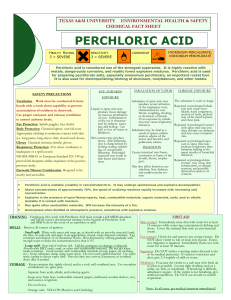

Guidelines for Using Perchloric Acid Perchloric acid (HClO4)

advertisement

Guidelines for Using Perchloric Acid Perchloric acid (HClO4) is a strong mineral acid. Under some circumstances it may act as an oxidizer and/or present an explosion hazards. These guidelines present information on how to handle and store perchloric acid safely. Please notify EH&S at 8-8182 if you are using perchloric acid in your laboratory. Using Perchloric Acid (< 72%) at Room Temperature At room temperature, perchloric acid up to concentrations of 72% has properties similar to other strong mineral acids. It is a highly corrosive substance and causes severe burns on contact with the eyes, skin, and mucous membranes. When used under these conditions, perchloric acid reacts as a strong non-oxidizing acid. The following precautions should be taken when using perchloric acid under these conditions: · Substitute with less hazardous chemicals when appropriate. Use dilute solutions (< 60%) whenever possible. · Conduct operations involving cold perchloric acid in a properly functioning chemical fume hood with current EH&S certification. If operations are conducted frequently or in large quantities contact EH&S to determine if a specially designed fume hood dedicated to perchloric acid use is required. · Always use impact-resistant chemical goggles, a face shield, neoprene gloves, and a rubber apron when handling perchloric acid. · When using or storing even dilute perchloric acid solutions avoid contact with strong dehydrating agents (concentrated sulfuric acid, anhydrous phosphorous pentoxide, etc.). These chemicals may concentrate the perchloric acid and make it unstable. · Always transfer perchloric acid over a sink or other suitable containment in order to catch any spills and afford a ready means of cleanup and disposal. · Perform all operations on chemically resistant surfaces. Avoid contact with cellulose materials such as wood, paper and cotton. Perchloric acid may become concentrated and cause a fire or explosion. Using Heated Perchloric Acid (<72%) When heated to temperatures above 150° C perchloric acid becomes a strong oxidizer and eventually becomes unstable. Concentrated solutions are very dangerous and can react violently with many oxidizable substances, such as paper and wood, and can detonate. Vapors may also contaminate work surfaces or ventilation equipment with perchlorate residues, which may form highly unstable compounds, such as metallic perchlorates. These compounds may ignite or detonate under certain conditions. The following additional precautions should be followed when heating perchloric acid: · Perchloric acid digestions and other procedures performed at elevated temperatures should be done in a specially designed perchloric acid fume hoods. Contact EH&S to schedule use. If procedures involving heated perchloric acid are performed only rarely other accepted methods to capture and contain vapors may be used in place of a perchloric acid hood. If you have been performing perchloric acid digestions in a fume hood not designed for perchloric acid, contact EH&S immediately for an evaluation of perchlorate contamination of the hood. · Lower the fume hood sash as much as possible so that it can function as a physical barrier or use a safety shield to provide splash/splinter protection. Perchloric acid fume hoods should have shatterproof glass. · Never heat perchloric acid in an oil bath or with an open flame. Electric hot plates, electrically or steam-heated sand baths, heating mantles, or steam baths are preferred. Use explosion proof electrical equipment. · Avoid allowing hot perchloric acid to come into contact with any organic materials, including paper or wood, because a fire or explosion can occur. Avoid storing these materials in perchloric acid work hoods. Avoid using greases or hoses that are incompatible with perchloric acid. · Be sure you understand the reaction(s) that can occur when using perchloric acid. Perchloric acid may react violently with many chemicals, including acetic anhydride, alcohol, reducing agents, and many metals. · In wet digestions with perchloric acid, treat the sample first with nitric acid to destroy easily oxidizable matter. · Do not distill perchloric acid in a vacuum, because the unstable anhydride may be formed and cause a spontaneous explosion. Protect vacuum sources from perchloric acid/perchlorate contamination. Vacuum pumps should be thoroughly flushed and refilled with Kel-F or Fluorolube. · Wash down perchloric acid hoods after each use, following operating instructions provided by the manufacturer of the perchloric acid hood. · If an apparatus cracks or breaks due to thermal or mechanical shock, the hazards are sufficient to make it desirable to consider using quartz apparatus since it is necessary in many experiments to chill perchloric acid rapidly from the boiling point. Glass-to-glass unions, lubricated with 72% perchloric acid, seal well and prevent joint freezing arising from the use of silicon lubricants. Rubber stoppers, tubes, or stopcocks are incompatible with perchloric acid. · When handling beakers of hot acid use properly designed tongs or other remote-handling devices. Using Anhydrous Perchloric Acid Anhydrous perchloric acid (> 85% concentration) is very unstable and will usually explode when it comes in contact with organic materials. Follow these additional precautions when working with anhydrous perchloric acid. · Allow only experienced research workers to handle anhydrous perchloric acid. These workers shall be thoroughly familiar with the literature on the acid. Assure that a second worker is informed of the intended use of the anhydrous perchloric acid. This second worker should be in sound or sight contact with the worker using anhydrous perchloric acid. · Use a safety shield to protect oneself against the effects of a possible explosion. · Use the acid in a designated, properly designed perchloric acid hood with a minimum of equipment present. No extraneous chemicals should be present in the hood. · Use thick gauntlets in addition to PPE previously recommended. · Use only freshly prepared acid. Do not make any more anhydrous perchloric acid than is required for a day/shift. Perchloric Acid Spills CLEAN UP SPILLS OF PERCHLORIC ACID ONLY IF YOU HAVE BEEN TRAINED TO DO SO AND THE APPROPRIATE EQUIPMENT IS AVAILABLE! If you need assistance, call EH&S. To clean a spill, neutralize it with soda ash (sodium carbonate) or other appropriate neutralizing agent. Soak up the neutralized spill with an inorganic based absorbent, if possible. If rags, paper towels are used, wet them and place them in a plastic bag and seal it. Do NOT use rags, paper towels, or sawdust and then put them aside to dry out, as such materials may spontaneously ignite. A second neutralization and rinsing of the wetted area is recommended. Label waste as flammable hazardous waste and submit an On-line Request for Hazardous Waste Pickup (www.cmu.edu/ehs). Storage The quantities of perchloric acid kept in storage should be kept to a minimum. Perchloric acid should be stored in its original container within compatible secondary containment, preferably glass or porcelain. Glass trays should be wiped periodically. It should be separate from other chemicals, but may be stored with other inorganic acids, preferably in a metal cabinet designed for acid/corrosive storage. It may also be stored in a perchloric acid fume hood. Perchloric acid must be stored away from organic chemicals, flammable or combustible materials and strong dehydrating agents such as sulfuric acid and anhydrous phosphorus pentoxide. If a bottle containing perchloric acid has turned dark and has crystals forming around the bottom of the bottle, there is a potential explosion hazard. Do NOT move the bottle, but contact EH&S for immediate assistance. Inappropriate and Appropriate Materials · The following materials are not recommended for use with 72% perchloric acid: Nylon/polyamides, Dynel/modacrylic ester, Dacron/polyester, Bakelite, Lucite, vegetable-based Micarta, cellulose-based lacquers, copper/brass/bronze (which form shock sensitive salts), aluminum (dissolves), high nickel alloys (dissolve), cotton, wool, wood, and litharge (glycerin and lead oxide). · The following are suitable for use with 72% perchloric acid: Viton, tantalum, chemically pure titanium, zirconium, niobium, Hastelloy C (slight corrosion rate), PVC, Teflon, polyethylene, polypropylene, Kel-F, vinylidene fluoride, Saran, epoxy resins, glass, glass-lined steel, alumina, and Fluorolube. Surface Contamination Tests for Perchlorates · Diphenylamine Test: Dissolve one gram of diphenylamine in 10 ml of "1 to 1" (18 normal) sulfuric acid to form a diphenylamine sulfate solution. Using a medicine dropper apply this solution to the test surface. The liquid turns black upon contact with perchlorate. The solution also reacts with nitrates, but turns blue. · Methylene Blue Test: Use 0.4% solution of methylene blue in water. Add a few drops of indicator solution to about 25 ml of trial solution, such as water used to test rinse from a length of potentially contaminated duct. Perchlorates will produce a violet precipitate. 1. Most of the information for this document was taken from Lawrence Livermore National Laboratory's ES&H Manual, Chapter 14.8 Working Safely with Corrosive Chemicals. Additional information is included from; CRC Handbook of Laboratory Safety, NFPA 45 Fire Protection for Laboratories Using Chemicals, and fact sheets from the University of Ottawa, University of Illinois at Urbana Champaign, University of California at San Francisco and the Oklahoma Medical Research Foundation.