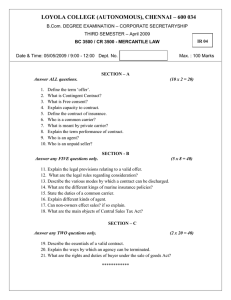

Novation MCHE

A L U M I N I U M M I C R O C H A N N E L H E AT E X C H A N G E R

Novation

®

MICROCHANNEL

The ultimate technology for various environments

Carrier introduces leading innovation for the HVAC industry

In 2006, Carrier was the first to introduce microchannel (MCHE) technology in the Commercial Air Conditioning industry. Already used in the automobile and aeronautical industry for many years, MCHE heat exchangers are entirely made of aluminium. Since 2011, a new generation of microchannel is available: NOVATION ® . Extending microchannel technology, Carrier offers exclusive coating solutions for various corrosive environments.

Superior reliability Factory Standard*

Fins

Tubes

■

Superior corrosion resistance due to one-piece material construction when compared to conventional Cu/Al coils. This significantly increases corrosion resistance by eliminating the galvanic currents that are created when two different metals (copper and aluminium) come into contact in traditional heat exchangers.

■

Superior mechanical resistance due to microchannel manufacturing process.

■

Superior reliability assembly

Coil brazed automatically in oven. Only one braze compared to conventional coils (up to 300 manual braze connections).

■

Proven technology used in the automobile and aeronautical industries for decades.

Manifold

Microchannel

Environmental

■

Up to 50% refrigerant charge reduction vs. traditional Cu/Al coils.

■

Better thermal performance vs. Cu/Al coils

Better efficiency and lower air pressure drop vs. Cu/Al coils.

■

Light weight reducing CO

2

environmental impact during transport.

■

Thinner to reduce air pressure losses by 50% and fan energy consumption.

■

Reduced fouling maintaining unit performance over the time.

* The warranty period for microchannel coils is 3 years from the date of factory assembly completion. Refer to contract for details on warranty coverage.

Coupling on MCHE

(Metal washer patent)

Zn-Ni plated steel

Copper tube

Metal washer

+ EPDM

Aluminium

ELIMINATE GALVANIC CORROSION

Now available on all Carrier Air Cooled Chillers

30RBS 30RB 30RBM / 30RBP 30XA / 30XAV

An appropriate coating process

M I C R O C H A N N E L C O I L S S t a n d a r d

MCHE coils are constructed utilizing all-aluminum alloys with brazed fin construction. MCHE standard coils are suitable for any non corrosive environments. In addition to standard MCHE coils,

Carrier offers Enviro-Shield ® and Super Enviro-Shield ® anti-corrosion protections as options to increase the application range of MCHE coils to mildly and severe corrosive environments.

E n v i r o - S h i e l d ® c o a t i n g

Enviro-Shield ® coating provides protection against many corrosive atmospheres.

Enviro-Shield ® is a nano-scale conversion coating which uniformly covers the entire surface of the coil. The coating is integral to the MCHE and will not flake or lose adhesion. The thin coating causes no variation in heat transfer or air flow.

Enviro-Shield ® utilizes corrosion inhibitors which actively arrest oxidation due to environmental or mechanical damage.

With Enviro-Shield ® protection, corrosion resistance of the MCHE coil is doubled without any impact on heat exchange performance.

Carrier Coil

Treatment is applied by

immersion (not spray or a vernish) which provides a reliable and complete protective

coverage.

Cleaning Water

Rinse

Enviro- shield ®

Conversion

Coating

Final

Rinse

S u p e r E n v i ro - S h i e l d ® c o a t i n g

Super Enviro-Shield ® coating provides superior protection against extreme corrosive atmospheres. Super Enviro-Shield ® MCHE coils have an extremely durable and flexible epoxy coating uniformly applied over all coil surfaces for complete isolation from the contaminated environment. A consistent coating is achieved through a precisely controlled electro coating process that bonds a thin, impermeable epoxy coating to the specially prepared coil surfaces.

Mastering the technology, integrated manufacturing:

Coil treatments directly applied during MCHE final manufacturing process before equipment assembly.

Transparent

Corrosion resistance* x 2

Degreasing Water

Rinse

E-Coat Final

Rinse

Oven

Bake

UV

Topcoat

*Testing by Carrier : Result of ASTM G85 and patented Carrier Marine accelerated corrosion testing.

ASTM G85, A3 – 600 hours, Proprietary Immersion Test – 2500 hours, Patented CM1 Salt Fog Test – 2000 hours, Beachfront Exposure – 2 years

Black

Corrosion resistance* x 4

...suited for every environment !

Urban

Light

corrosive environment

Low

Severity of environmental factors

Severe

Pollution level*

125 µg/m 3

50 µg/m 3

20 µg/m 3

MCHE COILS

Standard ✔

Enviro-Shield ®

MCHE Coils ✔

Super

Enviro-Shield ®

MCHE Coils

✔

*SO2 levels in cities with > 50 000 habitants

Industrial

Mildly

corrosive environment

Low

Severity of environmental factors

Severe

Coastal

Severe

corrosive environment

Severe

Severity of environmental factors

Low

Contaminant

Concentration

in ppm (parts per million)

100 ppm

50 ppm

0 ppm

MCHE COILS

Standard ✔

Enviro-Shield ®

MCHE Coils ✔

Super

Enviro-Shield ®

MCHE Coils

✔

Distance from coast

> 3 km

400 m

3 km

MCHE COILS

Standard

Enviro-Shield ®

MCHE Coils

✔

✔

Super

Enviro-Shield ®

MCHE Coils

✔

Information in those tables are provided as a guide; contact a Carrier Sales Engineer for a software selection.

Your expectations are at the core of Carrier Service engagement

Carrier Service is committed to protect your investment while, at the same time, reducing your operating costs.

Carrier Service proposes a comprehensive and sustainable preventive maintenance program, to protect the critical components of your chiller: regular inspections and preventive maintenance are key to ensure and enhance the efficiency and reliability advantages that microchannel ultimate technology can offer.

Moreover in situations where the environment can lead to excessive or early corrosion, Carrier comprehensive solutions provide a unique opportunity to:

■ Increase the life of coils

■ Prevent premature breakdowns

■ Reduce energy consumption

■ Improve efficiency of operations

Carrier Service coverage spans more than 180 countries, with regional and local branches throughout Europe.

Top-trained technicians are accessible 24 hours a day, 365 days a year, ready to respond to your requests and address your needs.

Carrier Service offer represents a unique, fully comprehensive model including:

■ Experienced and knowledgeable technicians

■ Consolidated and efficient maintenance process

■ First class factory certified products

FACTORY

AUTHORIZED

PARTS

Carrier Service teams propose a unique expertise built on a 110 years experience by your side.

Specific cleaning and repair kits have been developed by Carrier to ensure appropriate maintenance and efficiency of Novation ®

Microchannel.

To learn more about Carrier Service Solutions, please contact your Carrier representative or visit www.carrier.com

Carrier, for the environment

Carrier believes that industry leadership demands environmental leadership. In fact, environmental stewardship is one of Carrier’s core values. Carrier continuously works to improve the environmental performance of its products and services, operations and culture to help achieve a sustainable society.

Carrier, for performance

Carrier strives for continuous growth to reinforce its leadership position, achieve world-class financial performance and continuously improve the productivity of its assets and resources.

Carrier, for service

The Carrier service delivery model maintains a reputation for high customer satisfaction and delivers service excellence with strong communication channels, industryleading technicians, continuous improvement of contracts and a highly experienced management team.

Carrier, for innovation

Carrier is a company of ideas, committed to research and development, whose founder inspires the company to reach the next innovative, powerful and marketable idea.

Carrier, to be your expert

Carrier delivers global solutions across the broadest range of heating, cooling and refrigeration applications. With a proven track record of leadership and industry expertise, we are here to meet your needs with our portfolio of market-leading products and services.

www.carrier.com