Inspection Hot Topics

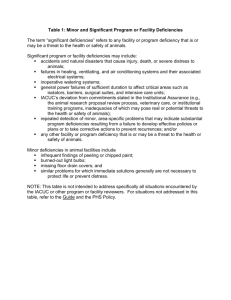

advertisement

Inspection Hot Topics QP Forum, Trinity College Ciara Turley, Inspector, HPRA 16th April 2015 Content • Hot topics = common deficiencies • Data based on 100 inspections conducted in 2014 • Inspections of non-sterile and sterile finished product manufacturing sites, API manufacturing sites and third country manufacturers 15/04/2015 2 Critical Deficiency • A critical deficiency is one which has produced, or leads to a significant risk of producing, either a product which is harmful to the human patient, or in the case of veterinary product, harmful to an animal or which could result in a harmful residue in a food-producing animal 15/04/2015 3 Major Deficiency A non-critical deficiency is one which has produced or may produce a product, which does not comply with its marketing authorisation; or which indicates a major deviation from EU Good Manufacturing Practice; or (within EU) which indicates a major deviation from the terms of the MIA or which indicates a failure to carry out satisfactory procedures for release of batches or (within EEA) a failure of the Qualified Person to fulfil their legal duties; or a combination of several ‘other‘ deficiencies, none of which on their own may be major, but which may together represent a major deficiency and should be explained and reported as such. 15/04/2015 4 Other Deficiency • A deficiency, which cannot be classified as either critical or major, but which indicates a departure from good manufacturing practice. 15/04/2015 5 Breakdown of deficiencies cited in 2014 140 120 100 80 60 critical major 40 other 20 0 15/04/2015 6 Quality system deficiencies 50 45 40 35 30 25 critical 20 major other 15 10 5 0 15/04/2015 7 Deviation / CAPA deficiencies • Lack of investigation detail documented • Lack of consideration of reoccurrence • No CAPAs raised • Root cause not stated or lack of supporting evidence for conclusions • Impact on other batches / equipment not considered • Lack of effectiveness checks • Inadequate trending • Lack of definition, particularly planned deviations and ‘events’ 15/04/2015 8 Example of Quality System deficiencies • For Deviation X relating to a faulty magnetic stirrer, the report did not include details of what had caused the stirrer to malfunction and if the repair had dealt with this • Deviation Y related to breaking of vials in the in-feed zone and at the crimping machine. There was no evidence in the file that training recommended for engineers and a microbiologist had been performed. • Deviations X, Y and Z related to cartons for product X (two instances) and product Y sticking together. The recommendation for each deviation was that Logistics would take the matter up with the carton supplier. There was no record that this had been done. • Deviation Notification X referred to an issue with the belt on the filling line a resulted in ampoule breakage. A new belt was installed again. There was no investigation or discussion of the root cause which was said to be due to the assembly of the belt. 15/04/2015 9 Examples of Quality System deficiencies • The root cause analysis was heavily weighted towards poor asepsis of the operator in question for that isolated incident. This was not considered a satisfactory assessment to determine the actual root cause of the contamination event. • Deviation reports included a section for reporting whether the deviation had occurred previously; the company were only entering deviations in this section if they had occurred within the same calendar year. • The root cause of the deviation (that a valve had not been completely closed during micronisation) did not have a preventive action assigned to prevent re-occurrence. • For deviation X the company had considered the impact isolated to one batch even though the same solution had been used in the manufacture of sixteen batches in total. There was no documented risk assessment to support this conclusion 15/04/2015 10 Examples of Quality System deficiencies The release disposition of batch X was not considered appropriate as: • There was inadequate data to show that the process was successfully revalidated and could consistently produce product that met specification. • There was inadequate data to support the rationale for the assigned root cause of the out of specification blend assay • There was no manufacturing investigation completed to determine the root cause at the time of batch release • There was no comparison of revalidation data with results from previous validation batches 15/04/2015 11 Premises and equipment deficiencies 70 60 50 40 30 critical major 20 other 10 0 15/04/2015 12 Examples of Premises and Equipment deficiencies With respect to the re-qualification of load X • The justification to accept qualification loads with breaches in the sterilization band during the hold phase was not considered acceptable. The approach did not consider the suitability of the cycle or ability of the autoclave to control such loads e.g. min load for X which contained a piece of tubing. • A number of items used appeared to have been previously subjected to sterilization. The controls in place to ensure they represented a normal load were not clearly described. E.g. stopper and crimp bags with multiple taped punctures. • Comparison to the original PQ was not performed. 15/04/2015 13 Examples of Premises and Equipment deficiencies The cleaning and storage of equipment was deficient in that: • The size, design and condition of the wash room was deficient. – The room was small and cleaned equipment was stored in close proximity to dirty equipment – The wash sinks were visually stained and contaminated as were some of the surrounding walls – The sinks were not flush and sealed against the walls – There was a particularly contaminated recessed area observed above the sink • Some balances and scales stored in another room had not been stored in a clean state as white residues and streak marks were observed on some of these items together with sticky residues which remained after the removal of obsolete calibration stickers. 15/04/2015 14 Examples of Premises and Equipment deficiencies Management of equipment maintenance at the site was deficient in that: • Unplanned maintenance activities had not been recorded and there was no requirement for these activities to be recorded under the company’s quality management system at the time of the inspection; • It was observed that the company’s investigations into the high number of incidences of rogue tablets had not considered that non-recording of unplanned maintenance activities may have been a contributing factor in this regard. 15/04/2015 15 Examples of Premises and Equipment deficiencies • The company relied on previous equipment qualification studies to determine the possibility of rogues entering a finished batch rather than challenging the packaging lines again during investigation to verify that the systems for identification and rejection of the rogues remained effective. 15/04/2015 16 Production deficiencies 14 12 10 8 critical major 6 other 4 2 0 sterile 15/04/2015 media fill visual data integrity line inspection clearance inspection cleaning validation general 17 Example of Production deficiencies Incoming receipt checks for raw materials were inadequate as: • The Approved Vendors Listing (AVL) did not specify all actors in within the supply chain, e.g. suppliers • The vendor / manufacturer address of product stored in the warehouse did not match the address listed on the AVL • AVLs were generated from information on labels of material stored in the warehouse rather than from the approved sites listed by the planning / purchasing department • The company had sourced a number of batches of active substance through a supplier that refused to disclose the actual manufacturer of the active substance. The material was used in the manufacture of aseptically prepared finished medicinal product. 15/04/2015 18 Example of Production deficiencies Labeling practices were considered to increase the overall risk to product in that: • It was accepted practice at the facility to place material labels on container lids unfixed for a period on time. This was considered to add undue risk to the process as labeling mixups would not be readily detected as SAP was utilized to manage material from this point. • Rejected material within the dispensary and warehouse was not physically segregated. They were not clearly marked as rejected. It was noted that reject materials were blocked on SAP but this was used for ‘on hold’ status also. The warehouse staging room was cluttered with a high volume of rejected material outside of the ‘on hold’ area. 15/04/2015 19 Example of Production deficiencies Aseptic process controls were considered deficient. • It noted that vials unloaded from the Lyos, were not afforded appropriate protection from the background environment during transfer to the capping station, which was classified by the company as Grade A, but which was considered Grade B background by the inspector. • There was no validated raised or displaced stopper detection system in place. Reliance was placed on a visual check prior to capping and vials were permitted to be stored in this area for a period up to 48 hours. 15/04/2015 20 Example of Production deficiencies During set-up activities on the it was noted that: • component contact parts were exposed for excessive periods of time in the background environment which was classified by the company as a Grade A room, which was considered the background Grade B to the Grade A critical zone and were permitted to be carried from the autoclave trolley across this room prior to transfer into the critical zone • In general component parts were considered to have been handled excessively and not in a manner conducive to good asepsis • Sporocidal agents were not proactively included in the disinfectant rotation in the site’s sanitisation programme, 15/04/2015 21 Example of Production deficiencies • The manner in which set up was conducted was considered cumbersome and due to the positioning of the product lines, the set up was made much more difficult to perform with a satisfactory level of asepsis due to the fact that when attempting to complete the aseptic connection, there was not a clear line of sight or a clear path to enable the operator to make a quick and clean connection. • Two media fill failures had occurred where growth promotion testing post filling failed. No growth had been obtained and the investigation had not determined a root cause for this failure. 15/04/2015 22 Example of Production deficiencies • The particulate monitoring system for both the oncology and non–oncology suites had been removed for repair from both areas and had not been replaced at the time of inspection. During the intervening period a mobile monitoring device was introduced but it was only possible to perform particulate monitoring in one location, the vial infeed location, leaving the filling zone without any particulate monitoring for an extended period. • There was a report for 5cfu/plate for a settle plate obtained in the sterility testing laboratory on the day after sterility testing of the batch. There was no discussion of any relevant implications of this result within the investigation report. 15/04/2015 23 Outsourced Activities 37 of 47 deficiencies related to technical agreements. • Absence of agreements • Lack of designation of responsibilities • Absence of key issues – e.g. Timelines regarding reporting of significant deviations 15/04/2015 24 Examples of deficiencies • With regard to contractual arrangements with a QP – the job description (dated August 2009) was not reflective of the current responsibilities, – approximately 48 SOPs were ‘read and understood’ over two days in 2014. • The contract QP was not formally required to read relevant quality summary documents prior to recommencing QP activities following long periods off site e.g. quarterly management reviews, PQRs etc. 15/04/2015 25 Learning • Review these elements as part of self inspection programme • Review investigations to ensure root cause, impact assessment and CAPA well defined and sufficient evidence included • Review equipment and production deficiencies within your own company processes • Ensure technical agreements in place and defined – review the content as part of PQR. 15/04/2015 26