product catalogue

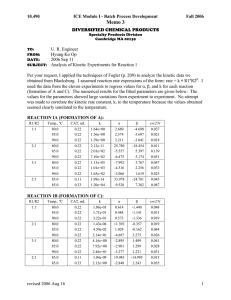

advertisement