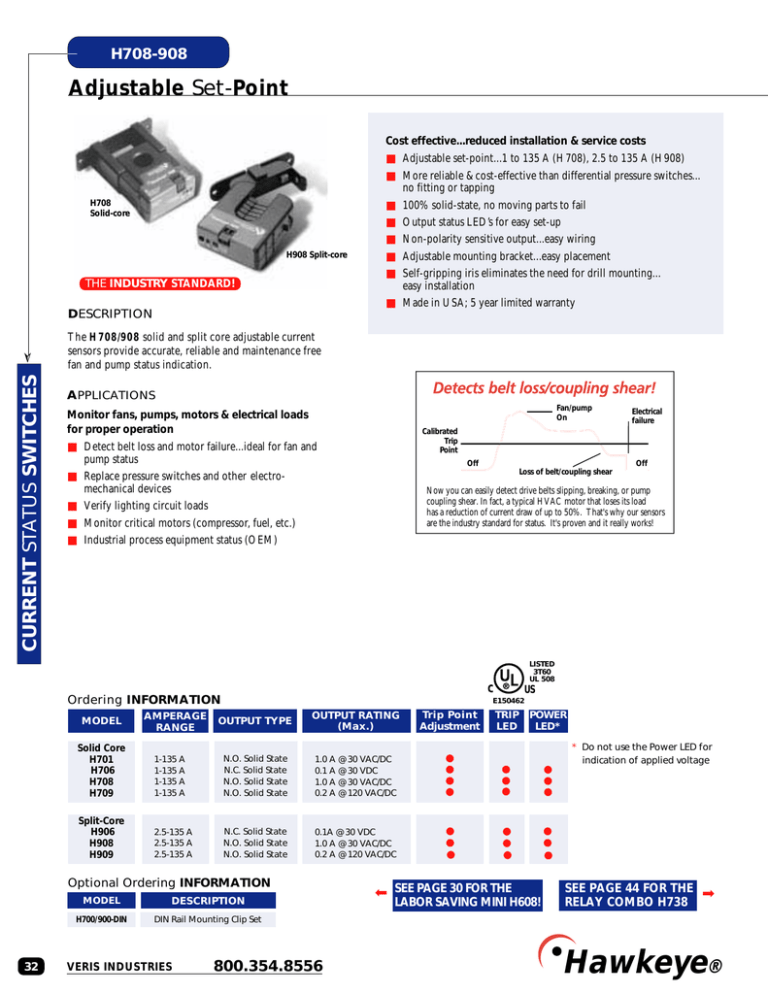

CURRENT STATUS SWITCHES H708-908 Adjustable Set

advertisement

H708-908 Adjustable Set-Point Cost effective...reduced installation & service costs ■ Adjustable set-point...1 to 135 A (H708), 2.5 to 135 A (H908) ■ More reliable & cost-effective than differential pressure switches... no fitting or tapping H708 Solid-core ■ 100% solid-state, no moving parts to fail ■ Output status LED’s for easy set-up ■ Non-polarity sensitive output...easy wiring H908 Split-core ■ Self-gripping iris eliminates the need for drill mounting... easy installation THE INDUSTRY STANDARD! ■ Made in USA; 5 year limited warranty DESCRIPTION ➢ CURRENT STATUS SWITCHES ■ Adjustable mounting bracket...easy placement The H708/908 solid and split core adjustable current sensors provide accurate, reliable and maintenance free fan and pump status indication. A PPLICATIONS Fan/pump On Monitor fans, pumps, motors & electrical loads for proper operation Electrical failure Calibrated Trip Point ■ Detect belt loss and motor failure...ideal for fan and pump status Off Off Loss of belt/coupling shear ■ Replace pressure switches and other electromechanical devices Now you can easily detect drive belts slipping, breaking, or pump coupling shear. In fact, a typical HVAC motor that loses its load has a reduction of current draw of up to 50%. That's why our sensors are the industry standard for status. It's proven and it really works! ■ Verify lighting circuit loads ■ Monitor critical motors (compressor, fuel, etc.) ■ Industrial process equipment status (OEM) LISTED 3T60 UL 508 US Ordering INFORMATION MODEL AMPERAGE RANGE E150462 OUTPUT TYPE OUTPUT RATING (Max.) Solid Core H701 H706 H708 H709 1-135 A 1-135 A 1-135 A 1-135 A N.O. Solid State N.C. Solid State N.O. Solid State N.O. Solid State 1.0 A @ 30 VAC/DC 0.1 A @ 30 VDC 1.0 A @ 30 VAC/DC 0.2 A @ 120 VAC/DC Split-Core H906 H908 H909 2.5-135 A 2.5-135 A 2.5-135 A N.C. Solid State N.O. Solid State N.O. Solid State 0.1A @ 30 VDC 1.0 A @ 30 VAC/DC 0.2 A @ 120 VAC/DC 32 MODEL DESCRIPTION H700/900-DIN DIN Rail Mounting Clip Set VERIS INDUSTRIES 800.354.8556 ➡ Optional Ordering INFORMATION Trip Point Adjustment TRIP LED POWER LED* SEE PAGE 30 FOR THE LABOR SAVING MINI H608! * Do not use the Power LED for indication of applied voltage SEE PAGE 44 FOR THE RELAY COMBO H738 ➡ Hawkeye® H708/908 APPLICATIONS/WIRING EXAMPLE: Monitoring Fan /Pump Motors for Positive Proof of Flow Status In Motor Control Center Belt/Shaft Sensed Amps 135A max. Starter utomation Control Panel Set Point N.O. STATUS OUTPUT 1.0 A @ 30 VAC/DC Open awkeye® 908 Status Closed Motor Fan/pump awkeye® 908 Split-Core Adjustable Current Status Sensor ➢ DIMENSIONAL DRAWINGS Mounting Bracket .90" (23 mm) .89" (22 mm) Mounting Bracket .75" Dia 1.10" (28 mm) 2.90" (74 mm) 2.93" (74 mm) Self-gripping Iris 708 908 Optional DIN Rail Clip ! ! CAUTION: Consult instructions prior to installation CAUTION: Consult instructions prior to installation LISTED 3T60 Class 2 2.56" (65 mm) DIN Rail Clip Side View 2.58" (65 mm) Sensed Amps 135A max. Set Point N.O. STATUS OUTPUT 1.0 A @ 30 VAC/DC Status Open Status Closed Optional DIN Rail Clip Sensed Amps 135A max. Set Point N.O. STATUS OUTPUT 1.0 A @ 30 VAC/DC 3.20" (81 mm) DIN Rail Clip Side View 2.65" (67 mm) .20" (5 mm) 1.04" (26 mm) LISTED 3T60 Class 2 2.55" (65 mm) Status Open Status Closed 1.05" (27 mm) R. .13" SPECIFICATIONS Sensor Power .................................................. Induced from line Isolation .......................................................... 600 VAC rms Temperature Range ......................................... -15º to 60ºC Humidity Range .............................................. 0 - 95% non-condensing Dimensions (708) ............................................ (L x W x H) 2.93" x 2.65" x 1.05" Sensor Hole Size (708) ................................... 0.75” diameter Dimensions (908) ............................................ (L x W x H) 2.90" x 2.58" x 1.04" Sensor Opening Size (908) .............................. (L x W ) 1.10" x .90” 33 VERIS INDUSTRIES 800.354.8556 Hawkeye® CURRENT STATUS SWITCHES ■ Monitor positive fan or pump status by sensing changes in current flow resulting from motor failure, belt loss or slippage, and other mechanical failures.Wiring runs are shorter than with differential pressure switches, since the Hawkeye does not have to be located at the fan or pump being monitored. ■ H708 (solid core) is ideal for new construction projects. ■ H908 (split-core) is ideal for retrofit projects. Flow