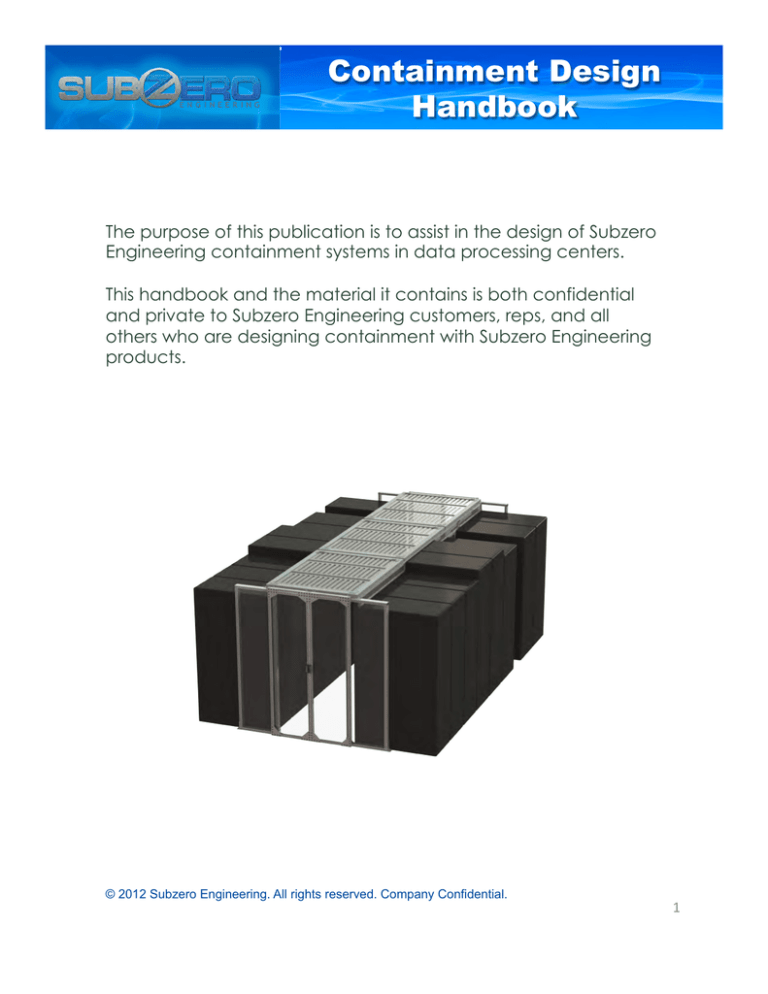

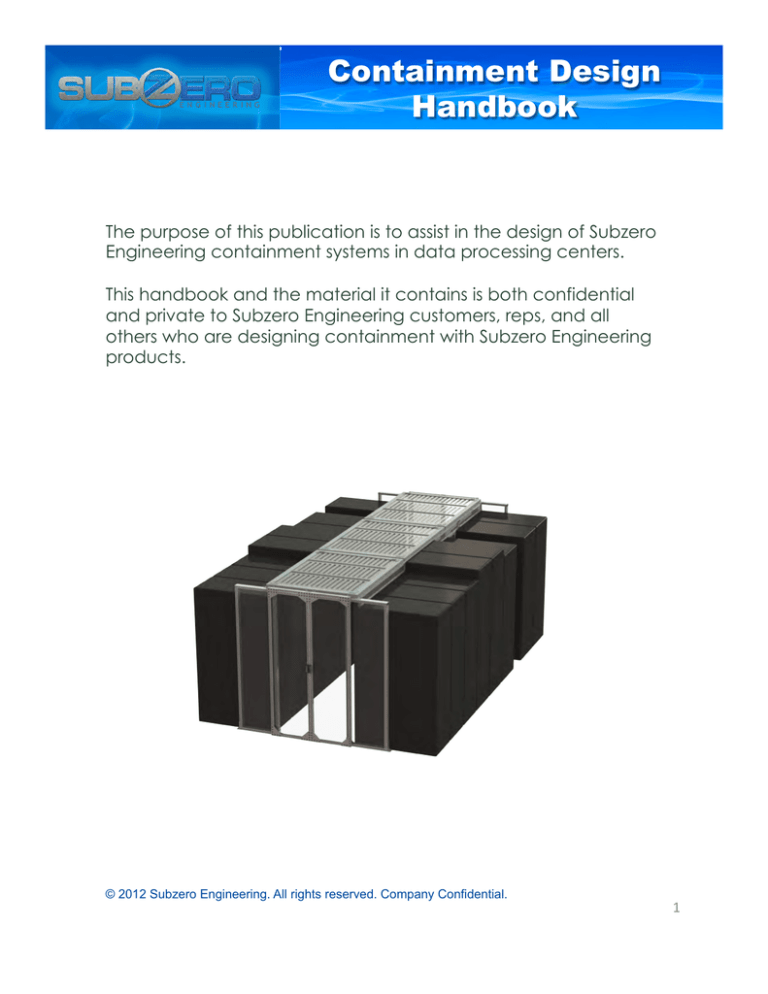

Containment Design

Handbook

The purpose of this publication is to assist in the design of Subzero

Engineering containment systems in data processing centers.

This handbook and the material it contains is both confidential

and private to Subzero Engineering customers, reps, and all

others who are designing containment with Subzero Engineering

products.

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

1 Containment, Why?

Containment has come a long way from being a novel

idea to a standard way to improve the cooling of IT

equipment. There are a variety of benefits that reach into

various areas of the data center. This section provides

information as to specific benefits of containment.

§ What are the benefits of containment?

§ Which containment is right for my data center?

§ Should I contain the hot or the cold aisle?

§ How can I harvest the energy savings?

§ Are there other benefits besides energy?

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

2 Intel White Paper

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

3 Intel White Paper

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

4 Intel White Paper

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

5 Intel White Paper

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

6 Optimized Cooling

of Data Center

Instead of cooling the

entire data center,

containment systems focus

the cooling only to the IT

equipment.

This approach will ensure

consistent cooling airflow

across the entire face of

the IT equipment. Colder

intake temperatures

ensure computer uptime.

It will also reduce the cost

of cooling by 30% or more.

Furthermore, it will increase

the efficiency of the AC

equipment. With warmer

and drier return airflow, AC

equipment will create as

much as double the

cooling capacity!

Colder IT equipment uses less energy!

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

7 Colder Intake

Temperatures

Below is a graph that is typical of the results of cold aisle containment.

Note that the in-row sensor reads an immediate change in temperature

and relative humidity. Colder supply and higher relative humidity will

translate into energy savings, increase cooling capacity and better rack

population.

9 Degrees Colder!

10% increase in RH!

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

8 Containment Benefits

§ Increase in temperature set point (energy $)

§ Decrease in humidity set point (energy $)

§ Increased cooling capacity (capital $)

§ Increase of facility longevity (capital $)

§ Increase of use of rack space (capital $)

§ Fast ROI (inside of one year or less)

§ Delay of capital expense

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

9 Hot or Cold Aisle

Containment?

There are good arguments for both cold and hot aisle containment.

That said…

Data center cooling experts must work with the natural properties of air.

In order to understand airflow you must recognize that air has both mass and

density. Thus:

Cold air is denser than warm air.

This fundamental helps us understand airflow.

In a data center, cold supply air is denser than warm air. What this means is that the

cold supply air must be managed or contained to the IT equipment intake.

Warmer exhaust air rises above the colder air and instantly moves up and away

from the IT cabinet. Thus, warmer exhaust air naturally moves in the direction we

want it to go. The key is to let warmer air travel back to the AC intake without

mixing with the cold supply airflow.

Hence, true containment is pooling cold supply air to the IT intake and directing hot

exhaust air back to the AC return without mixing with the cold.

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

10 Containment Roofs Purpose

§ Containment roofs prevent

warm air from recirculation into

the IT equipment intake.

§ This is due to two main

conditions:

1. Return air pathway

2. Lack of supply CFM and

throw rate

§ Also used in hot aisle with in-row

cooling systems

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

11 Containment Doors Purpose

Aisle End Doors are used

to prevent air from flowing

out the ends of the aisle.

Aisle End Doors can be

used on:

§ Hot aisles

§ Cold aisles

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

12 Containment Walls Purpose

§ Walls fill in the gaps between

missing equipment or other

smaller gaps due to cabinet

alignment or varying

dimensions (cityscape rows).

§ Walls can be rigid or made

of soft material like vinyl.

§ Walls can be full length or

makeup differences between

shorter cabinets and taller

ones.

§ Walls can be built to create

a cold or hot aisle when there

is no opposing cabinets.

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

13 Designing Containment

Systems

In order to design a containment

solution, we will need the following:

§ Floor plan

§ Cabinet dimensions

§ Aisle layout (cold/hot)

§ Floor type

§ Supply type and placement

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

14 Containment Design

Solutions

Polar Roof

Dual Sliding Door

Cold Aisle Containment

Solution:

§ Polar Roof UL/FM rated

drop panel continuous

roof system

§ Dual Sliding Door with

automatic closer and

digital lock

§ Modular wall system to

fill in missing cabinets

Modular Wall Panel

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

15 CFD Engineering Services

The best way to design and optimize an airflow

management program is through the use of

Computational Fluid Dynamics (CFD) simulations.

§ How are CFD’s created?

§ What kind of information is required to perform a CFD?

§ What does the CFD report include?

§ How can a CFD help to design a containment solution?

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

16 CFD Creation/Site Visit

Site Visit

On-site data gathering includes:

§

§

§

§

§

§

§

§

§

§

§

§

§

Floor plan

Alpha-Numeric order of floor

Depth of subfloor plenum

Under floor obstructions

CRAC make/model, CFM

Perforated tile placement and flow

percentage

Cable cut out size and placement

PDU placement

Rack make/model and placement

IT equipment make/model, thermal

signature

Height of ceiling

Interior walls

Columns

Unique room features such as:

§

§

§

§

§

Non raised floors

Facility AC

Ceiling cable treys

Drop ceiling voids

Triangle shaped rooms

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

17 CFD Report

The CFD report includes:

§ Performance analysis of CRAC units

§ Detailed rack-by-rack inlet and exit

temperatures

§ Compatibility with ASHRAE allowable

and recommended temperature

ranges according to Thermal

Guidelines for Data Center Processing

Environments publication

§ Subfloor air velocity

§ Subfloor air pressure

§ Above floor tracking of hot exhaust air

§ 3D thermal mapping of data center

and racks highlighting trouble areas

§ 2D and 3D color contour plots of

temperature, pressure, airflow and

flow distribution through tiles and grills

§ 3D color animations of temperature

distribution and airflow patterns

Visualize fundamental simulation

results by color-coding data

center components including:

§ CRAC units: supply or return

temperatures

§ Cooling capacity

§ Row of racks: maximum, minimum and

average inlet temperature

§ Exit temperature

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

18 CFD

Deliverables/Responsibilities

Deliverables

§ Data Center assessment report that

identifies problem areas based on

analysis performed

§ CFD findings in graphical format

§ Delivered in electronic media

§ Conference call to discuss findings

§ Suggested course of response to data

Customer Scope of

Responsibility

§ Meeting with customer to outline process

§ Provide qualified personnel required to

access data center and pertinent

information

§ Provide physical access to the data

center

§ Provide building diagrams

§ Security clearance for Subzero personnel

Features Measure exis4ng environmental condi4on. This creates the baseline as to how the data center is opera4ng currently. Temperature, humidity levels, airflow (both to the thermal load and back to the CRAC unit). Computa4onal Fluid Dynamics (CFD) Computer modeling allows us to make changes in the computer room to determine op4mal performance design. Side-­‐by-­‐side Comparison Comparing the “as found” computer room with a superior cooling design allows measurement of increased performance. Return on Investment Investment cooling performance has measureable characteris4cs that can be modeled to determine the energy savings. Disaster Recovery Computer modeling allows for test scenarios to determine the affect of certain condi4ons such as failed CRAC units. This will help determine whether addi4onal cooling capacity is needed (N+1). Other benefits include a detailed list of what computer components are affected by temperature changes created by the failed CRAC unit thus allowing for a planned shut down of affected equipment. Schedule

1.

2.

3.

4.

5.

6.

7.

8.

9.

Benefits Purchase Order

Information gathering, site plan development

Schedule site visit

Site visit

Data gathering

Digital computer model created

CFD preformed (multiple as necessary)

Report/video generated

Customer conference call to review data

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

19 Containment Products

Subzero Engineering containment products are designed to create a full

containment solution. Our product line covers every aspect of containment so as

to create one continuous solution from one manufacturer.

§ What design is right for my data center?

§ Should I contain the cold or the hot aisle?

§ What products will fit my budget?

§ What will the containment look like?

§ How will the containment’s fit and finish match my existing cabinets?

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

20 Premium

Dual Sliding Door

Aisle End Door System

Key Features

§ Custom sizes (height, width)

§ Fits all cabinets

§ No threshold

§ Modular design (attaches to

walls, roofs, etc.)

§ Gasket sealed for maximum

efficiency

§ Clear door panels provide light

and enhance security

§ Easy installation

Shipping and Installation

Ø Ships in 5 pieces

2# Side panels

2# Doors

1# Header

Installation instruction provided

with door

*YouTube installation video

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

21 Premium

Dual Sliding Door

Options & Accessories

§

Silver

§

Black

§

Digital Lock

§

Auto Door Closer

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

22 Premium

Single Sliding Door

Aisle End Door System

Key Features

§ Custom sizes (height, width)

§ Fits all cabinets

§ No threshold

§ Modular design (attaches to

walls, roofs, etc.)

§ Gasket sealed for maximum

efficiency

§ Clear door panels provide light

and enhance security

§ Easy installation

Shipping and Installation

Ø Ships in 3 pieces

1# Side panels

1# Doors

1# Header

Installation instruction provided

with door

*YouTube installation video

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

23 Premium

Single Sliding Door

Options & Accessories

§

Silver

§

Black

§

Digital Lock

§

Auto Door Closer

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

24 Premium Hinged Door

Aisle End Door System

Key Features

§ Custom sizes (height, width)

§ Fits all cabinets

§ No threshold

§ Modular design (attaches to

walls, roofs, etc.)

§ Gasket sealed for maximum

efficiency

§ Clear door panels provide light

and enhance security

§ Easy installation

Shipping and Installation

Ø Ships in 2 pieces

1# Doors

1# Frame

Installation instruction provided

with door

*YouTube installation video

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

25 Lite Door Series

Our Lite Doors have the same features as our Premium Door with the exception

of the dimensions of the aluminum. In low traffic aisles, this offers a less expensive

alternative to our premium door systems. The Lite door uses 1.0” aluminum frame

instead of the 1.5” used in our standard door.

§ Cost effective

§ Less weight then standard door

§ Same see-through acrylic panels

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

26 Lite

Dual Sliding Door

Aisle End Door System

Key Features

§ Custom sizes (height, width)

§ Fits all cabinets

§ No threshold

§ Modular design (attaches to

walls, roofs, etc.)

§ Gasket sealed for maximum

efficiency

§ Clear door panels provide light

and enhance security

§ Easy installation

Shipping and Installation

Ø Ships in 5 pieces

2# Side panels

2# Doors

1# Header

Installation instruction provided

with door

*YouTube installation video

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

27 Lite

Dual Sliding Door

Options & Accessories

§

Silver

§

Black

§

Digital Lock

§

Auto Door Closer

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

28 Lite

Single Sliding Door

Aisle End Door System

Key Features

§ Custom sizes (height, width)

§ Fits all cabinets

§ No threshold

§ Modular design (attaches to

walls, roofs, etc.)

§ Gasket sealed for maximum

efficiency

§ Clear door panels provide light

and enhance security

§ Easy installation

Shipping and Installation

Ø Ships in 5 pieces

2# Side panels

2# Doors

1# Header

Installation instruction provided

with door

*YouTube installation video

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

29 Lite

Single Sliding Door

Options & Accessories

§

Silver

§

Black

§

Digital Lock

§

Auto Door Closer

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

30 Polar Roof

UL Drop Panel Roof System

Key Features

§ Custom sizes (length, width)

§ UL listed molded translucent PVC

panels

§ UL/FM rated to operate underneath

fire suppression sprinklers

§ Lightweight clear panels 0.381 thick

§ Removable roof panels for easy

overhead maintenance

§ Modular design to attach to Subzero

door and wall systems

§ Designed to attach vinyl or hard wall

material for missing cabinets or space

Shipping and Installation

Ø Comes fully assembled

Ø Ships in wooden crate

Installation instruction provided

*YouTube installation video

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

31 Polar Panel Roof

Options & Accessories

§

Silver

§

Vinyl Hanger - allows vinyl to hang from the roof to fill in missing

cabinets

§

Black

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

32 Polar Cap

Retractable Roof System

The Subzero Polar Cap Retractable Roof

System is designed as the premium

containment roof system on the market.

Designed to work with fire suppression

systems, the roof can be rolled up into

the metal cassette should a fire occur.

There are two types of fire suppression

features:

1. Thermal

2. Smoke Detector

The spring loaded return can be held by

either a thermal splicer or by low voltage

magnetic coupling.

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

33 Polar Cap

Retractable Roof System

Options & Accessories

§

ELECTROMAGNETIC

LOCK

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

34 Walls - Rigid

Solid Modular Wall System

Key Features

§

Custom sizes (length, width)

§ Clear see through LuciteLux acrylic

panels

§ Modular design to attach to

Subzero door and roof systems

§ Designed to fill in for missing

cabinets or space

Shipping and Installation

Ø Comes fully assembled

Ø Ships in wooden crate

Ø Weight 5 to 50 lbs.

Installation instruction provided

*YouTube installation video

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

35 Walls - Rigid

Options & Accessories

§

Silver

§

Black

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

36 Walls - Soft

Soft Modular Wall System

Key Features

q Custom Length and Width

q Modular design to attach to

Subzero door and roof systems

q Designed to fill in for missing

cabinets or space

Installation instructions provided

*YouTube installation video

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

37 Rack Hat Ceiling

Partition System

Vertical Partition System

Key Features

§ Modular kits make design fast

§ Kits are self-contained and

complete

§ Vinyl curtain

§ Aluminum track

§ Splicer

§ Thermal or electronic fusible links

available

§ Available in 1’, 2’, 3’, 4’, 5’ and 6’ widths

§ Heights from 29” to 182”

§ Corner kits are 1’ on each side

§ All curtains overlap 4”

Installation instructions provided .

*YouTube installation video

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

38 Rack Hat Ceiling

Partition System

Options & Accessories

§

Corner System

§

1-6 Feet in length

§

Vinyl drop down from

17” – 144”

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

39 The CRACup

AC Extension

Key Features

§ Custom length and width

§ Custom colors

Shipping and Installation

Ø Easy to install

Ø Comes in four pieces

Ø Ships in wooden crate

Installation instruction provided

with door

*YouTube installation video

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

40 CRAC Extensions

Options & Accessories

§

Filter Access Doors

§

White

§

Black

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

41 Polar Booth

Isolated Equipment Containment

Key Features

§

Custom sizes (height, width)

§

Rolls on four casters

§

Assembles easily

§

Up to 6 ft. wide

§

Used for cold supply or hot

exhaust containment

Shipping And Installation

Ø Ships as three major components

Ø Ships in wooden crate

Installation instruction provided with door

*YouTube installation video

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

42 The Cube

Cable Cutout Cover & Subfloor Wall

Key Features

§ Non-flammable

§ Easy install

§ Easily reconfigured

§ Multiple stock sizes

(custom available)

§ Fireproof and fire

resistant models

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

43 Design Services

Let our design services team create mechanical drawings, floor plans, elevation views

and realistic 3D models of your custom containment system.

This section will answer:

How can Subzero’s design services help create custom solutions for my data center?

What kind of drawings/output can I expect?

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

44 Design Services

Engineering Services

The engineering department is

capable of providing the following:

Layout drawings to illustrate installation

of product

Mechanical drawings & details

Development for custom applications

3D Renderings of custom containment

Drawing Request Process

A written request for services is

presented.

A design meeting is scheduled with the

Engineering Department.

All the details pertaining to the design

are addressed.

An approved preliminary sketch may

be required.

Drawings are completed and sent in

one of the following formats:

§ Adobe Illustrator File (.ai)

§ Adobe Portable Document

Format (.pdf)

§ Adobe Photoshop File (.psd)

§ Drawing (.drw)

§ Dwg (.dwg)

§ eDrawings (.edrw)

§ JPEG (.jpg)

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

45 Acquire Dimensions

Step 1:

Configure Containment

Layout

§ Aisle dimensions

§ Rack dimensions

§ Room or area dimensions

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

46 Choose Product

Step 2:

Product Design

§

§

§

§

§

§

Roof

Doors

Walls

Hot Aisle Containment

Cold Aisle Containment

Dimensions

POLAR PANEL

ROOF

Polar Roof

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

47 Product Layout

Step 3:

Insert Products(s) into the

Layout

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

48 3D Drawings

Step 4:

Render Completed Assembly

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

49 Mechanical Drawings

Step 5:

Produce Mechanical Layout

Drawings

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

50 Shipping

Our shipping department’s goal is to

ship our product safely, on-time and

on-budget.

In order to do this we require

information in advance that will pave

the way for a smooth shipping

experience.

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

51 Shipping

Information required for shipping

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

52 Shipping

Shipping Cost Percentages (Average)

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

53 On-Site Services

Our on-site services group performs product

installs, airflow management audits, CFD

data gathering and containment design

services.

What kind of services are available?

Key Features

§ Expert Product Installation

§ Containment Design Audit

§ CFD Data Gathering

§ Professional Installation

increases the warranty period

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

54 Containment

Worksheets

In order to get the right product and the best fit and finish for your containment, it’s

imperative to have good measurements of the containment area.

Our containment worksheets will assist you to gather the proper measurements.

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

55 Acquire Dimensions

Job__________________

Area_________________

Aisle_________________

Use this sheet to gather key measurements for containment.

§ Key measurements include; ceiling height,

cabinet height, aisle width, and cabinet width.

Aisle:

§ Be sure to note any obstructions that may interfere

with the proposed containment.

q Hot Aisle

q Cold Aisle

OBSTRUCTIONS GRID

CEILING

Door

1

Door

2

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

Door 2

Door 1

FLOOR

56 Aisle End Door

Job__________________

Area_________________

Aisle_________________

Single Slider Door:

Double Slider Door:

Hinged Door:

q Right Hand Silver

q Silver

(Lite)

q Black

(Lite)

q Silver

(Premium)

q Black

(Premium)

q Right Hand Silver

q Right Hand Black

q Left Hand Silver

q Left Hand Black

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

q Right Hand Black

q Left Hand Silver

q Left Hand Black

57 Roof Systems

Job__________________

Area_________________

Aisle_________________

Polar Roof

Polar Cap

Overall Roof Length*________

q Silver

q Standard

Overall Roof Width#________

q Black

* Standard Polar Roof width is 55.5”.

# Roof length should exceed the

aisle width a minimum of 2”.

Be sure to indicate any

obstructions that may interfere

with the proposed containment.

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

58 Rack Hat

Job__________________

Area_________________

Aisle_________________

Rack Hat Sizing

q T-Bar Standard

Drop Down: Distance from ceiling to

the bottom of the vinyl.

q T-Bar Custom

Width: Defines the width of the track

that holds the vinyl.

q Corners*

* Rack Hat Corners will subtract 1’

from the aisle length because of

their 1’ Radius.

© 2012 Subzero Engineering. All rights reserved. Company Confidential.

59