owner`s operation manual

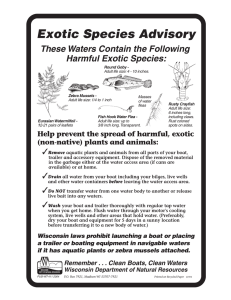

advertisement