Development of A Large-Scale Laboratory Facility for Sediment

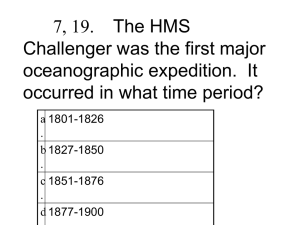

advertisement