Siemens Sample project SPS 2012

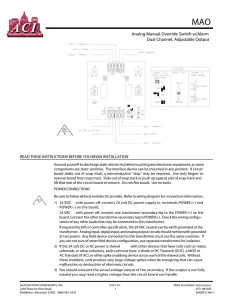

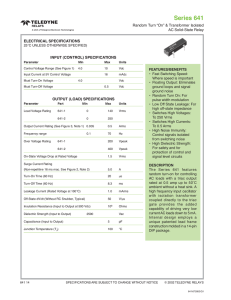

advertisement