Plug-in Hybrid Electric Vehicles for CO2

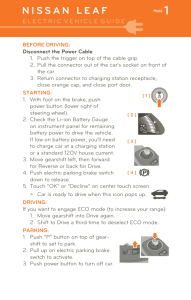

advertisement