The Exploration, Appraisal and Development of Unconventional

advertisement

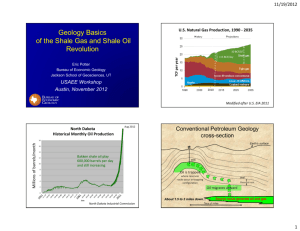

The Exploration, Appraisal and Development of Unconventional Reservoirs: A New Approach to Petroleum Geology* Richard K. Stoneburner1 Search and Discovery Article #41115 (2013)** Posted February 28, 2013 *Adapted from AAPG Distinguished Lecture presented at Tulsa Geological Society Luncheon Meeting, January 29, 2013 **AAPG©2012 Serial rights given by author. For all other rights contact author directly. 1 Formerly President North America Shale Production Division, BHP Billiton Petroleum, Houston, Texas, and AAPG Distinguished Lecturer, 2012-1013 (dstoneburner2@gmail.com) Abstract The discovery of commercial oil and gas production from shale, or mudstone, reservoirs has dramatically changed how we explore for and develop oil and gas accumulations. In conventional exploration, appraisal and development there is a fairly standard and accepted application of processes and technologies. However, the processes and technologies that are employed in the exploration, appraisal and development of mudstone reservoirs are significantly different, and they are often employed for different reasons and at different stages of the cycle. Prospect identification is always the initial phase of any exploration project. In most cases in the conventional world, this is a result of the interpretation of seismic data, either 2D and/or 3D, in order to identify the areal extent of the prospect, which would typically be on the order of a few hundred acres or in some instances a few thousand acres. However, in the unconventional world the identification is done at a basin level and is not typically supported by seismic, but rather by detailed analysis of a few key wells and their associated petrophysical attributes. Once those attributes are deemed to have the potential of supporting a commercially productive mudstone reservoir, then the utilization of seismic might be employed to help define the boundaries of the reservoir. However, that would typically be the exception as the reservoir boundaries are generally defined by the configuration of the basin, which is generally fairly well understood and can encompass a million acres or more. Once the prospect has been identified, the evaluation processes during the exploratory drilling phase are dramatically different. During conventional exploration the validation of the presence, or lack, of hydrocarbons is largely done by the acquisition and interpretation of data from open hole wireline logs. While cores, either whole or sidewall, will often be taken, they are typically acquired not to validate the productivity of the reservoir but rather to supplement the open hole log data. In unconventional exploration, the opposite is the case. While the open hole logs are extremely important once the discovery is made to calibrate the reservoir, the most critical data around the validation of the quality of the reservoir is the detailed analysis of the rock acquired from whole core. While some of the attributes that are measured from the mudstone core are common to conventional exploration, there are many more measurements that are taken on mudstone reservoirs that are totally unique to this type of reservoir. As the prospect moves into appraisal and development mode, there are also unique processes and technologies in the unconventional world that are used to more fully understand the reservoir. The most important of those is the calibration, through the use of specific algorithms, of the data acquired from the whole core data to the open hole data that is being acquired from the appraisal and development drilling. Because the cost and time necessary to acquire an extensive collection of whole core data can be prohibitive, there will be a limited number of wells from which whole core is taken in any given field. Therefore, it is critical to be able to calibrate the various measurements from the whole core to the open hole log data that will be available on many more wells. This is also the point during which 3D seismic would be acquired as opposed to the acquisition of that type of data during the identification process. In unconventional development, the primary benefit of the 3D seismic data is not to identify where you want to drill, but where you do not want to drill. Specifically, the horizontal lateral is placed to minimize the effect of faulting on the lateral. Throughout the entire period of field appraisal and development, the practice of geosteering is critical to the economic success of the field. Because virtually all of the unconventional development is done with the application of horizontal drilling, it is critically important that the drill bit maintain its position within the highest quality reservoir while the lateral is being drilled. Since the drilling operations are performed around the clock, and unexpected changes in dip or the presence of faults can cause the bit to rapidly change its relative stratigraphic position, a Gamma Ray tool is incorporated into the bottom hole drilling assembly in order to provide continuous measured depth Gamma Ray log data, which is then converted to a true vertical depth (TVD) log using software designed specifically for this process. This TVD log data is subsequently correlated with nearby well control to determine where the lateral is positioned stratigraphically at all times during the drilling operation. When the bit has been interpreted to be out of the desired stratigraphic section, or target window, it is the responsibility of the geosteerer to collaborate with the drilling organization to make the necessary changes to get the bit back into the target window. Reference Cited Herron, M.M., and S.L. Herron, 1998, Quantitative lithology; open and cased hole application derived from integrated core chemistry and mineralogy database, in P.K. Harvey, and M.A. Lovell, (eds.), Core-log integration: Geological Society Special Publications, v. 136, p. 8195. “The Exploration, Appraisal and Development of Unconventional Reservoirs: A New Approach to Petroleum Geology” Dick Stoneburner Formerly President North America Shale Production Division BHP Billiton Petroleum Winter 2013 AAPG Distinguished Lecture Tour.DStoneburner.11.1.12 Brief History of Shale Exploration George Mitchell and Mitchell Energy pioneered shale exploration in the Barnett in the early 1980‟s By the late 1990‟s they had proven that vertical Barnett wells were commercially viable In the early 2000‟s a move was made to drill horizontally in the Barnett, but completion technology was lagging and results were marginal In 2006 the use of isolated multi-stage completions was proven to be successful which was the true game changer for horizontal drilling in shale reservoirs Growth of North America Shale Production • • The development of isolated multi-stage hydraulic fracturing in 2006 caused a dramatic increase in shale production By 2011 the Haynesville Shale surpassed the Barnett as nation’s leading shale play AAPG Distinguished Lecture Tour.DStoneburner.11.1.12 ____ 1 Slide 1 Unconventional Exploration Process Contrasting the Methodologies of Exploration Conventional Unconventional Prospect identification focuses “outside in” Project identification focuses “inside out” Seismic control works “outside in” Seismic control works “inside out” Stratigraphic support eventually focuses on Stratigraphic support focuses on analysis facies analysis local to the prospect Reservoir quality issues are relegated to the area of the prospect of the entire basin Reservoir quality analysis is required over a very broad area of the basin Prospect Identification: Conventional Analogy K2 Shenzi Prospect Neptune Mad Dog Atlantis 0 Discoveries 20000 US feet Deep Water Gulf of Mexico Prospect Structurally controlled and supported by local analogs At time of Prospect Identification, there were three significant analogs in the area of the prospect The area of the prospect was on the order of 10K acres with Resource Potential in excess of several hundred MMBOE Prospect Identification: Unconventional Analogy GUADALUPE GONZALES BEXAR LAVACA WILSON DEWITT VICTORIA FRIO ZAVALA ATASCOSA GOLIAD MAVERICK CHOKE CANYON RESERVOIR BEE COLETO CREEK RESERVOIR DIMMIT LIVE OAK LAKE CORPUS CHRISTI WEBB DUVAL Eagle Ford Shale Prospect Known regional source rock across large petroliferous basin Reservoir quality and geochemical attributes poorly understood The area of the prospect was >10 MM acres with high-side Resource Potential of >10 BBOE Case Study for Unconventional Exploration: Hawkville Field In early 2008 the CEO of Petrohawk charged the Exploration team to find another “Haynesville-like” play We targeted the Eagle Ford Shale based on its significance as a regional source rock – Q1: Mapped the Eagle Ford across the entire Gulf Coast Basin and identified an anomalously thick, porous and highly resistive Eagle Ford section in La Salle and McMullen Counties – Q2: Acquired Eagle Ford cuttings on a key well and had them analyzed for TOC, VRo and other key parameters – Q3: Acquired ~160,000 acres and spudded the initial test well – Q4: Completed it in October 2008 for 7.6 Mmcf/d and 251 Bc/d Hawkville Field in Early 2008 X/Y: 1454700 1459700 1464700 1469700 1474700 1479700 1484700 1489700 1494700 1499700 1504700 1509700 1514700 1519700 1524700 1529700 1534700 1539700 1544700 1549700 1554700 1559700 1564700 1569700 1574700 1579700 1584700 1589700 1594700 1599700 1604700 1609700 1614700 1619700 1624700 1629700 1634700 1639700 1644700 1649700 1654700 1659700 1664700 1669700 1674700 1679700 1684700 1689700 1694700 1699700 1704700 1709700 1714700 1719700 1724700 1729700 1734700 1739700 1744700 1749700 1754700 1759700 1764700 1769700 1774700 1779700 1784700 1789700 1794700 1799700 1804700 1809700 1814700 1819700 1824700 1829700 1834700 1839700 1844700 1849700 1854700 1859700 1864700 1869700 1874700 1879700 1884700 1889700 1894700 1899700 1904700 1909700 1914700 1919700 1924700 1929700 1934700 1939700 1944700 1949700 1954700 1959700 1964700 1969700 1974700 1979700 1984700 1989700 1994700 1999700 2004700 2009700 2014700 2019700 2024700 2029700 2034700 2039700 2044700 2049700 2054700 2059700 2064700 2069700 2074700 2079700 2084700 2089700 2094700 2099700 2104700 2109700 2114700 2119700 2124700 2129700 2134700 2139700 2144700 2149700 2154700 2159700 2164700 2169700 2174700 2179700 2184700 2189700 2194700 2199700 2204700 2209700 2214700 2219700 2224700 2229700 2234700 2239700 2244700 2249700 2254700 2259700 2264700 2269700 2274700 2279700 2284700 2289700 2294700 2299700 2304700 2309700 2314700 2319700 2324700 2329700 2334700 2339700 2344700 2349700 2354700 2359700 2364700 2369700 2374700 2379700 2384700 2389700 2394700 2399700 2404700 2409700 2414700 2419700 2424700 2429700 2434700 2439700 2444700 2449700 2454700 2459700 2464700 2469700 2474700 2479700 2484700 2489700 2494700 2499700 2504700 2509700 2514700 2519700 2524700 2529700 2534700 2539700 2544700 2549700 2554700 2559700 2564700 2569700 2574700 2579700 2584700 2589700 2594700 2599700 2604700 2609700 2614700 2619700 2624700 2629700 2634700 2639700 2644700 2649700 2654700 2659700 2664700 2669700 2674700 2679700 2684700 2689700 2694700 2699700 2704700 2709700 2714700 2719700 2724700 Feet 535000 535000 530000 530000 525000 525000 520000 520000 515000 515000 510000 510000 505000 505000 500000 500000 495000 495000 490000 490000 485000 485000 480000 480000 475000 475000 470000 470000 465000 465000 460000 460000 455000 455000 450000 450000 445000 445000 440000 440000 435000 435000 430000 430000 425000 425000 420000 420000 415000 415000 410000 410000 405000 405000 400000 400000 395000 395000 390000 390000 385000 385000 380000 380000 375000 375000 370000 370000 365000 365000 360000 360000 355000 355000 350000 350000 345000 345000 340000 340000 335000 335000 330000 330000 325000 325000 320000 320000 315000 315000 310000 310000 305000 305000 300000 300000 295000 295000 290000 290000 285000 285000 280000 280000 275000 275000 270000 270000 265000 265000 260000 260000 255000 255000 250000 250000 245000 245000 240000 240000 235000 235000 230000 230000 225000 225000 220000 220000 215000 215000 210000 210000 205000 205000 200000 200000 195000 195000 190000 190000 185000 185000 180000 180000 175000 175000 170000 170000 165000 165000 160000 160000 155000 155000 150000 150000 145000 145000 140000 140000 135000 135000 130000 130000 125000 125000 120000 120000 115000 115000 110000 110000 105000 105000 100000 100000 95000 95000 90000 90000 85000 85000 80000 80000 75000 75000 70000 70000 65000 65000 60000 60000 55000 55000 50000 50000 45000 45000 40000 40000 35000 35000 30000 30000 25000 25000 20000 20000 15000 15000 10000 10000 5000 5000 0 0 -5000 -5000 -10000 -10000 -15000 -15000 -20000 -20000 WILSON Edwards Shelf Margin ZAVALA FRIO DE WITT KARNES ATASCOSA VICTORIA MAVERICK Phillips LaSalle #1 GOLIAD MCMULLEN DIMMIT BEE LA SALLE Swift Pielop #1 LIVE OAK Sligo Shelf Margin Very limited well control in prospective area 1454700 1459700 1464700 1469700 1474700 1479700 1484700 1489700 1494700 1499700 1504700 1509700 1514700 1519700 1524700 1529700 1534700 1539700 1544700 1549700 1554700 1559700 1564700 1569700 1574700 1579700 1584700 1589700 1594700 1599700 1604700 1609700 1614700 1619700 1624700 1629700 1634700 1639700 1644700 1649700 1654700 1659700 1664700 1669700 1674700 1679700 1684700 1689700 1694700 1699700 1704700 1709700 1714700 1719700 1724700 1729700 1734700 1739700 1744700 1749700 1754700 1759700 1764700 1769700 1774700 1779700 1784700 1789700 1794700 1799700 1804700 1809700 1814700 1819700 1824700 1829700 1834700 1839700 1844700 1849700 1854700 1859700 1864700 1869700 1874700 1879700 1884700 1889700 1894700 1899700 1904700 1909700 1914700 1919700 1924700 1929700 1934700 1939700 1944700 1949700 1954700 1959700 1964700 1969700 1974700 1979700 1984700 1989700 1994700 1999700 2004700 2009700 2014700 2019700 2024700 2029700 2034700 2039700 2044700 2049700 2054700 2059700 2064700 2069700 2074700 2079700 2084700 2089700 2094700 2099700 2104700 2109700 2114700 2119700 2124700 2129700 2134700 2139700 2144700 2149700 2154700 2159700 2164700 2169700 2174700 2179700 2184700 2189700 2194700 2199700 2204700 2209700 2214700 2219700 2224700 2229700 2234700 2239700 2244700 2249700 2254700 2259700 2264700 2269700 2274700 2279700 2284700 2289700 2294700 2299700 2304700 2309700 2314700 2319700 2324700 2329700 2334700 2339700 2344700 2349700 2354700 2359700 2364700 2369700 2374700 2379700 2384700 2389700 2394700 2399700 2404700 2409700 2414700 2419700 2424700 2429700 2434700 2439700 2444700 2449700 2454700 2459700 2464700 2469700 2474700 2479700 2484700 2489700 2494700 2499700 2504700 2509700 2514700 2519700 2524700 2529700 2534700 2539700 2544700 2549700 2554700 2559700 2564700 2569700 2574700 2579700 2584700 2589700 2594700 2599700 2604700 2609700 2614700 2619700 2624700 2629700 2634700 2639700 2644700 2649700 2654700 2659700 2664700 2669700 2674700 2679700 2684700 2689700 2694700 2699700 2704700 2709700 2714700 2719700 2724700 Prospect was located in a regional setting between two divergent shelf margins which suggested the presence of a “mini-basin” While the geochemical properties were unknown, the depth range (10,000-11,500‟) suggested a relatively mature source rock Key Finding #1: World Class Petrophysical Characteristics Atascosa_bee_dewitt_gonzales_liveoak_lasalle_maverick_webb_wilson 10920 10940 10960 10980 11000 11000 Log Depth(ft)0 10900 Primarily oil Pielop 1 Swift Significant portions derisked GR AT90 PHIDEDIT Resistivity Density 120 0 100 0.3 Early entry, low avg. cost Eagle Ford Scalable Shale Longer-term leases Low near-term capital requirements Swift Pielop #1 0 Log Depth(ft) 10900 10920 10940 10960 10980 11000 11020 11040 11040 11060 11060 11080 11080 11100 11020 11100 11100 11120 11140 11140 11160 11160 11180 11180 11200 11120 11200 11200 11220 11220 11240 11240 Buda 11300 11300 11260 11280 Top Eagle Ford 11260 11280 11300 Base Eagle Ford Key Finding #2: Positive Geochemical Characteristics Phillips LaSalle #1 D&A in 1952 Eagle Ford Shale Gas Risk Assessment Diagram TOC (0-5) AC EFS Tr (50 – 100) Ro (0.2 – 2.2) Minimum Threshold BUDA Phillips LaSalle #1 Tmax (435 - 470) Dryness (0 – 100) Key Finding #3: Seismic Definition of the Reservoir MT 3D CookWest MIG TVF, 401, 1130 SP: 4800.0 4820.0 MT GT LR-37, 160.74 MT 3D LAKEWOOD - BURKS MT RANCH, GT 77-16,1482, 378.02 125 4840.0 4920.0 4940.0 4960.0 Dora Martin 2H Dora Martin 4H at Hawkville could be identified with 2D seismic data Dora Martin 1H 1.600 - MT GT 65-253 616 MIG TVF 4900.0 4880.0 Dora Martin PH 1 Dora Martin 2H 1H 1.500 The anomalously thick Eagle Ford MT GT 927 MIG TVF, 1368.54 4860.0 Isochron Thick in Center of Hawkville Field 1.700 1.800 1.900 EFS Res Res EFS 2.000 EFRT EF SR es Buda A grid of 2D data was acquired 2.100 that allowed the mapping of the entire extent of the thick Eagle Ford reservoir 2.200 Eagle Ford Shale 2.300 2.400 2.500 Data Courtesy of Seitel, Inc. 498 Hawkville Field in Late 2008 Petrohawk Energy STS #1H Spud Date:08/2008 1st Prod: 10/2008 Petrohawk Energy Dora Martin #1H Spud Date:09/2008 1st Prod: 01/2009 Fall 2008 Petrohawk Acreage Position ~160,000 net acres The Eagle Ford Shale in 2012 Eagle Ford Shale Competitor Map Night View of Texas by Satellite Unconventional Appraisal Process Critical Data for Effective Appraisal Program: Core Data and “Core to Log” Data There is nothing more critical to the evaluation of a shale resource than the extensive data gathered from whole core analysis: • Measurement of “conventional” reservoir attributes such as Porosity, Sw, Permeability, etc. • Identify and measure the mineralogy, specifically clay minerals versus “coarsegrained” constituents • Measurement of key geochemical (TOC, Thermal Maturity, etc.) and geomechanical attributes (Young‟s Modulus and Poisson‟s Ratio) • Most importantly, calibrate core measurements to conventional open hole log suites, therefore expanding knowledge regarding reservoir characterization, formation evaluation (OGIP, Recovery and EUR) and optimization of the hydraulic fracture stimulation Pilot Wells During Appraisal Process • Essential to acquire acceptable “grid” of open hole data subsequent to discovery • Percentage of wells with pilot holes with complete data suite (core plus full complement of open hole logs) is low, but it is critical to have adequate baseline of core data • Collective data set will enhance: o Reservoir characterization o Identify optimum stratigraphic target for lateral o Help determine the optimum stimulation “recipe” (fluid compatibility , geomechanics, stress regime, fracture density, etc.) o Provide basis for creating algorithms that translate core data to log data Analytical Process from Core Complete Cored Interval o Spectral Core Gamma o Fracture & Sedimentological Description o Core Photography Basic Rock Properties o Porosity characterization (GRI method) o Steady-state nano-permeability (CT-Scan plugs) Reservoir Geology & Geochemistry o Geochemistry (TOC, Pyrolysis, Vitrinite Reflectance) o Thin Section Petrography & FIB SEM o X-Ray Diffraction Analytical Process from Core (continued) Adsorption & Desorption o Desorbed gas content & composition o Adsorption isotherm o Isotope Analysis Completion & Stimulation o Geomechanical Properties (Single-State & Multi-Stage) o Proppant Embedment and Fracture Conductivity o Capillary Suction (CST) and Roller-Oven Testing Basic Petrophysical Workflow Core Data Xplots lNTERPRETED LOG CURVES cluster analysis facies classification TOC Porosity Permeability Saturation Lithology Geomechanics ALGORITHMS Core to Log Calibration: TOC-PorosityPermeability-Saturation Triple Combo TOC Fair correlation coefficient r2 ~ 0.65 TOC 1 RHOB 2 3 4 5 6 Hydrocarbon-filled Porosity Ø-Total Highest correlation coefficient r2 ~ 0.93 Total porosity HC-filled porosity 4 Sw based on default Rw ~ 0.025 Max Perm Ø-HC Permeability Least dependable of the algorithms (use qualitatively and in localized zones) Ø-HC Core to Log Calibration: Lithology * Key Element to Mineral Conversions Dolomite 1.1% Pyrite 3.1% Plagioclase 3.2% QFM ~ 2.139 * Si Calcite ~ 2.497 Ca Calcite + Dolomite ~ -7.5 + 2.69 (Ca + 1.455 Mg) Pyrite = 1.8709 S Kerogen ~ 0.83 /TOC Clay ~ (1- sum of above) Quartz 15.4% Calcite 60.9% element data from ECS-type element to mineral PEF check conversion * logs (Source : Herron and Herron, 1998) Clay 15.2% Carbonate (chalk) composite lithofacies display calcareous mudstone marl clay-rich mudstone argillaceous mudstone siliceous mudstone 7 8 9 1 0 1 1 1 2 1 3 Core to Log Calibration: Geomechanics 1 4 1 5 1 6 Use as a “proxy” for estimating Vs | DTS when dipole or sonic scanner data is unavailable r2 ~ 0.94 Track 14 Softer Static YM Young’s Modulus Static ~ 0.65 * Dynamic R2 ~ 59% 1. Use industry standard algorithms to calculate dynamic elastic modulii (Vp, Vs, RhoB) Lambda Mu Bulk Modulus P-wave Modulus Poisson‟s Ratio Young‟s Modulus 2. Convert from dynamic to static modulii for fracture propagation modeling Dynamic-static relationships are derived from multi-stage Triaxial testing where both static and dynamic measurements are collected simultaneously Dynamic YM Uniaxial Compressive Strength (UCS *) from DTC or Vp Harder Softer Core to Log: QC and Interpretation 1 3 2 GR-TOC RES 4 5 PORO-PERM SATURATION 6 7 8 9 1 0 1 1 1 2 LITHOLOGY 1 3 1 4 1 5 FRACTURE PROPAGATION Top Shale Base Shale TOC distribution Sweetspot screening Rock properties from ECS-type tool should dovetail with geomechanical descriptions Frac properties from DTC-DTS 1 6 Facies Extraction Using Geomechanical Data YOUNG’S MODULUS F Facies extracted from Crossplot B Cluster Analysis Poisson’s Ratio vs. Young’s Modulus Lambda*Rho vs. Mu*Rho (or any other attribute combination) C E A-2 A-1 A-3 D A-4 POISSON’S RATIO The Whole Core Itself: Macro Observations From the Eagle Ford Marl Foraminifer Marl Foram-Rich Marl Limestone Calcareous Shale Ash Beds/Bentonite Courtesy of Core Laboratories The Relationship of Eagle Ford Core to Gamma Ray Showing Significant Vertical Heterogeneity GR 0 0 200 COREGR_ api DEPTH FT Courtesy of Core Laboratories PS 200 PS K 72 SB PS PS PS K 69 SB 12750 PS PS PS PS PS PS PS PS PS 12800 K 65 MFS PS PS PS K 64 SB PS PS 12850 PS PS PS PS PS PS 12900 BUDA PS K63 SB PS PS Buda 12950 PS PS Mineralogical Analysis: Relationship of Texture and Composition to Shale Reservoir Quality • Epi-fluorescence Petrography o Lithology o Rock Type o Mineralogy o Micro-Fractures • X-ray Diffraction Analysis o Mineralogy o V Clay • SEM Analysis Silica-Filled Algal Cyst 0.1 mm Courtesy of Core Laboratories Micro-Textural Relationships: The Importance of Scale to Proper Reservoir Identification 0.5 mm Standard 30-micron-thick slide: No apparent grain support which would suggest poor reservoir quality Ultra-Thin (20-micron) slide: Significant grain support which leads to better reservoir quality Courtesy of Core Laboratories 10387.0 10475.0 10643.0 10843.0 10925.0 11029.5 11047.5 11065.0 11086.5 11107.0 11131.5 11154.5 11176.5 11189.5 Bossier Haynesville Depth, feet The Importance of “Coarse-Grained Constituents”: MINERALOGY by XRD Haynesville Shale (Elm Grove Plantation #63 Well) 0 20 40 60 80 100 Volume Percent Qtz Ksp Plg Cal Dol Pyr I/S I/M Chl Ker Courtesy of Core Laboratories The Importance of “Coarse-Grained Constituents”: Marcellus Shale Courtesy of Core Laboratories Depth, feet The Importance of “Coarse-Grained Constituents”: MINERALOGY by XRD Eagle Ford Shale (PC-Q #1H) 11334.0 11350.5 11366.5 11382.5 11398.0 11414.0 11430.0 11446.0 11462.0 11478.5 11495.0 11510.5 11526.0 11542.0 11558.0 11574.0 11590.0 11606.0 11623.0 Austin Chalk Eagle Ford Buda 0 20 40 60 80 100 Volume Percent Qtz Plg Cal Dol Pyr Mar I/S I/M Chl Kao Ker Courtesy of Core Laboratories Eagle Ford: Mineralogical Variation Across the Trend Maverick Basin Area • Clay content increases from west to east Hawkville Area San Marcos Area East Texas Area QTZ % 20% • Kerogen content remains relatively constant CARBONATE % • Increase in clay resultant from clastic influence of the East Texas Basin 40% 60% CLAY % 80% KEROGEN % 100% XRD Data from Core Lab The Relationship of Porosity and Permeability to Mineralogy: Can’t Have One Without the Other BASIC ROCK PROPERTIES 1.00E-01 1.00E-02 Effective Gas Permeability, md 1.00E-03 3 MMCFGPD V 8 MMCFGPD H 1 md 1.00E-04 1.00E-05 1.00E-06 16 MMCFGPD H 1 md Raam Unit #3 (Barnett) 1.00E-07 (Haynesville) 1.00E-08 Mr Bill 1-30 (Caney) 1.00E-09 1.5 MMCFGPD V 1.00E-10 Mr Bill 1-30 (Woodford) Barnett (Avg) Haynesville (Avg) 1.00E-11 Caney (Avg) 1.00E-12 Woodford (Avg) 250 MCFGPD V 1.00E-13 1.00E-14 0 2 4 6 8 10 12 14 Gas-Filled Porosity, percent Courtesy of Core Laboratories Source Rock Reservoirs: Observed Maturity Effects Maturity (Ro) Oil Gravity (API) Burial Depth 0.5 GOR Organo Porosity Water Saturation Pore Pressure Gradient Recovery Factor Oil Window 0.6 0.7 0.8 0.9 1.0 Dry Gas Wet-Gas 1.1 Maximum Liquids Recovery Zone? 1.2 1.3 1.4 1.5 1.6 1.7 Courtesy of Core Laboratories The Importance of Stress Isotropic „Tempered‟ Glass Anisotropic „Natural‟ Glass Courtesy of Core Laboratories Measuring Stress: Essential to Understand Geomechanics of the Reservoir Laboratory Measurement oStatic and Dynamic Measurements on Core Samples (Young‟s Modulus) Log Data oFull-Waveform Acoustic Logs (Dipole Sonic) oBulk density oLithology Definition of Fracture Geometry Fracture Width Height Growth Closure Stress Fracture Production Zone Embedment Zone Courtesy of Core Laboratories Unconventional Development Process 3D Seismic Data: Critical to a Successful Development Program • The cost of 3D seismic data is minimal in the total field development cost • 3D seismic data is critical in identifying faults and dip changes that could compromise the stratigraphic targeting of a horizontal wellbore • Merged ~650 square miles of acquired proprietary data and licensed data in Hawkville Field Geo-Steering: An Important New Geoscience Skill Set Horizontal drilling creates significant geological challenges Unforeseen dip changes and/or faults can cause a well to be out of zone for a large portion of a lateral The combination of utilizing 3D seismic data and Measured Depth (MD) to True Vertical Depth (TVD) Gamma Ray correlation allows the geologist to direct the drilling operation to allow the well to stay within the target window The post-drill geologic interpretation of the wellbore also provides insight into the completion design and can cause the completion engineer to vary certain stages of the hydraulic fracture stimulation depending on the inferred reservoir quality within each stage Pre-Drill Well Plan Prior to 3D Seismic Data Acquisition Well plan is designed using subsurface mapping from well control and regional 2D seismic data Degree of confidence in the interpretation is fairly low 11,000’ Target Line: 11578’ TVD @ Zero Vertical Section Assuming Average 2 degree dip Pre-Seismic Geosteering Interpretation at TD Pilot Hole Gamma Ray Vertical Section Montage Horizontal Hole MD Gamma Ray Horizontal Hole TVD Gamma Ray 3D Seismic Acquired After Completion Faulting Geosteering Interpretation Using 3D Seismic Data Faults were conduit for “frac hit” by pressure and fluid transmission from offset well completion Stage by Stage Fracture Stimulation Montage Lost lateral section from “frac hit” from offset well Microseismic Data: Down-Hole View of Fracture Geometry Monitor Well Fault plane conduit for “frac hit” induced by offset well Lost Lateral Section Down-hole geophones Conclusions The geologic aspects of the Exploration process in shale reservoirs require an “inverted” thought process as compared to conventional exploration and usually is done with insufficient knowledge of reservoir quality The geologic aspects of the Appraisal process in shale reservoirs are highly dependent on an understanding of the “nano” elements of the reservoir and require a tremendous amount of data gathering and analysis over an extremely large area The geologic aspects of the Development process in shale reservoirs have generated a new set of skills, the most prominent being geo-steering, which is exciting, challenging and cross functional with several engineering disciplines Acknowledgments BHP Billiton Petroleum colleagues, specifically Vanon Sun Chee Fore, Terry Gebhardt, John Goss, Alan Frink, Andy Pepper, Melissa Florian and Kelley O‟Brien Core Laboratories, specifically Randy Miller Seitel, Inc.