4F Condulet® Conduit Bodies and Outlet Boxes

advertisement

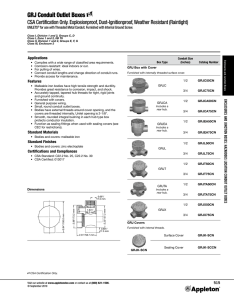

2: 5: SYS19: BASE2 PDFINFO 50: 95: 98: JOB: CRMAIN06-0047-2 Name: 4F-47 100: DATE: JAN 19 2006 Time: 4:58:20 PM Operator: RB COLOR: CMYK TCP: 15001 Condulet® Conduit Bodies and Outlet Boxes Hazardous Typedriver Name: TS name csm no.: 100 4F Description Page No. Application/Selection 48, 49 Lubricants HTL STL 59 59 Conduit Bodies & Outlet Boxes Cylindrical EKC 57 90° Elbow LBH LBY 58 58 Rectangular OE 56 Round CPS GUA EAB EAJ GUR Universal 55 50-52 53 54 60 Tees Short Radius ET US: 1-866-764-5454 STIBOINFO((CRH:66008com:4F:47)) CH0 0 0 0 4 F CAN: 1-800-265-0502 58 Copyright© 2006 Cooper Crouse-Hinds 47 Zoom: 100 2: 5: SYS19: BASE2 PDFINFO 50: 95: 98: 100: JOB: CRMAIN06-0048-1 Name: 4F-48 DATE: JAN 19 2006 Time: 4:58:21 PM Operator: RB COLOR: CMYK TCP: 15001 Typedriver Name: TS name csm no.: 100 Condulet® Conduit Bodies and Outlet Boxes 4F Application and Selection Application: Hazardous area conduit bodies and outlet boxes are installed in rigid conduit systems in Class I and II hazardous locations to: ɀ protect conductors ɀ act as pull and splice boxes ɀ connect lengths of conduit ɀ change conduit direction ɀ provide access to conductors for maintenance and future system changes ɀ act as mounting outlets for fixtures (with appropriate covers) ɀ act as sealing fittings (with appropriate covers) Considerations for Selection: ɀ Determine the area classification per National Electrical Code Hazardous Area Groups. Based on this classification, select the product families that are acceptable for use in the particular location. ɀ Establish functional physical requirements – these will help to determine box size, cover, shape and mounting for the particular installation. ɀ Each product family has features suitable for specific functions: ɀ i.e., boxes used as mountings for lighting fixtures are generally of a small size, and provided with mounting lugs when required to support lighting fixtures. ɀ Boxes used for wire pulling should generally be larger to provide room for easy pulling. ɀ Boxes used to splice and/or tap conductors should be large enough to permit ease of work and sufficient room for the required size and number of conductors. ɀ Hub size and configuration – dependent on the conduit system configuration and the conduit size used. ɀ Material and finish – determine from environmental conditions (corrosive fumes, weather, buried in concrete, etc.) Options and Accessories: ɀ Flat blank covers (surface and flanged flush), fixture support and sealing covers and extensions are available. See specific product listing for details. ɀ Lubricant (STL and HTL) are available to make joints raintight, provide for easy cover removal and to lubricate shafts over a wide temperature range. ɀ Corro-free TM epoxy powder coat – information available on request. Quick Selector Chart Series NEC Class I & II Groups Normal Function Cover Opening Diameter Hub Size† Cover Type GUA C, D Mtg. ltg. fixt., taps, pulling, splicing 2-5 1⁄2-2 Threaded EAJ A, B, C, D E, F, G Pulling, splicing, taps 33⁄16 & 5 1⁄2-2 Threaded EAB A, B, C, D E, F, G Pulling, splicing, taps 3 1⁄2-1 Threaded CPS C, D E, F, G Fixt. support, pulling, splicing 31⁄2 1⁄2 Ground joint OE C, D E, F, G Pulling 1⁄2-1 E, F, G & 3⁄4 ET C, D E, F, G Stub up LBY C, D E, F, G Pulling 1⁄2-11⁄4 Threaded LBH B, C, D Pulling 1⁄2-4 Ground joint EKC C, D Pulling 1-3 Ground joint GUR C, D Pulling, splicing 1⁄2-1 Threaded E, F, G E, F, G E, F, G † See following table for standard hub configuration. 48 STIBOINFO((CRH:66008com:4F:48)) CH0 0 4 F - 0 Ground joint 1⁄2-1 US: 1-866-764-5454 CAN: 1-800-265-0502 Copyright© 2006 Cooper Crouse-Hinds Zoom: 100 2: 5: SYS19: BASE2 PDFINFO 50: 95: 98: 100: JOB: CRMAIN06-0049-3 Name: 4F-49 DATE: JAN 19 2006 Time: 4:58:21 PM Operator: RB COLOR: CMYK TCP: 15001 Typedriver Name: TS name csm no.: 100 Condulet® Conduit Bodies and Outlet Boxes 4F Standard Shape and Hub Selector Shape SERIES Hub Style PAGE GUA GUA GUAB GUAC GUAD GUAL GUAM GUAN GUAT GUAW GUAX 50-52 EABC EAB EABL EABT EABX EAJL EAJT EAJX EABY 53 EAJB EAJ EAJC EAJD 54 CPS CPS 55 GUR GUR 60 OELB OE OEC OELL OELR OET 56 The fittings below are available only in the configurations shown. LBH PAGE 58 LBY PAGE 58 US: 1-866-764-5454 STIBOINFO((CRH:66008com:4F:49)) CH0 0 4 F - 1 EKC PAGE 57 CAN: 1-800-265-0502 ET PAGE 58 Copyright© 2006 Cooper Crouse-Hinds 49 Zoom: 100 2: 5: SYS19: BASE2 PDFINFO 50: 95: 98: JOB: CRTEST06-3050-0 Name: 4F-50 4F 100: DATE: JAN 19 2006 Time: 6:16:10 PM Operator: RB COLOR: CMYK TCP: 15001 Typedriver Name: TS name csm no.: 100 Condulet® Conduit Outlet Boxes Explosionproof Dust-Ignitionproof Raintight Wet Locations Cl. I, Div. 1 & 2, Groups C,D Cl. II, Div. 1, Groups E,F,G With Covers for Threaded Rigid and IMC Cl. II, Div. 2, Groups F,G Cl. III NEMA 3,4,7CD,9EFG Application: GUA series conduit outlet boxes are installed within hazardous area conduit systems to: ɀ protect conductors in threaded rigid conduit ɀ act as pull and splice boxes ɀ connect lengths of conduit ɀ change conduit direction ɀ provide access to conductors for maintenance and future system changes ɀ act as mounting outlets for fixtures (with appropriate covers) ɀ act as sealing fittings (with appropriate covers) Features: GUA conduit boxes have: ɀ Neoprene ‘‘O’’ ring standard to meet NEMA 4 requirements ɀ Cast ears on cover to permit easy removal and tightening ɀ Internal green ground screw ɀ Four standard mounting pads except for boxes with bottom hubs ɀ threaded cover openings ɀ ten different hub arrangements ɀ taper threaded hubs to provide grounding continuity ɀ smooth integral hub bushing protects conductor insulation when pulling ɀ surface covers furnished with boxes ɀ sealing covers, dome covers, and fixture hanger covers are available. ɀ cover threads are 12 pitch. Standard Materials: ɀ Bodies – Feraloy iron alloy ɀ Covers – Copper-free aluminum Standard Finishes: ɀ Feraloy iron alloy – electrogalvanized and aluminum acrylic paint ɀ Aluminum – natural Options: Suffix to be Added to Cat. # Description Bodies – copper-free aluminum . . . . . . . . . . . . . . . SA †* Covers – Feraloy iron alloy – electrogalvanized and aluminum acrylic paint . . . . . . . . . . . . . . . . . . . . WOD ɀ GUA Form 6 (with 3⍯ cover opening) are available with optional cover with viewing window. . . . . . . . . . . . . . . . . . . -VW Corro-free epoxy powder coat . . . . . . . . . . . . . S752 To order box less cover add ⍯0⍯ to end of catalog number ie.GUAT260. Certifications and Compliances: ɀ NEC/CEC: Class I, Division 1 & 2, Groups C,D Class II, Division 1, Groups E,F,G Class II, Division 2, Groups F,G Class III ɀ UL Standard: 886 ɀ ANSI Standard: C33.27 ɀ CSA Standard: C22.2 No. 30 ɀ NEMA/EEMAC 3,4 NOTE: When assembled with sealing type cover, GUA series outlet boxes provide adequate sealing for 40% fill in hazardous areas – Class I, Groups C,D; Class II, Groups E,F,G; and Class III. Seals can be made in either horizontal or vertical positions. Use Chico® ‘‘A’’ sealing compound or Chico® SpeedSeal only. Conductor splices or connections must not be made in enclosures where sealing compound is to be used per NEC. Dimensions GUAB Only GUA Hub Size 1⁄2 3⁄4 1⁄2 3⁄4 1 11⁄4 11⁄2 GUAC Cover Opening Dia. 2 2 3 3 3 35⁄8 5 Cat. # GUA14 GUA24 GUA16 GUA26* GUA36 GUA47 GUA59 Cover Opening Dia. 2 2 3 3 3 35⁄8 5 5 All others Size Ranges: ɀ Hub – 1⁄2⍯ to 2⍯ ɀ Cover opening – 2⍯ to 5⍯ dia. Hub Size 1⁄2 3⁄4 1⁄2 3⁄4 1 11⁄4 Cat. # GUAB14† GUAB24 GUAB16* GUAB26* GUAB36* GUAB47† GUAB59† GUAB69† Length of Hub Hub Size 1⁄2-3⁄4 1-11⁄4 11⁄2-2 Cat. # GUAC14† GUAC24† GUAC16* GUAC26* GUAC36* GUAC47† GUAC49 GUAC59† GUAC69† Cover Opening Dia. 2 2 3 3 3 5 Cat. # GUAD14† GUAD24 GUAD16 GUAD26† GUAD36† GUAD49 Dimension ‘‘e’’ Length 7⁄8 1 11⁄16 GUA, GUAD, GUAM, GUAW, GUAX Cat. # 14 24 16 26 36 37 47 49 59 69 † Available in copper-free aluminum, add suffix -SA. * Available in copper-free aluminum, add suffix -SA. GUA outlet boxes marked with * when ordered with suffix -SA are listed for Class I, Division 1 & 2, Groups B, C and D, Class II, Division 1, Groups E, F, G and Class III. Covers have 16 pitch threads. Replacement cover is a GUA06-GB. 50 Cover Opening Dia. 2 2 3 3 3 35⁄8 5 5 5 GUAD GUAB Hub Size 1⁄2 3⁄4 1⁄2 3⁄4 1 11⁄4 11⁄2 2 Hub Size 1⁄2 3⁄4 1⁄2 3⁄4 1 11⁄4 11⁄4 11⁄2 2 US: 1-866-764-5454 CAN: 1-800-265-0502 Copyright© 2006 Cooper Crouse-Hinds STIBOINFO((CRH:66008com:4F:50)) CH0 4 F - 0 3 S Crouse Hinds 1st Proof Authors Alterations A H M N a 21⁄2 21⁄2 31⁄2 31⁄2 31⁄2 41⁄4 41⁄4 53⁄4 53⁄4 53⁄4 b 113⁄16 2 2 2 25⁄16 25⁄16 211⁄16 313⁄16 313⁄16 41⁄16 c 13⁄4 2 17⁄8 17⁄8 23⁄16 23⁄8 23⁄4 33⁄4 33⁄4 4 d 5⁄8 3⁄4 5⁄8 3⁄4 7⁄8 7⁄8 13⁄32 13⁄32 19⁄32 19⁄16 Zoom: 100 2: 5: SYS19: BASE2 PDFINFO 50: 95: 98: 100: JOB: CRTEST06-3051-0 Name: 4F-51 DATE: JAN 19 2006 Time: 6:17:10 PM Operator: JB COLOR: CMYK TCP: 15001 Condulet® Conduit Outlet Boxes Hub Size 1⁄2 3⁄4 1⁄2 3⁄4 1 11⁄4 11⁄4 11⁄2 2 GUAN Cover Opening Dia. 2 2 3 3 3 35⁄8 5 5 5 Cat. # GUAL14† GUAL24† GUAL16* GUAL26* GUAL36* GUAL47† GUAL49† GUAL59† GUAL69† Hub Size 1⁄2 3⁄4 1⁄2 3⁄4 1 11⁄4 11⁄2 2 GUAT Cover Opening Dia. 2 2 3 3 3 35⁄8 5 5 Cat. # GUAN14 GUAN24 GUAN16 GUAN26 GUAN36† GUAN47 GUAN59† GUAN69 Cover Opening Dia. 2 2 3 3 Cat. # GUAW14† GUAW24† GUAW16 GUAL26† Hub Size 1⁄2 3⁄4 1⁄2 3⁄4 1 1 11⁄4 11⁄4 11⁄2 2 4F Exposionproof Dust-Ignitionproof Raintight Wet Locations Cl. I, Div. 1 & 2, Groups C,D Cl. II, Div. 1, Groups E,F,G With Covers for Threaded Rigid and IMC Cl. II, Div. 2, Groups F,G Cl. III NEMA 3,4,7CD,9EFG GUAL Typedriver Name: TS name csm no.: 100 GUAX Cover Opening Dia. 2 2 3 3 3 35⁄8 35⁄8 5 5 5 Cat. # GUAT14† GUAT24† GUAT16* GUAT26* GUAT36* GUAT37 GUAT47† GUAT49† GUAT59† GUAT69† Cover Opening Dia. 2 2 3 3 3 35⁄8 35⁄8 5 5 5 Hub Size 1⁄2 3⁄4 1⁄2 3⁄4 1 1 11⁄4 11⁄4 11⁄2 2 Cat. # GUAX14† GUAX24† GUAX16* GUAX26* GUAX36* GUAX37† GUAX47† GUAX49 GUAX59† GUAX69† GUAW GUAM Hub Size 1⁄2 3⁄4 1⁄2 3⁄4 1 11⁄4 2 Cover Opening Dia. 2 2 3 3 3 35⁄8 5 Cat. # GUAM14† GUAM24 GUAM16 GUAM26 GUAM36 GUAM47 GUAM69 Hub Size 1⁄2 3⁄4 1⁄2 3⁄4 Dimensions GUAC, GUAT Cat. # 14 24 16 26 36 37 47 49 59 69 a 21⁄2 21⁄2 31⁄2 31⁄2 31⁄2 41⁄4 41⁄4 53⁄4 53⁄4 53⁄4 b 21⁄4 2 2 2 25⁄16 25⁄16 211⁄16 313⁄16 313⁄16 41⁄16 c 23⁄16 2 17⁄8 17⁄8 23⁄16 23⁄8 23⁄4 33⁄4 33⁄4 4 d 5⁄8 3⁄4 5⁄8 3⁄4 7⁄8 7⁄8 13⁄32 15⁄32 19⁄32 19⁄16 GUAN Cat. # a b c d 14 24 16 26 36 47 59 69 21⁄2 21⁄2 31⁄2 31⁄2 31⁄2 41⁄4 53⁄4 53⁄4 21⁄8 25⁄16 2 2 25⁄16 211⁄16 41⁄16 41⁄16 21⁄16 21⁄4 17⁄8 17⁄8 23⁄8 23⁄4 4 4 5⁄8 3⁄4 3⁄4 3⁄4 7⁄8 13⁄32 19⁄32 19⁄16 GUAB, GUAL Cat. # a b 14 24 16 26 36 47 49 59 69 21⁄2 21⁄2 31⁄2 31⁄2 31⁄2 41⁄4 53⁄4 53⁄4 53⁄4 21⁄4 21⁄2 2 2 25⁄16 211⁄16 313⁄16 313⁄16 41⁄16 c d 23⁄16 27⁄16 17⁄8 17⁄8 23⁄16 23⁄4 33⁄4 33⁄4 4 5⁄8 3⁄4 5⁄8 3⁄4 7⁄8 13⁄32 15⁄32 19⁄32 19⁄16 * Available in copper-free aluminum, add suffix -SA. GUA outlet boxes marked with * when ordered with suffix-SA are listed for Class I, Division 1&2, Groups B, C and D, Class II, Division 1, Groups E, F, G and Class III. Covers have 16 pitch threads. Replacement cover is a GUA06-GB. † Available in copper-free aluminum, add suffix -SA. US: 1-866-764-5454 CAN: 1-800-265-0502 Copyright© 2006 Cooper Crouse-Hinds STIBOINFO((CRH:66008com:4F:51)) CH0 4 F - 0 4 S Crouse Hinds 1st Proof Authors Alterations A H M N 51 Zoom: 100 2: 5: SYS19: BASE2 PDFINFO 50: 95: 98: JOB: CRTEST06-3052-0 Name: 4F-52 4F 100: DATE: JAN 19 2006 Time: 6:17:15 PM Operator: RB COLOR: CMYK TCP: 15001 Typedriver Name: TS name csm no.: 100 Covers and Accessories For GUA Condulet® Conduit Outlet Boxes Application: Size Ranges: Threaded covers, canopies and extensions are used: ɀ to provide a seal in hazardous areas (sealing cover). See note at right ɀ to mount pendant lighting fixtures such as EVA listed in lighting section (fixture canopy) ɀ to mount EVA pendant lighting fixtures on cover which is then screwed into outlet box without twisting conductors (union hub cover) ɀ to mount pendant lighting fixtures on cover which is then screwed into outlet box as above, for wiring after fixture stem is installed (nipple cover) ɀ to provide means of increasing outlet box depth (threaded extension) ɀ Fixture stems – 3⁄4⍯ ɀ Body openings – 2⍯ to 5⍯ NOTE: Depth of sealing compound in body must satisfy requirements of NEC section 501-5 (C-3). Splices and taps in sealing fittings are prohibited by NEC. Features: ɀ Surface covers are supplied with GUA boxes ɀ Sealing cover has removable plug for filling enclosure with sealing compound after installation. Sealing cover meets 40% fill requirement of the NEC®. See note at right. ɀ Fixture canopy has a threaded cover in its side to provide access for making splices or taps. Fixture with its conduit stem and canopy can be assembled and wired before installation and conductors can be spliced in canopy after it has been screwed into the body ɀ Cover threads are 12 pitch. GUA Threaded Extension Cover Opening Ext. Dia. Depth 3 11⁄4 Surface Cover Cover Opening Dia. 2 3 3 35⁄8 5 Thread Pitch Cat. # 12 GUA04 12 GUA06 16 GUA06-GB* 12 GUA07 12 GUA09 Nipple Cover Cover Fixt. Opening Stem Thread Dia. Size Pitch Cat. # 3⁄4 3 12 GUA0672 Cat. # GUA0631 GUA Cover Opening 2⍯ 3⍯ 35⁄8⍯ 5⍯ Replacement O-Ring Gasket Cat. # GASK1713 GASK1151 GASK1589 GASK925 Fixture Cover Union Hub Type Dome Cover Cover Opening Ext. Thread Dia. Depth Pitch Cat. # 2 2 12 GUA047 3 2 12 GUA067 2 12 GUA077 35⁄8 4 12 GUA0716 35⁄8 5 4 12 GUA514 5 10 12 GUA5110 Cover Fixt. Opening Stem Thread Dia. Size Pitch Cat. # 3⁄4 3 12 GUA0687 Standard Materials: ɀ Surface and dome covers, union hub covers, nipple covers – copper-free aluminum ɀ Sealing covers, fixture canopies, threaded extensions – Feraloy® iron alloy Fixture Canopy Standard Finishes: ɀ Aluminum – natural ɀ Feraloy iron alloy – electrogalvanized and aluminum acrylic paint Sealing Cover Cover Opening Dia. 2 3 3 35⁄8 5 Options: ɀ Corro-free TM epoxy powder coat – add suffix S752 ɀ To order an iron surface cover, add suffix – WOD ie. GUA06 – WOD. 52 US: 1-866-764-5454 CAN: 1-800-265-0502 Thread Pitch Cat. # 12 GUA041 12 GUA062 16 GUA062-GB* 12 GUA072† 12 GUA092 Copyright© 2006 Cooper Crouse-Hinds STIBOINFO((CRH:66008com:4F:52)) CH0 4 F - 0 5 S Crouse Hinds 1st Proof Authors Alterations A H M N Cover Fixt. Opening Stem Thread Dia. Size Pitch Cat. # 3⁄4 3 12 GUA068 † Also used with GUP bodies on page 138 or GU and GUE bodies on page 122. * GUA covers with 16 pitch threads are used with GUA bodies ordered with -SA suffix identified with * symbol on pages 50 and 51. Zoom: 100 2: 5: SYS19: BASE2 PDFINFO 50: 95: 98: 100: JOB: CRMAIN06-0053-5 Name: 4F-53 DATE: JAN 19 2006 Time: 4:58:55 PM Operator: RB Condulet® Conduit Outlet Boxes With Covers COLOR: CMYK TCP: 15001 Cl. I, Div. 1 & 2, Groups A,B,C,D Cl. II, Div. 1, Groups E,F,G Cl. II, Div. 2, Groups F,G Cl. III NEMA 3,4,7ABCD,9EFG Typedriver Name: TS name csm no.: 100 Explosionproof Dust-Ignitionproof Raintight Wet Locations 4F Application: EAB series conduit outlet boxes are installed in conduit systems within hazardous areas to: ɀ provide protection against exterior explosion where acetylene, hydrogen and other hazardous gases are present ɀ protect conductors in threaded rigid conduit ɀ act as pull and splice boxes ɀ interconnect lengths of conduit ɀ change conduit direction ɀ provide access to conductors for maintenance and future system changes EABC Hub Size 1⁄2 3⁄4 1 Cat. # EABC16† EABC26† EABC36† Features: EAB series conduit outlet boxes have: ɀ five different hub configurations ɀ taper threaded hubs to provide ground continuity ɀ smooth integral hub bushing to protect conductor insulation when pulling ɀ threaded cover openings ɀ surface covers furnished with boxes ɀ Neoprene ‘‘o’’-ring gasket and green ground screw are both standard. ɀ Four standard mounting pads, except for EABY. ɀ Cover threads are 16 pitch. Standard Finishes: ɀ Feraloy – electrogalvanized and aluminum acrylic paint ɀ Aluminum – natural Options: Hub Size 1⁄2 3⁄4 1 Hub Size 1⁄2 3⁄4 Cat. # EABT16† EABT26† EABT36† Cat. # EABY16† EABY26† Replacement Cover: EABL Hub Size 1⁄2 3⁄4 1 Cat. # EABL16† EABL26† EABL36† Standard Materials: ɀ Body – Feraloy® iron alloy ɀ Cover – copper-free aluminum EABY EABT Cat. # 3⍯ EAB06 Replacement O-Ring: EABX Hub Size 1⁄2 3⁄4 1 Size Cat. # Cat. # EABX16† EABX26† EABX36† GASK1151 Dimensions EAB Series Fixture Cover: Suffix to be Added to Cat. # Union Hub Type Cover Fixt. Opening Stem Dia. Size 3⁄4 3⍯ Description Bodies – copper-free aluminum . . . . . . . . . . . . . . . . . SA † Covers – Feraloy iron alloy – electrogalvanized and aluminum acrylic paint . . . . . WOD Corro-free epoxy power coat . . . . . . . . . . . . . . . S752 Cat. # 16 26 36 Size Ranges: a 33⁄4 33⁄4 33⁄4 b 217⁄32 225⁄32 225⁄32 c 11⁄2 13⁄4 13⁄4 d 3⁄4 7⁄8 7⁄8 Cat. # EAB0687* e 55⁄16 59⁄16 59⁄16 f 33⁄32 33⁄32 33⁄32 ɀ Hub – 1⁄2⍯ to 1⍯ ɀ Cover opening – 3⍯ dia. Certifications and Compliances: ɀ NEC/CEC: Class I, Division 1 & 2, Groups A,B,C,D Class II, Division 1, Groups E,F,G Class II, Division 2, Groups F,G Class III ɀ UL Standard: 886 ɀ CSA Standard: C22.2 No. 30 † Available in copper-free aluminum, add suffix -SA. * EAB0687 is listed for Group C & D only. US: 1-866-764-5454 STIBOINFO((CRH:66008com:4F:53)) CH0 0 4 F - 5 CAN: 1-800-265-0502 Copyright© 2006 Cooper Crouse-Hinds 53 Zoom: 100 2: 5: SYS19: BASE2 PDFINFO 50: 95: 98: JOB: CRMAIN06-0054-1 Name: 4F-54 4F 100: DATE: JAN 19 2006 Time: 4:58:57 PM Operator: RB EAJ Condulet® Conduit Outlet Boxes With Covers Application: EAJ series conduit outlet boxes are installed in conduit systems within hazardous areas to: ɀ protect conductors in threaded rigid conduit ɀ act as pull and splice boxes ɀ interconnect lengths of conduit ɀ change conduit direction ɀ provide access to conductors for maintenance and future system changes Features: EAJ conduit outlet boxes have: ɀ water shedding cover – suitable for wet locations when mounted in upright position ɀ external cover threads on body protecting conductors from damage during pulling ɀ no pinching of conductors during cover installation ɀ six different hub arrangements ɀ taper threaded hubs to provide ground continuity ɀ smooth integral hub bushing to protect conductor insulation when pulling ɀ internally threaded cover openings for additional wiring room ɀ flat overlapping threaded covers furnished with boxes ɀ weather-resistant finish ɀ green ground screw standard in all boxes ɀ four standard mounting pads, except for EAJB and EAJD Standard Materials: COLOR: CMYK TCP: 15001 Typedriver Name: TS name csm no.: 100 Cl. I, Div. 1 & 2, Groups A‡,B,C,D Cl. II, Div. 1, Groups E,F,G Cl. II, Div. 2, Groups F,G Cl. III NEMA 3, 4, 7ABCD, 9EFG Explosionproof Dust-Ignitionproof Raintight Wet Locations Certifications and Compliances: ɀ NEC/CEC: Class I, Division 1 & 2, Groups A‡,B,C,D Class II, Division 1, Groups E,F,G Class II, Division 2, Groups F,G Class III ɀ UL Standard: 886 ɀ CSA Standard: C22.2 No. 30 Options: EAJD Cover Opening Dia. 33⁄16 33⁄16 33⁄16 Suffix to be Added to Cat. # Description Bodies – copper-free aluminum . . . . . . . . . . . . . . . . SA† Covers – Feraloy iron alloy – electrogalvanized and aluminum acrylic paint . . . . . . . . . . . . . . . . . . . . WOD Corro-free epoxy power coat . . . . . . . . . . . . . . S752 Hub Size 1⁄2 3⁄4 1 EAJX Cover Opening Dia. 33⁄16 33⁄16 33⁄16 Cat. # EAJD16† EAJD26† EAJD36† Flat Covers Cover Opening Dia. 33⁄16 33⁄16 33⁄16 EAJB Hub Size 1⁄2 3⁄4 1 Cat. # EAJX16† EAJX26† EAJX36† EAJ Threaded Covers EAJL Cover Opening Dia. 33⁄16 33⁄16 33⁄16 Hub Size 1⁄2 3⁄4 1 Hub Size 1⁄2 3⁄4 1 Cover Opening Diameter 33⁄16 Cat. # EAJ06 5 EAJ09 Cat. # EAJL16† EAJL26† EAJL36† Dome Covers Cat. # EAJB16† EAJB26† EAJB36† Cover Opening Dia. Depth Cat. # EAJ0612 33⁄16 2 ɀ Body – Feraloy® iron alloy ɀ Cover – copper-free aluminum Standard Finishes: EAJT ɀ Feraloy iron alloy – electrogalvanized and aluminum acrylic paint ɀ Aluminum – natural Cover Opening Dia. 33⁄16 33⁄16 33⁄16 5 5 5 Size Ranges: ɀ Hub – 1⁄2⍯ to 2⍯ ɀ Cover opening – 33⁄16⍯ to 5⍯ dia. Dimensions EAJC Cover Opening Dia. 33⁄16 33⁄16 33⁄16 Hub Size 1⁄2 3⁄4 1 Cat. # EAJC16† EAJC26† EAJC36† EAJ Series Cat. # 16 26 36 49 59 69 a 33⁄4 33⁄4 33⁄4 53⁄4 53⁄4 53⁄4 b 217⁄32 225⁄32 225⁄32 41⁄16 41⁄16 41⁄16 Hub Size 1⁄2 3⁄4 1 11⁄4 11⁄2 2 c 11⁄2 13⁄4 13⁄4 23⁄16 3 3 Cat. # EAJT16† EAJT26† EAJT36† EAJT49†‡ EAJT59†‡ EAJT69†‡ d 3⁄4 7⁄8 7⁄8 13⁄32 11⁄2 11⁄2 Fixture Covers Union Hub Type Cover Opening Dia. 33⁄16 e 55⁄16 59⁄16 59⁄16 75⁄16 713⁄16 713⁄16 f 33⁄32 33⁄32 33⁄32 43⁄4 43⁄4 43⁄4 * EAJ0687 is listed for Group C & D only. 54 STIBOINFO((CRH:66008com:4F:54)) CH0 0 4 F - 6 US: 1-866-764-5454 CAN: 1-800-265-0502 Fixt. Stem Size Cat. # 3⁄4 EAJ0687* Copyright© 2006 Cooper Crouse-Hinds † Available in copper-free aluminum, add suffix -SA. ‡ Form 9 products with 5⍯ cover opening are not suitable for Group A. Zoom: 100 2: 5: SYS19: BASE2 PDFINFO 50: 95: 98: JOB: CRMAIN06-0055-4 Name: 4F-55 100: DATE: JAN 19 2006 Time: 4:59:00 PM Operator: GK COLOR: CMYK Condulet® Conduit Outlet Boxes With Covers TCP: 15001 Cl. I, Div. 1 & 2, Groups C,D Cl. II, Div. 1, Groups E,F,G Cl. II, Div. 2, Groups F,G Cl. III NEMA 7CD,9EFG Explosionproof Dust-Ignitionproof Features: CPS conduit outlet boxes have: ɀ two types of cover: – blank for splice or pull box use – threaded hub for mounting light fixtures ɀ wide, accurately machined body and cover mating surfaces, to insure flametight joint ɀ blind tapped holes for cover screws to further insure flametightness ɀ removable mounting feet for flush or surface mounting to wall or ceiling 4F CPS Covers Application: CPS series conduit outlet boxes are installed in conduit systems in hazardous areas to: ɀ protect conductors in threaded rigid conduit ɀ act as pull and splice boxes ɀ change conduit direction ɀ interconnect lengths of conduit ɀ act as fixture hangers with hub covers ɀ provide access to conductors for maintenance and future system changes Typedriver Name: TS name csm no.: 100 Box with Hub Cover Box with Blank Cover Blank Covers Hub Size Body‡ Cover 1⁄2 3⁄4 3⁄4 3⁄4 Hub Size 3⁄4 Description Cat. # Form 20 CPS026 Cat. # CPS12021 CPS12022 Cat. # CPS12026 Hub Covers* Hub Size 1⁄2 3⁄4 Standard Materials: Description Form 20 Form 20 Cat. # CPS021 CPS022 ɀ Feraloy® iron alloy * Fixture weight up to 125 lbs. Standard Finishes: ɀ Electrogalvanized and aluminum acrylic paint Options: ɀ Corro-free TM epoxy powder coat add suffix - S752 Certifications and Compliances: ɀ NEC/CEC: Class I, Division 1 & 2, Groups C,D Class II, Division 1, Groups E,F,G Class II, Division 2, Groups F,G Class III ɀ UL Standard: 886 ɀ CSA Standard C22.2 No. 30 Note: complete line of fixture hangers are located in section 8L of this catalog. ‡ Furnished with four 3⁄4⍯ standard taper tapped, integrally bushed hubs. Three hubs are plugged. Dimensions US: 1-866-764-5454 STIBOINFO((CRH:66008com:4F:55)) CH0 0 4 F - 7 CAN: 1-800-265-0502 Copyright© 2006 Cooper Crouse-Hinds 55 Zoom: 100 2: 5: SYS19: BASE2 PDFINFO 50: 95: 98: JOB: CRMAIN06-0056-2 Name: 4F-56 100: DATE: JAN 19 2006 Time: 4:59:04 PM Operator: JB Condulet® Conduit Outlet Bodies With Covers 4F COLOR: CMYK TCP: 15001 Typedriver Name: TS name csm no.: 100 Cl. I, Div. 1 & 2, Groups C,D Cl. II, Div. 1, Groups E,F,G Cl. II, Div. 2, Groups F,G Cl. III NEMA 7CD,9EFG Explosionproof Dust-Ignitionproof Application: OE series are installed in conduit systems within hazardous areas to: ɀ protect conductors in threaded rigid conduit ɀ act as pulling and splice fittings ɀ interconnect lengths of conduit ɀ change direction of conduit ɀ provide access for maintenance and future system changes Features: OE conduit outlet bodies have: ɀ taper threaded hubs for ground continuity ɀ smooth integral hub bushings to protect conductor insulation when pulling ɀ five different hub arrangements ɀ accurately machined body with blind tapped screw holes ɀ most compact design of all hazardous area outlet bodies OEC OELL Hub Size 1⁄2 3⁄4 1 Hub Size 1⁄2 3⁄4 1 Cat. # OEC1 OEC2 OEC3-SA OET Hub Size 1⁄2 3⁄4 1 Cat. # OELL1 OELL2 OELL3-SA Cat. # OET1 OET2 OET3-SA Standard Materials: ɀ Feraloy® iron alloy (1⁄2⍯ and 3⁄4⍯ fittings) ɀ Copper-free aluminum (1⍯ fittings) Standard Finishes: ɀ Electrogalvanized and aluminum acrylic paint Options: ɀ Corro-free epoxy powder coat. . . . . . . . . . . add suffix - S752 TM OELR OELB Hub Size 1⁄2 3⁄4 1 Cat. # OELB1 OELB2 OELB3-SA Hub Size 1⁄2 3⁄4 1 Cat. # OELR1 OELR2 OELR3-SA Size Ranges: ɀ Hub – 1⁄2⍯ to 1⍯ Certifications and Compliances: ɀ NEC/CEC: Class I, Division 1 & 2, Groups C,D Class II, Division 1, Groups E,F,G Class II, Division 2, Groups F,G Class III ɀ UL Standard: 886 ɀ CSA Standard: C22.2 No. 30 Dimensions OE Series Hub Size 1⁄2 3⁄4 56 STIBOINFO((CRH:66008com:4F:56)) CH0 0 4 F - 8 US: 1-866-764-5454 CAN: 1-800-265-0502 a 41⁄16 45⁄16 b 19⁄16 17⁄8 Copyright© 2006 Cooper Crouse-Hinds c 113⁄16 21⁄16 d e f 11⁄16 7⁄8 5⁄8 11⁄16 7⁄8 3⁄4 Zoom: 100 2: 5: SYS19: BASE2 PDFINFO 50: 95: 98: JOB: CRTEST06-3057-0 Name: 4F-57 100: DATE: JAN 19 2006 Time: 6:17:16 PM Operator: RB Condulet® Pull Boxes and Outlet Bodies Options: EKC series conduit outlet bodies are installed in conduit systems within hazardous areas to: ɀ provide convenient opening in conduit system for pulling or splicing conductors ɀ EKC series: Corro-free TM epoxy powder coat – . . . . . . . . . . . . . . add suffix S752 Features: Certifications and Compliances: Size Ranges: Explosionproof Dust-Ignitionproof 4F EKC Standard Finishes: ɀ Feraloy – electrogalvanized and aluminum acrylic paint Dimensions ɀ EKC bodies – Feraloy iron alloy Typedriver Name: TS name csm no.: 100 ɀ EKC bodies – hub size – 1⍯ to 3⍯ ɀ NEC: EKC 30 – 60 Class I, Division 1 & 2, Groups C,D Class II, Division 1, Groups E,F,G Class II, Division 2, Groups F,G Class III EKC 70, 80 Class I, Division 1 & 2, Group D Class II, Division 1, Groups E,F,G Class II, Division 2, Groups F,G Class III ɀ UL Standard: 886 ɀ CSA Standard: C22.2 No. 30 Standard Materials: TCP: 15001 Cl. I, Div. 1 & 2, Groups C,D Cl. II, Div. 1, Groups E,F,G Cl. II, Div. 2, Groups F,G Cl. III NEMA 7CD,9EFG Application: EKC bodies have: ɀ accurately machined body and cover mating surfaces to ensure flametight joint when properly assembled ɀ extra long cover opening to facilitate pulling and splicing of conductors ɀ taper threaded hubs and integral bushing for rigid threaded conduit COLOR: CMYK EKC Outlet Bodies Hub Size Cat. # 1 11⁄4 11⁄2 2 21⁄2 3 EKC30 EKC40 EKC50 EKC60 EKC70 EKC80 EKC EKC Size 1 – 11⁄4 11⁄2 – 2 21⁄2 – 3 a 125⁄8 1515⁄16 213⁄4 US: 1-866-764-5454 b 31⁄16 37⁄8 51⁄2 c 37⁄16 45⁄16 6 d 13⁄4 21⁄2 33⁄4 CAN: 1-800-265-0502 e 9 12 16 Copyright© 2006 Cooper Crouse-Hinds STIBOINFO((CRH:66008com:4F:57)) CH0 4 F - 1 0 S Crouse Hinds 1st Proof Authors Alterations A H M f 4 5 65⁄8 N 57 Zoom: 100 2: 5: SYS19: BASE2 PDFINFO 50: 95: 98: JOB: CRMAIN06-0058-0 Name: 4F-58 4F 100: DATE: JAN 19 2006 Time: 4:59:06 PM Operator: CP COLOR: CMYK Condulet® Conduit Outlet Bodies, Elbows and Tees Application: Standard Materials: LBH conduit outlet bodies are installed in hazardous areas to: ɀ act as pull outlets especially for conductors that are stiff due to large size or type of insulation ɀ make 90° bends in conduit system, allowing straight pull in either direction ɀ provide for conduit service entrance to buildings ɀ provide for conductor entrance to motors ɀ provide access to wiring for maintenance and future system changes LBY elbows are installed in conduit systems within hazardous areas to: ɀ make 90° bends in conduit systems where space is limited ɀ act as pull outlets ɀ provide access to conductors for maintenance and future system changes ET series short radius tees are installed in conduit systems within hazardous areas to: ɀ allow single conduit stub up to outlet and device boxes located above or below main conduit runs. Eliminates separate feed and return conduits ɀ LBH, LBY and ET – Feraloy® iron alloy Features: LBH bodies have: ɀ cover openings on an angle, permitting conductors to be pulled straight through hubs from either direction ɀ domed covers to permit easy conductor bends (relieves strain on insulation) ɀ taper threaded hubs with integral bushings LBY elbows have: ɀ maximum volume for bends within a compact overall size ɀ screw on cover for ease of installation and removal ɀ cover opening on an angle, permitting conductors to be pulled straight through either hub ɀ taper threaded hubs and integral bushing for rigid threaded conduit ET short radius tees have: ɀ compact size and small radius of bend for use in concealed, or open conduit systems. Particularly suited for use in shallow floors or partitions ɀ taper threaded hubs and integral bushing for rigid threaded conduit STIBOINFO((CRH:66008com:4F:58)) CH0 4 F - 1 0 Typedriver Name: TS name csm no.: 100 Cl. I, Div. 1 & 2, Groups A,B,C,D* Explosionproof Cl. II, Div. 1, Groups E,F,G Dust-Ignitionproof Cl. II, Div. 2, Groups F,G Cl. III NEMA 7ABCD,9EFG Standard Finishes: ɀ LBH, LBY and ET – electrogalvanized and aluminum acrylic paint Options: Suffix to be Added to Description Cat. # LBH and LBY series – copper-free aluminum . . . . . . . . . . . . . . . . . . SA LBH and LBY series – Corrofree TM epoxy powder coat . . . . . . . . . . . . . . . . add suffix S752 Size Ranges: ɀ LBH bodies – hub size 1⁄2⍯ to 4⍯ ɀ LBY elbows – hub size 1⁄2⍯ to 11⁄2 LBY LBH Size 1⁄2 3⁄4 1 11⁄4 11⁄2 2 21⁄2 3 31⁄2 4 Size 1⁄2 3⁄4 1 11⁄4 11⁄2 Cat. # LBH10 LBH20 LBH30 LBH40 LBH50 LBH60 LBH70 LBH80 LBH90 LBH100 Cat. # LBY15 LBY25 LBY35 LBY45 LBY55 Certifications and Compliances: ɀ NEC: LBH 10-20 – Class I, Division 1 & 2, Groups B,C,D Class II, Division 1, Groups E,F,G Class II, Division 2, Groups F,G Class III LBH 30-100 Class I, Division 1 & 2, Group D Class II, Division 1, Groups E,F,G Class II, Division 2, Groups F,G Class III ET Size Cat. # ET218 3⁄4–3⁄4–3⁄4 ‡ ET228 1–3⁄4–3⁄4 ‡ ET328 3⁄4–1⁄2–1⁄2 ‡ Dimensions LBH LBY LBY – Class I, Division 1 & 2, Groups C,D Class II, Division 1, Groups E,F,G Class II, Division 2, Groups F,G Class III ET – Class I, Division 1 & 2, Groups A,B,C,D Class II, Division 1, Groups E,F,G Class II, Division 2, Groups F,G Class III ɀ UL Standard: 886 ɀ CSA Standard: C22.2 No. 30 * See Compliances for classification of each product. ET LBH Size 1⁄2 – 3⁄4 1 – 1⁄4 11⁄2 2 21⁄2 – 3 31⁄2 – 4 a 51⁄16 77⁄8 1015⁄16 1021⁄32 155⁄8 239⁄16 b 219⁄32 313⁄32 41⁄2 425⁄32 51⁄2 611⁄16 LBY Size 1⁄2 3⁄4 1 11⁄4 11⁄2 ‡ Largest hub is shown at top of photo. 58 TCP: 15001 US: 1-866-764-5454 CAN: 1-800-265-0502 c 4 51⁄4 73⁄32 73⁄32 91⁄2 113⁄4 d 13⁄16 13⁄4 21⁄2 21⁄2 3 4 e 4 7 10 10 153⁄4 24 f 23⁄4 4 5 5 55⁄8 71⁄8 ET a 29⁄16 213⁄16 33⁄32 33⁄4 41⁄4 b 2 21⁄4 21⁄2 215⁄16 33⁄8 Size 3⁄4–1⁄2–1⁄2 3⁄4–3⁄4–3⁄4 1–3⁄4–3⁄4 Copyright© 2006 Cooper Crouse-Hinds a 4 4 4 b 25⁄8 3 3 c 11⁄4 11⁄2 11⁄2 d 11⁄2 11⁄2 13⁄4 Zoom: 100 2: 5: SYS19: BASE2 PDFINFO 50: 95: 98: JOB: CRMAIN06-0059-1 Name: 4F-59 100: DATE: JAN 19 2006 Time: 4:59:07 PM Operator: RB COLOR: CMYK TCP: 15001 Typedriver Name: TS name csm no.: 100 Lubricants 4F Application: ɀ STL thread lubricant is used between any screw thread and its tapped opening, on any rotating shaft – threaded or plain, and to inhibit corrosion on any metal-to-metal joint of apparatus and control enclosures. ɀ HTL high temperature lubricant is used on lighting fixture threaded joints and on threaded joints of the enclosures of any heat-producing apparatus or control. Features: STL thread lubricant is lithium based, antigalling and: ɀ is especially effective between parts made of dissimilar metals ɀ is effective and stable from –20°F to +300°F ɀ maintains grounding continuity; should not be used on exposed current-carrying parts ɀ has excellent adhesion qualities A liberal application on threaded joints maintains raintightness and inhibits corrosion. HTL is a high temperature, anti-seize, conductive thread lubricant: ɀ effective and stable from –70°F to +1800°F ɀ prevents seizure, galling, rust, galvanic action ɀ maintains grounding continuity; should not be used on exposed current-carrying parts ɀ effective between parts made of dissimilar metals STL Thread Lubricant Net Wt. 13⁄4 oz. (tube) 8 oz. (can) Cat. # STL2 STL8 HTL High Temperature Thread Lubricant Net Wt. 4 oz. (tube) Cat. # HTL4 MSDS Sheets are available at www.crouse-hinds.com US: 1-866-764-5454 STIBOINFO((CRH:66008com:4F:59)) CH0 4 F - 1 1 CAN: 1-800-265-0502 Copyright© 2006 Cooper Crouse-Hinds 59 Zoom: 100 2: 5: SYS19: BASE2 PDFINFO 50: 95: 98: JOB: CRMAIN06-0060-7 Name: 4F-60 4F 100: DATE: JAN 19 2006 Time: 4:59:08 PM Operator: JB GUR Universal Outlet Box COLOR: CMYK TCP: 15001 Cl. I, Div. 1 & 2, Groups C,D Cl. II, Div. 1, Groups E,F,G Cl. II, Div. 2, Groups F,G Cl. III NEMA 3,4,7CD,9EFG Ordering Information Application: GUR conduit outlet boxes are installed within hazardous areas: ɀ to protect conductors in threaded rigid conduit ɀ to act as pull and splice boxes ɀ to connect lengths of conduit ɀ to provide access to conductors for maintenance and future system changes ɀ to change conduit direction ɀ where space is limited, such as underneath gasoline pumps Hub Size 1⁄2⍯ 3⁄4⍯ 1⍯ Cat. # GUR1 GUR2 GUR3 Features: GUR outlet boxes feature: ɀ neoprene O-ring standard in cover to meet NEMA 4/UL Type 4 requirements ɀ internal green ground screw ɀ five standard hubs with three pipe plugs included ɀ threaded cover opening ɀ recesses in cover to assist in cover tightening and removal ɀ smooth, integral hub bushing to protect conductor insulation when pulling ɀ compact design for confined spaces ɀ UL and cUL listing ɀ optional all-aluminum construction Standard Materials: ɀ Bodies – Feraloy® iron alloy ɀ Covers – copper-free aluminum Standard Finishes: ɀ Feraloy iron alloy – electrogalvanized with aluminum acrylic paint ɀ Aluminum – natural Certifications and Compliances: ɀ NEC/CEC: Class I, Division 1 and 2, Groups C and D Class II, Division 1, Groups E, F and G Class III Zone 1 and 2 ɀ UL Standard 886 ɀ cUL to CSA Standard C22.2 No. 30 ɀ NEMA 4 Dimensions Options: ɀ Bodies – copper-free aluminum (add suffix -SA) 60 STIBOINFO((CRH:66008com:4F:60)) CH0 4 F - 1 3 Typedriver Name: TS name csm no.: 100 US: 1-866-764-5454 CAN: 1-800-265-0502 Copyright© 2006 Cooper Crouse-Hinds Explosionproof Dust-Ignitionproof Raintight Wet Locations Zoom: 100