World appl. programming, Vol(6), No (1), March, 2016. pp. 1-4

TI Journals

ISSN:

World Applied Programming

2222-2510

www.tijournals.com

Copyright © 2016. All rights reserved for TI Journals.

Dynamic Hysteresis Band Fixed Frequency Current Control

Masoud Sabaghi*

Laser and Optics Research School, Nuclear Science and Technology Research Institute (NSTRI), Tehran, Iran.

Mohsen Dashtbayazi

Department of Electrical Engineering, Ferdowsi University of Mashhad, Mashhad, Iran.

Saeid Marjani

Department of Electrical Engineering, Ferdowsi University of Mashhad, Mashhad, Iran.

*Corresponding author: msabaghi@aeoi.org.ir

Keywords

Abstract

Current Hysteresis Control

Fixed Frequency CHC

Switching Power Supply

In this paper a new structure of Current Hysteresis Control has been proposed in which a variable hysteresis

band is used in such a way that decreases frequency variations of the current hysteresis control. The

proposed current hysteresis control is called Dynamic Current Hysteresis Control. The proposed method is

simple to be fully digitally implemented. The results were satisfying.

1.

Introduction

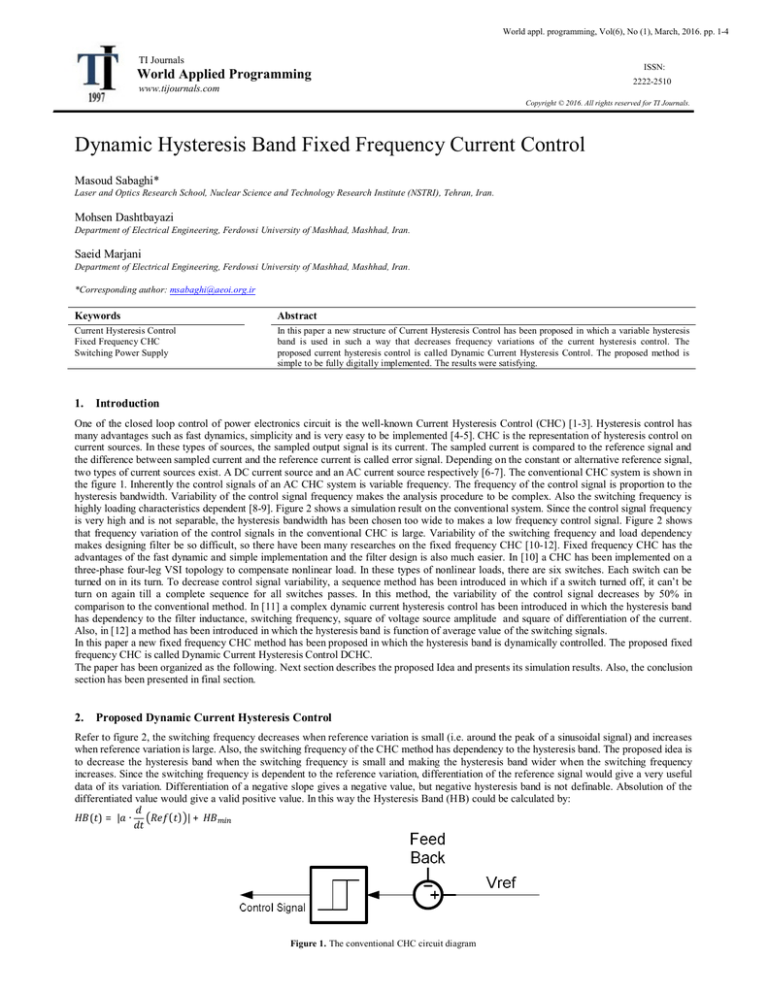

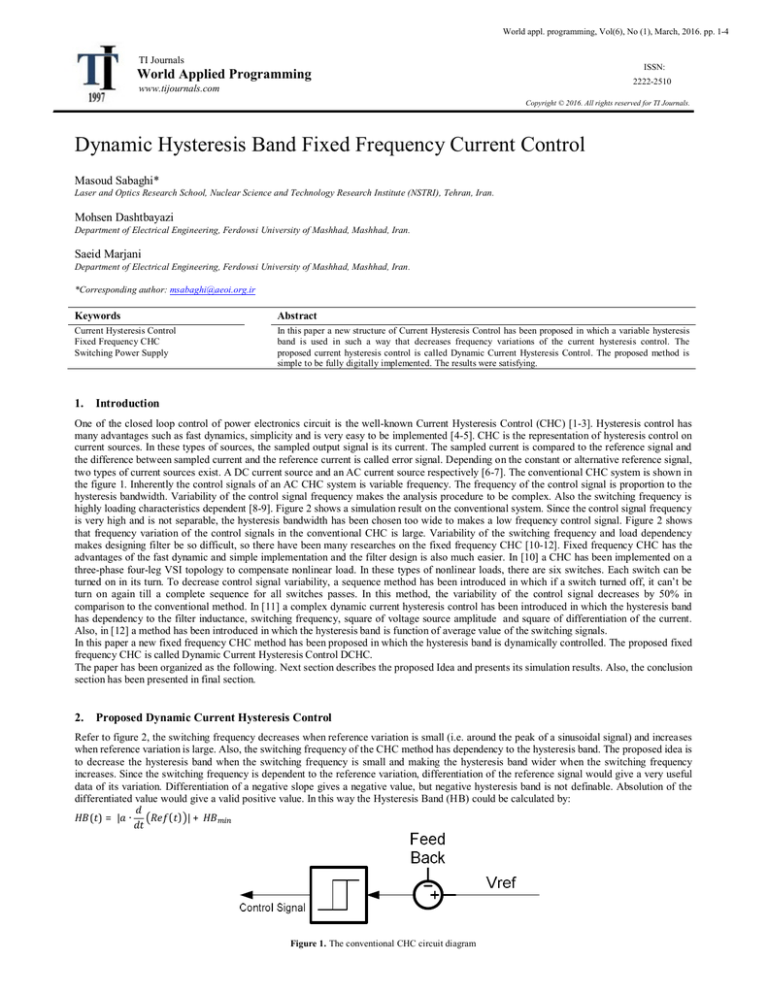

One of the closed loop control of power electronics circuit is the well-known Current Hysteresis Control (CHC) [1-3]. Hysteresis control has

many advantages such as fast dynamics, simplicity and is very easy to be implemented [4-5]. CHC is the representation of hysteresis control on

current sources. In these types of sources, the sampled output signal is its current. The sampled current is compared to the reference signal and

the difference between sampled current and the reference current is called error signal. Depending on the constant or alternative reference signal,

two types of current sources exist. A DC current source and an AC current source respectively [6-7]. The conventional CHC system is shown in

the figure 1. Inherently the control signals of an AC CHC system is variable frequency. The frequency of the control signal is proportion to the

hysteresis bandwidth. Variability of the control signal frequency makes the analysis procedure to be complex. Also the switching frequency is

highly loading characteristics dependent [8-9]. Figure 2 shows a simulation result on the conventional system. Since the control signal frequency

is very high and is not separable, the hysteresis bandwidth has been chosen too wide to makes a low frequency control signal. Figure 2 shows

that frequency variation of the control signals in the conventional CHC is large. Variability of the switching frequency and load dependency

makes designing filter be so difficult, so there have been many researches on the fixed frequency CHC [10-12]. Fixed frequency CHC has the

advantages of the fast dynamic and simple implementation and the filter design is also much easier. In [10] a CHC has been implemented on a

three-phase four-leg VSI topology to compensate nonlinear load. In these types of nonlinear loads, there are six switches. Each switch can be

turned on in its turn. To decrease control signal variability, a sequence method has been introduced in which if a switch turned off, it can’t be

turn on again till a complete sequence for all switches passes. In this method, the variability of the control signal decreases by 50% in

comparison to the conventional method. In [11] a complex dynamic current hysteresis control has been introduced in which the hysteresis band

has dependency to the filter inductance, switching frequency, square of voltage source amplitude and square of differentiation of the current.

Also, in [12] a method has been introduced in which the hysteresis band is function of average value of the switching signals.

In this paper a new fixed frequency CHC method has been proposed in which the hysteresis band is dynamically controlled. The proposed fixed

frequency CHC is called Dynamic Current Hysteresis Control DCHC.

The paper has been organized as the following. Next section describes the proposed Idea and presents its simulation results. Also, the conclusion

section has been presented in final section.

2.

Proposed Dynamic Current Hysteresis Control

Refer to figure 2, the switching frequency decreases when reference variation is small (i.e. around the peak of a sinusoidal signal) and increases

when reference variation is large. Also, the switching frequency of the CHC method has dependency to the hysteresis band. The proposed idea is

to decrease the hysteresis band when the switching frequency is small and making the hysteresis band wider when the switching frequency

increases. Since the switching frequency is dependent to the reference variation, differentiation of the reference signal would give a very useful

data of its variation. Differentiation of a negative slope gives a negative value, but negative hysteresis band is not definable. Absolution of the

differentiated value would give a valid positive value. In this way the Hysteresis Band (HB) could be calculated by:

( )=| ∙

( ) |+

Figure 1. The conventional CHC circuit diagram

Masoud Sabaghi *, Mohsen Dashtbayazi, Saeid Marjani

2

World Applied Programming Vol(6), No (1), March, 2016.

Figure 2. Signaling of the conventional CHC

Figure 3. The proposed DCHC method

In which, ‘Ref(t)’ is the reference signal, ‘a’ is scaling factor for the differentiation and ‘HBmin’ is minimum value of the hysteresis band. The

block diagram of the proposed idea is shown in the figure 3.

Since most of the currently commercialized switching power supplies are using microcontrollers as their processors, differentiation should be

calculated in discreet time domain. In this way the differentiation could be calculated by:

( )=

( )−

( − 1)

And for the absolution, it is calculated by:

(

}

( ) < 0){

( )=

( − 1) −

( )

Obviously implementation of the proposed idea is pretty simple and does not need a special processor.

3.

Simulation Results

To simulate the proposed idea a half-bridge topology has been chosen. The HB min and the scaling factor ‘a’ are chosen in such a way that the

switching frequency has a small variation. Figure 4 shows the simulation result for the HB min=0.1A and a=2.

To show effect of HBmin on the frequency variation it has been swept. The simulation result is shown in the figure 5. Maximum switching

frequency and minimum switching frequency are shown in the figure 5. Obviously decreasing the HBmin maximizes the lower boundary of the

switching frequency and as a result, the difference between upper boundary and the lower boundary decreases.

To show effect of sweeping ‘a’ on the frequency variation a simulation result is shown in the figure 6. Both maximum switching frequency and

minimum switching frequency are depicted in the figure 6. Obviously increasing the ‘a’ decreases the lower and upper boundaries of the

switching frequency and as a result, the variation of the switching frequency decreases.

If the conventional CHC method being applied on the circuit with same parameters as load, the minimum frequency boundary and the upper

frequency boundary would be 1.2 KHz and 5.5 KHz respectively. Hence the frequency variation is much larger than the proposed circuit. In the

proposed circuit, the frequency variation is less than 1 KHz. It means the frequency variation in the proposed circuit is less than 23% in

comparison to the conventional method. To compare the proposed DCHC with the conventional CHC method, a simulation result in which

various inductors as the load has been applied, is depicted in figure 7. It is completely obvious that the proposed idea decreased the frequency

variations and as a result there is less load dependency. In figure 8, for loads with more than 5mH inductance, the proposed method decreases the

frequency variability to less than 10%. Also, this factor is less than 20% for loads with inductance more than 2mH. In comparison to [10] the

frequency variability of the proposed method is much less than 50% variability which is presented in [10] with less complexity than the methods

in [10-12]. The proposed method is fully digital implementable on every normal processors. In the proposed method only differentiation of the

reference current is needed and it can be also as a lookup table to avoid online calculation.

3

Dynamic Hysteresis Band Fixed Frequency Current Control

World Applied Programming Vol(6), No (1), March, 2016.

Figure 4. Simulation result for HB min=0.1 and a=2

Figure 5. Simulation result sweeping HBmin and a=3

Figure 6. Simulation result for sweeping ‘a’ and HB min=0.05

Figure 7. Simulation result for sweeping load inductance and for the proposed DCHC, HB min=0.05 and a=3

Masoud Sabaghi *, Mohsen Dashtbayazi, Saeid Marjani

4

World Applied Programming Vol(6), No (1), March, 2016.

4.

Conclusion

In this paper a method has been studied which decreased the frequency variations of the CHC method effectively. The proposed idea is fully

digital implementable and doesn’t need any extra component outside of the processor.

References

[1]

Srikanthan, S.; Mishra, M.K.; Rao, R.K.V., "Improved hysteresis current control of three-level inverter for distribution static compensator application,"

Power Electronics, IET , vol.2, no.5, pp.517,526, Sept. 2009

[2] Li Jun; Wang Dazhi, "A Novel Hysteresis Current Controller Based on ITAE Optimal Control," Power and Energy Engineering Conference (APPEEC),

2010 Asia-Pacific , vol., no., pp.1,4, 28-31 March 2010

[3] Vazquez, G.; Rodriguez, P.; Ordonez, R.; Kerekes, T.; Teodorescu, R., "Adaptive hysteresis band current control for transformerless single-phase PV

inverters," Industrial Electronics, 2009. IECON '09. 35th Annual Conference of IEEE , vol., no., pp.173,177, 3-5 Nov. 2009

[4] Hai Lin; Lipo, T.A.; Byung-Il Kwon; Cheon, S.R., "Three-level hysteresis current control for a three-phase permanent magnet synchronous motor drive,"

Power Electronics and Motion Control Conference (IPEMC), 7th International , vol.2, no., 2012

[5] Ma Feng; Li Lei, "Research on constant-frequency hysteresis current control in differential three-level grid-connected inverter," IECON 2012 - 38th Annual

Conference on IEEE Industrial Electronics Society , vol., no., pp.730,733, 25-28 Oct. 2012

[6] Elsaharty, M.A.; Hamad, M.S.; Ashour, H.A., "Digital hysteresis current control for grid-connected converters with LCL filter," IECON 2011 - 37th Annual

Conference on IEEE Industrial Electronics Society , vol., no., pp.4685,4690, 7-10 Nov. 2011

[7] Shahalami, Seyed Hamid, "Special proposed hysteresis control method of current source inverter asynchronous drives," Power Electronic & Drive Systems

& Technologies Conference (PEDSTC), 2010 1st , vol., no., pp.235,242, 17-18 Feb. 2010

[8] Davoodnezhad, R.; Holmes, D.G.; McGrath, B.P., "A fully digital hysteresis current controller for current regulation of grid connected PV inverters," Power

Electronics for Distributed Generation Systems (PEDG), 2014 IEEE 5th International Symposium on , vol., no., pp.1,8, 24-27 June 2014

[9] Yihua Hu; Yan Deng; Quanwei Liu; Xiangning He, "Asymmetry Three-Level Gird-Connected Current Hysteresis Control With Varying Bus Voltage and

Virtual Oversample Method," Power Electronics, IEEE Transactions on , vol.29, no.6, pp.3214,3222, June 2014

[10] Prabhakar, N.; Mishra, M.K., "Dynamic Hysteresis Current Control to Minimize Switching for Three-Phase Four-Leg VSI Topology to Compensate

Nonlinear Load," Power Electronics, IEEE Transactions on , vol.25, no.8, pp.1935,1942, Aug. 2010

[11] Vahedi, H.; Pashajavid, E.; Al-Haddad, K., "Fixed-band fixed-frequency hysteresis current control used In APFs," IECON 2012 - 38th Annual Conference

on IEEE Industrial Electronics Society , vol., no., pp.5944,5948, 25-28 Oct. 2012

[12] Holmes, D.G.; Davoodnezhad, R.; McGrath, B.P., "An Improved Three-Phase Variable-Band Hysteresis Current Regulator," Power Electronics, IEEE

Transactions on , vol.28, no.1, pp.441,450, Jan. 2013