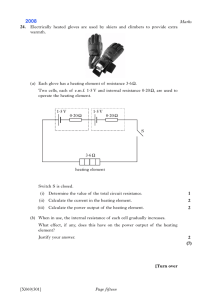

Industrial heating hoses

advertisement