Complete Gasket Product Range Guide

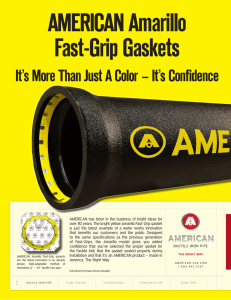

advertisement