advertisement

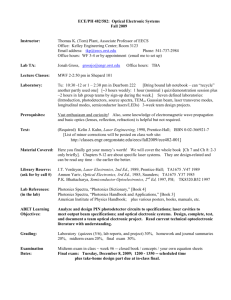

OPTOLINES JOURNAL FOR PHOTONIC SOLUTIONS OptiGrid – Structured Illumination Microscopy An Accessible Alternative to Confocal Imaging New: Shearplate-Interferometer Laser beam collimation testing – reliable results in seconds! Synthetic resin in lightweight construction Optical in-situ monitoring New: 4-segment LED ring light: RL4-S4 – Perfect contrast setting and ideal object illumination | Page 20 2 Editorial Content Innovas Gold coating: New technique | 75th Annual Meeting of the DPG and combined Spring | Page 4 Basics | Innovas Shearplate-Interferometer – Laser beam collimation testing | New USB Controller CF 30 | Beam-splitter cubes for near-infrared | Page 6 Dear Readers, International trade shows are rewarding opportunities for connecting with people; in fact, personal contact with customers is at least as important as the success of the show. Trade shows also serve as economic indicators: We were relieved to find out that the US economy has overcome the crisis. Photonics West was a stunning success for both the community and the industry. On the first day alone we generated more customer leads than during the entire show last year – and all were of high quality. We had substantial discussions with some 100 industry customers, and were pleased to note that our products and solutions are perfectly attuned to the needs of their market sectors. Qioptiq has guided many a product from innovation to marketability. A selection of these products will be presented in this issue of Optolines. We want to thank all of our guest authors from science and industry for their valuable contributions. Maybe we will see you at the major DPG conference in Dresden, or perhaps at the Laser World of Photonics in Munich? Let me be the first to cordially invite you to visit our exhibits and our booth! Best regards, Dr. Mario Ledig, Vice President of Technology, Qioptiq Innovas New focus-variable lenses – Production optimized: Price of Optotune lenses reduced | Quality control for technical medical products – Reliable measurement, secure documentation | Page 9 Innovas | Applications Lenses for the world’s smallest camera – Journey inside the human body | Synthetic resin in lightweight construction – Optical in-situ monitoringa | Page 11 Applications NANO 250 laser modules: Precise control made easy – New remote control unit | An Accessible Alternative to Confocal Imaging | Page 15 Innovas LED cold light source: CLS-LED USB – External control using ”e-Light” | New 4-segment LED ring light: RL4-S4 – Perfect contrast setting and ideal object illumination | Page 19 Service | Specials Powerful optical analysis software – Powerful optical analysis software TracePro® training courses | Page 21 Basics | Qioptiq live Lightweight mirrors for space telescopes – Materials, designs and manufacturing methods | Review Photonics West | Schedule of trade fairs 2011 | Recommended reading | Imprint | Page 22 No 26 | 2011 optolines Insight Qioptiq invests in coating technology Qioptiq is strengthening its core competency in coatings at its Göttingen location, as well as expanding the infrastructure. This expansion is focused around the acquisition of a new ion beam sputtering system. This is a high-precision coating technology that makes it possible to apply homogeneous and compact coatings with excellent reproducibility, including highly complex mirror and filter coatings. The new system can produce reflective coatings that achieve nearly 100% reflectivity. The system was put into operation in December 2010. Investment in cleanroom technology Qioptiq made further investments in its cleanroom assembly division, to optimize both production processes and quality assurance. Furthermore, this specialist in photonics has invested in a special cleaning technique for optical elements that further improves environmental protection and occupational safety while at the same time significantly increases the quality of the cleaning process. In addition to developing optical systems, the Göttingen location specializes in coatings for optical components that are integrated in systems in a broad variety of application areas. Qioptiq supplies highprecision coatings for head-up displays and for the semiconductor industry, to name just two examples. Ion beam sputtering system presented at a press conference in Göttingen; standing: Volker Brockmeyer, Qioptiq Executive Vice President. Integrated degree program: Students at Qioptiq Qioptiq’s integrated degree program combines in-house training with studies in the Natural Sciences and Technology Department at the University of Applied Sciences and Arts (Hochschule für angewandte Wissenschaft und Kunst, or HAWK) in Göttingen. Currently four Qioptiq students are taking part in this proven model for engineering science studies. The program has already helped many to obtain a degree that practically guarantees good career opportunities. One major advantage is that students have close, continual contact with both the university and the company from a very early stage. The combination of hands-on training with an academic program creates result-oriented, industrysavvy engineers who work well in teams. www.hawk-hhg.de/index_en.php No 26 | 2011 optolines Success with Qioptiq: Integrated degree program with R&D head Thomas Thöniß (2nd from r.) and Jasmin Gleitze, Lars Andreae, Björn Winkelbach and Anne Ledebuhr (l. to r.). 3 4 Innovas Excellent product and environmental properties Gold coating: New technique Coatings for applications in the near- and mid-infrared spectral ranges have been a core competency at Qioptiq in Göttingen for more than 40 years with a main focus on the gold coating. Now, Qioptiq has developed a new gold coating technique that significantly improves both the product properties and the environmental properties of the gold layer. ing, which becomes necessary when the element is exposed to dirt. Since gold is naturally a very soft material, such wear rapidly leads to visible damage, or even to destruction or detachment of the coating. This has made it impossible to fully meet the combined requirements of abrasion resistance, high reflectivity, weather resilience and adhesion strength – until now. Mirror with gold coating. The exceptional characteristic of gold is its extremely high reflectivity: Ravg >98% above 2 µm, a level not attained by any other material. Gold coatings are found primarily on optical elements used in astronomy, security technology, surveillance and in military applications. With so many different areas of application, gold coatings can be subjected to any of a range of extreme ambient conditions, such as the high humidity at high temperatures found in tropical regions, or extreme temperature fluctuation. Another potential source of wear on the coating’s surface is clean- New technique developed Qioptiq has developed a new coating technique that enables full conformity with the stringent environmental stability requirements for gold coatings. One technique for increasing environmental stability is to protect the metal with a thin dielectric coating. To preserve the advantage of high reflectivity provided by a gold coating, however, it was essential to ensure adequate transparency of the dielectric material in the IR range when developing a suitable meth- Standard test method Gold coating damaged during environmental testing. Properties Verified in accordance with Abrasion resistance MIL-M-13508C, 4.4.5 and DIN-ISO 9211-4-01-01 Adhesion strength MIL-M-13508C, 4.4.6 and DIN-ISO 9211-4-02-01 Thermal shock resistance MIL-M-13508C, 4.4.4 and DIN-ISO 9022-14-09-1 Solvent and cleaning resistance MIL-F-48616, 4.6.9.2 and DIN-ISO 9211-3-12-3 Water solubility MIL-F-48616, 4.6.10.3 and DIN-ISO 9022-4-04-02 Damp heat MIL-C-48497, 4.4.6 and DIN-ISO 9022-12-07-1 Environmental properties of the new gold coating from Qioptiq. No 26 | 2011 optolines Innovas Gold-coated prism system for infrared applications. od for combining the gold layer with the protective dielectric coating. Alongside the production process and good control of the process parameters, this is essential for high reflectivity values. Environmental stability assured The new coating developed in the Coating Center at Qioptiq in Göttingen meets the requirements for environmental stability listed in the table above. This has been demonstrated in accordance with standard test methods, which were applied to various batches of gold coating material on a variety of substrate materials including B270, N-FK5 and diamond-turned and diamond-milled aluminum. Contact: Wolfgang Wilhelm wolfgang.wilhelm@qioptiq.de Comparison of gold coating reflectivity values at various angles of incidence. 75th Annual Meeting of the DPG and combined Spring Meeting of the Condensed Matter (SKM) and AMOP (S-AMOP) sections The Spring Meeting of the German Physics Society (Deutsche Physikalische Gesellschaft e.V., or DPG) was held once again in the familiar surroundings of the lecture hall center at the Dresden University of Technology. No 26 | 2011 optolines The DPG meetings address young physicists in particular and other experts in the field, as well as students. This year, some 7500 participants were expected. As in previous years there was a parallel industrial exhibition and book fair, where Qioptiq once again showed its products. Visitors had a chance to see first-hand the innovations presented in this issue of Optolines, and also got a general overview of our extensive range of optomechanical products. 5 6 Basics Laser beam collimation testing: reliable results in seconds! New: Shearplate-Interferometer For fast collimation testing of laser beams under laboratory conditions, Qioptiq offers a new, compact Shearplate-Interferometer that delivers outstanding value for money. Even under unfavorable ambient conditions – whether vibration, dirt, or temperature fluctuations – it provides fast, reliable results with certified, consistent quality. Wedge-shaped shear plates are used to check the collimation of a laser light beam. In the case of an ideally collimated light beam, a smooth wave front is incident on the wedge plate and parallel interference fringes perpendicular to the wedge are formed. This is indicated by a reference band on the observation plane (Fig. 3). With this technique, for example, expansion systems can be adjusted for reproducible collimation [1]. Fig. 1: Reliable measurement results, outstanding value for money: the new ShearplateInterferometer. When expanded laser beams are used in the laboratory, the quality of the laser beam collimation is crucial for the application; in particular when collimated laser light serves as a solid measure. Collimation can be checked using applicable metrology devices, such as a Shack-Hartmann sensor (see the article beginning on page 22 in this issue of Optolines). Shearplate-Interferometers (see Fig. 1) offer an interesting and, moreover, economical alternative. Principles of Shear Plate Interferometry Shearplate-Interferometers are based on the principle of superimposing a wave front on itself. The light beam being tested is split into two waves which are shifted laterally to one another, producing the shear. The division and shifting of the wave fronts is a result of the reflectivity on the two surfaces of an extremely flat plate, called the shear plate. The two partial waves interfere in the overlap area (Fig. 2). The original wave front can be derived from the resulting interferogram. Evaluating the tilt angle If the expansion system is not aligned properly – it shows either a positive or negative focusing effect – the interference fringes tilt clockwise (negative) or counter-clockwise (positive). This effect can be evaluated quantitatively. Using the tilt angle of the interference fringes, the radius of curvature of the incident wave front, R, can be derived with the following equation: Many assembly options The interference fringes are easy to evaluate visually on the integrated dispersion plate. A reference band is embedded in the plate to detect the tilt angle of the fringes. Qioptiq Shearplate-Interferometers are available in three different models, each optimized for a different beam-diame- No 26 | 2011 optolines Basics Fig. 3: Interfere.nce pattern of a collimated laser beam Fig. 2: Operating principle of the Shear Plate Interferometer. ter range between 1 mm and 25 mm: 1 mm to 3 mm 3 mm to 8 mm 8 mm to 25 mm Moreover, these Shearplate-Interferometers are designed with flexible mounting options for trouble-free integration in highly individual optical assemblies. They are compatible out-of-the-box with Qioptiq Rail and Column systems, and adapter plates can be ordered separately for mounting the Shearplate-Interferometer in other systems. Bore holes for versatile mounting options are a standard feature of the interferometer housing. Mounting compatibilities Microbench compatibility: use Mounting Plate 25 with Mounting Holes (G061041000) Tube-C system compatibility: use C-Mount/Microbench Adapter (G061659000) No 26 | 2011 optolines Applications and typical accuracies Shearplate-Interferometers are primarily used for testing the collimation of laser beams. With a beam diameter of 25 mm, collimation can be determined with a precision of 50 µrad. Because it can determine the radius of curvature of the wave front, the Shear Plate Interferometer can also be used to determine the focal length of weakly focused optical systems, or to determine the radius of curvature of weakly focused convex and concave mirrors in the range above 8 m. For example, using a Shear Plate Interferometer and an expanded 25 mm laser beam, the radius of curvature of a 45 m mirror can be determined with a precision of +/- 3 % by reading off the relevant parameters, given in the equation above. results for beam diameters of 1 mm to 25 mm in Vis-NIR spectra Determination of wave front radius of curvature opens up a wide range of application areas Adapter plates available for a broad variety of assembly options Robust design thanks to common path interferometry and an operating principle without electronic parts [1] Malacara, D.; Optical Shop Testing. Third Edition Wiley-Interscience Publication New York 2007 Author: Jan-Martin Heidrich Qioptiq Göttingen Other applications and typical accuracies Refractive index determination of 10 mm thick plane-parallel plates to +/- 0.001 Focal length determination of lenses/ mirrors to +/- 0.03 % Tested by MPI in Göttingen A prototype of the Shear Plate Interferometer (Fig. 1) has already been used at the Max Planck Institute, where it was employed in the Nano-Biophotonics Department for measurement tasks in connection with 4Pi microscopy. Focus on the Qioptiq ShearplateInterferometer Optimum collimation determination; three models to provide immediate S Φ df Fig. 4: Example of tilt in the interference fringes. 7 8 Innovas New USB Controller CF 30 Compact solution: New USB Controller CF 30. Positioning movement now smoother than ever Piezoelectric inertial drives make precise positioning easier than ever before. Thanks to the incremental drive principle, positioners can be adjusted in the millimeter range with precision in the nanometer range. Spacesaving and efficient drive engineering has produced extremely compact solutions for a variety of positioning tasks. And now a new USB controller enables even smaller steps, as well as simultaneous movement along three axes. The new USB Controller CF 30 makes it possible to adjust micropositioning elements from Qioptiq, such as the MS 30 series positioners with piezoelectric inertial drive, more smoothly and precisely than ever. It connects to the computer’s USB 2.0 interface and operates in the microstep range. For this, the full step voltage (familiar from Manual Control Unit CN 30) is digitally divided into 64 stages, enabling a step size of < 10 nm. Only every 64th step is held without power, however, and at that step the controller can be disconnected from the computer without causing any change in the position of the micropositioner. A separate power supply unit, included in delivery, is connected to supply the CF 30 Controller with sufficient power for simultaneous operation of all three axes. Furthermore, the USB Controller CF 30 offers a ramp function that can be used to minimize the reverse motion of the sliding carriage when a full step is taken, as well as to adapt the load ratio. The result is a more uniformly shaped motion sequence. The USB Controller CF 30 can be connected to a computer running a 32-bit operating system or the 64-bit version of Windows Vista or Windows 7. It is also compatible with Linux operating systems. Other software utilities included in delivery are drivers and interfaces for LabView and MathLab. New in the Qioptiq product line Beam-splitter cubes for near-infrared Effective immediately, the proven beam-splitter cubes with edge lengths from 5 mm to 40 mm are also available in a version for the near-infrared range. These economical and high-quality optics for low laser output are ideal for splitting and combining light beams and, unlike beam-splitter plates, do not cause any deflection of the beam. The layered design of this cube, available through the LINOS catalog, is optimized for the wavelength range from 750 nm to 1200 nm. On request the coating can be adapted to individual requirements in the range from 700 nm to 2000 nm and for various directions of polarization. In addition to the standard 50:50 split, customized versions with division ratios of 40:60, 20:80 and 10:90 can be supplied on short notice. NIR beam-splitter cube. No 26 | 2011 optolines Innovas Save up to 40%! Production optimized: Price of Optotune lenses reduced New focus-variable lenses The Optotune family of focus-variablelenses has a new member: in addition to the familiar electronically controlled lens with a focal length range of +15 mm to +50 mm, a new variant with a focal length range of +30 mm to +100 mm is available starting immediately. The focus-variable lenses from Optotune are manufactured from elastic polymers and have unique properties: The lens shape can be changed from convex to concave mechanically or electronically. The variable focal length of these innovative spherical lenses enables the design of very compact optical systems. Optotune lenses are available in versions for the visible spectral range of 400 nm to 700 nm as well as for the near-infrared range from 700 nm to 1100 nm. Thanks to optimized production methods, all lenses from Optotune can now be offered at savings of up to 40 percent. Prices range from 150 euros for the lens with mechanical focal length adjustment to 300 euros for the electronically adjusted NIR variants. Easy to integrate in optical designs The focal lengths can be adjusted within a few millimeters, and the aperture is 10 mm. Thanks to their good optical The electronically controlled EL-10-30 lens and the ML-20-35 mechanical lens are both available from Qioptiq. properties, these lenses are ideally suited to be used both in compact imaging systems and in illumination systems, such as LED-based systems. They can easily be controlled electronically and integrated in optical designs. in your optics, or are interested in a complete OEM optics design with a focusvariable lens, contact us to talk about your options! If you would like expert consultation or other support in integrating these lenses Contact: Wolfgang Wilhelm wolfgang.wilhelm@qioptiq.de Focus-variable lenses from Optotune Designation Adjustment ML-20-35 VIS HR Mechanical Focal length range Order number Price* in euros -40 to +40 mm G39 9551 000 150.00 EL-10-30 VIS HR EL-10-30 VIS LD Electronic +15 to +50 mm G39 9552 000 250.00 Electronic +30 to +100 mm G39 9553 000 250.00 EL-10-30 NIR LD Electronic +30 to +100 mm G39 9554 000 300.00 *Sales tax not included; prices valid only in Germany and Austria. No 26 | 2011 optolines 9 10 Innovas Quality control for technical medical products Reliable measurement, secure documentation The Fetura VMS optical coordinate measurement system is designed for fast and efficient testing of medical products and supplies. Important quality-related data are collected and documented automatically and extensively, with unbeatable speed and precision. These excellent quality-assurance characteristics make Fetura unique among metrological instruments. The new FETURATM Vision Metrology System from Qioptiq excels in the optical metrology market with its highquality design. We have been supplying high precision optics for machine vision, quality control and inspection applications for nearly 120 years. Now, we’ve taken that expertise, coupled it with cutting-edge technology and innovative designs, and developed a unique system that integrates state-of-the-art components to deliver outstanding productivity, flexibility, and precision. Image acquisition with ring light illumination to test medical products with the Fetura – now with long-term storage of measurement results. Qioptiq has developed new methods and designs to give customers the maximum possible flexibility in generating measurement results. Using the Visual Basic programming language in the Fetura coordinate measurement machine is yet another example of built-in versatility. All the standard functions of the metrology software are available to the user, while at the same time equipment operators have the option of writing their own scripts. This makes it easy to meet customers’ individual requirements with regard to data storage and documentation. Thanks to sophisticated interfaces and use of the latest object-oriented development tools, the system can easily be combined with applications from other manufacturers. All of the measurement data created are stored as objects and can be loaded in other applications for processing. Moreover, no modifications are required for implementing existing user interfaces. The test specifications automatically produced by the script generator can document the entire process sequence – this feature is especially useful when the system is used in automated work shifts. Focus on Fetura Multi-sensor design, zoom optics, lasers and 3D scanners open up a wide range of application areas Rapid and extensive collection of quality-related data Open to customization thanks to state-of-the-art object-oriented development platform Upgradeable to meet future requirements Economical purchase price means fast ROI Contact: Robert Wegard robert.wegard@qioptiq.de Fetura with Visual Basic programming. No 26 | 2011 optolines Innovas Lenses for the world’s smallest camera Journey inside the human body For more than 10 years Qioptiq has been developing and manufacturing high-resolution “chip-on-the-tip” lenses for the use in flexible endoscopes. In cooperation with a long-time partner, Qioptiq has now created and produced a number of different lenses, each with an outer diameter of 1.2 mm, for the world’s smallest camera. When it was introduced at the OPTATEC 2010, the mini-chip lens generated considerable interest among potential customers. Looking at internal organs The tiny camera lets doctors take a virtual voyage into the human body to observe living, functioning organs – and sometimes to pinpoint the source of problems, e.g. such instruments can be used to document how blood enters and Camera unit System components 1.2 mm camera head with lens, plus video processing unit Image sensor CMOS Effective pixels 49,280 Resolution 220 H x 224 V Video signal NTSC or PAL System functions Gain, white balance, automatic gain control, red/blue enhancement, zoom, brightness Power supply AC 100-240 V, 50/60 Hz Aperture angle 100° or 130° Unbeatably small and efficient: the smallest camera in the world. leaves the heart. For this, an endoscope with a camera travels directly through blood vessels into the heart and supplies a live image. The smallest camera in the world offers a broad array of medical possibilities, from facilitating the diagnostic process to improving precision in surgery. What previously had been hidden from the doctor’s searching eye is now vividly revealed. areas offered only limited possibilities in such dimensions up to now. In the medical field, the camera can be integrated directly in flexible or rigid endoscopes. Contact: Yvonne Franz yvonne.franz@de.qioptiq.com Dimensions: Camera head Shape Round Outer diameter 1.2 mm Length 5 mm Camera cable length Up to 3 meters Dimensions: Video processing unit Width 300 mm Height 70 mm Depth 250 mm No 26 | 2011 optolines Other areas of application There is an extensive range of application areas in which the miniature camera can be put to use. Thanks to its ultracompact design, the system is universally adaptable for use in industry. Great potential is seen in such areas as machine vision, image processing and inspection systems – up to now, all of these Dimensions of the camera. 11 12 Applications Synthetic resin in lightweight construction Optical in-situ monitoring Monitoring and measuring applied loads in highly stressed lightweight construction systems made of fiberreinforced plastics (FRP) calls for reliable and adaptable technology. Optical measuring techniques in particular become more important in this field. An economical and versatile solution is created by using the very materials from which the product is made – such as the epoxy resin used in lightweight structures – as photoelastic in-situ measuring equipment. Lightweight construction with fiber-reinforced plastics is being pushed in industrial production for the design of highly stressed systems. Examples can be found in the aerospace industry, motor sports and in the rotor technology employed in wind turbine generator systems. These developments are accompanied by an increased demand for in-situ monitoring of the pertinent characteristics in stress situations. In addition to classic stress measurement techniques such as electromechanical pressure sensors and strain gauges, optical sensors are rapidly gaining in importance for many such applications. “Quasi-waveguide” An extremely economical and versatile measurement method can be implemented by using the very material that the test piece is made of, or components of the material, as an optical measuring device. A simple approach for measuring the load case is to analyze variations in the polarization state of light as a consequence of stress-induced birefringence in the material. Epoxy resin, the matrix material in fiber-reinforced plastics, generally has the high transparency required for use as an optical sensor and exhibits a pronounced stress birefringence even at low mechanical loads. Using the epoxy resin component of the fiber-reinforced material as a “quasi-waveguide” for linear polarized laser light, the load case of a construction element can be monitored over a given surface area. The primary focus of this monitoring is not on the measurement of minor stressdependent variations of the resulting polarization state, but rather on monitoring significant variations in this variable Resin Epoxy resin, crystal clear Araldite Hardness, HB 1.75 Elasticity module 3300 186.2 4500 Fig. 1: Schematic test setup: a) supercontinuum source (fiberware I-LUM100, fiberware), b) polarizer, c) test machine, d) sample with irradiation point in the homogeneous load distribution range, e) analyzer, f) spectroscope. Fig. 2: Experimental setup in the load assembly with A) supercontinuum source (I-LUM100, fiberware), b) optical bench, c) test machine (Instron 4505, Instron Ltd.), d) spectroscope. over time as a consequence of extreme stresses or material failures. Testing raw materials To analyze principle dependencies, the first step was a photoelastic examination of two selected epoxy resins in monolithic form within the visible wavelength range. Figure 1 is a diagram of the experimental setup, and Figure 2 shows the integration of the setup in a commercial stress-measurement assembly. The white light source and spectrometer in the experimental setup enable broadband monitoring for evaluation of wavelength-selective effects. The light source is a supercontinuum source with a microchip laser-pumped photonic crystal fiber (I-LUM 100, fiberware). No 26 | 2011 optolines Applications testing show a significant dependence on the working wavelength. Figure 4 depicts stress relaxation over time at a wavelength of 750 nm, and shows that relaxation times can range from seconds (Araldite) to minutes (epoxy resin, crystal clear). Fig. 3: Load-dependent static measurement signal as a function of the measured wavelength. The load-dependent properties of the test piece are clearly subdivided into two ranges. In the lower load range (less than 0.5 MPa), the signal amplitude is low and exhibits only very weak dependence on load and wavelength. In the upper load range, on the other hand, the signal amplitude alternates strongly with the load and shows distinct wavelength dependence. Stress-induced modulation of the measurement signal is described by the photoelastic constant, which is a dimension of the measuring sensitivity of the basic material at the corresponding wavelength. Thus the selection of the appropriate working wavelength proves to be decisive for both the material in question and the particular application. No 26 | 2011 optolines Relaxation behavior of the material Another important characteristic for practical use in load sensors is the relaxation behavior of the material in relation to the optical signal. Equivalent to the static load, the results of stress-relaxation Application scenarios The special properties described above yield a number of possible scenarios for metrological applications. Because the photoelastic constants are very low and the sensitivity correspondingly high, even slight load variations can be measured with high resolution. With this type of measurement, however, it is important to bear in mind that the relaxation behavior can lead to excessive dead times in the sensor signal (Fig. 4a). Another application area for in-situ photoelastic measurements is in monitoring extreme load cases and mechanical breakage. This type of application involves mea- Fig. 4: Measurement signal during relaxation of sample upon removal of load. b) Differentiated measurement signal after sudden complete unloading of sample (simulated break). 13 14 Applications Fig. 5: Testing a high-performance rowing oar: a) rowing oar made of FRP, b) light guide, c) epoxy resin sensor element, d) measuring line. suring the variation in the measurement signal over time (first derivative). In such cases, rapid, forceful loading or unloading (typical of material breakage) would produce high measurement amplitudes while slow changes would be filtered out (Fig. 4b). Signal processing here is considerably simplified because the actual polarization state of the test light is no longer significant for the measurement process. Practical use: A sample application To demonstrate the method described for derivative signal evaluation in a practical application, an epoxy resin sensor was integrated in a high-performance rowing oar made of fiber-reinforced plastic (Fig. 5). Figure 6 shows the derivative of the measurement signal under intermittent application of force on the oar. Pronounced load and unload peaks are seen at the beginning and end of the drive phase of the rowing stroke. The periods of very low fluctuation during the recovery phase (between drive phases), on the other hand, are averaged out. Outlook Photoelastic analysis and monitoring of mechanical loads present an economical alternative to conventional load sensors in testing state-of-theart lightweight structures made with optically transpa-rent construction elements, such as epoxy resin. This method is particularly well suited for reliable and accurate detection of extreme loads and mechanical breakage. It is just as useful, however, for in-situ measurement of unexceptional intermittent load cases, as seen in the example presented here. www.fh-zwickau.de Authors: Christopher Taudt, Tobias Baselt, Uwe Gieland, Holger Klose, Peter Hartmann (Westsächsische Hochschule Zwickau) Fig. 6: Sensor signal as a function of rowing cycle. No 26 | 2011 optolines Applications NANO 250 laser modules: Precise control made easy New remote control unit The NanoControl user software supplied with the NANO 250 series laser modules enables perfect adjustment of the optimum working area using a computer. This facilitates both adaptation to individual requirements and long-term storage of working area data. Fig. 1: The new RemoteControl unit. Laser diode temperature control The RemoteControl can be used to switch the laser on and off, as well as to adjust and display the laser output level. Furthermore, this remote control unit offers the unique option of influencing the wavelength by adjusting the laser diode temperature (shift of up to ± 5 nm). The temperature can also be viewed on the display. The new RemoteControl unit (Fig. 1) offers users all of the functionality found in the familiar NanoControl software – and makes it accessible without the computer. This unit is simply connected to the laser controller using the microUSB cable that comes with the laser system (Fig. 2). Power is supplied to the unit over the USB cable. The RemoteControl has a 5-button pad for operating the laser modules, as well as a 3-line display. Features: Focus on RemoteControl 5-button operating pad 3-line display Contrast and brightness can be adjusted separately Powered by the laser controller; no separate power supply for the remote control Simple connection to the laser system using micro-USB cable (included with the laser system) Display and adjustment of laser temperature (if this function is supported by the laser system) Display and adjustment of laser output power On/off switch for laser operation Displays operating status of both key switch and interlock input Contact: Norbert Henze nobert.henze@qioptiq.de Fig. 2: NANO 250 controller with micro-USB cable. No 26 | 2011 optolines 15 16 Applications Structured Illumination Microscopy An Accessible Alternative to Confocal Imaging Biomedical scientists are constantly searching for innovative imaging techniques to enhance details of the intracellular and intercellular environments of biological samples. The combined requirements of high spatial resolution, low noise, and optical slicing may call for complex and very costly techniques (e.g., laser scanning confocal microscopy). These techniques can be somewhat limiting due to cell damage, photo-bleaching, and unavailable excitation wavelengths associated with lasers. Costs associated with the techniques can be prohibitive as well. As an alternative, researchers are looking to new groundbreaking techniques to acquire the highly focused and detailed imagery necessary to support their research. cence illuminator field stop slot of a wide field microscope (Olympus, Center Valley, PA, Nikon, Melville, NY, Zeiss, Thornwood, NY, and Leica, Bannockburn, IL upright and inverted microscopes), a controller containing motor focus and DAC piezo controllers and a calibration slide. Fig. 1: OptiGrid system components as implemented by Leica Microsystems, (Wetzlar, Germany) on D5500 upright microscope and a DMI6000 inverted microscope. One particularly noteworthy alternative to complex confocal methods of imaging is the emergence of structured light technology. Structured light imaging provides highly focused, rich contrast images similar to those produced by confocal technologies. However, structured light technology eliminates out of focus information and noise through an innovative, cost effective system that is integrated into a conventional wide-field microscope and desktop PC. Structured light theory was developed in 1997 by Professor Tony Wilson and his colleagues at Oxford University (Oxford U.K.). The technology has become commercially available in the last few years. Specialty optics manufacturer Qioptiq Inc. (Rochester, NY) purchased the license for developing structured light technology from Professor Wilson’s group, resulting in the OptiGrid Structured light imaging system. Imaging with Structured Light The OptiGrid system comprises three components (Fig. 1): the piezo slider, which is inserted into the epi-fluores- Images are acquired through a variety of digital research grade cameras (e.g., Hamamatsu, Bridgewater, NJ, Photometrics, Q-Imaging, Tucson, AZ or Andor, South Windsor, CT, etc.). OptiGrid imaging is supported by three major software platforms MetaMorph (Molecular Devices, Downingtown, PA), Volocity (Perkin Elmer, Lexington, MA) and NIS Elements (Nikon Instruments, Melville, NY). System compatibility with these popular software packages enables users to employ software they currently own and minimize their learning curve in setup, image capture, and microscope automation. Three dimensional images can also be acquired by simply adding ‘Z’ stage control to the microscope focus drive, which allows the user to capture a ‘Z’-stack of OptiGrid images at gradually elevated planes. Once the piezo slider is inserted into the light path, the system captures No 26 | 2011 optolines A B the specific in-focus portions of the sample without the distraction of extraneous (out-of-focus) information (Fig. 2). The system maintains the conventional functionality of the host microscope. Simply removing the piezo slider allows resumed utilization of the microscope for other wide-field applications (Fig. 3). By integrating a fluorescence microscope with a digital camera and imaging software, researchers are able to view an OptiGrid image on the screen economically, utilizing a standard fluorescence light source. At the heart of the system is a onedimensional custom OptiGrid grating, mounted on a piezo-electrically driven actuator. Once inserted into the light path of the epi-fluorescence illuminator, voltage is applied to the piezo crystal to change its length. The piezo crystal provides highly accurate repositioning of the grating pattern. The grating pattern is projected onto the sample and is moved perpendicularly to the grid lines across the sample. Three images must be captured to produce one OptiGrid image. The first image is taken at any position of the grating. The grating is then moved linearly, by onethird prior to capturing the second image, and moved again another one-third of the grating period to capture the third image (Fig. 4). A patented algorithm then eliminates the parts of the image that are above or below the primary image plane, as well the projected grid pattern. The resulting image is sharp, clean, No 26 | 2011 optolines Applications Fig. 2: Comparison of conventional widefield fluorescence image (A) and the same specimen image through an OptiGrid structure light imaging system. The systems enhanced contrast and haze-free imaging is shown in B). Speciman: Mouse Brain, olfactory bulb (40um section). Stained for glial fibrilary acidic protein (red) with nucleic acid counterstain (white). 60x/1.4NA oil immersion objective. Courtesy of :Dr. Adam Puche – University of Maryland (Baltimore). and haze free, and can be viewed simultaneously on the screen. The two-point discrimination of the system is the same as the resolving power of the selected microscope objective. A microscope objective lens with a high degree of spherical aberration correction and UV transmission capability is desirable (e.g., the OptiGrid resolution using a 60X 1.4NA Plan Apo oil objective would be 1/5um). As with any electronic microscope system, an anti-vibration platform is required for optimal performance. Because the system utilizes the illumination source of the host microscope, all wide-field capabilities of that microscope are maintained. When using fluorescence with the system, the excitation and emission filters and dichroic mirrors should be optimized to the specific fluorophore being used. Putting structured light to work The system’s inherent light efficiency and wide-field versatility make it well suited for live cell imaging, such as visualizing organelle dynamics labeled with Green Fluorescent Protein (GFP). JSW-Research (Graz, Austria) is focusing on neurodegenerative disorders such as Parkinson’s disease and Alzheimer’s disease. The histology department of JSW-Research uses the system for 3D imaging and evaluation of drug effects on brain morphology and pathological hallmarks such as synaptic loss, neuronal inclusion bodies, and plaques. One distinct advantage the company has realized using OptiGrid structured light imaging over conventional imaging is the lack of scattered fluorescent light. The system disregards the out-of-focus signals, eliminating blur and haze. The structured light images show enhanced contrast, clarity, and detection sensitivity, making image analysis easier and more accurate. Fig. 3: OptiGrid piezo slider inserts into the epi-fluorescence illuminator. Simple removal of the slider returns the microscope to full conventional functionality. 17 18 Applications Through comprehensive research in neurodegeneration, acute brain damage and neuropharmacology, JSW-Research has at its disposal a variety of valuable disease-relevant in vitro and in vivo models for characterizing drug effects on the central nervous system. Transgenic animals with highly complex pathologies have emerged as relevant tools for preclinical research under in vivo conditions, especially in neuroscience. Loss of synapses in the hippocampal formation and cortex is correlated with memory and learning deficits. This kind of neurodegeneration is especially pronounced in Alzheimer’s disease, in which a significant number of synapses disappear in these areas. Animal models for studying the effects of (drug) treatments on synapse densities exhibit disturbances in their learning and memory abilities but also show a marked loss of synapses in the aforementioned brain structures. Conclusion The OptiGrid technology has circumvented many of the problems that other image capture devices have failed to resolve. Point scanning confocal microscopes are expensive, dedicated systems that rely on highly tuned technical knowledge to operate and maintain. Point scanning systems also have limited use in some applications due to photo-bleaching and shallow penetration depth, particularly those involving living cells and/or thicker tissue samples. Spinning disk (Nipkow) confocal systems have very limited light efficiencies due to the small pinhole size, presenting a challenge for imaging live specimens because intense illumination is required. De-convolution software can result in post-processing algorithmic inaccuracies as well as z-axis image shift, introducing potential uncertainty into imaging results. OptiGrid’s structured light imaging system presents widefield microscopy versatility, combined with specimen-friendly illumination and affordable entry-cost, resulting in a viable and accessible research alternative to confocal microscopy. Author: Mr. Thomas is Market/Product Manager, and Mr. Zinter is Director of Technology, Qioptiq Inc., 78 schuyler Baldwin Drive, Fairport, NY 14450, USA.; Tel. 585-223-2370; fax: 585223-1999; email: info@qioptiqlinos. com. Dr. Cseresnyes is a Research Associate, Dept. of Bio-Chemistry and molecular Biology, University of Maryland (Baltimore), USA. Dr. Hutter-Paier is director of Preclinical Research, and Dr. Hofmeister is a Research Associate, Histology, JSW-Research, Graz, Austria. Fig. 4. Diagram illustrating functional properties of structured light imaging. No 26 | 2011 optolines Innovas LED cold light source: CLS-LED USB External control using “e-Light” The high-performance LED cold light sources in the CLS-LED series of Qioptiq present an economical and energy-saving alternative to conventional light sources for virtually all of the most common applications. An LED cold light source converts far more energy into visible light than a halogen cold light source can, and yet has a service life of approximately 50,000. Storage of up to 4 output adjustment settings for each light source Noiseless and vibration-free thanks to passive cooling system Extremely homogenous, flicker-free illumination Constant color temperature: typically 5,600 K LED service life: approx. 50,000 h (manufacturer’s specification) Fig.1: CLS-LED USB with USB interface and function control port. The light output of the new CLS-LED USB light source can be adjusted quickly and directly using the brightness controller on the front panel. Another option is external control: with a PC connected to the USB port (Fig. 1), the power level can be adjusted through the “e-Light” program that is included in the delivery of the CLS-LED USB (Fig. 2). Up to four different output settings can be stored per light source – for as many as 255 light sources – and then loaded again the next time the source is put into operation. This makes it easy to ensure reproducible conditions for every use. The light source can also be operated in flash mode. When using this mode, the pulse duration, the switch-on delay following No 26 | 2011 optolines the start pulse and the quantity of repeat sequences can be adjusted. Another feature of this light source is its additional function control port (Fig.1). An external device can be connected to this port, for example, to set the brightness using analog voltage (1 V to 10 V) or to set up external trigger pulses for flash operation. Focus on CLS-LED USB: USB interface and function control port for external brightness control and flash control Manual brightness setting with memory function Operating software included Order no. Product designation Price (À)* G405760000 CSL-LED USB 769.00 *Sales tax not included; prices valid only in Germany and Austria Contact: Norbert Henze nobert.henze@qioptiq.de Fig. 2: Easy-to-use software. 19 20 Fig. 1: 4-segment LED ring light with 48 bright, high-quality LEDs. Innovas Perfect contrast setting and ideal object illumination New 4-segment LED ring light: RL4-S4 Ring lights are ideal for shadowless, homogenous illumination of objects with matt finish or only slightly reflective surfaces. The new 4-segment ring light RL4-S4 (Fig. 1) enables professional users to establish the perfect contrast setting and the best possible lighting for the object by selecting the optimum direction of illumination. The RL4-S4 is a state-of-the-art and energy-saving 4-segment LED ring light specially developed for the best object illumination possible as well as excellent contrast properties. It is ideal for use in both science and industry. The four independent light segments can be adjusted separately or in combination using the illuminated push-button control (Fig. 2). The brightness can be continuously adjusted between 0% and 100%. The RL4-S4 has a standard inner diameter of 66 mm. Adapters are available for reducing the inner diameter by as much as 16 mm, down to 50 mm. Thanks to a broad range of accessories, from diffusion plates to polarizing filter sets to protective glass panels and more, the ring light can be adapted to suit practically any illumination task, no matter how complex. Focus on RL4-S4 4-segment LED ring light with 48 bright, high-quality LEDs Energy-saving, environmentally friendly lighting technology Very homogeneous, flicker-free illumination Long LED service life: approximately 50,000 h Continuous brightness control from 0% to 100% Working area from 50 mm to 160 mm Inner diameter: 66 mm Adapters available for inner down to 50 mm Color temperature: 5000 K; other temperatures on request Extensive range of accessories Product Order no. designation Price* (À) G40 5760 000 4-segment LED 529.00 ring light RL4-S4 *Sales tax not included; prices valid only in Germany and Austria. Contact: Norbert Henze norbert.henze@qioptiq.de Fig. 2: Continuous and extremely smooth brightness control with handy table control unit. No 26 | 2011 optolines Service Powerful optical analysis software TracePro® training courses Professional instructors with extensive knowledge of the TracePro® software can help you discover the broad range of application options available in the powerful TracePro® optical analysis program. Simulation of light distribution of a ring light. TracePro® training is designed both for first-time users and for experienced TracePro® experts. The first two days of the three-day seminar provide an introduction to the software and then take a closer look at the basic principles of the program. The primary focus here is on the TracePro® user interface with its many options for configuration of modeling parameters and creation of design models. This part of the seminar also explores the many possibilities for displaying results and analyzing collected data, as well as the use of the new ray tracing options. The third day concentrates on advanced topics such as the analysis of light scattering. Various options in connection with the Monte Carlo method are both discussed on the theoretical level and demonstrated in practical examples. In addition, the third day includes a presentation of the TracePro® Optimizer and an introduction to macro programming in the Scheme language. In their TracePro® seminars Qioptiq empha-sizes a mixture of teaching – which includes addressing questions from the participants – and practical exercises on a PC with models that are highly relevant to real-world use. Registration is limited to ten participants to ensure close interaction and individual attention. The TracePro® software utility TracePro® is a versatile and comprehensive optomechanical design program. Because it is made with the industrystandard CAD-kernel ACIS®, used by a number of CAD software manufacturers, integration of models in other 3D CAD applications is not a problem. The modeling of light propagation in illumination and imaging systems is among the major strengths of TracePro®. No 26 | 2011 optolines Furthermore, the software can be used to calculate intensity structures and the illumination on surfaces, and can model any surface type. The program is also capable of defining any surface as a light source. Another distinguishing feature is its intuitive user interface. Analysis capabilities Light distribution in illumination and imaging systems Scattered light and diffraction in diaphragms Losses or system transmission Absorption of luminous flux or power by surfaces or volume media Light scattering in biological tissue Polarization effects Fluorescence effects Birefringence effects The next TracePro® course will be held in Göttingen, Germany in conjunction with this year’s LASER World of Photonics trade show: Thu. to Sat., May 26 to 28, 2011 To register, send e-mail to: sales@qioptiq.de We will send you detailed information before the course begins. 21 22 Basics Materials, designs and manufacturing methods Lightweight mirrors for space telescopes Telescopes installed in space probes and satellites open realms of exploration that cannot be reached by Earth-bound instruments. Whether in orbit or traveling through space, they supply information that cannot be detected by telescopes on Earth, which are limited by light attenuation and the filtering effect and turbulence of the Earth’s atmosphere. The optics and mirrors in space telescopes have to be specially designed to withstand extreme conditions. When reducing weight of telescope mirrors – known as “lightweighting” – it is essential to take the mechanical stress into account that has an impact on the mirrors such as when the equipment is launched into space. During operation in space, too, the telescope mirrors must withstand considerable stress in various forms. The SEVIRI radiometer (Spinning Enhanced Visible and Infrared Imager) on board the Meteosat Second Generation satellite, or MSG-1, for example, is spin-stabilized and rotates at some 100 revolutions per minute. This is equal to an applied load of up to 30 m/ s2 (5 3 g), which in turn causes significant vibration. The mirrors require a certain degree of stiffness to resist these forces. Extreme temperature fluctuations can also impose excessive mechanical stress on the mirror material. Aside from the thermally induced changes in length of the mechanical retainer, the expansion properties of the mirror material alone can lead to a change in the distance, ∆z, between the primary and secondary mirrors in a telescope. Such variations in this distance can seriously degrade the imaging quality, as illustrated in Figure 1. This shows an example, created with the WinLens3D optical design software from Qioptiq, of a simulated wavefront diagram of a Cassegrain telescope. A significant change of the peak-to-valley value (PV) and the root mean square (RMS) deviation from the ideal form is discernible. Materials for lightweight mirrors The materials used in the construction of lightweight mirrors must meet a variety of requirements if they are to withstand Fig. 1: WinLens3D simulation of the effects of a variation in distance, ∆z, of 500 µm between the primary and secondary mirrors in a Cassegrain telescope. the conditions under which they will operate. The ability to construct an optical surface of sufficient precision is essential, while at the same time a low coefficient of thermal expansion (CTE) coupled with a comparatively high fracture toughness is imperative. Ultra-low expansion (ULE) glasses made of silicon and titanium oxides are well suited for this purpose, as are glass ceramics like ZERODUR® [1]. Other materials that are commonly used in such applications include ceramics such as silicon carbide (SiC) and composites such as carbon fiber re-inforced silicon carbide (C/SiC) [2]. A wide range of techniques are available for processing these materials. An overview of the methods and designs described in the following is presented in Figure 2. Monolithic telescope mirrors Hollow grinding is one of the methods used to create a honeycomb web structure, a design that enables lightweighting in conjunction with mechanical stabilization provided by a structure of solid material on the back of a mirror. This method, however, has considerable disadvantages, because the microscopic geometry of the tools used in this processing step causes microfissures. The depth of these fissures depends on the diamond grit of the grinding tool. A hollow-grinding tool with an average diamond grit size of 9 µm (D9) for example No 26 | 2011 optolines Basics causes microfissures that penetrate to approximately 30 µm. This compromises the stability of the component and results in stresses, which in turn negatively affect the optical quality of the mirror surfaces. An additional processing step, etching, can eliminate the microfissures. The acid used for etching may be hydrofluoric acid (HF), or an aqueous hydrofluoric acid solution, hydrogen fluoride. When the ground glass surface is treated with this wet etching technique, approximately 0.5 mm to 1 mm of material is ablated. Etching is used for other purposes as well, in addition to the finishing treatment of ground surfaces. For example, the Zeiss company has developed an etching technique that is used in manufacturing delicate stabilizing ribs for lightweight construction elements made of glass and glass ceramic, which due to their low wall thickness would break if manufactured with a hollow-grinding tool. This etching method has already been implemented on materials with a wall thickness of just 3 mm. Lightweighting Another method for producing the stabilizing ribs required for lightweight mirrors employs bonded composite elements [3]. With this method, the web structure is implemented by joining individual plates. Aside from the properties of the materials used in the mirrors and their support structures, properties of the cement or other bonding material are important factors in this technique, including its coefficient of thermal expansion and shrink properties. When the adhesive shrinks during the hardening process, the resulting No 26 | 2011 optolines Fig. 2: Various designs and construction methods for implementing lightweight mirrors in space telescopes. tractive forces and tensions can lead to deformations of the mirror surface. Such negative effects can be minimized by the use of a monolithic honeycomb structure made of ceramic [4] or a carbon fiber reinforced composite [5]. This entails cementing a stabilizing element between the actual mirror surfaces, made of glass or glass ceramic, and a base plate. Foamed substrates The use of foamed silicon-infiltrated silicon carbide (SiSiC) as a substrate is another “sandwich method” for the production of lightweight mirrors. This process begins with the production of a polyurethane mold with a specific porosity. The SiSiC is injected and then bonded and hardened in a vacuum by means of a sintering process. In the next step, the substrate is closed off with a sealing layer of the same material that forms the mirror surface [6]. NGST: The future is here One ground-breaking development in the area of lightweight mirror construction for use in space exploration is the Next Generation Space Telescope (NGST), also known as the James Webb Space Telescope (JWST). This is an adaptable mirror element designed to be the successor to the Hubble telescope. The basic structural element of the NGST is a thin sheet of borosilicate glass. Pliable as a membrane, this plate is mounted on motorized positioners [7, 8]. The actuators enable dynamic correction of the curvature and contouring accuracy of the glass membrane. Summary There is a number of special structural features and environmental conditions that must be taken into consideration when designing and manufacturing lightweight mirrors for use in space telescopes. A variety of materials come into play, including glass, glass ceramic and ceramic, to meet these complex requirements. Dynamically correctable, adaptive mirrors are among the designs implemented in this field, alongside monolithic mirrors and various composite or sandwich construction methods. Authors Jennifer Hoffmeister B.Eng. trained as a precision mechanical optician and subse- 23 24 Basics Reflecting telescope in use: Hubble space telescopes (source: NASA). quently studied precision manufacturing Christoph Gerhard, M.Sc. Dipl.-Ing. (FH), ate at the Bremer Institut für angewandte at the University of Applied Sciences and trained as a precision mechanical opti- Strahltechnik (BIAS - Bremen Insitute of Arts (Hochschule für angewandte Wis- cian and subsequently studied precision Applied Beam Technology). Today he is senschaft und Kunst, or HAWK) in Göt- production engineering in Göttingen and a research associate at the Niedersäch- tingen. Currently she is working on her Paris. Gerhard completed his Master’s sischen Innovationsverbund Plasmatech- Master’s degree in optical engineering/ degree in optical engineering/photonics nik (NIP; Lower Saxony Plasma Technol- photonics and is a research associate at while employed as Product Manager for ogy Innovation Association). HAWK. Optics at LINOS and as a research associ- References [1] L. E. Matson, D. H. Mollenhauer: Advanced Materials and Processes for Large, Lightweight, Space-Based Mirrors, The AMPTIAC Quarterly 8/1 (2004) 67-74 [2] B. Harnisch, B. Kunkel, M. Deyerler, S. Bauereisen, U. Papenburg: Ultra-lightweight C/SiC Mirrors and Structures, esa bulletin 95 (1998) [3] T. Frank, T. Hackel, G. Höhne, M. Lotz, R. Theska: Extreme Lightweight Stage Mirrors For Precision Positioning Combining Silicon And Zerodur®”, ASPE 20th Annual Meeting (2005) Norfolk, Virginia, USA. [4] C. L. Davis, M. W. Linder: Low cost light weight mirror blank, PCT/US2000/028808 [5] B. Catanzaro, D. Keane, S. Connell, D. Baiocchi, J. Burge, A. Maji, M. Powers: UItraLITE Glass/ Composite Hybrid Mirror, Proc. SPIE 4013, UV, Optical, and IR Space Telescopes and Instruments (2000) 663-671 [6] A.Novi, G. Basile, O.Citterio, M. Ghigo, A.Caso, G.Cattaneo, G.F. Svelto: Lightweight SiC foamed mirrors for space applications, Proc. SPIE 4444, Optomechanical Design and Engineering (2001) 59-65 [7] J. H. Burge, J. R. P. Angel, B. Cuerden, H. M. Martin, S. M. Miller, D. G. Sandler: Lightweight mirror technology using a thin facesheet with active rigid support, Proc. SPIE 3356, Space Telescopes and Instruments V (1998) 690-701 [8] D. Baiocchi, J. H. Burge, B. Cuerden: Demonstration of a 0.5-m ultralightweight mirror for use at geosynchronous orbit, Proc. SPIE 4451, Optical Manufacturing and Testing IV (2001) 86-95 Exhibitions Qioptiq, May – September 2011 Exhibition Location Country Date Internet IDEF11 Istanbul Turkey 10 – 13 May www.idef11.com/ SID 2011 Los Angeles USA 15 – 20 May www.sid.org/conf/sid2011/sid2011.html EastTec Springfield, MA USA 17 – 19 May Cyto Baltimore, MD USA 21 – 25 May Laser World Munich Germany 23 – 26 May Photo Dubai Dubai Dubai May 2011 MoleSpec 2011 Columbus OH USA June 2011 Photonics Festival Taipei Taiwan 14 – 16 June www.optotaiwan.com/en DGaO Ilmenau Germany 14 – 18 June www.dgao.de/info/tagung11_d.php Paris Air Show Paris France 20 – 26 June http://www.paris-air-show.com/en SPIE Optics & Photonics San Diego, CA USA 21 – 25 Aug PMA Las Vegas USA 6 – 11 Sept http://www.pmai.org/ DSEI Excel UK 13 – 16 Sept http://www.dsei.co.uk/ EMO Hanover Germany 19 – 24 Sept http://www.emo-hannover.de/homepage_d Qual. Expo/MD&M Midwest/Plastec Chicago, IL USA 20 – 22 Sept world-of-photonics.net http://www.photoworld-dubai.com/ No 26 | 2011 optolines Dr. Martin Laging explains the functional layout of a laser to visitors. Insight Photonics West 2011 Trade show retrospective The Photonics West trade show, widely acknowledged to be the most important trade show of its kind in the world, was held in San Francisco at the end of January. This year saw everyone at the top of their game: a positive year in 2010 with good prospects for 2011 for the photonics industry in general, a high point in the semiconductor sector and a strong boost for the telecommunication market. And when the weather in California favored us with a sunny 18°C (a real treat for those of us coming from icy climates!), all signals turned green. The Qioptiq team at Photonics West 2011. Back row (l. to. r.): Fiona Evans (QPUK), Gary Avery (QROC), Bob Zinter (QROC), Martin Laging (QPKG), Joe Delfino (QROC), Michele Durochat (Qioptiq Paris), Mark Radin (QROC), Tom Goundry (QROC), Bill Gilman (QROC), Tan Kiat Beng (QSG). Front row (l. to. r.): Peter Griffith (QROC), Yvonne Chao (QROC), Ruth Wezel (QPKG), Joe Mulley (QROC), Aleem Saleh (QPL), Scott Orr (QROC). QPKG: Qioptiq Photonics, Germany; QPUK: Qioptiq, UK; QROC: Qioptiq Inc., Rochester, USA; QSG: Qioptiq, Singapore. A total of 1162 exhibitors appeared at their best – this was immediately evident given that the booths made a great visual impact as could be seen while touring the two exhibit halls at the Moscone Center in San Francisco. And it went beyond outward appearances: the development cycles of new and innovative products become shorter and shorter. Thus the Photonics West show not only showcases the latest products, but also has the effect of driving innovation throughout the entire sector. No 26 | 2011 optolines Thanks in part to the remarkable recovery of the German economy last year, both the number of German companies – some 100 exhibitors – and the visitors’ interest in products distinguished by the “Made in Germany” label were remarkably high at this year’s Photonics West. The directions from which the most exciting future innovations are expected to come were presented by an “Executive Panel” of management executives from six large companies in this industry sector. They predicted significant advances in the areas of biophotonics, two-photon processes, imaging and image processing, LEDs, DPSS lasers, laser diodes with special properties or new wavelengths, and display technology. The three-day show provided an excellent opportunity for its 19,360 visitors to see the state of the art in the broad field of photonics. The two-day BiOS conference, which directly preceded Photonics West, provided a wealth of information to experts in the field of biophotonics, with 184 exhibitors presenting products relevant to this area. At our green trade show booth we presented Qioptiq’s contributions on the most important technological topics of the day: A highly motivated team from locations on three different continents guided visitors through “The World of Qioptiq.” The range of products offered by Qioptiq is extremely broad so that it sometimes took a few moments to find out which field a visitor was most interested in. But all of the visitors were impressed by the fascinating solutions 25 26 Insight Qioptiq can provide in a wide range of markets. The large number of technical discussions between visitors and booth staff led in turn to some very interesting quotation requests. We look forward processing these together. We were pleased with the popularity of our functional laser layout, equipped with a remote control to give visitors the opportunity to steer and control laser beams and focusable lenses. We also gave away prizes: the lucky winners each received a green Qioptiq stunt kite. Anyone who did not win a kite at Photonics West will have another chance at the LASER World of Photonics in Munich. We are eager to see how the positive resonance of the Photonics West will carry over into the LASER, and are looking forward to seeing you there! DAVID MARKS “This year’s Photonics West was a clear indicator of a strong and resilient optics industry. Qioptiq returned good results in 2010 with a noted rebound in semiconductor and continued growth in the medical and life sciences sectors. We are poised for another good year in 2011 and are enthused with the prospects uncovered last month in San Francisco. Our teams are eager to hit the floor running at Laser World of Photonics in May”, said Qioptiq CEO, David Marks. BILL GILMAN “Based on my interactions on the floor of Photonics West, it is clear to me that Qioptiq has established a strong presence for the new “Q” brand with our many and varied markets. We enjoyed a steady flow of visitors to the booth who were seeking specific solutions that they knew Qioptiq could deliver.”, said Bill Gilman, President of the Rochester, NY Qioptiq operations. “Photonics West was a tremendous success for Qioptiq! I don’t recall booth activity of that level since the glory days of North American expo marketing in the 1980s.”, Gilman added. Author: Dr. Martin Laging martin.laging@qioptiq.de JOE DELFINO “Photonics West 2011 far exceeded our sales expectations producing the highest quality leads I’ve seen in many years. Our marketing efforts of the past year were self-evident in the number of visitors who were familiar with Qioptiq capabilities and came to the booth with specific agendas. Our booth team received visitors from major medical, surgical and biotech companies querying us on projects with definitive funding and timelines… factors sorely been missing through the economic volatility of the past few years.”, said Joe Delfino, Vice President of Sales & Business Development. “Adding to our success, stood more than 30 hours of detailed meetings prior to and during the show with current and prospective customers in the electro optics, dental, biophotonics, semiconductor and surgical markets.”, Delfino continued. No 26 | 2011 optolines Insight Advanced Optics Using Aspherical Elements (SPIE Press Book) Editors: Bernhard Braunecker; Rüdiger Hentschel; Hans J. Tiziani ISBN: 978-0-8194-6749-2 / Vol: PM173 434 pages, $92.00 Recommended reading Advanced Optics Using Aspherical Elements Today’s optical imaging systems accomplish demands that used to be thought impossible. The same is true of the optics used in communications technology, metrology, materials processing, and many other fields. The improvements in performance can be attributed both to the new materials that have become available and to the introduction of new surface treatment and assembly process techniques. An important milestone was reached when the physics of both material ablation in polishing and material application in the coating process were quantified to the extent that they could be modeled mathematically, which in turn enabled computer-aided implementation. This advance makes it possible that to a certain extent, aspheres can be implemented in high-quality optical systems. Previously the high cost would have prevented the wide use seen today, for example in the mass-produced articles of predominantly Asian manufacture such as mobile telephone cameras. Overall value chain To estimate the potential risks and rewards inherent in the use of aspheres it is essential to understand the entire value chain involved. The value chain extends from design and material properties to surface treatment options and coating designs, and all the way to system assembly. Reliable information on all of these aspects can only come from experts. This book brings together contributions from almost 60 authors in 30 noted institutes and optics companies throughout the German-speaking countries. It is gratifying to see that many of the authors and their firms and institutes have in common their membership in the „Deutschen Gesellschaft für angewandte Optik” (DGaO; German branch of the European Optics Society). It shows that the traditional collegiality in the field of optics, which has always transcended company boundaries, is alive and well. Their contributions are complemented by an informatively written introduction that provides an overview and No 26 | 2011 optolines Marketing high technology The objective of the book is to outline the most suitable path for each optics application through the entire value chain, explaining along the way the recommended methods while also pointing out their limitations. Estimated investment and operating costs are detailed as well, and references are provided for those who wish to look up more detailed information on the Internet. This book is highly recommended not only for technicians, but also for decision-makers and consultants in the optics industry. Imprint Editorial staff We want to extend a warm “thank you” to all of our guest authors, who very kindly provided us with their articles, graphs and images. Would you be interested in contributing an article for a future issue? We look forward to hearing from you! Best regards from the editorial staff: Bastian Dzeia, Norbert Henze, Petra Aschenbach, and Thomas Thöniß (Left to right.) analysis of the book’s contents, as well as a look at future trends. The introduction was written almost entirely by the editors, Bernhard Braunecker (former head of optics development at Leica Geosystems AG, Heerbrugg), Rüdiger Hentschel (former head of optics production at Schott AG) and Prof. Hans J. Tiziani, long-time head of the Institute of Applied Optics at the University of Stuttgart. Contact: petra.aschenbach@qioptiq.de Published by: Qioptiq Photonics GmbH & Co. KG, Königsallee 23, 37081 Göttingen, Germany Phone: +49 (0)551/6935 0 www.qioptiq.com Corporate design: abc cross media GmbH, Munich © Editing and production: BEISERT & HINZ Unternehmenskommunikation GmbH www.BEISERT-HINZ.de 27 Take your innovation to new heights! Qioptiq designs and manufactures photonic products and solutions that serve a wide range of markets and applications Gold coating High IR reflectivity Enhanced stability Cost efficient LED cold light USB ShearplateInterferometer Determination of laser divergence Easy to use Micro bench compatible Visit us at: May, 23–26, 2011 Munich, Hall B1, stand 107 USB Interface Memory Funktion Operational Software included QIOPTIQ E-mail: sales@qioptiq.de Tel.: +49 (0) 551 / 69 35-0 www.qioptiq.com ShearplateInterferometer LED cold light CLS-LED USB Gold coating Available for purchase online from the Qioptiq Q-Shop www.qioptiq.com