ORC Green Machine

advertisement

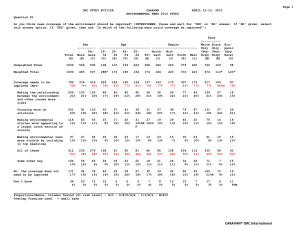

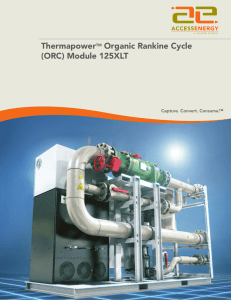

Presentation Technology ORC GREEN MACHINE 1) GB Consulting COMPANY INTRODUCTION 2) TECHNICAL PART 3) BIOGAS STATION CONNECTION EXAMPLE 4) REFERENCES IN CZECH REPUBLIC 1) GB Consulting COMPANY INTRODUCTION GB Consulting s. r. o. company is major in dealing with savings of energy expenses which are related with running of large technological complex or factory units through resulting utilization and transformation for production of electric energy, coolness or heat. odpadní teplo elektřina chlad teplo GB Consulting s. r. o. company uses certified foreign technologies based on utilization of waste heat from industrial process, renewable sources of energy and increase of energy efficiency for every provided application with maximum efficiency and brief payback period. GB CONSULTING activities are divided in seven spheres: • delivery of ORC systems for electric energy production • delivery of absorption refrigerating systems • delivery of special high potent heat exchangers • delivery of technologies for cogeneration and trigeneration GB CONSULTING activities are divided in seven spheres: • delivery of GB Gasifired technologies– biomass gasification with resulting utilization for production of electric energy or heat • delivery of GB Pyrolysis technology– polymerization of waste plastic, tires and waste oils with resulting production of electric energy or heat • delivery of biomass heating plant 2) TECHNICAL PART Green Machine Green Energy Solution Green Machine convert low and high potential heat into electric energy. GREEN MACHINE Schematic diagram function Patented Twin Screw Expander ElectraTherm has patented „twin screw expander“ which offers significant benefits for small ORC Top efficiency even by low rotates < 1500 RPM , just as by compressor Noticeable lower than turbine (> 10000 RPM) Lubrication process Lubrication process ORC is underway in pursuance of working fluid. No classical lubrication process needed. Screwed expander Working fluid R245Fa Honeywell circulation pump Screwed expander Generator of electric energy with control panel ORC Green Machine – heat in electric energy Low waste heat system of transformation heat in electric energy Function include : • Modular construction / variety • Compact device – Easy installation • Automatic system of proceeding and control • Only tree major components with movable parts • Distant monitoring and control • Automatic start/stop system 30-75 kW Green Machine Green Machine converts 8-10% low waste heat in electric energy , depending on condensation temperature How works Green Machine Green Machine SERIES 4000 (output 30 – 75 kW) ElectraTherm Green Machines can be integrate parallely and make together max. output 375 kW electric energy. Evaporator - input waste heat: • • • • Required total permanent heat input: 300 - 860 kW Range of input water temperature: min 80 - 116 °C max. Target temperature of input water: 110 °C Flow rate of hot water: 7.6 – 12.6. l/s Condenser – cooling part : • Total rate of waste heat : 270 -790 kW • • • Temperature of input cooling liquid: min 73 °C Maximal temperature of condensation water: 38 °C (minimum 4 °C) Flow rate of hot water: 9.5 – 15.5 . l/s Simplified connection diagram GPR 9.5 – 15.7 l/s Cooling tower Circulation pump Reverse temperature 18 – 49 0C 480V, 3Ø ~60A/phaze Cooling - médium 10 -41 0C Filtr ElectraTherm and GB Consulting perform optimization of use coolness for your application's Sources of waste heat: • • • • • Stacionary engine Solar Thermal Biomass Geothermal Combustion productchimney - Or - Green Machine waste 370 – 790 kW energy in condenser Safety valve Green Machine Expansion vessel Green Machine Green Machines can be integrate in modules depending on increasing x 10 capacity of waste heat source till 3 000 kW Bypass Input temperature 88 -1160C HEAT SOURCE Reverse temprerature 76 – 99 0C Cirkulation pump Every aplication Green Machine needs Q = 7,6 – 12,5 l/s ∆ 370 – 860 kW energy from hot water Broad range of use Green Machine works with all kind of waste heat Applikations: Stationary gensets • • Device works with engine output from 500 kW – 3 000 kW > 300 000 instaled units Co-Produced Water – Oil & Gas Biomass Solar Thermal Main advantages and design GREEN MACHINE Environmental Green Machine made by ElectraTherm company use sources of waste, useless or technological heat for electric energy production and in the same time: • • • • • Are absolutely fuel free– utilize waste, useless or technological heat Are emission free – safe environment and production CO2 Have low service costs Have attractive pay back period Have intended life time 20 years Free in the area Container design Container design Green Machine – Sampling Gas, oil or biomass boiler Geothermal Boiler room– combustion products fro chimneys Solar Thermal Cogeneration units, Waste heat and combustion products engines and compressor from industrial production 3) BIOGAS STATION CONNECTION EXAMPLE INSTALED UNITS „BPS Strážnice“ General supplier : Envitec Biogas Europe Cogeneration unit: Jenbacher - output 800 kWe Available heat: < 600 kW Intended input temperature: 103° C Jenbacher CHP Engine block CHP Biogas inlet Jenbacher CHP Combustion exchanger Interconnection with primary hydraulic circle and increase of temperature 103°C Jenbacher CHP hydraulic circle Distributor CHP Hydraulic circle pump , heat piping into ORC Jenbacher CHP hydraulic circle – heat piping into ORC Heat piping into ORC – CHP measuring, piping of heat thru a building into ORC Heat piping into ORC Cooling part ORC hydraulic circle – hot ant cold water piping Coolers circulation pump, Media connection Hot water tree-way valve cold (cooling)water connection Insulated hydraulic system ORC, including measuring ORC hydraulic circle – hot and cold water piping ORC cooler Emergency cooler CGU Oil engine cooling CGU ORC Green Machine – compact box ORC Green Machine - front part - control panel - PLC PLC panel ORC Green Machine – distant monitoring + control PLC – control panel ORC Green Machine 4) REFERENCES IN CZECH REPUBLIC Basic information INVESTOR Pavlík - ENERGO spol. s r.o. Moravská Třebová, Dvorní 1489/2b, PSČ 571 01 1 pc Green Machine < 50 kW Service hours > 6000 hours Cogeneration unit: MWM - 2 x 499 kW Available heat value: < 400 kW Achieved input temperature: 90 ° C Average output of Green Machine: 36 kW Basic information INVESTOR Fosfa, a.s Břeclav - Poštorná, Hraniční 268, PSČ 691 41 2 ks Green Machine < 50 kW Cogeneration unit : Tedom 2 x 500 kW Available heat value : < 800 kW Achieved input temperature: 92 ° C Average output of Green Machine: 76 kW Basic information INVESTOR TORO VM, a.s. Vysoké Mýto, Hradecká 251/1 PSČ 566 01 1 ks Green Machine < 50 kW Cogeneration unit : Schnell 4 x 250 kW Available heat value : < 650 kW Achieved input temperature: 95 ° C Average output of Green Machine: 39 kW Basic information INVESTOR Stavos s.r.o. Brno, U Svitavy 2 PSČ 618 00 1 ks Green Machine < 50 kW Cogeneration unit : Schnell 3 x 250 kW Available heat value : < 600 kW Achieved input temperature: 95 ° C Average output of Green Machine: 39 kW Basic information INVESTOR Rudos Zemplínska Teplica 1 ks Green Machine < 75 kW Cogeneration unit : Jenbacher 1036 kW Available heat value : < 780 kW Achieved input temperature: 115 ° C Average output of Green Machine: 60 kW Basic information INVESTOR ZD Žerotín a.s. Strážnice, Za Drahou 1331PSČ: 696 62 1 ks Green Machine < 50 kW Cogeneration unit: Jenbacher 800 kW Available heat value: < 550 kW Achieved input temperature: 100 ° C Average output of Green Machine: 41 kW Next project ORC Green Machine (Preparation) Signed contracts for realization in 2012 and 2013: BPS Kyselov ……………………...800 kW (BPS) BPS Šlapánov……………………. 800 kW (BPS) BPS Rybníček……. ……………...526 kW (BPS) Spalovna Rumpold…………... 1500 kW (Kotel) BPS Bečváry……………………….526 kW (BPS) Slovak republic ………….together 7 projects THANK YOU FOR YOUR ATTENTION! ElectraTherm 4750 Turbo Circle Reno, Nevada 89502 USA GB Consulting, s.r.o. Hudcova 533/78c 612 00 Brno - Medlánky Czech Republic Toll-free: 877-883-7101 Fax: (775) 398-4672 gsm: +420 603 201 285 gsm: +420 731 604 962 gsm: +420 733 133 888 e-mail: info@gbconsulting.cz www.gbconsulting.cz www.gbgasifired.com www.gbpyrolysis.com