURERS PUBLISHED REQUIREMENTS. UPON COMPLETION OF INSTALLATION OF EMERGENCY LIGHTING AND AFTER BUILDING CIRCUITRY HAS BEEN ENERGIZED WITH NORMAL POWER SOURCE, APPLY ELECTRICAL ENERGY TO DEMONSTRATE CAPABILITY AND COMPLIANCE WITH REQUIREMENTS. TEST EMERGENCY LIGHTING TO DEMONSTRATE OPERATION UNDER EMERGENCY CONDITIONS. WHERE POSSIBLE, CORRECT MALFUNCTIONING UNITS AT SITE, THEN RETEST TO DEMONSTRATE COMPLIANCE; OTHERWISE, REMOVE AND REPLACE WITH NEW UNITS, AND PROCEED WITH RETESTING. REILLY JOHNSON ARCHITECTURE COPYRIGHT C 2008 DRAWN CHECKED JAH JAH DRAWING TITLE March 1, 2010 E0.2 REILLY JOHNSON ARCHITECTURE COPYRIGHT C 2008 DRAWN CHECKED JAH JAH DRAWING TITLE March 1, 2010 E1.1