Data Sheet

advertisement

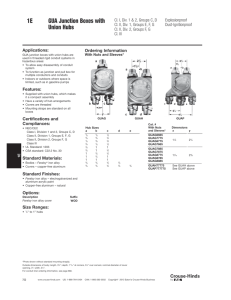

K-6 GUBB Series: Class I, Div. 1 and 2, Groups ifp»D Class II, Div. 1 and 2, Groups E,F,G Class III GUBB Cast Junction Boxes for Drilling and Tapping. Explosion-Proof, Dust-Ignition-Proof. Drilled and tapped openings from 1/2" thru 4" as specified. Cover Catalog Number Opening Malleable (Inches) Form No. Iront Aluminum' Size (Inches) LxWxD $ Malleable iron and aluminum boxes furnished with aluminum cover. GROUP BANDC SEALING REQUIREMENTS Box Group Seals Required* GUBB B,C Yes GUBB 7 x 6-1/2 x 6-3/8 5.38 1 GUBB-11 GUBB-11 A 0x8x6-9/16 7.19 2 GUBB-22 GUBB-22A 12 x 12 x 7-7/8 9.81 3 GUBB-33 GUBB-33A * Shaded area indicates items also suitable for Groups B and C. GUBB-11,11A (2 Lugs) GUBB-22,22A (2 Lugs) GUBB-33,33A (4 Lugs) No 'Sealing fitting must be installed within 2" of each conduit entrance (max. conduit for Group B and C is 2"). H Dimensions In Inches tlnside dimensions. Cat. No. GUBB-11 GUBB-11 A A B Ct Dt E F G H J K L M N U 7.00 5.50 5.94 5.38 6.00 7.75 .50 6.38 3.69 4.88 4.63 6.25 10.00 7.13 9.00 7.19 9.00 9.25 .50 6.56 3.50 4.63 4.63 8.00 10.25 12.00 10.75 10.75 9.88 10.00 13.13 .63 7.88 3.94 5.25 5.38 Dimensions in Centimeters flnside dimensions. GUBB-11 16.5 17.8 14.0 15.1 13.7 GUBB-11 A 15.2 19.7 GUBB-22 GUBB-22A 20.3 25.4 18.1 22.9 18.3 22.9 23.5 GUBB-33 GUBB-33A 30.5 30.5 27.3 27.3 25.1 25.4 6 50 ' GUBB-22 GUBB-22A 80 GUBB-33 GUBB-33A 120 ° ° Effective October, 1993 Copyright 1993 Printed in U.S.A. PAGE 6 33.3 11.00 8.75 14.38 1.3 16.2 9.4 11.8 11.8 15.9 22.2 1.3 16.7 8.9 11.4 11.8 15.9 26.0 1.6 20.0 10.0 11.1 13.7 27.9 36.5 1701 West Wellington Avenue Chicago, Illinois 60657 K-2 Cast Junction Boxes: Explosion-Proof, Dust-Ignition-Proof. UNILETS® for Use with Threaded Metal Conduit. Applications • Explosion-Proof and Dust-IgnitionProof, for use in classified locations containing such gases as butane, gasoline, hexane, naphtha, benzene, lacquer solvent vapors and alcohol. • Corrosion-resistant— ideal indoors or outdoors. • Junction or pull box for pulling and splicing of wires and as an enclosure for electrical devices. • Ideal where number and size of conductors require a junction box with additional space. • Excellent for use in classified-area wiring of motors, circuit breakers, panelboards, entrances to buildings, etc. Features: All Boxes • Provided with mounting lugs (except DER). • Furnished with covers. • All conduit hubs and openings provide a minimum of five full threads to meet UL requirements. • Accurately tapped, tapered conduit threads provide tight, rigid joints and ground continuity. B Features: GUB/GUBB Series QWide selection of sizes and locations for brazed threaded hubs or drilled and tapped conduit openings. • Suitable for use as an enclosure for relays, instrument and other control apparatus in classified locations. • Available in high tensile strength malleable iron or copper-free aluminum bodies. • Smooth, rounded integral bushing in every brazed hub protects conductor insulation. • Provided with mounting lugs. • O-Rings available for forms 1, 2 and 3 to provide raintight fit. Features: GUBD Series (Dome and Plate) 0 GUB junction boxes with dome cover and mounting plate provide flexibility for a wide variety of applications. • Ideal for housing relays, contactors, terminal blocks and other classifiedarea applications. • Mounting plate can be drilled to accommodate a variety of devices. Effective October, 1993 Copyright 1993 Printed in U.S.A. PAGE 2 1701 West Wellington Avenue Chicago, Illinois 60657 K-3 Cast Junction Boxes: Explosion-Proof, Dust-Ignition-Proof UNILETS® for Use with Threaded Metal Conduit. • Dome cover has nominal depth of 6" to 17", depending upon box selected. Provides significant increase in cu. in. capacity. • Smooth, rounded integral bushing in every brazed hub protects conductor insulation. • O-Rings available to provide raintight fit. • Provided with mounting lugs. Features: GUBM Series (Instrument) © GUBM junction boxes serve as an enclosure for meters, gauges and similar devices. • Complete with round, explosion-proof glass window cover. Permits direct reading of enclosed instrument. • Furnished with one 3/4" hub. • Mounting bosses provided in back of GUBM can be drilled and tapped for fastening of instrument mounting bracket. • Smooth, rounded integral bushing in every brazed hub protects conductor insulation. • O-Rings available to provide raintight fit. • Provided with mounting lugs. Features: DER Series O Available with brazed hubs. • Malleable iron bodies for high tensile strength and ductility. Provides greater resistance to impact, shock and corrosion. • Smooth, rounded integral bushing in every brazed hub protects conductor insulation. • O-Rings available to provide raintight fit. • Function as sealing fittings when used with sealing cover (see NEC for restrictions). Features: EJB Series (Aluminum) 0 Furnished with O-rings in most sizes—provides watertight fit. • Cast copper-free aluminum box and cover. Provides greater resistance to certain types of corrosive atmospheres. • Outboard ground joint cover opening provides maximum usable space for Effective October, 1993 Copyright 1993 Printed in U.S.A. pulling wires and installing devices. • Extra wide, accurately ground mating surfaces with closely spaced steel hex-head cap screws with dichromate finish assure a flame-tight joint. • Provided with mounting lugs. • Bosses are blind tapped as a provision for securing MP Mounting Plates. • Two stud bolts with nuts furnished on 12x12 and larger boxes. For use in diagonally opposite corners of body to aid in aligning cover (not furnished with hinge cover). • Hinge holes provided as standard on 12x12 and larger boxes. Features: EXB Series (Cast Iron) O Wide selection of sizes and locations for drilled and tapped openings. • Cast iron box and cover with aluminized finish. • Extra wide, accurately ground mating surfaces with closely spaced stainless steel hex-head cap screws assure a flame-tight joint. • Provided with mounting lugs. Standard Materials • DER, GUB, GUBB, GUBD: malleable iron bodies and copper-free aluminum covers. • GUBM: malleable iron bodies with copper-free aluminum and glass cover. • EJB: copper-free aluminum bodies and covers. • EXB: cast iron bodies and covers for sizes up to 30x12; 30x12 and larger sizes in aluminum. • Separate Covers: DER Sealing Cover—malleable iron. DER, GUB and GUBB Surface Covers and GUB and GUBB Dome Covers— aluminum. Standard Finishes • DER, GUB and GUBB malleable iron bodies: triple-coat—(1) zinc electroplate, (2) dichromate, and (3) aluminum polymer enamel. • DER, GUB and GUBB aluminum covers and GUBB aluminum bodies: aluminum polymer enamel. • DER malleable iron sealing covers: triple-coat—(1) zinc electroplate, (2) dichromate, and (3) aluminum polymer enamel. Appleton • • ELECTRIC COMPANY • EXB cast iron bodies and covers: hotdip galvanized. • EJB aluminum bodies and covers: natural finish. Options: DER, GUB and GUBB • O-Rings. Suffix—OR. • Less Cover. Suffix —LC. • Terminal Blocks. Information provided upon request (except DER-1). • Instrument Mounting Plate and Bracket for GUBM. Information provided upon request (submit complete dimensions of instrument to be used). Options: EXB and EJB • Hinged Covers. Hinges on 12x12x8 and larger EJB boxes: Suffix —H. EXB hinges: Information provided on request. • Mounting Plates. Mounting plates on all EJB boxes: Suffix —MP. EXB mounting plates: Information provided on request. • Terminal Blocks. Information provided upon request. Compliances • UL Standard 886. • Appleton malleable iron products conform to ASTM A47-77, Grade 32510, which has the following properties: tensile strength, 50,000 psi; yield, 32,000 psi; and elongation, 10%. • Appleton aluminum products are produced from a high strength copperfree (4/10 of 1% max.) alloy. • Suitable for Class I, Div. 1 & 2, if installed in compliance with NEC 5014(a)(b) and for Class II, Div. 1 & 2, if in compliance with NEC 502-4(a)(b). 1701 West Wellington Avenue Chicago, Illinois 60657 PAGE 3 a K-7 Ordering Information: GUBB Boxes; Blank Bodies for Drilling and Tapping. Determine catalog number as follows: (1) select GUBB junction box catalog number; (2) select "Conduit Opening Arrangement Diagram" number; and (3) select symbols that represent conduit opening sizes from "Symbol Table." Where no opening is required, the symbol 0 must be inserted. Add suffix for other Optional Features. The various divisions of the complete catalog number should be separated by dashes. Example The junction box selected is GUBB-33 and the "Conduit Opening Arrangement" is diagram #1. Opening "a" is to be 3/4"; "b", no opening required; "c", 2"; and "d", 1-1/4. In this example, the complete catalog number is: GUBB-33—1—BOFD Standard Conduit Opening Arrangement Diagrams Minimum Recommended Spacing Between Conduit Openings Allowance made for clearance over bushings. When unions or seals are used, additional space must be allowed. Table shows minimum distances between conduit-opening centerlines in various size combinations. For example, if 1-1/2" and 3/4" openings are to be drilled and tapped into one side of box, the minimum spacing between centerlines would be 2.13". Conduit Size (Inches) 1/2 1/2 1.25 3/4 1.38 1 1.56 1.69 1.88 1-1/4 1.88 2.00 2.19 2.44 1-1/2 2.00 2.13 2.31 2.63 2.75 2 2.38 2.50 2.69 2.94 3.13 3.44 2-1/2 2.50 2.63 2.81 3.13 3.25 3.63 3.75 3 2.88 3.00 3.19 3.44 3.63 3.94 4.13 4.44 3-1/2 4 3.13 3.25 3.44 3.75 3.88 4.25 4.38 4.75 5.00 3.44 3.56 3.75 4.06 4.19 4.56 4.69 5.06 5.31 1.50 5.63 Diameters of Bushings, Unions, Conduit and Seals, Inches Opening "a" is always TOP of box Side Minimum space between conduit opening centerlines, inches 3-1/2 4 1-1/4 1-1/2 2 2-1/2 3 3/4 1 Diameters of fittings for 1/2 thru 4' conduit Conduit Size (Inches) 1/2 3/4 1 1-1/4 1-1/2 2 2-1/2 3 3-1/2 4 BBU Bushing 1.06 1.31 1.56 1.94 2.19 2.69 3.19 3.88 4.38 4.88 BU Bushing 1.13 1.25 1.63 2.06 2.31 2.94 3.25 3.88 4.56 5.06 UNY-UNF (R) Union 1.50 1.75 2.00 2.81 3.06 3.75 4.94 5.44 5.94 6.50 1.06 1.38 1.69 1.94 2.38 2.88 3.50 4.00 4.50 1.19 1.38 1.75 2.06 2.31 2.69 3.13 3.44 3.69 Conduit EYM-EYF Seals T.R.t .88 1.06 tTR. is turning radius. Wall Thickness and Maximum Conduit Size, Inches m I k j Symbol Table Drilling and Tapping (Five Threads Win.) Box Type Top, Bottom and Sides Wall Maximum Thickness Conduit Size GUBB-11, GUBB-11A GUBB-22, GUBB-22A GUBB-33, GUBB-33A .44 .44 .56 2 2 2 .44 .63 .81 Symbol Blank 1/2 0 A B C D E 3/4 1 1-1/4 1-1/2 Size (In.) Symbol 2 F G H 2-1/2 3 3-1/2 4 J K Back Maximum Conduit Size 2 4 4 All conduit openings will be located in centerline of walls and evenly spaced unless otherwise specified. Back Top Size (In.) Wall Thickness If a "Standard Conduit Opening Arrangement" is not suitable for the ap- Front plication, or when openings are to be more accurately spaced, submit sketch, locating openings (1) from centerlines of box and (2) from outside back of box (or from mounting lug surface if lugs are supplied). Top Side GUBB-11,22 GUBB-33 (also GUBB-11 A, 22A) (Also GUBB-33A) Refer to Pricing Index for price, weight, and standard package Copyright 1984 Printed in U.S.A. Effective Jan. 1984 1701 W. Wellington Ave. Chicago, Illinois 60657 PAGE 7