Characterizing the Metastable Zone Width and

advertisement

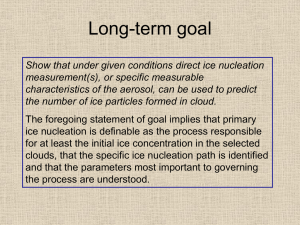

0263–8762/02/$23.50+0.00 # Institution of Chemical Engineers Trans IChemE, Vol 80, Part A, October 2002 www.catchword.com=titles=02638762.htm CHARACTERIZING THE METASTABLE ZONE WIDTH AND SOLUBILITY CURVE USING LASENTEC FBRM AND PVM P. BARRETT and B. GLENNON Department of Chemical Engineering, University College Dublin, Dublin, Ireland A successful industrial crystallization typically requires the development of a robust process in the laboratory. Knowledge of the solubility curve and the stability of the solution in the vicinity of the equilibrium point, as indicated by the metastable zone width, is essential to the successful development, optimization, and scale-up of a crystallization process. Use of the Lasentec Focused Beam Re ectance (FBRM) system, with aqueous potash alum solutions, to determine both the metastable zone width and solubility curve is demonstrated. The measured metastable zone width data are also used to estimate the nucleation kinetics of the system. Lasentec Particle Vision and Measurement (PVM) images are also employed to validate the results. The data collected using the FBRM system compare very well with published literature values for potash alum solubility and metastable zone width in aqueous solutions. Keywords: nucleation; metastable zone width; solubility curve; Lasentec; FBRM; PVM. INTRODUCTION For the work presented in this paper, a Focused Beam Re ectance (FBRM) probe (model M400LF, Lasentec Inc., USA) is used as the tool to help characterize both the nucleation and dissolution properties of the material. FBRM measures a chord length distribution (CLD), which is a function of the number, size, and shape of particles under investigation13 . FBRM uses a focused beam of laser light, which scans in a circular path. As this light scans across a particle or particle structure passing in front of the probe window, light is scattered in all directions. The light scattered back towards the probe is used to measure a chord length off the given particle. Typically, many thousands of chords are measured per second, providing a robust measurement that is sensitive to the change in the size or number of particles under investigation. Unlike, for example, optical turbidity or laser diffraction, FBRM does not depend on the presence of a threshold nuclei concentration before a nucleation event is detected—as soon as one particle is in the detectable size range it will be detected. A more detailed description of the operation of the FBRM probe is provided by other authors 14 ,1 5 . FBRM has been used by previous researchers to help characterize the metastable zone width1 6 and is widely used as a tool for both batch and continuous crystallization development and scale-up1 7,18 , crystallization control19 , and the troubleshooting and optimization of downstream processing problems20 ,21 . A Particle Vision and Measurement (PVM) probe (model PVM 700L, Lasentec Inc., USA) was also integrated into these experiments. PVM is a probe-based high resolution in-situ video microscope providing images of crystals and crystal structures as they exist in a process. PVM uses six independent laser sources to illuminate a xed area within General Introduction A solute will remain in solution until a suf ciently high level of supersaturation has been developed to induce spontaneous nucleation. The extent of this supersaturation is referred to as the metastable zone width. It will typically be in uenced by a variety of process parameters including saturation temperature, rate of supersaturation generation, impurity level, mixing, and solution history1 . It is therefore important to characterize the metastable zone width under a speci c set of operating conditions, which relate closely to the conditions of the nal scale crystallization. There are a variety of correlations available in the literature, which can be applied to help indicate the dominant nucleation mechanisms and can be used to predict the metastable zone width2 –4 . An excellent overview of published metastable zone width experiments is available in the literature5 . The polythermal technique6 is perhaps the most widely used technique for determining the metastable zone width. This methodology involves cooling a saturated solution at a xed rate until nucleation occurs. This process is repeated for a variety of cooling rates and saturation temperatures, with the recorded nucleation temperature allowing the calculation of the metastable zone width for a given cooling rate, which in turn allows an estimation of the nucleation kinetics6 . A wide variety of measurement techniques have been applied to detect the onset of nucleation including visualization7 , electrozone sensing8 , and optical turbidity9 . The method of detection frequently has an in uence on the success of the kinetics estimation, as often there is a time lag following nucleation as the material grows to a detectable size range1 0– 1 2 . 799 800 BARRETT and GLENNON the slurry. Light scattered back towards the probe is used in conjunction with a CCD element to produce an image. The image has a eld of view of 860 mm £ 645 mm, with the pixel size on the CCD array 0:67 mm, with allowing image resolution down to approximately 5 mm. The software allows up to 10 images per second to be stored. These images help validate particle shape and give an indication of particle dimension and structure following nucleation and during dissolution. Nucleation Kinetics Utilizing classical nucleation theory, it can be shown that the nucleation rate, or rate of change in the number of crystals, can be expressed as6 dN ˆ k00 Dcn …1† dt When a solution is cooled, the rate of supersaturation generation can be expressed as a function of the cooling rate, r1 ; 12 J ˆ dDc dc¤ ˆ r1 …2† dt dT With knowledge of the solubility curve, the temperature coef cient of solubility is simply the slope for a given saturation temperature. When nucleation occurs, the maximum possible undercooling is given as DTmax ˆ T ¤ ¡ Tnuc This corresponds to the maximum supersaturation …3† dc¤ …4† dT At the point of nucleation it is assumed that the rate of formation of new crystals equals the rate of supersaturation generation. The mass of nuclei formed relates directly to the number of crystals formed6 : Dcmax ˆ DTmax dM ˆ k0 arr3 Dcm ˆ kN Dcm dt Combining equations (2), (4) and (5) yields, µ³ ¤ ´ ¶m ³ ¤´ dc dc m DTmax ˆ r1 e kN D c ˆ kN dT dT …5† solutions were prepared using reagent grade potash alum and 0:22 mm Millipore ltered water. The crystallization vessel used has a maximum working volume of 2 L, but the starting volume used was about 1 L. The agitated jacketed vessel had an inner diameter of 13 cm with a domed bottom and is equipped with a standard Ruston turbine, of diameter 5 cm. The crystallizer has ports to accommodate the FBRM and PVM probes, which were positioned to ensure good ow against the probe windows, allowing a representative sample of the particle system to be measured (Figure 1). For this work, the vessel was operated with four standard baf es, with both probes themselves offering additional baf ing. An impeller speed of 400 rpm was employed for all experiments, which helped ensure adequate mixing, but also avoided excessive splashing in the vessel. The vessel was sealed and operated with a condenser at 10¯ C. Programmed cooling and heating pro les were implemented using a Julabo HP50 Heating= Cooling system. Temperature data were recorded on PC via a PT-100 probe which was in the crystallizer and connected to the Julabo heating=cooling system. To minimize the amount of material consumed and to help aid in the future automation of the process, the same saturated solution was ‘recycled’ batch to batch. Solution history is known, in some cases, to have a bearing on the measured metastable zone width2 2 . Prior to completing the proposed experiments, the effect, if any, of solution history on the nucleation behaviour of potash alum in water was investigated. A potash alum solution saturated at approximately 35¯ C was heated to 50¯ C and aged for 1.5 hours to help ensure full dissolution. A similar protocol was recommended by previous researchers on the nucleation behaviour of the potash alum system23 . The solution was then cooled, at ¡ 0.7¯ C min 1 , to 20¯ C. At this point the solution is reheated, ¡ again at 0.7¯ C min 1 , to 50¯ C and the aging and cooling process is repeated. This process is then repeated eight times using the same ‘recycled’ solution, with FBRM used to monitor the system. With reference to Figure 2, initially as the solution is cooled and becomes supersaturated, FBRM detects no particles and the count data indicate no change in particle number. However, as soon as nucleation occurs, crystals are formed, and there is a corresponding increase in counts in …6† where e is de ned as1 2 eˆ 100R ‰100 ¡ c…R ¡ 1†Š2 …7† Rearranging equation (6) and taking logarithms yields, ³ ¤´ dc ¡ ln e ln…r1 † ˆ m ln…DTmax † ‡ ln kN ‡ …m ¡ 1† ln dT …8† Therefore, a plot of r1 versus DTmax will yield the apparent nucleation order, m, and the nucleation rate constant, kN . MATERIALS AND EXPERIMENTAL METHODS Kinetic studies were performed on aluminum potassium sulphate KAl(SO4 )2¢12H 2 O (potash alum) in water. All Figure 1. Schematic drawing of probe positions relative to the impeller. Trans IChemE, Vol 80, Part A, October 2002 FBRM, PVM, AND METASTABLE ZONE WIDTH AND SOLUBILITY CURVE 801 Figure 2. FBRM data and temperature pro le for a typical batch. the FBRM data. An advantage of using FBRM is that the measured count data can be split into speci c population regions, permitting the isolation of the size range in which a change occurs. A 10-s measurement duration was used for all FBRM measurements. As the FBRM measures over a 10-s period, the number of counts in the 0–20 mm range was used as the indication of nucleation. Published growth data for potash alum2 4 predict that nuclei may grow by up to 15 mm in this 10-s period. Zooming in on the region around the point of nucleation (Figure 3) will illustrate the sensitivity of FBRM to the nucleation event, and the importance of selecting the most suitable statistic. FBRM is used to detect the point of nucleation for all batches, and the temperature of nucleation is recorded on the PC and tabulated for this process (Table 1). Ignoring the one outlier (batch 5), the point of nucleation is taken as 26.4¯ C (average of all batches) with a standard deviation of 0.34¯ C. The reproducibility, therefore, from batch to batch is excellent. In this case, the potash alum nucleated consistently at the same temperature, validating that, for this material at the conditions under examination, solution history did not have a bearing on the point of nucleation. Figure 3. FBRM data and temperature data at the point of nucleation. Trans IChemE, Vol 80, Part A, October 2002 802 BARRETT and GLENNON Table 1. Nucleation temperatures for initial trials. Batch # 1 2 3 4 5 6 7 8 Nucleation temperature (¯ C) 26.07 26.06 26.35 27.06 29.12 26.22 26.58 26.42 Immediately following nucleation, the FBRM reports a rapid increase in coarse chords counts (Figure 3) indicating the presence of large crystals, either through rapid growth or agglomeration. To validate this rapid increase in dimension, a series of PVM images were captured within the rst few minutes of nucleation (Figure 4), highlighting the presence of nes, but also the presence of both large single crystals and agglomerates. Figure 4. PVM images taken within 2 minutes of the point of nucleation for a typical batch. Following the cooling period, the slurry is reheated. During this reheating process, the material will begin to dissolve. PVM images taken during this dissolution period give an indication of the complexities of the dissolution mechanism. There is a clear transition from the distinctive octahedral shape of the potash alum crystals to a more rounded structure (Figure 5). Extensive investigation con rmed that this transition was indeed due to dissolution, and not to crystal breakage or attrition. Fine particles have a high surface area to volume ratio in comparison with coarse particles, and by applying basic thermodynamic theory, these ne particles will have a tendency to dissolve before the coarser particles. Therefore to successfully track when the material goes back into solution ( point of disappearance) counts in a coarse size range (50–250 mm) are used, and the point of disappearance is detected using these coarse counts in a similar manner to the nucleation work above. During the heating process, as the point of saturation is approached, the rate of dissolution decreases. Therefore, for fast heating rates, the temperature measured at the point of Figure 5. PVM image sequence taken during dissolution process. Trans IChemE, Vol 80, Part A, October 2002 FBRM, PVM, AND METASTABLE ZONE WIDTH AND SOLUBILITY CURVE Figure 6. Calculating the saturation temperature via extrapolation. disappearance may be signi cantly greater than the actual saturation temperature. For this work, the point of disappearance is tracked using FBRM for a variety of different heating rates. As the heating rate is reduced, the temperature of the point of disappearance approaches the saturation temperature. Extrapolation of the data back to an in nitely slow heating rate will yield an estimate of the point of solubility (Figure 6). The cooling=heating rates used for these experiments are 0.7, 0.6, 0.5, 0.4, 0.3, 0.2, and 0.15¯ C per minute. The experimental protocol used is similar to the initial nucleation trials, with the saturated solution heated to 15¯ C above the estimated point of solubility, holding for 1.5 hours and then cooling at a xed rate to 5–10¯ C below the detected point of nucleation, and then reheating at the same xed rate back to 15¯ C above the estimated point of solubility and again holding for 1.5 hours. This process is repeated for each of the temperature rates and the order in which they are performed is randomized. Each rate is repeated at least three times to ensure good reproducibility. FBRM and temperature data are recorded throughout this process at 10-s intervals. Following the completion of the heating=cooling cycles, the concentration is adjusted by addition of water to the crystallizer. The experiments outlined above are then repeated for the new concentration. Repeated dilutions were made until the total volume in the crystallizer was 2 L. At this point, a fresh 1 L solution at a lower concentration was made and the process repeated. Experiments with different liquid volumes but the same concentration, while maintaining a constant impeller speed, show no signi cant variation in the measured nucleation temperature. This indicates that the power input per unit volume does not have a marked effect on the point of nucleation for this material. Figure 7. Measured and literature solubility data. available for relating solubility, typically in the format of mole fraction, to temperature1 2 . Assuming ideal solution behaviour, the original van’t Hoff solubility relationship2 5 can be used to correlate the solubility of any substance in any solvent26 . Extrapolation via the van’t Hoff solubility curve is often subject to errors and an overview of how to treat, extrapolate, and interpret measured solubility data is available in the literature27 . In this case, the solubility data are tted to equation (9)2 7 using a non-linear regression: ln…x† ˆ 12:10 ‡ 10:47 ln…T † ¡ 65:73 T Trans IChemE, Vol 80, Part A, October 2002 …9† Figure 7 shows the excellent correlation obtained between the experimental data, the tted solubility curve, and literature values2 8 . The metastable zone width is calculated as the difference between the point of solubility and the measured point of nucleation. The solubility curve and the metastable zone width data measured for two cooling rates over the entire experimental temperature range are plotted in Figure 8. Figure 9 shows the measured metastable zone width for a variety of cooling rates as a function of the saturation temperature. There is a clear trend of a widening of the EXPERIMENTAL RESULTS Applying the technique described in the previous section to solutions of varying concentrations, the metastable zone width and solubility curve over a wide temperature range can be generated. It is often useful to t a solubility curve to measured solubility points and extrapolate the curve over a wide range of temperatures. There are many relationships 803 Figure 8. Measured solubility and metastable zone width data. 804 BARRETT and GLENNON CONCLUSIONS Figure 9. Metastable zone width as function of saturation temperature. FBRM demonstrated that it is a valuable tool to aid in determining both the solubility curve and nucleation properties of the potash alum water system. FBRM as a measurement technique offers the advantage of sensitivity to nes for detecting a nucleation event, but also one can isolate and track the coarse material during dissolution. PVM images helped illustrate the shape of the crystals, but more importantly showed the presence of large crystals after nucleation, con rming the rapid growth expected. The solubility data collected via the FBRM technique showed excellent correlation with literature values. The measured nucleation order will help give an indication of the ease at which material will nucleate. This should serve as a useful parameter to help assess the effect of different solvents or solvent compositions on the metastability of a solution. The metastable zone width and solubility technique presented lends itself to easy automation, which should prove invaluable, particularly in a pharmaceutical development laboratory where many solutes=solvents are screened for both solubility and metastable zone width. In these experiments, the solution was recycled batch to batch and a series of dilutions were made to the system to change the concentration. This approach used less material and allowed the rapid screening of the solubility curve. However, it is recommended that the effect of both solution history and mixing on the measured metastable zone width be considered. If metastable zone width is in uenced on a laboratory scale, it is likely that this effect will be exacerbated during process scale-up, and is worthy of further investigation. NOMENCLATURE Figure 10. Nucleation order for a typical batch. measured metastable zone width as the saturation temperature decreases. Using equation (8), a plot of the cooling rate versus the metastable zone width allows an estimate of the nucleation order (Figure 10). Therefore, in this case the apparent nucleation order is 2.03. The nucleation constant is also calculated using equation (8), with the temperature coef cient of solubility estimated from the slope of the solubility curve at a particular temperature. This data analysis is applied to all the batches, to give an indication of nucleation properties over a variety of concentrations. Table 2 shows the calculated nucleation parameters for this material over the conditions examined. The nucleation order ranged from 1.57–2.03, which is in good agreement with previously reported values of 1.1–3.5 for this material2 3 . Table 2. Calculated nucleation parameters. T (K) 322 318 313 309 306 298 m kN 1.86 1.83 1.78 2.03 1.97 1.57 10.39 £ 10 6 ¡ 11.79 £ 10 6 ¡ £ 12.58 10 6 ¡ 8.87 £ 10 6 ¡ 7.53 £ 10 6 ¡ 7.28 £ 10 6 ¡ A1 , A2 , A3 c c¤ Dc Dcmax dM =dt dN =dt constants ¡ concentration, g solute (100 g solvent) 1 ¡ saturation concentration, g solute (100 g solvent) 1 ¡ supersaturation , g solute (100 g solvent) 1 supersaturation at point of nucleation, g solute (100 g ¡ solvent) 1 ¡ ¡ nucleation rate, m 3 s 1 constant nucleation rate constants apparent nucleation order nucleation order ¡ cooling rate, K s 1 nuclei size, m ratio of molecular weight of hydrate: anhydrou s temperature, K saturation temperature, K nucleation temperature, K maximum undercooling, K solute mole fraction temperature coef cient of solubility, g solute (100 g ¡ solvent K) 1 ¡ mass nucleation rate, g crystal (g free solvent s) 1 ¡3 ¡1 nucleation rate, m s Greek symbols a e r crystal shape factor conversion factor de ned by equation (7) ¡ density, kg m 3 J k kN , k0 m n r1 r R T T¤ Tnuc DTmax x dc¤ =dT REFERENCES 1. Nyvlt, J., Sohnel, O., Matuchova, M. and Broul, M., 1985, The Kinetics of Industrial Crystallization (Elsevier, Amsterdam, The Netherlands). 2. Mersmann, A., 1996, Supersaturation and nucleation, Trans IChemE, 74: 812–820. Trans IChemE, Vol 80, Part A, October 2002 FBRM, PVM, AND METASTABLE ZONE WIDTH AND SOLUBILITY CURVE 3. Mersmann, A. and Bartosch, K., 1998, How to predict the metastable zone width, J Crystal Growth, 183: 240–250. 4. Mersmann, A., 1999, Crystallization and precipitation, Chem Engng Proc, 38: 345–353. 5. Tavare, N. S., 1987, Batch crystallizers: A review, Chem Engng Commun, 61: 259–318. 6. Nyvlt, J., 1968, Kinetics of nucleation in solutions, J Crystal Growth, 3,4: 377–383. 7. Sohnel, O. and Mullin, J. W., 1998, The role of time in metastable zone width determination, Trans IChemE, Part A, Chem Eng Res Des, 66: 537–540. 8. Mullin, J. W. and Jancic, S. J., 1979, Interpretation of the metastable zone width, Trans IChemE, 57: 188–193. 9. Gerson, A. R., Roberts, K. J. and Sherwood, J. N., 1991, An instrument for the examination of nucleation from solution and its application to the study of precipitation from diesel fuels and solutions of n-alkanes, Powder Technol, 65: 243–249. 10. Nyvlt, J., Rychly, R., Gottfried, J. and Wurzelova, J., 1970, Metastable zone-width of some aqueous solutions, J Crystal Growth, 6: 151–162. 11. Janse, A. H. and De Jong, E. J., 1978, On the width of the meta stable zone, Trans IChemE, 56: 187–193. 12. Mullin, J. W., 1985, Crystallization (Butterworth-Heinemann , Oxford). 13. Barrett, P. and Glennon, B., 1999, In-line FBRM monitoring of particle size in dilute agitated suspensions, Part Part Syst Charact, 16: 207–211. 14. Sparks, R. G. and Dobbs, C. L., 1993, The use of laser backscatter instrumentation for the on-line measurement of particle size distribution for emulsions, Part Part Sys Charact, 10: 279–289. 15. Tadayyon, A. and Rohani, S., 1998, Determination of particle size distribution by Partec 100: Modeling and experimental results, Part Part Sys Charact, 15: 127–135. 16. Liotta, V., 2001, Automated metastable zones, Lasentec Users Forum, 25–28 Feb., 2001, Barcelona, Spain. 17. Andrews, A. and Osifchin, R., 2001, Crystallization developmen t and scale-up: Controlling polymorphism and particle size, AIChE Annual Meeting, 4–9 Nov. 2001, Reno. 18. Alvarez, M. and Brown, M., 2001, Mixing of slurry systems in continuous stirred tanks, AIChE Annual Meeting, 4–9 Nov. 2001, Reno. 19. Farrell, R. J. and Tsai, Y., 1995, Nonlinear controller for batch crystal- Trans IChemE, Vol 80, Part A, October 2002 20. 21. 22. 23. 24. 25. 26. 27. 28. 805 lization: Developmen t and experimental demonstration, AIChE J, 41: 2318–2321. Johnson, B. K., Szeto, C., Davidson, O. and Andrews, A., 1997, Optimization of pharmaceutical batch crystallization for ltration and scale-up, AIChE Annual Meeting, 16–21 Nov. 1997, Los Angeles. Alvarez, M., Lee, T., Girard, K., Moore, T., Escobar, C. and Srivastava, S., 2001, Good mixing and attrition minimization: Con icting goals in crystal drying operations, AIChE Annual Meeting, 4–9 Nov. 2001, Reno. Hussain, K., Thorsen, G. and Malthe-Sørenssen, D., 2001, Nucleation and metastability in crystallization of vanillin and ethyl vanillin, Chem Engng Sci, 56: 2295–2304. Meenan, P. and Roberts, K. J., 1993, The application of an automated crystallization cell used to study the nucleation kinetics of potash alum, J Mater Sci Lett, 12: 1741–1744. Girolami, W. and Rousseau, R. W., 1985, Size dependen t crystal growth—A manifestation of growth rate dispersion in the potassium alum–water system, AIChE J, 31: 1821–1828. van’t Hoff, J. H., 1886, L’éuilibre chimique dans les systèmes gazeux on dissous à l’état dilué, Arch. Néerl. Sci. Exact. Natur., 20: 239–302. Atkins, P. W., 1994, Physical Chemistry, 5th edn, 222–226 (Oxford University Press, Oxford, UK). Grant, D. J. W., Mehdizadeh, M., Chow, A. H. L. and Fairbrother, J. E., 1984, Non-linear van’t Hoff solubility—temperature plots and their pharmaceutical interpretation, Int J Pharmaceutics, 18: 25–38. Mullin, J. W., Garside, J. and Unahabhokha , R., 1965, Diffusivities of ammonium and potassium alums in aqueous solutions, J Appl Chem, 15: 502–505. ADDRESS Correspondence concerning this paper should be addressed to Dr B. Glennon, Department of Chemical Engineering, University College Dublin, Bel eld, Dublin 4, Ireland. E-mail: brian.glennon@ucd.i e The manuscript was received 19 March 2002 and accepted for publication after revision 6 August 2002.