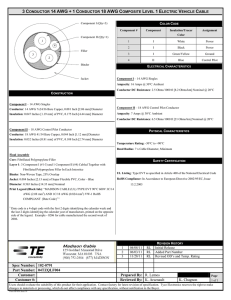

Electronics Cable Catalog

advertisement