2 2015 MN E N MECH Effectiv HANICA CH e Date: AL AND ANGES

advertisement

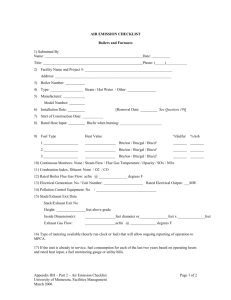

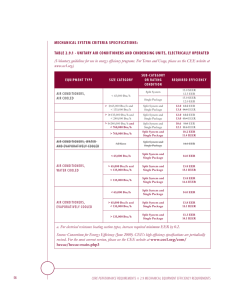

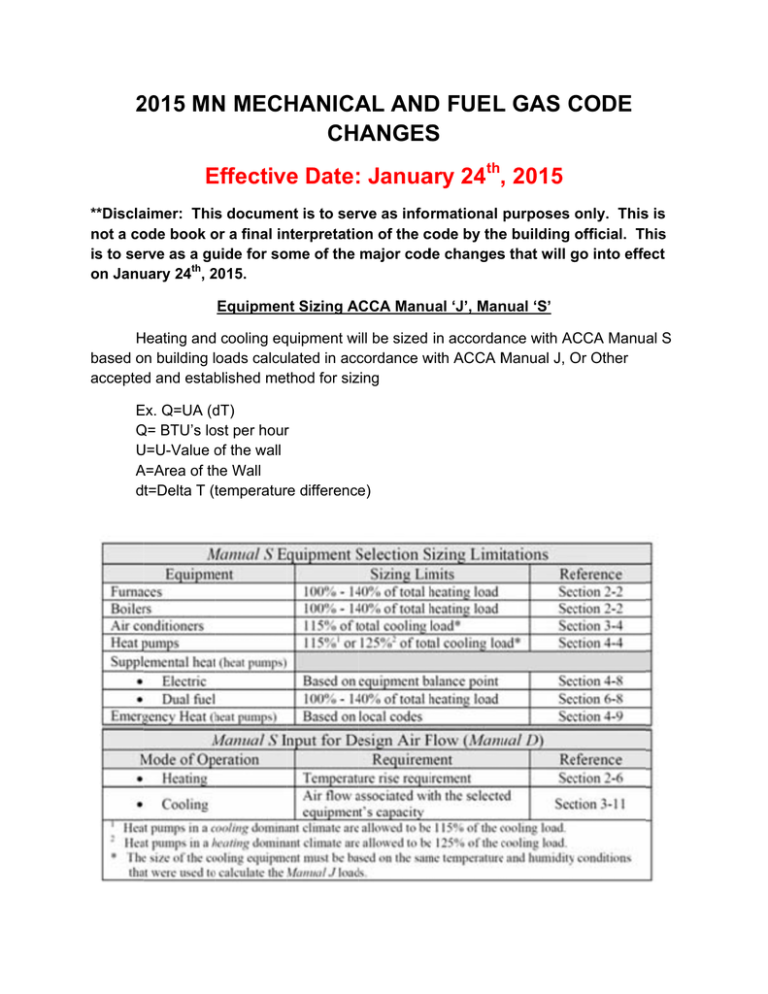

2015 2 MN N MECH HANICA AL AND D FUEL L GAS C CODE CHANGES S Effectiv E ary 24th, 2015 e Date:: Janua **Discla aimer: This s documen nt is to serrve as informational purposes only. This s is not a co ode book or o a final in nterpretatio on of the c code by the e building official. Th his is to serrve as a gu uide for so ome of the major cod de changes s that will g go into effe ect th on Janu uary 24 , 2015. 2 Equipmen nt Sizing ACCA Manu ual ‘J’, Man nual ‘S’ Heating H and d cooling eq quipment will be sized in accordance with AC CCA Manual S based on building loads calculated in acc cordance w with ACCA M Manual J, O Or Other accepted and estab blished metthod for siz zing Ex. E Q=UA (d dT) Q= Q BTU’s lo ost per hourr U=U-Value U of o the wall A=Area A of th he Wall dt=Delta T (ttemperaturre difference e) Ven ntilation Sy ystem Req quirements s Exhaust Only Sys stems (no longer l Allo owed) ced System ms” a ventilation system in whiich the air intake is w within 10% % of “Balanc the exhaust outpu ut. -H HRV/ERV -A An intake and exhaustt fan linked together to o operate equally ake-Up Air Ma e 1346 curre ently in tables 501 calculates Ma ake-up air. Mn Rule The tablles have be een updated d, Exhaust only system ms were removed from m the table.. (balance ed only), an nd dwellings s are now changed c to Dwelling U Units, separrating each unit as its ow wn dwelling. Type I an nd Type II H Hoods Required use for sp pecific applliances is now determ ined by AS SHRAE Stan ndard 154, not the IMC. Duct Gage Round ducts and exposed rectangular ducts: < 14” = 28 gage galv. 16”and 18” = 26 gage galv 20” and over = 24 gage galv Duct Sealing 2012 IMC 603.9 Amendment: Pressure-sensitive tape shall not be used as the primary sealant on ducts, unless it has been certified to comply with UL-181A or UL-181B by a nationally recognized lab and used in accordance with that certification. Boiler sizing and state inspections 1001.2 states Anyone who installs a boiler must ensure that the boiler is inspected by DLI before placed in operation IF BTU/hr values exceed: 100,000, 500,000, and 750,000 BTU/HR (same BTU’s as existing) Essentially, it means that once a boiler of this size is installed, the installer must contact the DLI pressure vessel inspector for this region for a final inspection. The burden is on the installer for the inspection. DLI deals with: A. Boilers 100,000 BTU’s for steam 500,000 BTU’s for hot water supply 750,000 BTU’s for hot water heating boilers B. High pressure piping for boilers. Steam systems operating at or below 15psi, or Hot water or other heating medium operating at or below 30psi and 250 F. Refrigeration Section 1101.1 Scope: “This chapter shall govern…” Now there is an exception: Exception: For all ammonia refrigeration systems, refer to Minnesota Rules, chapter 5230. Metallic piping joints & fittings Pipe joints. Pipe joints shall be threaded, flanged, brazed, welded, or made with pressconnect fitting complying ANSI LC-4.