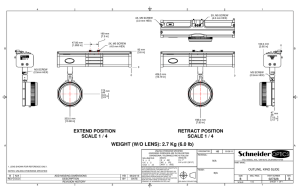

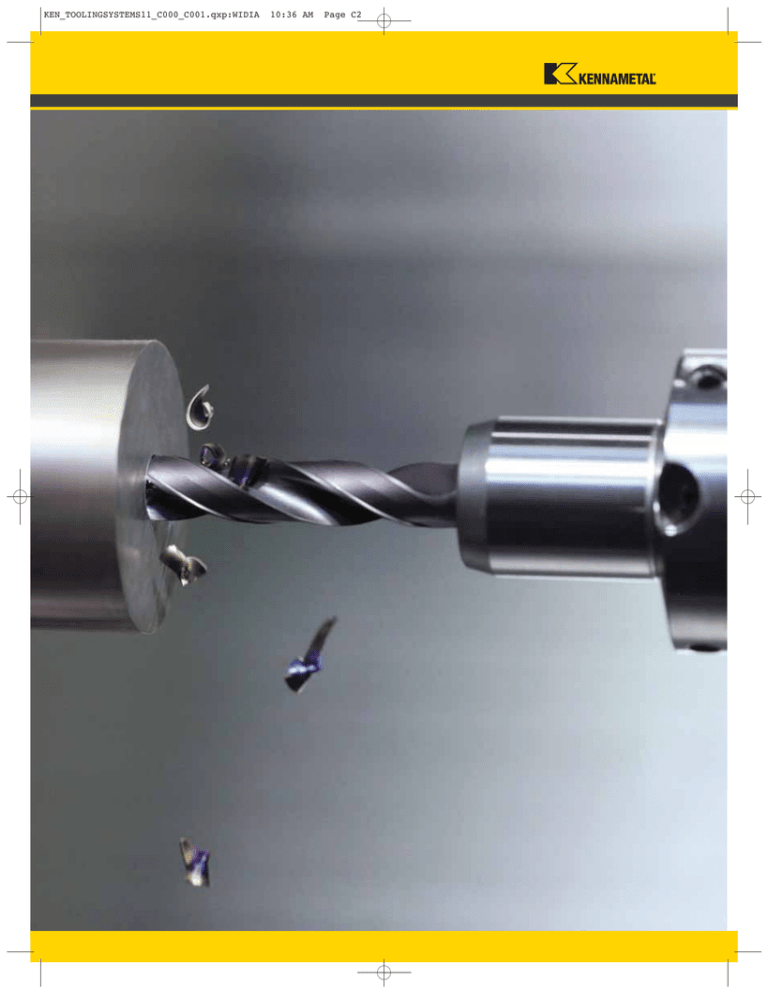

HSK tooling - Kennametal

advertisement