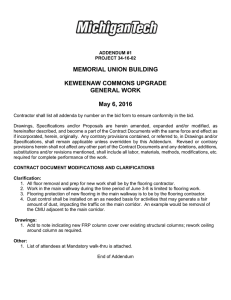

KKE Fax - Metro Sales Online Planroom

advertisement