Top of the House

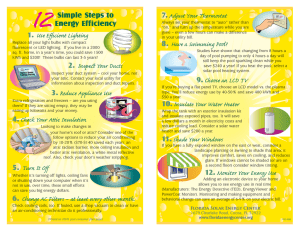

advertisement