Consider using alternative carrier gases

advertisement

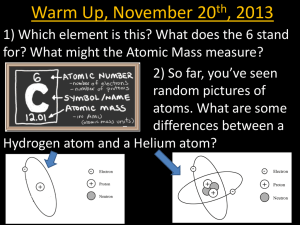

When your GC/MS is out of Breath Helium and the use of alternative GC carrier gases Lee Marotta, Mike Baylerian, Alan Gallaspy, Andy Tipler, Miles Snow Outline Some background to Helium: where it comes from, who uses it, how much it costs and why we should be concerned about consuming it. How to reduce wastage of Helium on a GC: method optimization and elimination of leaks. Using alternative carrier gases. Benefits and trade-offs. Compatibility with detectors, especially MS. Conclusion and questions. Page 2 Background Element Abundance (%) Hydrogen 73.90 SpaceHelium (or to give it a more24.00 technical Oxygen name, 'The Universe') is big.1.07 Really Big. Carbon Neon 0.46 0.13 Iron Nitrogen Silicon Magnesium Sulfur Others 0.11 0.10 0.07 0.06 004 0.07 Douglas Adams, The Hitchhiker’s Guide to the Universe Page 4 A1689-zD1 Helium is constantly being formed in stars by thermonuclear fusion of hydrogen at ~15,000,000K Page 5 Gas Abundance (%) Nitrogen 78.08 Oxygen The Earth: 20.95 0.93 Argon Carbon Dioxide 0.04 Neon 0.0018 Mostly Harmless: a small, blue-green 0.00052 world inHelium one of the less fashionable 0.00017 sectorsMethane of the galaxy. Krypton Hydrogen 0.00011 0.000055 Water ~1 Douglas Adams, The Hitchhiker’s Guide to the Universe Page 6 NASA Helium is able to Escape the Confines of Gravity Helium goes this way Page 7 Helium Formation on Earth Produced by the radioactive decay of isotopes of uranium and thorium This is a very slow reaction Current natural reserves have been generated over the last 4.5 billion years! The earth’s crust contains 0.0008% helium Some natural gas contains up to 7% helium Page 8 Helium Mining USA (83%) Algeria (11%) Canada Poland Russia Qatar Amarillo, Texas Page 9 Applications of Helium Application Lifting 15.1 Magnetic Resonance Imaging (MRI) 15.0 Welding 14.9 Chromatography 7.6 Heat Transfer 6.4 Leak Detection 5.6 Pressurizing 5.5 Fibre Optics 4.1 Diving Mixtures 4.0 Superconductors 2.9 Inert Atmospheres 2.7 Nuclear Magnetic Resonance (NMR) 1.3 Other Page 10 Usage (%) 14.9 The Price of Helium in the USA United States Bulk Helium Cost vs. Year 14,000 12,000 Price per Metric Ton (U.S. $) 10,000 Price of Helium dramatically 8,000 Increasing every year Price no longer controlled by US government 6,000 4,000 2,000 0 1930 1940 1950 1960 1970 Year Source: U.S. Geological Survey Page 11 1980 1990 2000 2010 One Man’s View - Helium will be Exhausted in 8 Years! "The government had the good vision to store helium, and the question now is: Will industry have the vision to capture it when extracting natural gas, and consumers the wisdom to capture and recycle? This takes long-term vision because present market forces are not sufficient to compel prudent practice. When they stick that straw into the ground to suck out oil and gas, the helium comes out, and if it doesn't get captured it drifts into the atmosphere and is lost. Helium production is a side industry to oil and natural gas, an endeavor that nobody wants to lose money on." Lee Sobotka, Ph.D., professor of chemistry and physics in Arts & Sciences at Washington University in St. Louis, December 2007 Government not funding the mining of Helium leaving it to industry A lot of helium is not capture during drilling for oil, etc. Page 12 Helium Balloons Balloon retailers, which use about 7 percent of the (USA) national supply, are already promoting conservation. The International Balloon Association, a Wichita, Kan.based group of balloon manufacturers and distributors, is asking its members to consider alternatives to helium, such as good, old-fashioned air, particularly for balloons that don't have to float. It's also promoting products that can extend the float time of a balloon and decrease helium use by about 25 percent. Helium drifting away St.Louis Post, January 2008 Page 13 Helium in Gas Chromatography Despite conflicting opinions and statistics, there is growing concern about the availability and cost of helium Chromatography consumes 7.6% of the world’s helium supply As chromatographers, we can make a significant impact on the total amount of helium consumed by: • Eliminating wastage • Using alternative gases such as hydrogen and nitrogen As instrument vendors we can design and provide tools and techniques to assist users in this enterprise Page 14 Saving Helium Causes of Helium Waste Deliberate (e.g. from injector split settings in GC method) Non-Deliberate (e.g. from leaks) Both of which can be easily addressed by the user Page 16 What Lifetime is Expected from a Standard 8000L Cylinder? Mode Column Flow Rate, mL/min Split flow Rate, mL/min Septum Purge Flow Rate, mL/min Estimated Cylinder Lifetime with 1 GC, days On-column capillary (POC) 2 - - 2771 On-Column Capillary (PSS) 2 10* 3 369 Packed column 20 - - 277 Packed Column 50 - - 111 Splitless injection 2 25** 3 180 Split injection 2 25 3 185 Split injection 2 50 3 101 Split injection 2 100 3 53 Split injection 2 200 3 27 Split injection 2 500 3 11 * A small split flow is recommended to help keep the injector swept and clean ** The split vent is closed during injection so total usage is slightly reduced Page 17 Cost of a Cylinder Containing 8000L 5N-Grade Helium Page 18 Country Example Cost (€) USA 35 Taiwan 117 Germany 146 France 150 Italy 160 China 299 Brazil 507 The PerkinElmer Clarus Gas Chromatographs with PPC Pneumatics Clarus 600 All these have support for automated leak limitation and detection Clarus 500 Page 19 Conserve Helium by Turning Down the Split Flow Whenever Possible! Use a simple timed event on the Clarus 500 or 600 GCs to reduce the split flow rate after the injection is complete For a lab of 5 GCs running with 200mL/min split flows, this single action, that takes just a moment to enter, will: • • • Page 20 Save up to €10,000/year in helium costs Eliminate up to 60 cylinder exchanges/year Contribute significantly to helium conservation Sources of Leaks Tank regulator Laboratory plumbing Connections to the GC Internal plumbing in the GC Injector septa and o-rings Column ferrules Column breakage Page 21 Buy a Helium Sniffer – it will Save You Thousands of Euros! Never use soap solution to locate leaks! Page 22 Clarus GC PPC Split Pneumatics – Split Mode Controller Controller Pressure Sensor Flow SensorProportional Valve Proportional Valve Injector Column Solenoid Valve • Leaks are detected by a sudden loss in pressure and the system is subsequently shutdown after 2 minutes • An automatic system leak-check may be performed at the start of each run – again the system is shutdown after 2 minutes if a fault is detected • In split mode, the PPC controller regulates the gas-flow into the injector so leakage will never exceed this rate. PPC Split Pneumatics – Splitless and Leak-Check Mode Controller Flow Sensor Pressure Sensor Proportional Valve Injector Monitored Output Column Page 24 Solenoid Valve Automatic Leak Checking with PPC Flow rate into injector checked as a pre-run event If flow rate exceeds limit, GC will shutdown Prevents major loss of carrier gas Also reduces explosion risk with hydrogen carrier gas Page 25 Summary of Options to Reduce Helium Wastage Reduce or eliminate split flows when not needed Detect and eliminate leaks Page 26 A Proposed Charter for Chromatographers Chromatographers • Know how much helium you use (your Helium Footprint) • Use instrument features to reduce splitting when it Is not necessary • Be mindful about detecting and eliminating leaks • Consider using alternative carrier gases Vendors • Provide tools for reducing and tracking helium usage • Optimize injectors and detectors for use with other carrier gases • Develop example applications and proof statements with other carrier gases • Encourage end users to reduce helium usage Page 27 Using Alternative Carrier Gases Content Review of available gases Advantages and tradeoffs Compatibility with injectors, columns and detectors Mitigating the risks in using hydrogen Effect on performance Special considerations for MS Options for ATD and HS Page 29 Review of Carrier Gases Gas Cost Speed of chromatography Chromatographic efficiency Flow permeability Supply Safety concerns Helium Hydrogen Nitrogen Expensive Medium Low cost Fast Low cost Slow Low Medium High Low High Low Pressurized tank Pressurized tank or Pressurized tank electrolytic hydrogen or nitrogen generator generator Highly explosive Hydrogen cylinders Pros Can keep up with substantial demand if necessary Can usually get spare cylinder quickly Cons Safety concerns with flammability especially with large leaks or catastrophic failures Inconvenient (and can be dangerous) to move and exchange Hydrogen generator Pros No heavy high pressure cylinders to lug around Low internal volumes at low pressure means small hazard potential Intelligent shutdown in the event of a fault Cons High initial cost May not have spare generator on hand for backup Need to assess demand accurately Injector and Column Compatibility Injector Considerations • Hydrogen – Very low viscosity requires low inlet pressure. – Potential problems with short (30 m or less), wide bore columns (530 μm). – MS further limits column dimensions – Potential Problems with splitless and pressure pulse injections. • Nitrogen - Optimal linear velocity requires low inlet pressure. – Potential problems with short (30 m or less), wide bore columns (530 μm). – MS further limits column dimensions – Potential Problems with splitless and pressure pulse injections. Injection Method Considerations with MS Detector Compatibility Combustion Detectors (i.e. FID, FPD) • Constant flow mode is preferable • Baseline may change in constant pressure or velocity type operation. • Remember to combine carrier flow for total hydrogen for combustion NPD • Requires constant flow of hydrogen at ~1 mL/min • Hydrogen is not a good choice for a carrier gas Single Quad MS • Hydrogen potential reduces sensitivity by 2x • High vacuum column outlet may constrain injector pressure settings MS System Performance GC Sample Handling Devices Hydrogen is not an acceptable carrier gas for thermal desorption type sample introduction. Hydrogen is not an acceptable carrier gas for pyrolysis sample introduction, since a heated wire glows red hot in the injector. Hydrogen is an acceptable carrier gas for headspace sample introduction when using appropriate safety measures (including a special hydrogen needle). Detailed Hydrocarbon Analysis using Helium and Hydrogen Helium 160+ Minutes Hydrogen 70 Minutes More Available Time Column Efficiency Column efficiency (hence peak shape and resolution) is very similar in this region for all three gases Clarus GC PPC Systems Support Velocity Control and Display Capillary column carrier gas may be controlled by setting the pressure, flow or velocity. In each mode of control, the current values of all three are displayed in real time Method migration with carrier gas velocity control 30cm/s at 20°C/min Helium Same separation with the same method with all three gases! Hydrogen Nitrogen 5.5 6.0 6.5 7.0 7.5 8.0 8.5 9.0 9.5 10.0 10.5 11.0 11.5 12.0 Can I migrate methods with flow or pressure carrier gas control? Constant Pressure at 10°C/min with Initial Velocity of 30cm/s Helium Same separation if the initial velocity is the same! Hydrogen Nitrogen 7.0 7.5 8.0 8.5 9.0 9.5 10.0 10.5 11.0 11.5 12.0 12.5 13.0 13.5 14.0 14.5 15.0 15.5 16.0 16.5 17.0 17.5 18.0 18.5 19.0 19.5 20.0 20.5 21.0 21.5 Clarus GC PPC Split Pneumatics – Split Mode Controller Controller Pressure Sensor Flow SensorProportional Valve Proportional Valve Injector Column Solenoid Valve • Leaks are detected by a sudden loss in pressure and the system is subsequently shutdown after 2 minutes • An automatic system leak-check may be performed at the start of each run – again the system is shutdown after 2 minutes if a fault is detected • In split mode, the PPC controller regulates the gas-flow into the injector so leakage will never exceed this rate. Automatic Leak Checking with PPC Flow rate into injector checked as a pre-run event If flow rate exceeds limit, GC will shutdown Prevents major loss of carrier gas Also reduces explosion risk with hydrogen carrier gas Things the user can do to minimize risks in using hydrogen Ensure systems are leak free (and re-check them periodically) Use an in-line snubber if you are using high pressure cylinders Use a hydrogen generator rather than a high pressure cylinder Route gas vents away from the instrument Use PPC pneumatic systems to limit and detect leakage and to shutdown the system if necessary Install capillary columns so that they don’t rub against other surfaces Special considerations for GC/MS Use caution when venting • Shut down carrier gas before MS pumps Use extra caution after a power failure or unexpected failure of vacuum system • • • • Page 46 Shut down carrier flow Do not turn MS system on immediately Allow hydrogen to dissipate Use a nitrogen purge accessory GC/MS Drinking Water Tuning Mass 51 68 69 70 127 197 525.1 10-80% of base peak <2% of 69 n/a <2% of 69 10-80% of base peak <2% of 198 525.2 10-80% of base peak <2% of 69 n/a <2% of 69 10-80% of base peak <2% of 198 525.3 n/a <2% of 69 present <2% of 69 n/a <2% of 198 Helium DFTPP Helium 46.6 1.3 52.0 0.1 56.6 0.2 Hydrogen DFTPP Hydrogen 43.9 1.6 45.6 0.5 47.1 0.7 198 199 275 365 441 base peak or >50% of 442 base peak or >50% of 442 5-9% of 198 5-9% of 198 10-60% of base peak 10-60% of base peak >1% of base peak >1% of base peak Present and < 443 Present and < 443 present 5-9% of 198 n/a >1% of base peak <150% of 443 100.0 5.4 23.2 1.9 79.5 100.0 6.3 24.3 2.5 78.8 442 443 base peak or >50% of 198 base peak or >50% of 198 15-24% of 442 15-24% of 442 present 15-24% of 442 64.7 19.7 75.3 17.7 Summary There is a compelling need to switch GC methods away from using helium • • • Cost Sustained supply Free up helium supplies for ‘more important’ purposes (e.g. MRI) There are feasible alternative carrier gases • • Hydrogen Nitrogen Chromatography equivalent to that obtained with helium carrier is possible with hydrogen or nitrogen on GC systems that control and monitor gas velocity through the GC column. Although there is risk of an explosion when using hydrogen, this will be very small if the following are followed: • • • • • Hydrogen generator Use PPC pneumatic controllers Ensure that systems are leak-free Route split vents etc. to the instrument exterior Use a hydrogen sensor in the GC oven Thank you!!!!!