Avoiding Fluorinated Greenhouse Gases

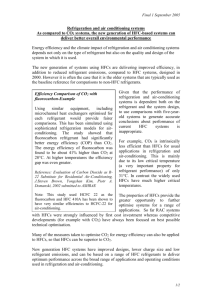

advertisement