17.28

STAINLESS STEEL PIPE – GROOVED VALVES

Super Duplex Stainless Steel

Vic-Ball Valve

SERIES 726D

The Series 726D is a high-pressure full port ball valve with grooved ends. This two-piece,

end-entry valve features a floating ball for lower torque requirements. Series 726D valves are

rated up to 1200 psi/8273 kPa. The valve features a super duplex stainless steel ball, body

and end cap. The Series 726D also features a unique composite seat design which provides

excellent sealing ability. Series 726D features an ISO 5211 standard mounting

pattern for convenient mounting of remote actuation. A full range of power actuators can also

be mounted on the valve.

MATERIAL SPECIFICATIONS

Body and End Cap: Super duplex stainless steel, ASTM A890-5A (CE3MN).

Ball: Super duplex stainless steel, ASTM A182-F53 or ASTM A890-5A (CE3MN).

Seats: (PTFE) Polytetrafluoroethylene, (HDPE) High-density polyethylene

Seals: EPDM.

Stem: Super duplex stainless steel, ASTM A890-5A (CE3MN) or Zeron 100

Optional handle kits: (For 2"/50mm and 3"/80mm valves only) 300 Series stainless steel

JOB/OWNER

CONTRACTOR

ENGINEER

System No._______________________________

Submitted By_____________________________

Spec Sect________________Para____________

Location_________________________________

Date____________________________________

Approved________________________________

Date____________________________________

www.victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2011 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

REV_B

17.28_1

17.28

STAINLESS STEEL PIPE – GROOVED VALVES

Super Duplex Stainless Steel

Vic-Ball Valve

SERIES 726D

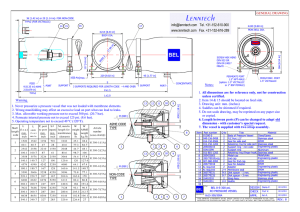

DIMENSIONS

SERIES 726D BARE VALVE

2 – 6"/60 – 150 mm

B

A

J

K

90°

P

R

M

CDE F

L

Valve Size

Actual

Outside

Nominal

Diameter

Diameter

Inches/mm Inches/mm

PERFORMANCE

N

G

H

Approx.

Weight Each

Dimensions – Inches/mm

A

B

C

D

E

F

G

H

J

K

L

M

N

P

R

Lbs/kg

2

50

2.38

60.3

.562

14.3

.313

7.95

2.38

60.3

2.25

57.2

2.00

50.8

1.90

48.3

3.03

77.0

6.07

154.2

3.32

84.3

3.95

100.3

2.13

54.0

3.38

85.9

0.55

13.97

0.27

6.80

1.97

50.0

8.9

4.0

3

80

3.50

88.9

.562

14.3

.313

7.95

3.50

88.9

3.34

84.9

3.07

78.0

2.92

74.2

4.01

101.8

8.00

203.2

4.69

119.1

5.38

136.7

3.13

79.4

4.75

120.6

0.67

16.99

0.33

8.33

2.76

70.0

26.8

12.2

4

100

4.50

114.3

.625

15.9

.375

9.52

4.52

114.7

4.33

110.1

4.00

101.6

3.85

97.8

4.62

117.3

9.21

233.9

5.88

149.4

6.68

169.7

3.82

97.2

6.00

152.4

0.75

19.00

0.43

10.80

4.02

102.0

46.9

21.3

6

150

6.63

168.3

.625

15.9

.375

9.52

6.64

168.7

6.46

164.0

6.00

152.4

5.90

149.9

6.15

156.3

12.31

312.6

7.63

193.8

8.78

233.0

5.63

142.9

8.25

205.7

1.06

27.00

0.50

12.80

4.92

125.0

126.5

57.4

CV values for flow of water at +60˚F/+16˚C through the valve in the fully open position are shown in

the table below.

Formulas for CV Values:

Formulas for KV Values:

Where:

m3

Q = Flow (hr. )

∆P = Q2

Kv

Q = Kv x

∆P

Valve Size

Max.

Working

Pressure

Flow Coefficient

(Fully Open)

Actual

Outside

Nominal

Diameter

Diameter

Inches/mm Inches/mm

psi/kPa

Cv Values

Kv Values

2

50

2.38

60.3

1200

8273

600

519

3

80

3.50

88.9

1200

8273

1350

1168

4

100

4.50

114.6

1200

8273

2500

2163

6

150

6.63

168.3

1200

8273

6000

5190

∆P = Pressure (bar)

Kv = Flow Factor

www.victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2011 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

17.28_2

REV_B

17.28

STAINLESS STEEL PIPE – GROOVED VALVES

Super Duplex Stainless Steel

Vic-Ball Valve

SERIES 726D

VALVE TORQUE REQUIREMENTS

Source:

These torque values were derived from test data in water ambient temperature.

Torque Factors:

All torque values are for normal service conditions where corrosion is expected to be minor, and

the media is clean and nonabrasive. The torque shown should be multiplied by the appropriate

factor listed below.

Typical fluid torque factors commonly used in the industry are:

Water and other liquids: 1.0; Dry gases: 1.5 to 2.0

Breakaway Factor:

Ball valves will require additional torque if they are fully closed under pressure for a few hours. A

breakaway factor of 2:1 should be applied or decrease the system pressure to break the ball loose.

Actuator Factor:

A minimum factor of 1.2 is recommended for direct actuated valves. Apply the actuator factor to

the higher of the breakaway or service factor.

Combining Torque Factors:

When multiple torque factors apply, they are combined by multiplying them. Example: A 4-inch/

114.3mm direct actuated ball valve is used in water service at 800 psi/55Bar. The minimum

torque output from the actuator would be 634 ft-lbs/850 N.m 264 (torque from the table) x 1.0

(service factor for water) x2.0 (breakaway factor) X 1.2 (actuator factor) = 634 ft-lbs.

Size

Torque – Foot Pounds/Newton Meters

Differential Pressure – psi/Bar

Nominal

Size

In./mm

Actual

Outside Dia.

In./mm

0/0

200/14

400/28

600/41

800/55

1000/69

1200/83

2

50

2.375

60.3

4

5

14

19

18

24

30

41

40

54

55

75

62

84

3

80

3.500

88.9

5

7

20

27

29

39

42

57

54

73

68

92

87

118

4

100

4.500

114.3

10

14

71

96

101

137

204

277

264

358

294

399

333

451

6

150

6.625

168.3

35

47

223

302

351

476

448

607

509

690

682

925

811

1100

www.victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2011 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

REV_B

17.28_3

17.28

STAINLESS STEEL PIPE – GROOVED VALVES

Super Duplex Stainless Steel

Vic-Ball Valve

SERIES 726D

BALL VALVE NUMBERING SYSTEM

FOR SERIES 726D

B - 020 - 2 3 7 7 - 00

Type

Act.

In.

Size

Code

2"

3"

4"

6"

020 2 - 1200 psi

030

040

060

B

Pressure

Rating

Body

3 - Super Duplex

Ball & Stem

7 - Super Duplex

Seat

7 - Reinforced

PTFE

w/ E Seals

Operator

00 - Bare

01 - Manual handle

(2"/50mm & 3"/80mm valves only)

INSTALLATION

Reference should always be made to the I-100 Victaulic Field Installation Handbook or www.victaulic.com

for the product you are installing. Handbooks are included with each shipment of Victaulic products

for complete installation and assembly data, and are available in PDF format on our website at

www.victaulic.com.

WARRANTY

Refer to the Warranty section of the current Price List or contact Victaulic for details.

NOTE

This product shall be manufactured by Victaulic or to Victaulic specifications. All products to be

installed in accordance with current Victaulic installation/assembly instructions. Victaulic reserves the

right to change product specifications, designs and standard equipment without notice and without

incurring obligations.

For complete contact information, visit www.victaulic.com

17.28

5812 REV B

UPDATED 07/2011

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2011 VICTAULIC COMPANY. ALL RIGHTS RESERVED.

17.28