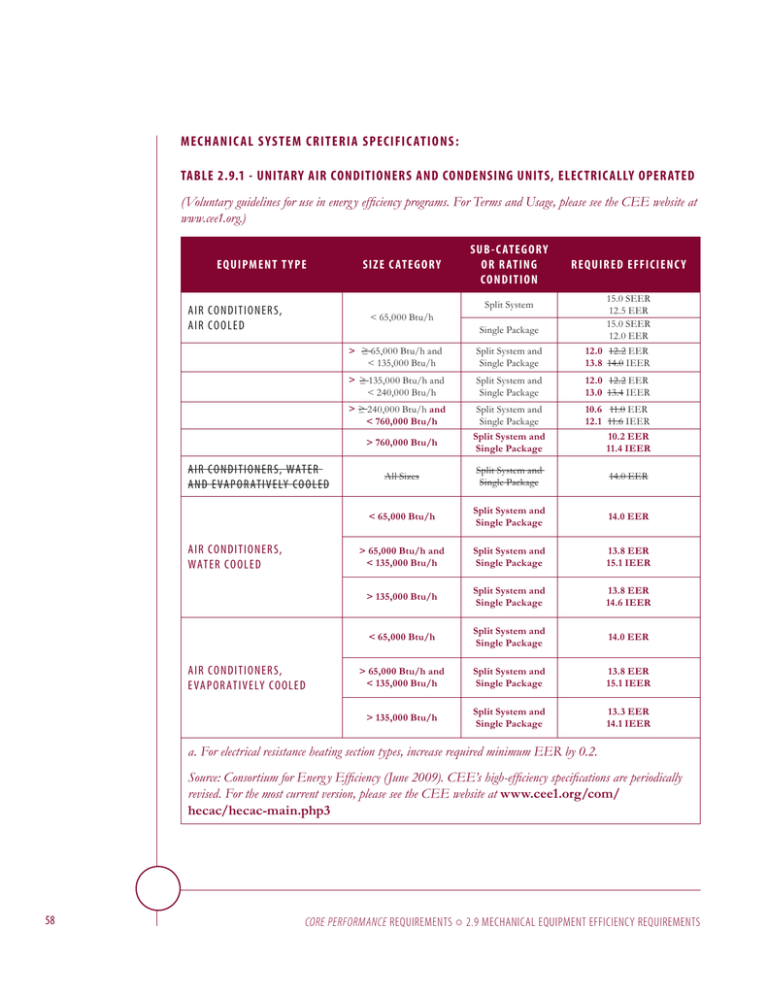

mechanical system criteria specifications

advertisement

MECHANIC AL S YS TEM CRITERIA SPECIFIC ATIONS : TABLE 2.9.1 - UNITARY AIR CONDITIONERS AND CONDENSING UNITS, ELECTRICALLY OPERATED (Voluntary guidelines for use in energ y efficiency programs. For Terms and Usage, please see the CEE website at www.cee1.org.) EQUIPMENT T Y PE AIR CO ND ITI O NER S, AIR CO O LED SIZ E C ATEG O R Y AIR CO ND ITI O NER S, WATER CO O LED AIR CO ND ITI O NER S, E VAP O R ATI V ELY CO O LED REQUIRED EFFICIENC Y > ≥ 65,000 Btu/h and < 135,000 Btu/h Split System and Single Package 15.0 SEER 12.5 EER 15.0 SEER 12.0 EER 12.0 12.2 EER 13.8 14.0 IEER > ≥ 135,000 Btu/h and < 240,000 Btu/h Split System and Single Package 12.0 12.2 EER 13.0 13.4 IEER > ≥ 240,000 Btu/h and < 760,000 Btu/h Split System and Single Package 10.6 11.0 EER 12.1 11.6 IEER < 65,000 Btu/h AIR CO ND ITI O NER S, WATER AND E VAP O R ATI V ELY CO O LED SUB- C ATEG O R Y O R R ATING CO ND ITI O N Split System Single Package > 760,000 Btu/h Split System and Single Package 10.2 EER 11.4 IEER All Sizes Split System and Single Package 14.0 EER < 65,000 Btu/h Split System and Single Package 14.0 EER > 65,000 Btu/h and < 135,000 Btu/h Split System and Single Package 13.8 EER 15.1 IEER > 135,000 Btu/h Split System and Single Package 13.8 EER 14.6 IEER < 65,000 Btu/h Split System and Single Package 14.0 EER > 65,000 Btu/h and < 135,000 Btu/h Split System and Single Package 13.8 EER 15.1 IEER > 135,000 Btu/h Split System and Single Package 13.3 EER 14.1 IEER a. For electrical resistance heating section types, increase required minimum EER by 0.2. Source: Consortium for Energ y Efficiency (June 2009). CEE’s high-efficiency specifications are periodically revised. For the most current version, please see the CEE website at www.cee1.org/com/ hecac/hecac-main.php3 58 CORE PERFORMANCE REQUIREMENTS ○ 2.9 MECHANICAL EQUIPMENT EFFICIENCY REQUIREMENTS TABLE 2.9. 2 - UNITARY AND APPLIED HE AT PUMP S, ELEC TRIC ALLY OPER ATED (Voluntary guidelines for use in energ y efficiency programs. For Terms and Usage, please see the CEE website at www.cee1.org.) EQUIPMENT T Y PE AIR CO O LED, ( CO O LING MO DE ) AIR CO O LED ( HE ATING MO DE ) SIZ E C ATEG O R Y ≥ 65,000 Btu/h and < 135,000 Btu/h Split System and Single Package 15.0 SEER* 12.5 EER 15.0 SEER* 12.0 EER* 11.1 11.7 EER 12.1 13.0 IEER ≥ 135,000 Btu/h and <240,000 Btu/h Split System and Single Package 10.7 11.7 EER 11.7 12.5 IEER ≥240,000 Btu/h Split System and Single Package 10.1 10.7 EER 10.7 11.5 IEER Split System < 65,000 Btu/h Single Package Split System 9.0 HSPF Single Package 8.5 HSPF 47 F db/43 F wb Outdoor Air 3.4 COP 17oF db/15oF wb Outdoor Air 2.4 COP < 65,000 Btu/h (Cooling Capacity) ≥ 65,000 Btu/h and < 135,000 Btu/h (Cooling Capacity) > ≥ 135,000 Btu/h (Cooling Capacity) WATER S OURCE ( CO O LING MO DE ) WATER-S OURCE ( HE ATING MO DE ) SUB- C ATEG O RY O R R ATING REQUIRED EFFICIENC Y CO ND ITI O N o o 47oF db/43oF wb Outdoor Air 3.2 COP 17oF db/15oF wb Outdoor Air 2.1 COP < 135,000 Btu/h (Cooling Capacity) 85oF Entering Water 14.0 EER < 135,000 Btu/h (Cooling Capacity) 70 oF Entering Water 4.6 COP a. For electrical resistance heating section types, increase required minimum EER and IEER by 0.2. Source: Consortium for Energ y Efficiency (2010). CEE’s high-efficiency specifications are periodically revised. For the most current version, please see the CEE website at www.cee1.org/com/ hecac/hecac-main.php3 * These CEE Tier 2 values (as of June 2010) were incorporated into Core Performance in June 2010, version 1.02. TABLE 2.9. 3 – PACK AGE TER MINAL AIR CONDITIONER S AND HE AT PUMP S, ELEC TRIC ALLY OPER ATED EQUIPMENT T Y PE AIR CO ND ITI O NER S & HE AT PUMP S ( CO O LING MO DE ) SIZ E C ATEG O R Y REQUIRED EFFICIENC Y < 7,000 Btu/h 11.9 EER ≥ 7,000 Btu/h and < 10,000 Btu/h 11.3 EER ≥ 10,000 Btu/h and <13,000 Btu/h 10.7 EER ≥13,000 Btu/h 9.5 EER CORE PERFORMANCE REQUIREMENTS ○ 2.9 MECHANICAL EQUIPMENT EFFICIENCY REQUIREMENTS 59 TABLE 2.9.4 – BOILER S T Y PE FUEL SIZ E C ATEG O R Y < 300,000 Btu/hr GAS 300,000 - 2,500,000 Btu/hr > 2,500,000 Btu/hr S TE A M < 300,000 Btu/hr OIL 300,000 - 2,500,000 Btu/hr > 2,500,000 Btu/hr < 300,000 Btu/hr GAS 300,000 - 2,500,000 Btu/hr > 2,500,000 Btu/hr H OT WATER < 300,000 Btu/hr OIL 300,000 - 2,500,000 Btu/hr > 2,500,000 Btu/hr TE S T PRO CEDURE EFFICIENC Y REQUIREMENT (3 MANUFACTURERS) DOE 10 CFR Part 430 83.4% 83% AFUE 80.6% 81% Et DOE 10 CFR Part 431 80.5% 82% Ec 85.6% 85% AFUE DOE 10 CFR Part 430 83.0% 83% Et DOE 10 CFR Part 431 83.5% 84% Ec 97.3% 97% AFUE DOE 10 CFR Part 430 94.5% 97% Et DOE 10 CFR Part 431 94.5% 94% Ec 88.6% 90% AFUE DOE 10 CFR Part 430 85.3% 88% Et DOE 10 CFR Part 431 86.2% 87% Ec E t = t h e r m a l e f f i c i e n c y, E c = C o m b u s t i o n E f f i c i e n c y * Systems must be designed with lower operating hot water temperatures (<150◦F) and use hot water reset to take advantage of the much higher efficiencies of condensing boilers. TABLE 2.9. 5 – CHILLER S EQUIPMENT T Y PE REQUIRED EFFICIENC Y- CHILLER S O P TI O NAL CO MPLIANCE PATH REQUIRED EFFICIENC Y- CHILLER S WITH VSD FULL LOAD ( K W / TO N ) IPLV ( K W / TO N ) FULL LOAD ( K W / TO N ) IPLV ( K W / TO N ) AIR CO O LED W / CO NDENSER All 1.2 1.0 N/A N/A AIR CO O LED W / O CO NDENSER All 1.08 1.08 N/A N/A WATER CO O LED, RECIPRO C ATING All 0.840 0.630 N/A N/A < 90 tons 0.780 0.600 N/A N/A 0.730 0.550 N/A N/A 0.610 0.510 N/A N/A 0.600 0.490 N/A N/A WATER CO O LED, ROTARY S CRE W AND S CRO LL 60 SIZ E C ATEG O R Y ≥ 90 tons and < 150 tons ≥ 150 tons and ≤ 300 tons > 300 tons CORE PERFORMANCE REQUIREMENTS ○ 2.9 MECHANICAL EQUIPMENT EFFICIENCY REQUIREMENTS EQUIPMENT T Y PE SIZ E C ATEG O R Y WATER CO O LED, CENTRIFUG AL < 150 tons REQUIRED EFFICIENC Y- CHILLER S ≥ 150 tons and ≤ 300 tons > 300 tons and ≤ 600 tons > 600 tons O P TI O NAL CO MPLIANCE PATH REQUIRED EFFICIENC Y- CHILLER S WITH VSD 0.610 0.620 0.630 0.400 0.590 0.560 0.600 0.400 0.570 0.510 0.580 0.400 0.550 0.510 0.550 0.400 a. Compliance with full load efficiency numbers and IPLV numbers are both required. b. Only chillers with variable speed drives (VSD) may use the optional compliance path for chiller efficiency. c. Water-cooled centrifugal water-chilling packages that are not designed for operation at ARI Standard 550/590 test conditions (and thus cannot be tested to meet the requirements of Table 2.9.5) of 44° F leaving chilled water temperature and 85° F entering condenser water temperature shall meet the applicable full load and IPLV/NPLV requirements. TABLE 2.9.6 – ABS ORP TION CHILLER S REQUIRED EFFICIENC Y FULL LOAD CO P ( IPLV ) EQUIPMENT T Y PE AIR CO O LED, SING LE EFFEC T WATER CO O LED, SING LE EFFEC T D OUBLE EFFEC T – DIREC T FIRED D OUBLE EFFEC T – INDIREC T FIRED 0.60, but only allowed in heat recovery applications 0.70, but only allowed in heat recovery applications 1.0(1.05) 1.20 For additional references and information about this measure, visit www.advancedbuildings. net/reference-materials/reference-materials-access-form. TABLE 2.9.7 – VARIABLE REFRIGER ANT FLOW MULTISPLIT AIR CONDITIONER S EQUIPMENT T Y PE V RF AIR CO O LED ( CO O LING MO DE ) SIZ E C ATEG O R Y HE ATING SEC TI O N T Y PE < 65,000 Btu/h All > 65,000 Btu/h and < 135,000 Btu/h > 135,000 Btu/h and < 240,000 Btu/h > 240,000 Btu/h Resistance or None Resistance or None Resistance or None 15.0 SEER 12.5 EER 11.7 EER 14.9 IEER 11.7 EER 14.4 IEER 10.5 EER 13.0 IEER LEED Relationship SS WE EA credit 1 MR EQ CORE PERFORMANCE REQUIREMENTS ○ 2.9 MECHANICAL EQUIPMENT EFFICIENCY REQUIREMENTS 61 TABLE 2.9. 8 – VARIABLE REFRIGER ANT FLOW MULTISPLIT HE AT PUMP EQUIPMENT T Y PE SIZ E C ATEG O R Y HE ATING SEC TI O N T Y PE SUBC ATEG O R Y < 65,000 Btu/h All Multisplit > 65,000 Bth/h and < 135,000 Btu/h V RF AIR CO O LED ( CO O LING MO DE ) > 135,000 Btu/h and < 240,000 Btu/h > 240,000 Btu/h V RF AIR CO O LED ( HE ATING MO DE ) Multisplit Resistance or None Multisplit Resistance or None Resistance or None Multisplit with Heat Recovery Multisplit 12.5 EER 11.3 EER 14.2 IEER 11.1 EER 14.0 IEER 10.9 EER 13.7 IEER 10.7 EER 13.5 IEER 10.3 EER 12.5 IEER 10.1 EER Multisplit with Heat Recovery 12.3 IEER - Multisplit 9.0 HSPF > 65,000 Bth/h and < 135,000 Btu/h - 47°F db/43°F wb Outdoor Air 3.4 COP - 17°F db/15°F wb Outdoor Air 2.4 COP - 47°F db/43°F wb Outdoor Air 3.2 COP - 17°F db/15°F wb Outdoor Air 2.1 COP Multisplit System 86° Entering Water 14.0 EER < 135,000 Btu/h All Multisplit System with Heat Recovery TE S T PRO CEDURE 15.0 SEER < 65,000 Btu/h ≥ 135,000 Btu/h V RF WATER S OURCE ( CO O LING MO DE ) Multisplit with Heat Recovery MINIMUM EFFICIENC Y REQUIREMENT S AHRI 1230 13.8 EER 86° Entering Water V RF WATER S OURCE ( HE ATING MO DE ) 62 < 135,000 Btu/h 68° Entering Water 4.6 COP CORE PERFORMANCE REQUIREMENTS ○ 2.9 MECHANICAL EQUIPMENT EFFICIENCY REQUIREMENTS Introduction Design Process Strategies Core Performance Requirements 3.3 Additional Lighting Power Reductions Enhanced Performance Strategies Energy Modeling Purp ose To reduce connected lighting load to achieve the requirements of the Energy Policy Act of 2005 and qualify for Federal tax incentives. Appendices Criteria Reduce connected lighting load by at least 40% below the allowances of the ASHRAE 90.1 reference standard used by EPAct 05, while meeting all of the lighting control requirements of that standard. (Note that EPAct05 uses the 2001 version of the ASHRAE 90.1 standard as a reference point, even though newer versions of 90.1 are in force.) Gener al Projects which meet the lighting power density (LPD) and control requirements of Core Performance are well on their way to qualifying for federal tax incentives under the Energy Policy act of 2005 (EPAct 05). An additional effort on the part of the design team to reduce connected lighting load can result in eligibility of the project to receive tax incentives. For tax-exempt public projects, the tax incentive can be transferred directly to the design team. The basic requirements of EPAct 05 are to reduce LPD by 25% to 40% below the requirements of ASHRAE 90.1-2001, and to implement the interior and exterior lighting control requirements of that standard. Achieving this qualifies the project for a Federal tax deduction of $0.30 to $0.60 per square foot of building area under the current policy. (Increases in Table 3. 3.1 - approx im ate LPD the incentive level and program extensions are requirement s for achie ving EPAC T05 currently under consideration; current program 40% requirements should be verified.) Lig hting The goal of this Criteria is to achieve a 40% reduction in connected lighting load (compared to the EPAct 05 baseline) which represents approximately a 20% reduction below the a reduction of 10% or more from the requirements listed in Criteria 2.8. Specific targets are shown in the LPD table below, which is derived from typical LPD requirements of ASHRAE 90.1-2001 as listed in Table 9.3.1.1 of that standard and Criteria 2.8 of the Core Performance Guide. Note that the values in this table represent only a subset of building. For additional references and information about this measure, visit www.advancedbuildings. net/reference-materials/reference-materialsaccess-form. Build ing Are a T y pe Co n v enti o n Center D ining E x ercise Center G ymna sium H ospital / He alth C are Libr ary O ffice Perfo r ming Ar t s The ater P o lice / Fire S tati o n Relig i ous Building Re tail Sch o o l / Uni v er sit y Town Hall Wareh ouse National Wildlife Federation Headquarters, Reston, Virginia Courtesy of Hedrich-Blessing P ower Densit y R educ ti o n Targ e t 0.85 0.89 0.9-1.15 0.79 0.85 0.9 1.0 0.95 0.9 0.73 0.78 0.9 0.78 0.95 1.32 1.15 0.89 0.9 0.83 0.85 0.59 0.72 (For additional space types, see ASHR AE 90.1-2001 Table 9.3.1.1) LEED Relationship SS WE EA credit 1 MR EQ 75