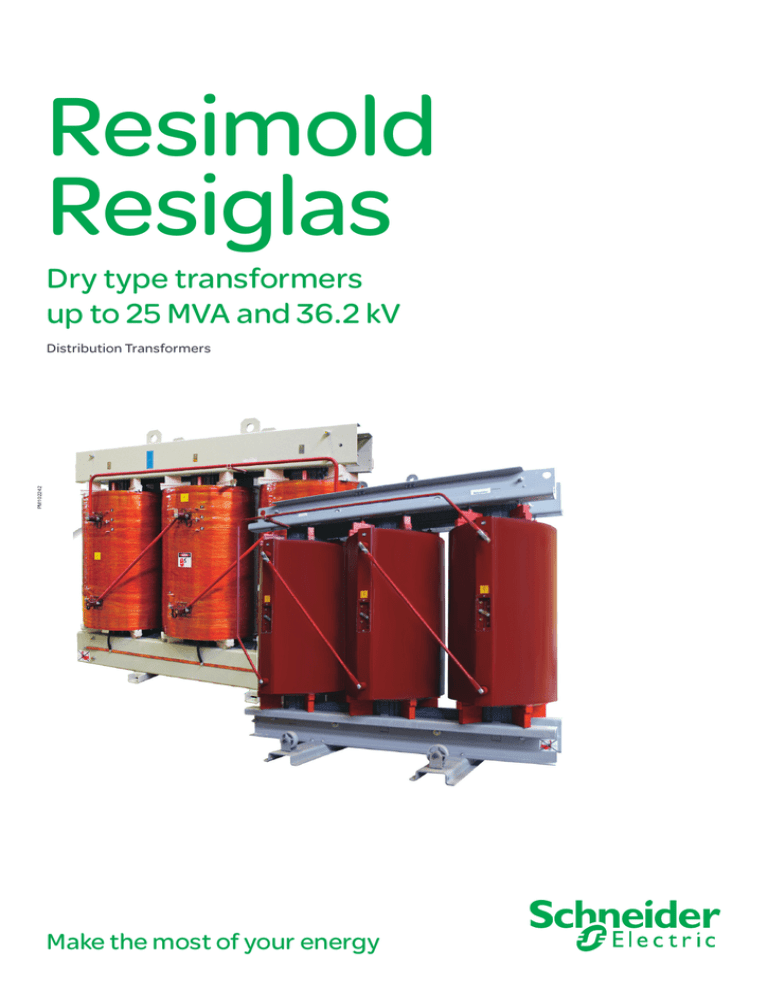

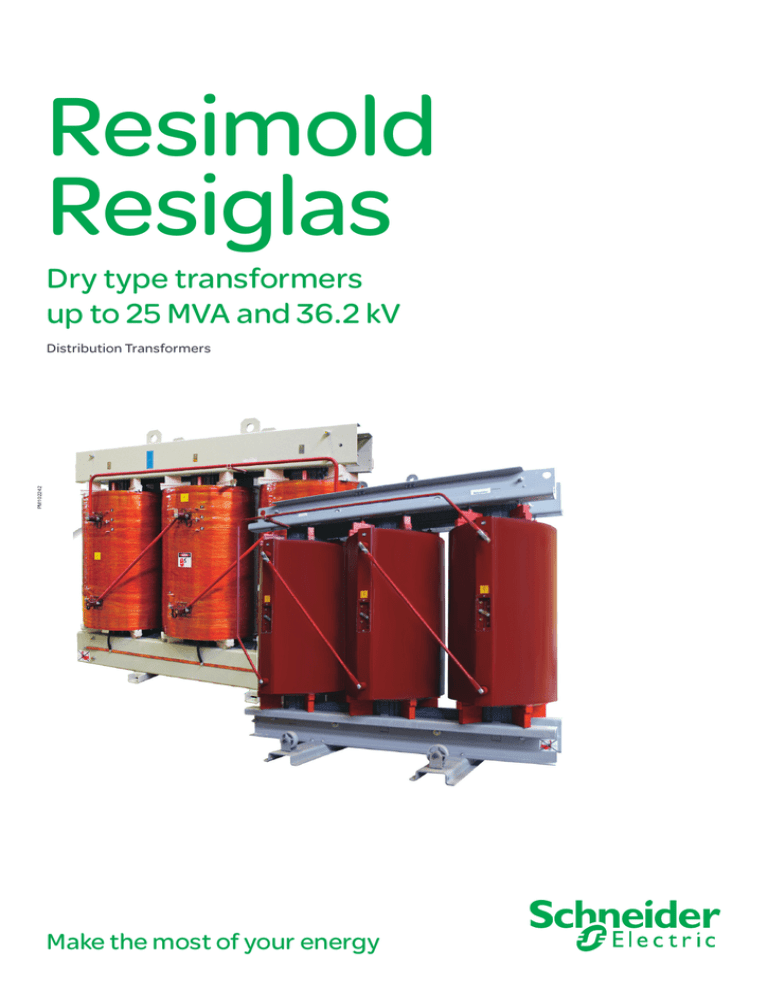

Resimold

Resiglas

Dry type transformers

up to 25 MVA and 36.2 kV

PM102242

PM102242

Distribution Transformers

Make the most of your energy

01

Distribution Transformers

Resimold / Resiglas

PM102236

PM102237

Dry type ransformers up to 25 MVA and 36.2 kV

Resimold dry type transformers are what you need for

all standard applications.

Resiglas dry type transformers are the perfect solution

for special applications

Worldwide, customers are demanding more

efficient solutions both to protect their users

and to ensure the reliability of their electrical

installations and networks. As an added constraint, new equipment must have a reduced

environmental impact and preserve the Earth’s

natural resources - We have the solution.

The safe and green solution for all distribution

applications

Schneider Electric produces safe and environmentally friendly equipment.

Resiglas and Resimold dry type transformers

have been specifically designed for infrastructure

projects such as: distribution substations, public

and commercial buildings and industrial and custom applications.

Schneider Electric’s dry type transformers

meet all national and international standards:

• IEC 60076-11

• NBR 10295

• NBR 5356

• NR10

• NBR 14039

Distribution Transformers

02

Resimold

Main characteristics

• Single and three-phase units

• Ratings up to 5 MVA, 36.2 kV

• Frequency: 50/60 Hz

• AN cooling for continuous indoor service

(with AF and outdoor options)

• Normal or reduced losses

Cost savings and safety are our priorities

Encapsulated in epoxy resin under vacuum,

Resimold dry type transformers ensure high performance, safety and cost savings. With no risk of

explosion or release of toxic fumes, they comply

with rigorous international safety standards.

The metallic enclosures developed by Schneider Electric offer various levels of protection and

provide maximum operator and equipment safety.

This permits installation next to the load center,

thus providing power-savings and reduced low

voltage cable requirements.

In addition, insurance costs are reduced. They

don’t require special storage construction and are

maintenance-free. Their design is well adapted

for shopping malls, office buildings, hospitals,

airports, industrial plants and auxiliary services in

power-supply plants.

Resimold dry type transformers are the right

choice when cost-savings and safety are required

in a single product.

Flame resistant and self-extinguishing,

Resimold provides an effective solution for

infrastructure projects and public buildings

confronted by fire hazards.

PM102238

Applications

• Skyscrapers

• Airports

• Railway stations

• Wind farms

• Substations

• Commercial or public buildings

• Industrial factories

PM102236

Resimold for a modern world

Minimizing space requirements and associated

civil works costs is a major issue in most building

projects today. Whether it is for a new city center

office block, an expansion in industrial process

capacity or a wind farm project, the compact

design of Resimold provides a cost-effective solution.

Distribution Transformers

03

Resimold

HV winding

The exclusive casting system and advanced technology used in our HV windings give Resimold

transformers the reliability and operating characteristics needed in high-technology applications

which demand maximum availability of electricity

supply.

This HV winding technology results in a compact

single block.

Casting system

In the face of increasingly strict regulations with

regard to the risk of fire and pollution, Schneider

Electric practices a policy of permanent research

on the behavior of insulating materials in fires.

This has led to the exclusive Class F casting

system (temperature of insulation system: 155°C)

developed in our laboratories.

This system is comprised of three main components:

• Epoxy resin

• Hardener

• Mineral filler

When polymerized, the epoxy resins associated

with the hardener form a stable three-dimensional

network.

These systems have better properties than most

plastics. Their use in transformers is justified owing to their:

• Excellent resistance to thermal aging

• Remarkable adherence to almost all known

materials.

Exceptional performance renders the windings

resistant to many chemicals. Mechanical strength

and a high-thermal conductivity are achieved by

incorporating selected mineral fillers. This enables

heat to be evacuated during use, improving fire

resistance and dramatically reducing the quantity

of combustible materials.

After hardening by polymerization, the casting

system becomes permanent. It offers excellent

fire behavior and immediate self-extinction, well

beyond the rated conditions of use. Resimold

transformers can hence be qualified as truly

flame-resistant and self-extinguishing.

PM102240

The HV winding design is in disc format with a

choice of aluminum strips or insulated aluminum

wire (or copper for special projects) cast under

vacuum in molds.

The solid insulation is obtained by vacuum casting in pre-heated molds, followed by a hardening

period under controlled temperatures.

Distribution Transformers

04

Resiglas

Resiglas - the perfect solution for special

applications

Resiglas is flame resistant and self-extinguishing. It is designed for flexibility and

sturdiness in order to meet special needs. It is

suitable for industrial installations susceptible

to fire hazards and for special applications

such as wind farms and off-shore oil and gas

platforms.

•

•

•

•

Resiglas is the innovative transformer suited

to special applications in industrial installations such as mining plants, and oil & gas

refineries. It complies with all your distribution

network specificities.

The Resiglas range of dry type encapsulated

resin transformers complies with all distribution

transformer requirements, and is the perfect

replacement for PCB transformers.

PM102237

Applications

• Off-shore oil and gas platforms

• Off-shore vessels

• Refining mills

• Paper & cellulose mills

• Steel & mining plants

• Car manufacturers

• Power supply plants

• Railways (trains, subway)

PM102241

Main characteristics

• Single and three-phase units

• Ratings up to 25 MVA, 36.2 kV

• Frequency: 50/60 Hz

• AN cooling for continuous indoor service

(with AF and outdoor options)

• Normal or reduced losses

Resiglas - flexibility and sturdiness for

special requirements

With all the intrinsic features of encapsulated

epoxy resin dry transformers (flame-resistant, no

toxic fumes, no partial discharges as per standard

IEC 60076-11), Resiglas brings you even more.

Thanks to the epoxy resin encapsulated coils

reinforced with fiberglass, as well as immunity to

environmental conditions and its fire-resistant categories E1/F1/C1, Resiglas technology presents

considerable advantages over conventional dry

transformers:

• Higher mechanical sturdiness since the

encapsulating process consists of continuous

fiberglass filaments

• Higher resistance to short-circuits and earthquake strains

Higher resistance to transient over-voltages

Safe for long-distance shipments

The exclusive cooling ducts designed for this

technology provide for optimal performance

when forced ventilation is required

Design flexibility in order to meet system

requirements (dimensions, impedance, etc).

05

Resiglas

Resiglas adapted to special applications

Resiglas dry type transformers can be

designed to meet special requirements, such as:

• Power distribution on off-shore oil platforms

to supply heavy-duty machinery

• Generator static excitement (6-pulse rectifiers)

• Power supply to low and medium voltage

drives for frequency inverters (6, 12, 18, 24,

36 pulses)

• Installation in outdoor locations and in rooms

with aggressive conditions

• Power supply of non-linear loads with high

harmonic contents (transformers with kfactor)

• Grounding systems

• Set-up transformers for generating group

outputs

• Power supply for induction furnaces

• Electrical drive systems for railway lines

HV winding

The winding consists of round or rectangular copper or aluminum wires. It is wound continuously.

The coil is formed by blocks, typically from 2 to 3

blocks of insulating material and winding, which

allows cooling ducts to be formed in the mediumvoltage coil itself. These cooling ducts also allow

a separation of the superimposed winding.

Casting system

The Resiglas technology consists of the encapsulation of the medium-voltage coils with epoxy

resin and fiberglass without the need to use steel

molds. The winding occurs over an expandable

radius cylinder, which is adjusted according to

design needs. The epoxy resin has the function of

assuring the dielectric strength of the coil, while

the fiberglass, in continuous strings, provides

mechanical strength in the coils.

Medium voltage drives

Cost-savings, quality and system reliability

With the technological improvements in medium voltage starters for heavy-duty motors, the

Resiglas dry transformers are now equipped with

intelligent solutions. One example is dephasing

transformers, supplying drives with medium voltage.

Our dry transformers are capable of withstanding

those electrical and mechanical strains resulting

from harmonic currents and voltage transients

caused by the rectifying system - while maintaining excellent performance levels.

Our design flexibility allows for the adjustment of

impedances, obtaining proper angular dephasing and voltage relationships, thus optimizing

the drive operation with a minimum of harmonic

distortion in the power supply mains.

Resiglas can be used with rectifiers of 6,12,18,24

and 36 pulses, meaning that the dephasing

obtained for each of the rectifier types allows for a

significant reduction in the harmonics returning to

the mains.

All Schneider Electric transformers, when requested, can be specially designed for non-linear loads

in order to minimize losses caused by harmonic

currents and generate less heat to be dissipated.

Examples of k-factor applicable to a few types of

loads:

• Excitement of power generators: k = 6 or

k=8

• Frequency rectifiers / converters: k = 8

• No breaks: k = 13 or k = 20

PM102243

Distribution Transformers

Distribution Transformers

Resimold / Resiglas

Resiglas

• Power rating: 0.15 to 25 MVA

• Voltage class: 7.2 / 15 / 24.2 / 36.2 kV

• Protection class: IP-00 / IP-21 / IP-44 / IP-54

(others available on request)

• Temperature class: F / H

• Temperature rise: B / F / H

• Impedance: as required by the project

• Category: E1 / F1 / C1 (or as specified by the

customer)

• Winding material: copper or aluminum

• Noise level as per NBR 10295

• Standards: IEC 60076-11 / NBR 10295 / NBR

5356 / NR10 / NBR 14039

So safe

To ensure total compliance with most national and

international standards, our transformers have

been put through the most stringent tests:

• C1 Resistant to thermal shocks

• E1 Immune to corrosive environments:

Very resistant to polluted environments andhumidity.

• F1 Fire behavior

Flame proof and self-extinguishing

Excellent classification according to HD 464

S1 standards.

So eco-friendly

Because preserving the environment is one of the

most important issues today, we have designed

our products to help you meet the latest international environmental protection guidelines and

regulations.

Resimold & Resiglas dry-type cast resin transformers are not only flame resistant and selfextinguishing, they are also free from the risk of

leakage of flammable or contaminating substances. Using non-toxic, high quality materials,

Resimold components are designed for maximum

recyclability.

Resiglas is the best solution to replace existing

PCB transformers.

Main technical features

Resimold

• Power rating: 30 to 5000 kVA

• Class 15 kV (others on request)

• HV winding: 13.8 / 13.2 / 12.6 / 12.0 / 11.4 kV

(Delta)

• LV winding: 380/220 or 220/127 V (Star)

• Insulation class HV/LV: 15 / 0.6 kV

• Temperature class HV/LV: F(155ºC)

• Temperature rise HV/LV: 105ºC

• Connection group: Dyn-1

• Frequency: 60 Hz NBI: 95 kV

• Protection degree: IP-00 or IP-21 (others on

request)

• Class: E1 / F1 / C1

• Noise level as per NBR 10295

• Standards: IEC 60076-11 / NBR 10295 / NBR

5356 / NR10 / NBR 14039

PM102244

Safe and eco-friendly

Resimold and Resiglas are the best solutions

for public safety: whether for industrial plants

susceptible to fire hazards or for use in public

buildings and high rise developments

06

Distribution Transformers

07

Resimold / Resiglas

Technical characteristics and dimensions

As per NBR 14039:2005 (medium voltage installations ranging from 1.0 kV to 36.2 kV), any

transforming substation being part of any industrial building should use only dry transformers.

Any transforming substation being part of any

residential and/or business building should use

only dry transformers, even if brick walls and

fireproof doors are available.

Resimold - dry type transformers encapsulated with epoxy resin under vacum

Power Rate

[ kVA ]

Impedance

[%]

Noise Level

[ dB ]

Height

[ mm ]

Length

[ mm ]

Width

[ mm ]

AN

IP-00 IP-21

IP-00 IP-21

IP-00 IP-21

Spacing

between

Wheels

[ mm ]

Total Mass

[ kg ]

IP-00 IP-21

45

4.0

58

1110 1335

790 1020

665

900

520

350 500

75

4.5

58

1200 1435

800 1020

665

900

520

390 560

112.5

4.5

58

1270 1565

920 1170

665 1000

520

550 770

150

4.5

58

1270 1565

970 1170

665 1000

520

650 870

225

4.0

58

1370 1665

1010 1270

665 1050

520

850 1100

300

4.5

58

1420 1735

1170 1420

665 1100

520

1200 1500

500

5.75

60

1560 1885

1325 1550

665 1100

520

1600 1950

750

5.75

64

1780 1925 1475 1700

815 1200

670

2200 2650

1000

5.75

64

1850 2135

1685 1900

815 1300

670

2670 3250

1250

5.75

65

1870 2250

1805 2000

910 1300

670

3250 3900

1500

5.75

65

1980 2350

1865 2100

1001 1300

820

4030 4730

2000

5.75

65

2160 2500

2025 2400

1001 1400

820

4900 5900

2500

6.5

65

2260 2520

2150 2450

1010 1500

820

6100 7600

3000

6.5

65

2350 2650

2300 2600

1020 1700

820

7500 8900

5000

6.5

71

3100 3700

2550 3250

2200 2350

1200

10500 12500

Resiglas - dry type transformers encapsulated with epoxy resin reinforced system

with fiberglass

Power Rate

[ MVA ]

Height

[ mm ]

Length

[ mm ]

Width

[ mm ]

IP-00

IP-21

IP-00

IP-21

IP-00

IP-21

2

2150

2600

2100

2450

1000

1500

2.5

2150

2600

2150

2450

1000

3

2200

2600 2200

2550

Spacing

between

wheels

[ mm ]

Total Mass

[ kg ]

IP-00

IP-21

820

4750

5500

1500

820

5350

6790

1000

1600

820

6800

8200

5

2850

3200 2500

2900 1500

2000

1000

10500

12500

7.5

3100

3600 2850

3200

1700

2200

1000

16000

19000

10

3250

3750

3200

1900

2200

1200

18600

20700

12.5

3650

4000 3450

3900

2000

2300

1400

26500

29000

15

4000

4500 3600

4000

2000

2500

1400

31000

33500

20

4500

5000

4000

4500 2500

2900

1500

40000

45000

25

4900

5500

4600

5200 2500

2900

1500

52000

58000

295

Resimold / Resiglas

IP Liquids

0 - Not protected.

1 - Protected against vertical water drops.

2 - Protected against water drops at a

maximum inclination of 15º.

3 - Protected against sprinkled water.

4 - Protected against water projections.

5 - Protected against jets of water.

Accessories

• Lifting lugs

• Terminal busbars with NEMA drilling

• Grounding terminals

• Two-way wheels

• Ratings nameplate

Examples of IP-applications

IP-00: Indoor installation, inside a brick substation, requiring the use of barrier against unintentional touching.

IP-21: Indoor installation, has a grounded metallic

housing that works as a barrier against unintentional touching, suitable to be installed coupled to

the switchboards and next to the load center.

IP-44: Suitable for either outdoor or indoor

installation.

PM102248

IP-55: Pressurized housing, being suitable for

either outdoor installation or indoor facilities

under aggressive conditions.

PM102246

Protection classes

NBR IEC 60529:2005

IP Solids

0 - Not protected.

1 - Protected against 50 mm-diameter solid

objects.

2 - Protected against 12 mm-diameter solid

objects.

3 - Protected against 2,5 mm-diameter solid

objects.

4 - Protected against 1 mm-diameter solid

objects.

5 - Protected against dust.

IP-54: Suitable for installation in either outdoor

locations or indoor facilities under aggressive

conditions.

PM102245

Options

• Thermal protection relay

• Metallic enclosure

• Forced ventilation kit

• Anti-vibrating wedges

• Disconnectable HV terminals

• Electrostatic shield

• Dragging base

• Seal Box for LV terminals

• Flange and bars duct

PM102247

Distribution Transformers

08

35 rue Joseph Monier

92500 Rueil Malmaison France

Phone: + 33 (0) 1 41 29 71 00

Fax: + 33 (0) 1 41 29 71 00

http://www.schneider-electric.com

Document Number NRJED311025EN

This document has been

printed on recycled paper

03/2011

© 2011 Schneider Electric. All rights reserved.

Schneider Electric