Brochure

advertisement

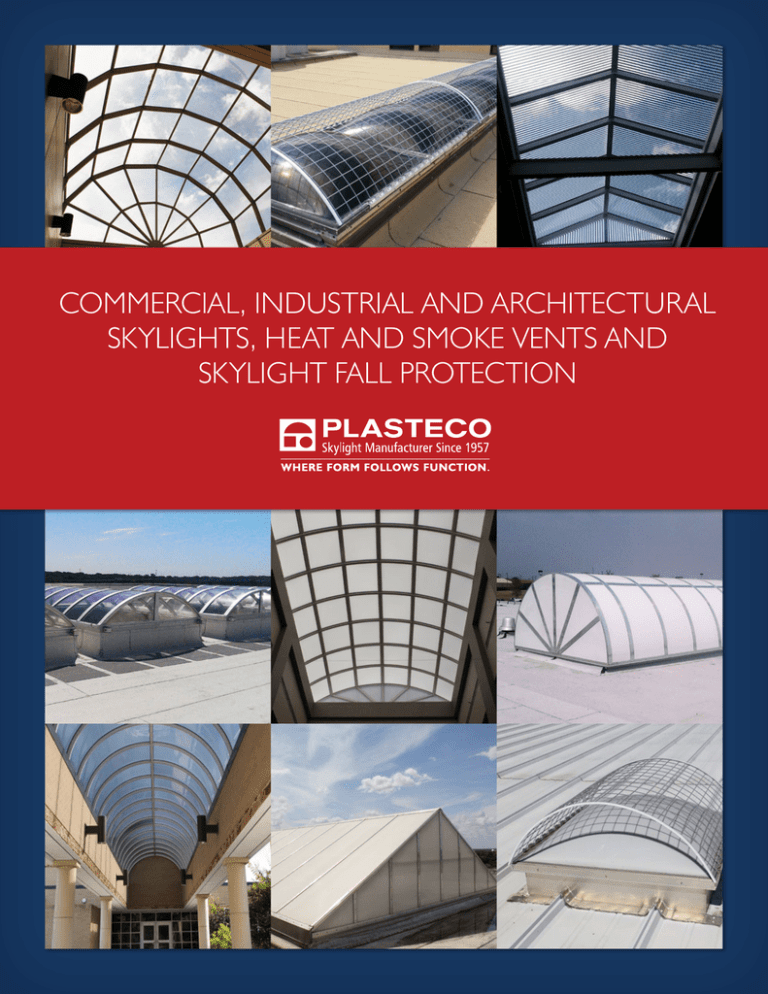

COMMERCIAL, INDUSTRIAL AND ARCHITECTURAL SKYLIGHTS, HEAT AND SMOKE VENTS AND SKYLIGHT FALL PROTECTION OVER 50 YEARS OF INNOVATION & DESIGN Plasteco Acrylic, Polycarbonate/Glass Units and Structural Skylights Would you like to add more natural light to your building? Brighten your space by adding skylights from Plasteco. Based in Houston and run by the same management team, Plasteco has been manufacturing and providing skylights across Texas since 1957. As Houston’s most trusted source for skylight engineering, manufacturing and installation, Plasteco provides the highest quality product in the industry, proven to withstand the test of time. Whether you want to add skylights to new construction or retrofit an existing skylight design, trust the professionals at Plasteco with all your skylight needs. Daylighting with Plasteco Skylights Daylight from skylights is free and is our coolest source of illumination, offering more light per unit of heat than any other source and providing about three times the amount of daylight as windows. Daylighting provided by skylights does not require the consumption of fuels and does not pollute the atmosphere. Skylights provide more lumens per BTU than artificial lighting. For the same lighting level, solar heat gain through dome skylights is one-eighth of incandescent lighting and one-half florescent lighting. Daylighting with Unit Skylights When daylighting using unit skylights, the best results are obtained with glazing that diffuses the transmitted light while lowering the solar energy transmitted through the glazing. Clear or tinted transparent glazing with smooth surfaces, regardless of the glazing material, does not diffuse the transmitted daylight. White translucent acrylic domes diffuse transmitted daylight while reducing the transmitted solar energy. This has been proven for more than 50 years. IT’S THE LAW SINCE 1992 SKYLIGHTS MUST BE PROTECTED. FallGuard® for Dome Skylights FallGuard® for Translucent Panels Install FallGuard® safety screens on your dome skylights and translucent panels on metal roofs. Skylights are not designed to support the weight of a human. OSHA requires all skylights have fall protection installed — it’s the law. With over 50 years of experience and a proven dedication to safety, trust the professionals at Plasteco for your skylight safety needs. While the information other skylight companies provide may say otherwise, skylights will not withstand a fall. Your own employees, contractors and passersby are all at risk for falling through your skylights. If your skylights don’t have safety screens, and someone falls, you are liable. FALLS ARE THE LEADING CAUSE OF DEATH IN CONSTRUCTION. In 2013†, there were 294 fall fatalities (284 falls to lower level) out of 796 total fatalities in construction. These deaths are preventable. By installing FallGuard®, you can help lower that statistic. CHOOSE FALLGUARD®: 1. T he ORIGINAL skylight safety screens proven for more than 20 years 2. Eliminates the top deadliest accident — Falls 3. 100% Passive protection, no further action or training required 4. Cost-effective 5. Easy to install on existing skylights 6. A FallGuard® for all types and brands of skylight INSTALL YOUR FALLGUARD® BEFORE IT’S TOO LATE. Compliant 36.9% Percentage of deaths in the construction industry RELATED TO FALLS IN 2013. TECHNICAL DATA GLASS Certain Plasteco models are available with insulated glass. The outer glass can be either clear or bronze while the inner glass is laminated safety glass. Plasteco should be consulted early in the planning stages to determine whether we can meet your design requirements with insulated glass. ACRYLIC Plasteco skylights may be ordered single-glazed or double-glazed and in the following acrylic colors: • clear colorless for maximum daylight and outside view • standard white translucent for excellent diffused light • bronze or gray transparent for sun and outside view Note: Double dome skylights are subject to formation of condensate between domes. This may be objectionable when both are transparent. Typical Lighting Levels 50 – 60 footcandles: classrooms, offices, drafting, merchandise, reading areas. 25 – 30 footcandles: gymnasiums, lobbies, recreation rooms, libraries, machine shops, laboratories. 10 – 15 footcandles: corridors, stairways, warehouses, stockrooms, locker rooms, washrooms, kitchens, dining areas, baths. TECHNICAL ASSISTANCE Plasteco offers technical assistance on all its products. Consultation is especially advisable when planning custom or structural skylights. Plasteco reserves the right to make design improvements without notice. RESPONSIBILITY Plasteco is responsible for furnishing skylight to fit specified outside curb dimensions or roof opening dimensions. It is the responsibility of others, however, to assure the integrity, strength and dimensional accuracy of the supporting structure — factors which are essential to a successful installation. Percent of Roof Area to be Skylighted Ratio Building Width to Ceiling Height 15fc 30fc 60fc 1.0 3.0% 6.0% 9.0% 1.25 2.5 5.0 7.5 1.50 2.2 4.4 6.6 2.0 1.8 3.6 5.4 3.0-5.0 1.6-1.4 3.2-2.8 4.8-4.2 6.0 & over 1.3 2.6 3.9 GENERAL INFORMATION Condensation: Since acrylic domes cannot be hermetically sealed, condensation may form between domes. In most instances, the condensation is temporary. Noise: In some installations a "popping" noise may be heard. For example, when a passing cloud covers a tinted dome which was in direct sunlight, the dome may suddenly contract. Design: Plasteco, Inc. reserves the right to make design changes without notice. Any design changes will be presented on approval drawings. Safety: Plasteco, Inc. skylights are not designed to support body weight. Further information on FallGuard® Skylight Screens fall protection is available in this brochure. This table is based on a #4848 single dome of standard white translucent acrylic with 12" deep well and the conditions given below. Sky: 4000 footcandles Reflectance factors: Wells 60%, Ceiling 70%, Maintained Walls 50%, Floor 10% Notes: Adjust the 4000 footcandles to suit average local condition. Larger skylights are more efficient; deeper wells are less efficient. Winter Heat Loss 15 mph wind Summer Heat Gain 7 1/2 mph wind Single-Glazed 1.2 0.8 Double-Glazed 0.7 0.5 Transmittance Acrylic Color U-values – BTU/hr/sq ft/°F 16" Acrylic ALUMINUM FRAME FINISHES Anodic finishes are available in clear (natural) or integral color coatings of light, medium or dark bronze. Typical trade name for integral color coatings are Duranodic and Kalcolor. Color matching is sometimes difficult with these finishes. Paint finishes are available in a wide range of colors. Select either baked-on powder coat paint or fluoropolymer finish. Mill finish is standard and will be furnished by Plasteco unless another finish is specified. Shading Coefficient Visible Light Solar Energy Single-Glazed Double-Glazed *Colorless 92% 89% 0.98 0.89 *STD White (1/8") 52% 52% 0.45 0.41 2064 Gray 27% 35% 0.53 0.43 2537 Gray 33% 41% 0.59 0.49 2094 Gray 45% 55% 0.71 0.61 2514 Gray 59% 62% 0.78 0.68 2370 Bronze 10% 20% 0.40 0.30 *2412 Bronze 27% 35% 0.53 0.43 2404 Bronze 49% 56% 0.72 0.62 2539 Bronze 61% 62% 0.78 0.68 All figures are average, and may vary with thickness of sheet. Double-glazed coefficient is based on gray/bronze outer dome, colorless inner dome. ¼" air space. *These colors are normally carried in stock. GLAZING MEDIA SELECTION MEDIA SELECTION CHART Welcome to the industry’s broadest range of glazing media choices. Review the Media Selection Chart and you’ll get a head start on putting the power of Plasteco’s design flexibility behind your project. Plasteco skylights are designed to accommodate monolithic glazing, structured sheet and glass. For detailed assistance, contact your Plasteco representative. Notes: 1. U-value is the heat-transfer rate through materials, measured in BTU/hr/sq ft/°F temperature difference. Winter nighttime U-values are calculated assuming an outdoor temperature of 0°F, an indoor temperature of 70°F and a wind velocity of 15 mph. 2. Shading coefficient compares the total solar heat gain through any other glazing with that through a single pane of 1/8" glass — which has a shading coefficient of 1. 3. Visible light transmission indicated the percentage of the visible spectrum that passes through the glazing. 4. UV (ultraviolet) transmission is given because the sun’s shortwave UV energy afades fabrics. 1 U-value 2 Shading Coefficient Visible Light Transmission 3 4 UV Transmission Flammability Rating Acrylic 3/16 Single 1.2 3/16 Double 0.7 Triple 0.3 .98 to .10 .92 to .10 — cc/2 — cc/2 — cc/2 Greater impact resistance than glass and more cost efficient. Facilitates open design. Polycarbonate (monolithic) 3/16 Single 1.2 3/16 Double 0.7 Triple 0.3 .98 to .10 .92 to .10 — cc/1 — cc/1 — cc/1 Greater impact resistance than acrylic. Less costly than glass. Glass Single 1.15 Double 0.56 Triple 0.37 cc/1 1.00 to .10 1.00 to .10 .80 to .12 cc/1 cc/1 Traditional beauty, UV stable, good U-values. Public safety & building codes are important concerns when specifying glass. More expensive than other media. Structured Sheet (Polycarbonate) 6 mm 0.63 0 cc/1 8 mm 0.60 0 cc/1 10 mm 0.53 0 cc/1 1.00 to .94 .82 to .20 16 mm 0.41 0 cc/1 25 mm 0.31 0 cc/1 Excellent U-values. Cost efficient. Durable. Easy installation. 3 UNIT SKYLIGHTS MODELS 100 & 101 MODEL 197 THERMAL BREAK FALLGUARD SKYLIGHT SCREEN (PATEN NO. 5,237,788) (SEE SPEC- ADD ALTERNATE) FALLGUARD SKYLIGHT SCREEN (PATEN NO. 5,237,788) (SEE SPEC- ADD ALTERNATE) SINGLE GLAZE (MODEL 100) FALLGUARD RAIL (OPTIONAL) INNER GLAZE (MODEL 101) ACRYLIC GLAZING (DOMES OR PYRAMIDS) FALL GUARD RAIL (Optional) WEEP HOLES INNER FRAME EXTRUDED ALUMINUM OUTER FRAME W/#10 x 1/2" HWHSDS AT 18" O.C. INNER FRAME THERMAL BREAK 4" MIN TO TOP OF CAT STRIP 6" MIN TO ROOF LINE #10 X 2"HHSMS AT 15" O.C. (NOT BY PLASTECO) #10 X 2"HHSMS AT 15" O.C. (NOT BY PLASTECO) WOOD CURB (NOT BY PLASTECO) ROOF MEMBRANE OR FLASHING (NOT BY PLASTECO) STANDARD SKYLIGHT SIZES 1 21" OUTSIDE CURB DIM. 1 1/2" MIN. CURB THICKNESS TYPCAL SECTION TYPCAL SECTION OUTSIDE CURB DIMENSION (custom sizes also available) Dome Curb Mount Pyramid Curb Mount Double Wall SelfFlashing Insulated 9" Curb Thermalized Curb Mount Thermalized SelfFlashing Insulated Curb OSHA Required FallGuard® Skylight Screen Model Single Glaze 100 120 208 — — ASM-1 Model Double Glaze 101 121 209 197 297 ASM-1 — — — Add “P” for Pyramid Square Rectangular Inside Curb Dimension Outside Curb Dimension Inside Curb Dimension Outside Curb Dimension 25 ½" x 49 ½" 2424 22 ¼" x 22 ¼" 25 ½" x 25 ½" 2448 22 ¼" x 46 ¼" 3232 30 ¼" x 30 ¼" 33 ½" x 33 ½" 3248 30 ¼" x 46 ¼" 33 ½" x 49 ½" 3939 37" x 37" 40 ¼" x 40 ¼" 3272 30 ¼" x 69 ½" 33 ½" x 72 ¾" 4848 46 ¼" x 46 ¼" 49 ½" x 49 ½" 4872 46 ¼" x 69 ½" 49 ½" x 72 ¾" 5858 55" x 55" 58 ¼" x 58 ¼" 4892 46 ¼" x 89 ½" 49 ½" x 92 ¾" 7272 69 ½" x 69 ½" 72 ¾" x 72 ¾" 6072 57 ¼" x 69 ½" 60 ¾" x 72 ¾" 7777 75" x 75" 78 ¼" x 78 ¼" 6092 57 ¼" x 89 ½" 60 ¾" x 92 ¾" 9494 92 ½" x 92 ½" 95 ¾" x 95 ¾" — — — Specifications: Dome Skylights shall be factory assembled as manufactured by Plasteco, Inc., Houston, Texas (713.673.7710; Fax 713.673.7236). Each unit shall have an inner frame (.072") and an outer frame (.055") of 6063-T5 extruded aluminum. Inner frame shall have a 6° sloping condensation gutter with weepage, a dome elevating leg with continuous EPDM gasket. Dome shall be formed of (clear, white translucent or bronze) acrylic to support a uniform 40 psf load. (For Model 101, add: Inner dome shall be formed of (clear or white translucent) acrylic.) MODELS 208 & 209 FALLGUARD SKYLIGHT SCREEN (PATEN NO. 5,237,788) (SEE SPEC- ADD ALTERNATE) MODEL 297 THERMAL BREAK FALLGUARD SKYLIGHT SCREEN (PATEN NO. 5,237,788) (SEE SPEC-ADD ALTERNATE) SINGLE GLAZE (MODEL 208) FALLGUARD RAIL (OPTIONAL) INNER GLAZE (MODEL 209) DOUBLE GLAZE (MODEL 297) FALLGUARD RAIL (OPTIONAL) WEEP HOLES INNER FRAME EXTRUDED ALUMINUM OUTER FRAME W/#10 x 1/2" HWHSDS AT 18" O.C. 4" MIN TO TOP OF CAT STRIP 6" MIN TO ROOF LINE #10 X 2"HHSMS AT 15" O.C. (NOT BY PLASTECO) #10 X 2"HHSMS AT 15" O.C. (NOT BY PLASTECO) WOOD NAILER (OPTIONAL) WOOD NAILER (OPTIONAL) INSULATED CURB (9" OR 12") ALUM. OUTER MIN. 0.040" INSULATED CURB (9" OR 12") ALUM. OUTER MIN. 0.040" ALUM. LINER MIN. 0.040" 3" ALUM. LINER MIN. 0.040" ROOF MEMBRANE OR FLASHING (NOT BY PLASTECO) ROOF MEMBRANE OR FLASHING (NOT BY PLASTECO) TYPCAL SECTION TYPCAL SECTION 3" Specifications: Dome Skylights shall be factory assembled as manufactured by Plasteco, Inc., Houston, Texas (713.673.7710; Fax 713.673.7236). It shall consist of a skylight mounted on a 9" high insulated double wall aluminum curb. The insulation shall be 1-1/2" thick polyisocyanurate. Dome shall be formed of (clear, white translucent or bronze) acrylic to support a uniform 40 psf load. (For Model 209, add: Inner dome shall be formed of (clear or white translucent) acrylic.) 4 Add alternate: Fall protection as required by OSHA Regulation 1926.501 “Duty to Have Fall Protection” shall be provided by Model A FallGuard® Skylight Screens. FallGuard® Skylight Screens shall be shipped separately and installed prior to the installation of the skylight. NON-INSULATING ALUMINUM MODELS 204 & 205 Models 204 & 205 ACRYLIC GLAZING (DOMES) SET ON SANTOPRENE GASKET (GC190) FALLGUARD (OPTIONAL) OUTER FRAME (AC177) ATTACH W/ #10 X 1/2" HWHSDS AT 18" O.C. Inner Frame Dimension Inside Bottom Curb 2424 22 7/8" x 22 7/8" 24 1/2" x 24 1/2" 3232 30 7/8" x 30 7/8" 32 1/2" x 32 1/2" 3939 37 5/8" x 37 5/8" 39 1/4" x 39 1/4" 4848 46 7/8" x 46 7/8" 48 1/2" x 48 1/2" 5858 55 5/8" x 55 5/8" 57 1/4" x 57 1/4" 7272 70 1/8" x 70 1/8" 71 3/4" x 71 3/4" 7777 75 5/8" x 75 5/8" 77 1/4" x 77 1/4" 9494 93 1/8" x 93 1/8" 94 3/4" x 94 3/4" 2448 22 7/8" x 46 7/8" 24 1/2" x 48 1/2" 3248 30 7/8" x 46 7/8" 32 1/2" x 48 1/2" 3272 30 7/8" x 70 1/8" 32 1/2" x 71 3/4" 4872 46 7/8" x 70 1/8" 48 1/2" x 71 3/4" 4892 46 7/8" x 90 1/8" 48 1/2" x 91 3/4" 6072 58 1/8" x 70 1/8" 59 3/4" x 71 3/4" 6092 58 1/8" x 90 1/8" 59 3/4" x 91 3/4" INNER FRAME DIM. INNER FRAME (AC178) W/ WEEP HOLES IN DOME ELEVATING LEG 1/4" DIA. HOLES AT 18" O.C. ROOF MEMBRANE OR FLASHING (NOT BY PLASTECO) INSIDE BOTTOM CURB DIM. TYPICAL SECTION CIRCULAR 4" & 9" INSULATED CURB SKYLIGHTS MODELS 800, 801, 802 & 803 FALLGUARD SKYLIGHT SCREEN (PATEN NO. 5,237,788) (SEE SPEC- ADD ALTERNATE) SINGLE GLAZE (MODEL 800 & 802) FALLGUARD RAIL (OPTIONAL) INNER GLAZE (MODEL 801 & 803) OUTER FRAME EXTRUDED ALUMINUM 4" High Curb 9" or 12" INSULATION 9" High Curb ALUMINUM CURB Single Dome Double Dome Dia. A Dome Height Single Dome Double Dome 800-36 801-36 31 8 802-36 803-36 800-48 801-48 43 11 802-48 803-48 800-60 801-60 54 15 802-60 803-60 800-72 801-72 67 17 802-72 803-72 800-84 801-84 79 20 802-84 803-84 800-96 801-96 91 22 802-96 803-96 ROOF OPENING 3" 1" 4" Specifications: Circular Skylights shall be factory-assembled Plasteco Model 802 (or 803). Each unit shall have a .050" thick aluminum integral curb and an extruded aluminum outer frame. Dome shall be formed of (color) acrylic. (For double-glazed models add: Inner dome shall be (white or clear) acrylic.) Add alternate: Provide fall protection as required by OSHA regulation 1926.501 “Duty to Have Fall Protection.” 5 CONTINUOUS VAULTED SKYLIGHTS ALSO AVAILABLE WITH THERMAL BREAK DESIGN Plasteco’s Continuous Vaulted Skylight Model 300 (single-glazed) and Model 301 (double-glazed) are available in widths ranging from 2'-6" to 7' with unlimited length. They are composed of pre-assembled half dome or vertical ends and intermediate sections which are shipped K-D. The intermediate sections consist of flat, acrylic, monolithic polycarbonate, or structured sheet polycarbonate sheets cold formed over pre-formed aluminum arches. The curb frame comes with a self-adjusting counter-flashing to reduce the amount of air infiltration (or exfiltration) that occurs between the top of the curb and the skylight curb frame. These skylights are light in weight and provide an economical solution to daylighting of relatively large rectangular areas. Since the skylight opening is rectangular, the construction of the structural framing, curbs, roofing, flashing and the interior finish is simplified resulting in a lower completed cost. Although the skylights are normally furnished K-D (except for the ends), Plasteco has shipped pre-assembled 20' sections. The pre-assembled 20' sections have special designed ends that can be mulled together with a special EPDM gasket. Projects consisting of 20,000' have been installed using the 20' pre-assembled sections. 3 Since skylights are not designed to support body weight, some method of fall protection should be provided. See add alternate for information on OSHA regulations on fall protection. 1 CONTINUOUS VAULTED SKYLIGHTS 2 (custom sizes also available) Single-Glazed Model 300 Double-Glazed Model 301 Dome Ht. 300-30 301-30 7" 33 ¼" 300-36 301-36 8" 39 ¼" Outside Curb Dim. A 300-42 301-42 9" 45 ¼" 300-48 301-48 10" 51 ¼" 300-54 301-54 11" 57 ¼" 300-60 301-60 12" 63 ¼" 300-72 301-72 14" 75 ¼" 300-84 301-84 16" 87 ¼" Add TB to Model Number for Thermal Break Design OUTER ACRYLIC (MODEL 300) 1 INNER ACRYLIC (MODEL 301) CURB 1 1/2" CURB THICKNESS CURB BY OTHERS STAINLESS STEEL SCREW GASKET ACRYLIC INNER ARCH MODEL 300 ACRYLIC 3 STAINLESS STEEL SCREW GASKET INNER ARCH INNER ACRYLIC 6 SELF-ADJUSTING COUNTER-FLASHING DIMENSION A Curb frame, inner and outer arch supports shall be 6063-T5 extruded aluminum. Exterior exposed aluminum can be mill finish, clear anodized, bronze anodized, and powder coating or flouropolymer (color). Curb frame shall have self-adjusting counter-flashing. All gaskets shall be black EPDM. Skylights are designed to support a 20 psf load. Add alternate: Fall protection as required by OSHA Regulation 1926.501 “Duty to Have Fall Protection” shall be provided by Model A FallGuard® Skylight Screens. FallGuard® Skylight Screens shall be shipped separately. CURB FRAME EXTRUDED ALUMINUM 1 1/2" CURB THICKNESS SELF-ADJUSTING COUNTER-FLASHING DOMED END 2 INNER ACRYLIC (MODEL 301) CURB FRAME EXTRUDED ALUMINUM CURB & ROOFING BY OTHERS Specifications: Continuous Vaulted Skylights shall be single-glazed Model 300 (double-glazed Model 301) as manufactured by Plasteco, Inc. (713.673.7710; Fax 713.673.7236). Curb (by others) shall have a minimum thickness of 1-1/2". Each skylight shall consist of a pair of pre-assembled half domes (or vertical ends). The intermediate sections are shipped K-D with arch sections over nominal 4' spacing. Model 300 acrylic shall be clear, bronze or #2447 white translucent. Model 301 inner acrylic shall be clear or white translucent. OUTER ACRYLIC (MODEL 300) MODEL 301 ARCH STRUCTURAL BARREL VAULT SKYLIGHTS ALSO AVAILABLE WITH THERMAL BREAK DESIGN Plasteco’s Structural Barrel Vault Skylights provide an economical and practical means of presenting daylight and spaciousness to a lobby, atrium or the interior of a building. They have also been used as entrance canopies, walkway canopies and as a cover between adjacent buildings. They are available in widths from 8' to 24' with unlimited lengths, single- or doubleglazed. The curved aluminum rafters and acrylic, monolithic polycarbonate, or structural sheet polycarbonate glazing combination results in a lightweight, economical skylight. Since the skylight opening is rectangular, the construction of the structural framing, curbs, roofing, flashing and the interior finishing is simplified, resulting in a lower completed cost. Skylights are not designed to support body weight, and some method of fall protection should be provided. See “add alternate” for information on OSHA regulations on fall protection. STRUCTURAL BARREL VAULTS Single-Glazed Double-Glazed Outside Curb Dim. A Dome Ht. 310-8 311-8 8'-0" 1'-5 1/2" 310-10 311-10 10'-0" 1'-10" 310-12 311-12 12'-0" 2'-2" 310-16 311-16 16'-0" 2'-11" 310-20 311-20 20'-0" 3'-8" 310-24 311-24 24'-0" 4'-4 1/2" INNER GLAZE (MODEL 311) 5 3 1 Add TB to Model Number for Thermal Break Design RAFTER TUBE ACRYLIC ANCHOR BOLT CL CL MULLION COVER SANTOPRENE GASKET OUTER GASKET (GC064) WEEP SLOTS @ 18" O.C. 1 1/4-20 1.3/4" HHSTS @ 18" O.C. MULLION COVER ACRYLIC ROOF MEMBRANE 5 CURB FLASHING ( NOT BY PLASTECO) 1 3/16" OUTER GASKET (GC064) INNER GLAZE MULLION COVER CLAMP BARARCH TUBE OUTER GLAZE WET SEALED SANTOPRENE GASKET 2" X 2" X 3/16" ARCH TUBE OUTER GASKET (GC064) OUTSIDE CURB DIMENSION CLAMP BAR INNER GLAZE OUTER GLAZE SECTION AT RAFTER INNER GLAZE CURB FLASHING ( NOT BY PLASTECO) SECTION AT STANDARD VAULTED SILL MULLION COVER (2) 2 X 4 WOOD (BY OTHERS) OUTER GASKET (GC064) CLAMP BAR GLAZING MULLION ARCH TUBE 2" X 2" X 3/16" ARCH TUBE SECTION AT SINGLE GLAZE RAFTER (MODEL 310) GLAZING MULLION SECTION AT RAFTER SECTION AT SINGLE GLAZE RAFTER (MODEL 310) 5 21 " MIN CURB THICKNESS OUTER GLAZE ARCH TUBE PURLIN TUBE 2" X 2" X 3/16" ARCH TUBE SECTION AT PURLIN ARCH TUBE GLAZING MULLION SECTION AT RAFTER PURLIN TUBE OUTSIDE CURB DIMENSION GLAZING MULLION GLAZING MULLION ARCH TUBE SECTION AT STANDARD VAULTED SILL 2" X 2" X 3/16" ARCH TUBE SECTION AT SINGLE GLAZE RAFTER (MODEL 310) SECTION AT PURLIN SECTION AT RAFTER HALF ROUND VAULTS INNER GLAZE SANTOPRENE GASKET INNER GLAZE INNER GLAZE ACRYLIC GLAZING Single-Glazed CLAMP BAR OUTER GLAZE GLAZING MULLION 1 3/16" 4 WOOD HERS) RAFTER SANTOPRENE GASKET GLAZING MULLION WET SEALED ARCH TUBE 3 ACRYLIC GLAZING CL CL GLAZING MULLION ROOF MEMBRANE OUTER GLAZE CL GLAZING MULLION CL SECTION AT SINGLE GLAZE RAFTER (MODEL 310) 5 21 " MIN CURB THICKNESS SANTOPRENE GASKET CLAMP BAR SANTOPRENE GASKET GLAZING MULLION WET SEALED 1/4-20 1.3/4" HHSTS ACRYLIC GLAZING @ 18" O.C. PURLIN CL ANCHOR BOLT WEEP SLOTS @ 18" O.C. OUTER GLAZE ACRYLIC GLAZING (2) 2 X 4 WOOD RAFTER TUBE (BY OTHERS) CL CLAMP BAR WET SEALED CURB INNER GLAZE (MODEL 311) R BOLT LASHING Y PLASTECO) (custom sizes also available) (custom sizes also available) Double-Glazed 5 Outside Curb Dim. A Dome Ht. 312-6 313-6 6'-0" 3'-0" 312-8 313-8 8'-0" 4'-0" 312-10 313-10 10'-0" 5'-0" 312-12 313-12 12'-0" 6'-0" 312-16 313-16 16'-0" 8'-0" 3 Standard End Pattern (sunburst pattern is a custom end) 1 Specifications: Structural Half Round Vault Skylights shall be as manufactured by Plasteco, Inc., Houston, Texas (713.673.7710; Fax 713.673.7236). All extruded aluminum shall be 6063-T5. Exterior exposed aluminum can be mill finish, (clear anodized, bronze anodized, and power coating or flouropolymer (color)). Model 312 outer acrylic can be clear, (2412 bronze, or 2447 white translucent). Model 313 inner acrylic can be clear, (or 2447 white translucent). Rafters shall be mounted on nominal 4' centers. The skylight shall be designed to support 20 psf live load and a 20 psf wind load. Curbs (by others) shall have a minimum thickness of 5-1/2" and shall be designed to support the skylight and thrust of a 20 psf live load. Add alternate: Fall protection as required by OSHA Regulation 1926.501 “Duty to Have Fall Protection” shall be provided by Model A FallGuard® Skylight Screens. FallGuard® Skylight Screens shall be shipped separately and installed prior to the installation of the skylight. 7 GLAZING MU STRUCTURAL RIDGE & PYRAMID SKYLIGHTS Specifications: Structural Ridge Skylights shall be as manufactured by Plasteco, Inc., Houston, Texas (713.673.7710; Fax 713.673.7236). Manufacturer shall furnish a complete K-D structural framing consisting of curb rail, of 6063-T5 mill finish (anodized, bronze hardcoat or painted finish also available) extruded aluminum or field assembly by others to support a minimum load of 20 psf. Units shall be furnished mounted in a 6063-T5 extruded aluminum frame (specify finish). Glazing to be as specified by architect. PCS RP Curbs shall be furnished by others to Plasteco’s dimension. Structural integrity of curb and supporting structure is responsibility of architect/engineer. Curbs to be flashed by others. Skylight shall have an integral system of condensation gutters with drainage to exterior. Weepholes shall not be exposed to view and shall have a buffer type air cover. GLAZING: Acrylic; Monolithic & Structured Sheet Polycarbonate R DIMENSION A STRUCTURAL RIDGE ELEVATION/PLAN VIEW STRUCTURAL RIDGES HR PCS GLAZING: Glass Hipped Ends Hipped Ends Single-Glazed Double-Glazed Outside Curb Dimension A Height Laminated Insulated Outside Curb Dimension A Height 180-12 181-12 12' 2'-6" 184-12 185-12 12' 2'-6" 180-16 181-16 16' 3'-4" 184-16 185-16 16' 3'-4" 180-20 181-20 20' 4'-2" 184-20 185-20 20' 4'-2" Gabled Ends Gabled Ends Single-Glazed Double-Glazed Outside Curb Dimension A Height Laminated Insulated Outside Curb Dimension A Height 182-12 183-12 12' 2'-6" 186-12 187-12 12' 2'-6" 182-16 183-16 16' 3'-4" 186-16 187-16 16' 3'-4" 182-20 183-20 20' 4'-2" 186-20 187-20 20' 4'-2" STRUCTURAL PYRAMID ELEVATION/PLAN VIEW DIMENSION A P HR PCS R PCS GLAZING: Acrylic; Monolithic & Structured Sheet Polycarbonate 8 GLAZING: Glass Single-Glazed Double-Glazed Outside Curb Dimension A Height Laminated Insulated Outside Curb Dimension A Height 160-12 161-12 12' x 12' 2'-6" 162-12 163-12 12' x 12' 2'-6" 160-16 161-16 16' x 16' 3'-4" 162-16 163-16 16' x 16' 3'-4" 160-20 161-20 20' x 20' 4'-2" 162-20 163-20 20' x 20' 4'-2" STRUCTURAL POLYGON SKYLIGHTS Specifications: Structural Polygon Skylights shall be as manufactured by Plasteco, Inc., Houston, Texas (713.673.7710; Fax 713.673.7236). Manufacturer shall furnish a complete K-D structural framing consisting of curb rail, of 6063-T5 mill finish (anodized or painted finish also available) extruded aluminum or field assembly by others to support a minimum load of 20 psf. Units shall be furnished mounted in a 6063-T5 extruded aluminum frame (specify finish). Glazing to be as specified by architect. STRUCTURAL POLYGON ELEVATION/PLAN VIEW DIMENSION A Curbs shall be furnished by others to Plasteco’s dimension. Structural integrity of curb and supporting structure is the responsibility of architect/engineer. Curbs to be flashed by others. Skylights shall have an integral system of condensation gutters with drainage to exterior. Weepholes shall not be exposed to view and shall have a buffer type air cover. R GLAZING: Acrylic; Monolithic & Structured Sheet Polycarbonate Single-Glazed Double-Glazed Outside Curb Dimension A Height No. of Segments 170-10 171-10 10'-0" 2'-1" 8 170-12 171-12 12'-0" 2'-6" 8 P 170-16 171-16 16'-0" 3'-4" 12 170-20 171-20 20'-0" 4'-2" 16 Single-Glazed Double-Glazed Outside Curb Dimension A Height No. of Segments 172-10 173-10 10'-0" 2'-1" 8 PCS GLAZING: Glass 172-12 173-12 12'-0" 2'-6" 8 172-16 173-16 16'-0" 3'-4" 12 172-20 173-20 20'-0" 4'-2" 16 GLASS STRUCTURAL RIDGE, PYRAMID & POLYGON DETAILS END CAP COVER CLAMP BAR GLASS PER SPECS 6" CLOSURE ADAPTER .040" ALUMINUM CLAMP BAR RIDGE CAP SILL PURLIN 3" x 5" x 1/4" ALUM. ANGLE (2) PER RAFTER ATTACHED TO RAFTER GLASS PER SPECS GLASS PER SPECS HIP RAFTER ADAPTER RAFTER 1/4" .040" ALUM. CURB FLASHING TOP OF CURB SECTION PURLIN P 2" PURLIN BASE ROOF MEMBRANE OR FLASHING (NOT BY PLASTECO) - MUST BE 3/4" IN PLACE PRIOR TO INSTALLATION OF CLOSURE CLIP AND PAN FLASHING SECTION SILL PCS CLAMP BAR RAFTER RAFTER SECTION RAFTER R SECTION HIP RAFTER HR FULL PENETRATION WELD OUTSIDE CURB DIMENSION PLASTIC STRUCTURAL RIDGE, PYRAMID & POLYGON DETAILS DOME GLAZING CLAMP BAR PURLIN TOP DOME GLAZING DOME GLAZING GASKET DOME GLAZING CLAMP BAR GASKET PURLIN TOP 1" x 2" x 1/8" SILL PURLIN CLIP - ATTACH TO RAFTER W/ (2) #14 x 1" HWHSDS .040" ALUM. CURB FLASHING - MIN. 3" OVERLAP AT SPLICES .040" ALUM. SILL CLOSURE ATTACH TO ADAPTER W/ #8 x 3/4" HWHSDS @ 24" O.C. MIN. 3" OVERLAP @ SPLICES HIP RAFTER ADAPTER RAFTER PURLIN BOTTOM 3" x 5" x 1/4" ALUM. ANGLE (AC801) (2) PER RAFTER ATTACHED TO RAFTER HHMB, HEX NUT & LOCK WASHER ATTACH TO WOOD CURB CLAMP BAR 6" HIP RAFTER CLAMP BAR PURLIN BOTTOM INNER GASKET RAFTER 3 4" TOP OF CURB INNER GASKET 3" 2"X6"(2) WOOD BLOCKING (NOT BY PLASTECO) 1.1/8" DIA. OPEN CELL BACKER ROD RAFTER OR JACK RAFTER SECTION HIP RAFTER (HR) SECTION RAFTER (R) SECTION PURLIN (P) ROOF MEMBRANE OR FLASHING (NOT BY PLASTECO) - MUST BE IN PLACE PRIOR TO INSTALLATION OF CLOSURE CLIP AND PAN FLASHING 5 21" MIN. OUTSIDE CURB DIMENSION SECTION SILL PCS 9 TANDEM & GRID SKYLIGHTS • Factory assembled under a controlled environment • Pre-glazed at factory under dust-free conditions • Completely welded modular units • Baffle weep and internal gutter system — no leaks • Installation is simple — screw in place — no miscellaneous hardware • Installation is faster — there is no roof assembly of components • Installation is economical — no glazier required Specifications: Manufacturer: Skylights shall be Custom Skylight System 71-TG as manufactured by Plasteco, Inc., Houston, Texas (713.673.7710; Fax 713.673.7236). Alternate manufacturers must have architect’s approval in writing ten (10) days prior to bid date. Design requirements: All skylights shall be of type and size shown on architect’s plans in accordance with standard Plasteco details. Skylight system shall consist of factory-assembled, pre-glazed units and all split mullion covers, gaskets and fasteners required to make field joints between units. Skylights shall have an integral, interior system of condensation gutters capable of draining across slope and down slope. Outer skylight members at split mullions and walls shall have an integral elevated coaming as a waterstop and for attachment (by others) of split mullion covers and flashings. Material: All skylight frames, inner and outer mullions, and mullion covers shall be of extruded or sheet aluminum with standard mill finish. Factoryassembled frame members, except movable parts, shall be heliarc-welded. Exposed fasteners throughout shall be stainless steel. Glazing: Domes (or pyramids) shall be formed of (color) acrylic to support a 40 psf live load. (Where applicable, add: Inner domes (or pyramids) shall be formed of (color) acrylic. All glazing shall bear on continuous neoprene gaskets and have continuous butyl sealant. MODEL 71-TG TANDEM & GRID PRE-GLAZED SKYLIGHT SYSTEM Work by others: Curbs, supports and blocking; installation of skylight units and metal flashings. Add alternate: Fall protection as required by OSHA Regulation 1926.501 “Duty to Have Fall Protection” shall be provided by Model A FallGuard® Skylight Screens. FallGuard® Skylight Screens shall be shipped separately. IM SM MULLION COVER FALLGUARD SKYLIGHT SCREEN (PATEN NO. 5,237,788) (SEE SPEC- ADD ALTERNATE) FALLGUARD RAIL (OPTIONAL) CENTER SUPPORT MULLION CENTER SUPPORT MULLION 5 1 16 " 1 1 2" SECTION IM OUTSIDE CURB DIMENSION OUTSIDE CURB DIMENSION INNER FRAME SPLIT MULLION SPLIT MULLION COVER PERIMETER CURB SECTION OUTS IDE C IMEN SION PC SECTION IM SM END UNIT END UNIT 3 1/2" MIN. 2"X4" WOOD CURB (NOT BY PLASTECO) 3 1/2" MIN. SECTION SM SECTION SM OUTER GASKET 45∞ Square Pyramid GLAZING (SINGLE OR DOUBLE) 4 OR 5 UNIT TYPICAL INNER FRAME SPLIT MULLION SM OUT SIDE 2"X4" WOOD CURB (NOT BY PLASTECO) 3 1/2" MIN. 10 ON NSI IME D URB EC SID OUT MIN. SLOPE 1/4" PER FT. (SM must follow slope) OUTER FRAME EXTRUDED ALUM. URB D PC INTERMEDIATE UNIT PERIMETER CURB SECTION NG E OR DOUBLE) 5 1 16 " OUTER GASKET INNER FRAME SPLIT MULLION INNER GASKET 4" MIN. TO TOP OF CANT STRIP 6" MIN TO ROOF LINE 7 16 " 1 21" GLAZING (SINGLE OR DOUBLE) WEEP HOLES AT 9" O.C. WEEP HOLES SELF-ADJUSTING AT FLASHING 9" O.C. COUNTER OR T BY CO) STANDARD SIZE TANDEM & GRID UNITS INNER GASKET #10 X 2 HHSMS @ 15" O.C (NOT BY PLASTECO) INNER GASKET 4" MIN. TO TOP ROOF OF MEMBRANE OR CANT STRIP FLASHING (NOT BY 6" MIN TO ROOF LINEPLASTECO) GLAZING (SINGLE OR DOUBLE) OUTER FRAME EXTRUDED ALUM. GLAZING (SINGLE OR DOUBLE) INNER GASKET OUTER & INNER GLAZE (DOMES OR PYRAMIDS) OUTER FRAME EXTRUDED ALUM. SPLIT MULLION COVER MULLION COVER OUTER & INNER GLAZE (DOMES OR PYRAMIDS) 3/16" X 1/2" BUTYL TAPE 7 16 " PC SPLIT MULLION COVER GLAZING (SINGLE OR DOUBLE) 3/16" X 1/2" BUTYL TAPE REEN ,788) ATE) IM SECTION SM CUR B DIM IM PC ENS ION OUT SID RB E CU ION ENS DIM MIN. SLOPE 1/4" PER FT. (SM must follow slope) AUTOMATIC MELT-OUT (DROP-OUT) HEAT AND SMOKE VENTS MODEL 417-MB-5098 MODEL 417D-5098 MODELS 417 AND 418 MODELS 407 AND 408 Plasteco Model 417, 417D, 418 and 418D automatic melt-out (drop-out) heat and smoke vents feature plastic glazing that will melt-out (drop-out) in less than 5 minutes at a temperature not exceeding 500°F. Models 407 and 408 curb mounted heat and smoke vents are identical in design to our 417 and 418 models, except the units that do not have a 12" high curb. Models 417 (single glazed) and 418 (double glazed) have a 12" high aluminum curb. The curb has 1-1/2" thick insulation and a 2" x 4" wood nailer. Models 417D (single glazed) and 418D (double glazed) have a 12" high double wall, 1" thick insulated curb normally used on membrane roofs. Wood Nailer Double Wall Single-Glazed Double-Glazed Outside Curb Dimension A 407-5050 408-5050 51” x 51” 407-5098 408-5098 51” x 99” Inside Curb Single-Glazed Double-Glazed Single-Glazed Double-Glazed Dimension “A” 417-5050 418-5050 417D-5050 418D-5050 48" x 48" 417-5098 418-5098 417D-5098 418D-5098 48" x 96" MODEL 417D-MB AND 418D-MB Plasteco Model 417D-MB automatic melt-out (drop-out) heat and smoke vents feature plastic glazing that will melt-out (drop-out) in less than 5 minutes at a temperature not exceeding 500°F. Models 417-MB and 418MB double wall are for mounting on standing seam metal roofs. FALLGUARD SKYLIGHT SCREEN (PATEN NO. 5,237,788) (SEE SPEC- ADD ALTERNATE) CAP OUTER PYRAMID (MODEL 417) INNER PYRAMID (MODEL 418) OUTER FRAME INNER FRAME 1 21" MIN. CENTER SUPPORT DOUBLE WALL ALUM. CURB Single-Glazed Double-Glazed Inside Curb Dimension A 417D-MB-5050 418D-MB-5050 48" x 48" 417D-MB-5098 418D-MB-5098 48" x 96" FALLGUARD SKYLIGHT SCREEN (PATEN NO. 5,237,788) (SEE SPEC- ADD ALTERNATE) CURB BY OTHERS OUTSIDE CURB DIMENSION "A" MODEL 407 & 408 Fall protection as required by OSHA Regulation §1926.50 “Duty to have Fall Protection” shall be provided by FALLGUARD® Skylight Screens. FALLGUARD® Skylight Screen shall be shipped separately and installed prior to the installation of the melt-out heat and smoke vent. CAP OUTER PYRAMID (MODEL 417) Add alternate: Hail Stone Screens shall be 1" x 1" x .063" galvanized welded wire mesh overlaid onto the FALLGUARD® Skylight Screens. Screens shall have been tested to resist without permanent deformation, the impact energy of a 2" diameter hail stone (22 ft lbs). INNER PYRAMID (MODEL 418) OUTER FRAME Specifications: Automatic Melt-out Heat and Smoke Vents shall be single glazed or double glazed as manufactured by Plasteco, Inc. Houston, Texas. DOUBLE WALL ALUM. CURB 12" CURB HEIGHT INNER FRAME CENTER SUPPORT INSIDE CURB DIMENSION "A" 3" FLANGE Units shall have a 12-inch high double wall insulated aluminum curb. Inner and outer frames shall be mill finish 6063-T5 extruded aluminum. Glazing shall be white translucent acrylic designed to withstand a 40 psf snow load. (Double glazed unit add the words “inner pyramid shall be of a clear acrylic”.) MODEL 417 & 418 11 PLASTECO’S ACRYLIC SKYLIGHTS STAND THE TEST OF TIME Brand new skylights offer aesthetic appeal and allow the beauty of natural light to fill your building. However, choose the wrong skylights, and it’s only a matter of time before that fades. Acrylic skylights from Plasteco are proven to withstand the test of time. While translucent sandwich panel skylights may originally appear white and clear, time and conditions such as UV rays, pollution, chemical exposure and weather will cause yellowing and increased cloudiness long before the skylight has reached the end of its life cycle. Ensure your skylights will look like new for years to come when you choose acrylic skylights from Plasteco. Plasteco provided and installed the skylights in Houston’s Astrodome, a structure more than 40 years old that still has the same acrylic glazing. BEFORE This translucent sandwich panel skylight already shows extreme signs of wear, with yellowing and cloudiness preventing the admittance of light into the building. AFTER With acrylic skylights from Plasteco, the same building is flooded with natural light. Our skylights last longer than those made of fiberglass without succumbing to yellowing and cloudiness. 12 This is an actual piece of panel skylight that was replaced. The left side was protected from the elements by aluminum flashing, while the right side was exposed. Notice the drastic difference. 13 OSHA REQUIRES THAT ALL SKYLIGHTS HAVE ADDITIONAL FALL PROTECTION OSHA considers falls one of constructions “fatal four.” According to OSHA’s 2012 report, 34.6 percent of deaths in the construction industry are related to falls. In order to prevent one of the deadliest workplace hazards, OSHA regulation 29 CFR 1910.30 (a)(4) requires all skylights have some sort of fall protection. While some skylight manufacturers claim that their skylights are OSHAcompliant and meet weight requirements, this isn’t true. Although they may support the weight of a human when brand new, ALL plastic skylights degrade over time and should be protected by a skylight screen or fixed standard railing in order to meet OSHA regulation 29 CFR 1910.30 (a) (4), but even more importantly, to prevent fatal accidents caused by falls through skylights. ALL PLASTIC SKYLIGHTS DEGRADE OVER TIME Manufacturers’ claims that skylights can withstand a 200 to 300 pound load only apply to brand new skylights. The composition of all plastic skylights will degrade over time from exposure to normal weather conditions and pollution, causing the weight-bearing capabilities diminish long before your skylight has reached the end of its life cycle. This degradation can be seen in the yellowing and increased cloudiness of your skylight over time. The label on the skylight stated it was tested in accordance with OSHA Fall Protection standards. According to California Fatality Assessment and Control Evaluation (CA/FACE) Report #09CA003, the label on a skylight involved in a fatal fall stated it was tested in accordance with OSHA fall protection standards. Because of this label, no other fall protection was implemented. DO NOT BE MISLED. While a skylight may meet OSHA standards when new, its weight-bearing capacity will diminish over time and must be protected. Don’t put workers at risk by taking a chance on unprotected skylights that may fail! Install FallGuard® Safety Screens from Plasteco today. The same skylight, years later, breaks in real-world conditions. Source: FACE Report #09CA003 THE ONLY WAY TO PREVENT TRAGIC ACCIDENTS IS WITH FALL PROTECTION Ensure worker safety and OSHA compliance with FallGuard® Skylight Screens from Plasteco. Plasteco was the first to offer FallGuard® screens for all skylight models, including all models from outside manufacturers. For more than 20 years, Plasteco’s FallGuard® Skylight Safety Screens have been protecting workers and saving lives. 14 SINCE 1992 MODEL F FALLGUARD® SKYLIGHT SCREENS The Model F FallGuard® Skylight Screens PREVENTS falls through corrugated fiberglass (CF) skylights. They are simple to install and will prove to be cost effective in view of the exposure in time and dollars expended as a result of a fall through a CF skylight. Being at the same level and having the same profile as the corrugated metal roof panels, they are at times difficult to detect by persons on the roof. Patent No. 5,419,090 MODEL TSSR FALLGUARD® SKYLIGHT SCREENS Model TSSR FallGuard® Skylight Screens PREVENT falls through trapezoidal standing seam skylights. These skylights are similar to the regular corrugated fiberglass skylights in that they are at the same level as the roof and have the same profile. They can be easily overlooked when a person is working or walking on the roof. The FallGuard® Skylight Screens are easy to install and allow for a proactive rather than reactive solution to a safety hazard. They, like other FallGuard® Skylight Screen models, will prove to be more than cost effective considering the alternative of a fall through a skylight. Patent Pending INSTALLATION INSTRUCTIONS Do not place body weight on skylight during installation. Use extreme caution when installing the FallGuard® Skylight Screens. Wear gloves when handling skylight screens. 5. Proceed to lower end of the FallGuard® channel. Clean area under the three holes in the channel and install the 3" x 3" adhesive sealant pads. Fasten the lower end of the FallGuard® channel to the corrugated metal. 1. The FallGuard® Skylight Screen channel is to be mounted on the highest corrugation nearest to the center of the skylight. 6. Center the FallGuard® Skylight Screen over skylight and insert the FallGuard® Skylight Screen under the tabs. Bend tabs over the FallGuard® Skylight Screen. 2. On the high end, the fiberglass skylight should be under the corrugated metal. Clean and install the 3" x 3" adhesive sealant pads on the corrugated metal approximately 1" from the edge. Be sure to remove the release liner from the adhesive sealant pads. Specifications: Skylight Screens shall be Model F FallGuard® Skylight Screens manufactured by Plasteco, Inc., Houston, Texas (713.673.7710; Fax 713.673.7236). Each skylight screen shall consist of a 3" x 4" welded wire mesh having a minimum transverse diameter of .195". A plastic bumper extrusion shall be installed around the perimeter of the skylight screen. The skylight screen is to be field installed on a 20 gauge galvanized steel channel. The steel channel shall have tabs to receive the skylight screens and pre-punched holes for the mounting screens. Two 3" x 3" sealant adhesive pads and six hex washer head self-drilling screws shall be furnished with each channel. 3. Position the FallGuard® channel so that the three mounting holes in the channel are positioned over the 3" x 3" adhesive pads. 4. Fasten the high end of the FallGuard® channel to the corrugated metal using the self-drilling screws. 16