AUT842 - DMACC

advertisement

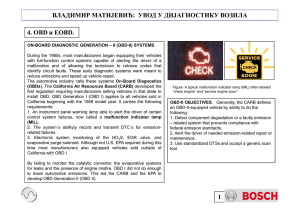

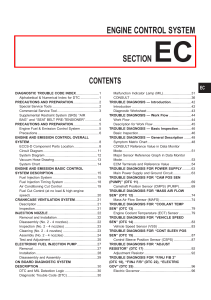

Des Moines Area Community College Course Information – EFFECTIVE FL 2013-01 Acronym/Number AUT 842 Title Historical Ref AUT 842 Auto Computerized Eng Controls Credit Breakout 4 2 4 0 0 (credit lecture lab practicum work experience) PREREQUISITE(S): AUT 834, AUT 652 COURSE DESCRIPTION: This course builds upon the knowledge and skills learned in previous automotive courses to prepare the student to service On-Board Diagnosis 2 computer controlled vehicles. The theory and operating principles of automotive computers, sensors, and control devices will be emphasized. Lab instruction on late model cars will be included. COURSE COMPETENCIES: During this course, the student will be expected to: 1. Describe electronic engine control terminology. 1.1 Examine government standards for engine performance. 1.2 Explain SAE acronyms. 1.3 Describe OBD2 diagnostic monitors. 1.4 Discuss enabling criteria. 1.5 Define an OBD trip or drive cycle. 2. Explain the function of onboard engine computers. 2.1 Discuss central processing units. 2.2 Explain types of memory. 2.3 Define baud rate. 2.4 Explain driver circuits. 2.5 Explore module communication. 2.6 Explain types of data communication protocols. 2.7 Check for module communication (including CAN/BUS) errors. 3. Examine generic and manufacturer specific diagnostic trouble codes (DTC’s). 3.1 Discuss type A, B, C, and D DTC’s. 3.2 Explain freeze frame data. 3.3 Examine malfunction indicated lamp (MIL) operation. 3.4 Obtain and interpret scan data. 3.5 Retrieve and record stored OBD 2 DTCs. 3.6 Clear stored DTCs. 3.7 Access and follow service information diagnostic charts. 3.8 Diagnose the cause of DTC related engine performance conditions, determine necessary action. AUT 842 4. Evaluate inputs sensors. 4.1 Identify thermistor type sensor operation. 4.2 Describe variable reluctance sensor operation. 4.3 Explain pressure sensor operation. 4.4 Examine mass airflow sensor operation. 4.5 Discuss oxygen sensor operation. 4.6 Identify potentiometer sensor operation. 4.7 Measure input device voltage, current and resistance values. 4.8 Test input devices with graphing multimeter or oscilloscope. 5. Evaluate output actuators. 5.1 Describe solenoid operation. 5.2 Discuss stepper motor operation. 5.3 Identify relay operation. 5.4 Explain lamp indicator operation. 5.5 Measure output device voltage, current, and resistance values. 5.6 Test output devices with graphing multimeter or oscilloscope. 5.7 Command output device operation with a scan tool. 6. Examine ignition system operation. 6.1 Identify primary and secondary component operation. 6.2 Explain ignition timing theory. 6.3 Examine crank and cam sensors. 6.4 Discuss ignition system computer interface. 6.5 Test and inspect ignition components, determine necessary action. 7. Discuss fuel injection operation. 7.1 Examine injector driver circuits. 7.2 Compare speed density to mass airflow systems. 7.3 Describe idle control systems. 7.4 Discuss fuel trim strategies. 8. Inspect and test computer controlled engine performance systems. 8.1 Locate components on vehicles. 8.2 Perform functional checks on related emission control systems. 8.3 Diagnose faults by symptom, determine necessary action. AUT 842 COMPETENCIES REVIEWED AND APPROVED BY: Jerry Burns DATE: July 2011 FACULTY: 1. 2. 3. COMPETENCIES REVIEWED AND APPROVED BY: Jeff Calkin DATE: October 2008 FACULTY: 1. Brett Gimer 2. Jeff Calkin 3. 4. 5. 6. Effective date August 2012 Originated by: Campus: extension: Revision(s): A Brett Gimer B C 6594 8/09; 7/11; U N W OC