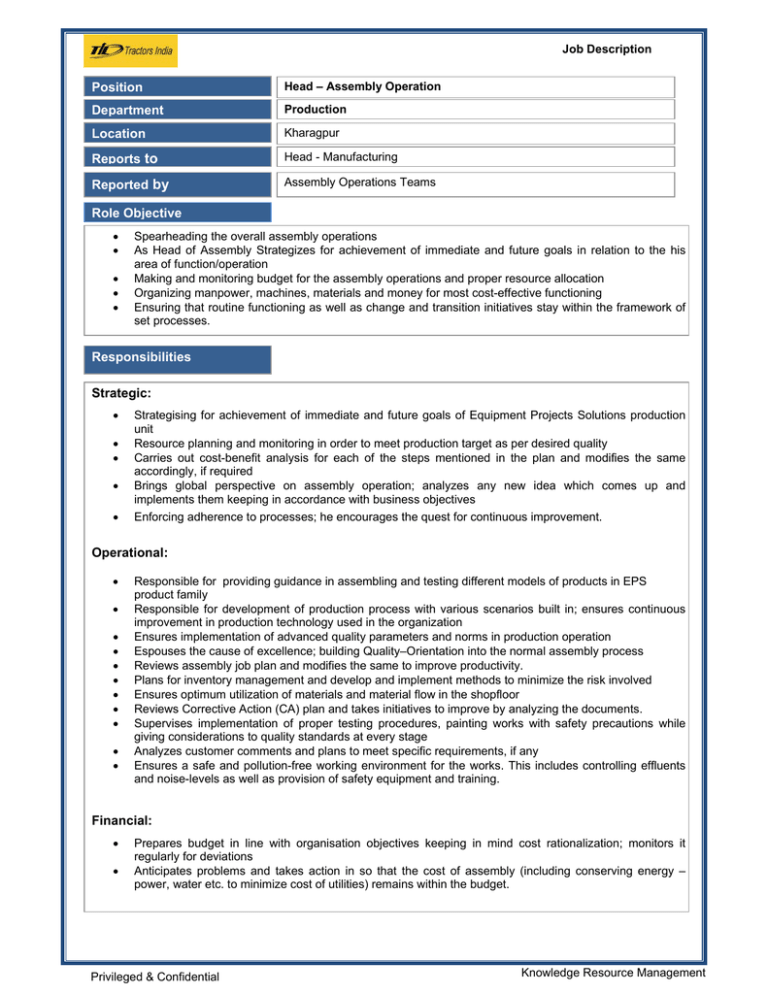

Head-Assembly-Operat..

advertisement

Job Description Position Head – Assembly Operation Department Production Location Kharagpur Reports to Head - Manufacturing Reported by Assembly Operations Teams Role Objective • • • • • Spearheading the overall assembly operations As Head of Assembly Strategizes for achievement of immediate and future goals in relation to the his area of function/operation Making and monitoring budget for the assembly operations and proper resource allocation Organizing manpower, machines, materials and money for most cost-effective functioning Ensuring that routine functioning as well as change and transition initiatives stay within the framework of set processes. Responsibilities Strategic: • • • • • Strategising for achievement of immediate and future goals of Equipment Projects Solutions production unit Resource planning and monitoring in order to meet production target as per desired quality Carries out cost-benefit analysis for each of the steps mentioned in the plan and modifies the same accordingly, if required Brings global perspective on assembly operation; analyzes any new idea which comes up and implements them keeping in accordance with business objectives Enforcing adherence to processes; he encourages the quest for continuous improvement. Operational: • • • • • • • • • • • Responsible for providing guidance in assembling and testing different models of products in EPS product family Responsible for development of production process with various scenarios built in; ensures continuous improvement in production technology used in the organization Ensures implementation of advanced quality parameters and norms in production operation Espouses the cause of excellence; building Quality–Orientation into the normal assembly process Reviews assembly job plan and modifies the same to improve productivity. Plans for inventory management and develop and implement methods to minimize the risk involved Ensures optimum utilization of materials and material flow in the shopfloor Reviews Corrective Action (CA) plan and takes initiatives to improve by analyzing the documents. Supervises implementation of proper testing procedures, painting works with safety precautions while giving considerations to quality standards at every stage Analyzes customer comments and plans to meet specific requirements, if any Ensures a safe and pollution-free working environment for the works. This includes controlling effluents and noise-levels as well as provision of safety equipment and training. Financial: • • Prepares budget in line with organisation objectives keeping in mind cost rationalization; monitors it regularly for deviations Anticipates problems and takes action in so that the cost of assembly (including conserving energy – power, water etc. to minimize cost of utilities) remains within the budget. Privileged & Confidential Knowledge Resource Management Job Description • Proper resource allocation in terms of manpower, raw materials, inventory planning and monitoring • Effective cost rationalization by reducing re-work and redo. People: • • • • • • Assumes overall responsibilities to develop motivate and lead his team and establish mechanisms to groom potential employees Ensures timely implementation of Performance Management Systems as per guidelines. Takes initiatives and encourages team to undergo technical trainings to upgrade their skill levels. Provides inputs to individual developmental plan of all the subordinates and also evaluate the effectiveness of the training provided. Ensures optimum allocation of resource. Monitors the initiation steps to demonstrate cultural change and enhancing image building of the organization. Internal Interface • All related internal departments External Interface • • • Experience Education • • 10-15 years of relevant experience in related industry • Minimum experience of 5 years in heavy engineering industry BE / B-Tech in Mechanical Behavioural Skills Functional Skills • • • • • Understanding of heavy industry related products Production process understanding Planning & Scheduling Assembly process understanding Environment, Health & Safety understanding Privileged & Confidential Customer Collaborator Supplier and Vendors • • • • • • • • Customer Orientation Change Management Execution Excellence Achievement Orientation Decision Making Personal Effectiveness Impact and Influence Nurturing Teams Knowledge Resource Management