EMC filters - General technical information

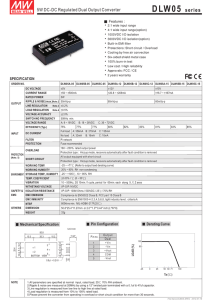

advertisement