6 CYLINDERS IN LINE - DIESEL CYCLE 200 kW (272 Hp) @ 2100

advertisement

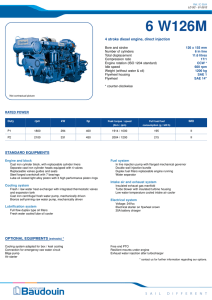

6 CYLINDERS IN LINE - DIESEL CYCLE 200 kW (272 Hp) @ 2100 rpm - 1300 Nm @ 1400 rpm 230 kW (313 Hp) @ 2100 rpm - 1400 Nm @ 1400 rp pm 260 kW (354 Hp) @ 2100 rpm - 1500 Nm @ 1400 0 rpm TIER 3 / STAGE III A C87 ENT FOR INDUSTRIAL APPLICATIONS Specifications Thermodynamic cycle Air intake Arrangement Bore x Stroke Total displacement Valves per cylinder Cooling Direction of rotation (viewed facing flywheel) Compression ratio Diesel 4 stroke D.I. TAA 6, in line 117 X 135 8.7 4 liquid CCW 16 : 1 mm l Injection system Electronic Common rail Performances Maximum rating * At speed Maximum torque At speed Maximum no load governed speed at max rating Minimum idling speed Minimum starting temperature without auxiliaries Oil and oil filter maintenance interval for replacement ** Dry weight (standard configuration) kW(Hp) rpm Nm(kgm) rpm rpm rpm °C hours kg 200 (272) 2100 1300 (133) 1400 230 (313) 260 (354) 2100 2100 1400 (143) 1500 (153) 1400 1400 2300 800 -15 600 865 FOR INFORMATION ON THE AVAILABLE RATINGS NOT LISTED IN THIS DOCUMENT PLEASE CONTACT THE FPT SALES NETWORK. * Power at flywheel according to 2004/26 EC (without fan), after 50 hours running, 3% tolerance, fuel Diesel EN 590 Test conditions : ISO 3046/1, 25 °C air temperature, 100 kPa atmospheric pressure, 30 % relative humidity - Applicable also to DIN 6271, BS 5514, SAE J1349 Standards. ** Oil type: ACEA E3 - E5. Torque - Nm Power - kW 200 kW (272 Hp) @ 2100 rpm 230 kW (313 Hp) @ 2100 rpm 260 kW (354 Hp) @ 2100 rpm 350 300 350 300 350 300 250 200 150 250 200 150 250 200 150 100 50 100 50 100 50 0 0 0 1800 1800 1800 1600 1400 1200 1000 800 600 800 1000 1200 1400 1600 1800 2000 2200 2400 2600 1600 1400 1200 1000 800 600 800 1000 1200 1400 1600 1800 2000 2200 2400 2600 1600 1400 1200 1000 800 600 800 1000 1200 1400 1600 1800 2000 2200 2400 2600 rpm rpm rpm C87 ENT FOR INDUSTRIAL APPLICATIONS Standard configuration Flywheel housing Flywheel size Intake manifold location Turbo exhaust connection Turbocharger Turbocharger location Fan transmission ratio Distance between fan - crankshaft centers Fuel filter Fuel prefilter Fuel pump Lift pump Oil filter Oil sump Oil vapours blow-by circuit Oil heat exchanger Oil fill Starting motor Alternator Engine stop device Wiring harness Power take off (optional) - transmission ratio PTO arrangement Painting type inch SAE 1 - cast iron 14 right side / outwards v-clamp / upwards fix geometry, no waste gate valve middle / left side 1.03 : 1 x = 0 , y = 250 single cartridge - right side included, supplied loose high pressure pump (H.P.P.) mechanical - incorporated in the H.P.P. ecological cartridge - left side suspended sheet steel / 19° angularity limits continuous in all directions close case ventilation incorporated into the block on valve cover 24 V - 4.5 kW 24 V - 90 A by electronic control unit interface wiring loom with accessories 1.1 : 1 PTO optional (200 Nm), cover plate only grey mm n° n° colour Not included in the standard configuration Battery - minimum capacity recommended Battery - minimum cold cranking capacity recommended 180 Ah (24 V) 800 A (24 V) FPT OFFERS THE WIDEST AVAILABILITY OF ENGINE BUILD OPTIONS TO CUSTOMER SPECIFIC REQUIREMENTS WITHIN THE ENGINE SUPPLY. TO FIND OUT MORE ABOUT THE CONFIGURATIONS AND ACCESSORIES WHICH ARE AVAILABLE, CONTACT THE FPT SALES NETWORK. Dimensions L = mm 1253 W = mm 852 H = mm 1008 ENGINE BENEFITS • PERFORMANCE: New engine designed specifically for industrial application; lean lay-out; starting temperature without auxiliaries down to – 15°C (with grid heater down to -25°); performance achieved without external EGR or VGT; new blow-by system; very compact 2nd generation Common Rail System; engine inclination up to 19° continuous in all directions. • SERVICEABILITY: Worldwide service network. • RELIABILITY: For life warranty on Poly V belts; front camshaft layout. • COST EFFECTIVENESS: New extended 600h maintenance intervals (oil and filters change); reduced oil/fuel consumption; fine oil/fuel filtering. • ENVIRONMENTALLY FRIENDLY: Reduced noise; rear geartrain layout; suspended oil pan. • CUSTOMER ORIENTATION: Standard transmission interface SAE1; two possible PTO arrangements; air conditioning compressor arrangement; turbocharger low position. LOCAL DISTRIBUTOR FIAT POWERTRAIN TECHNOLOGIES V.le dell’Industria, 15/17 - 20010 Pregnana Mil.se Milano IT www.fptpowertrain.com Publication P2G04C007E - 07.07 Specifications subject to change without notice Illustrations may include optional equipment. FIAT POWERTRAIN TECHNOLOGIES Via Puglia, 15 - 10156 Torino IT