P35 Pressure Transducer and VFD66 Control

advertisement

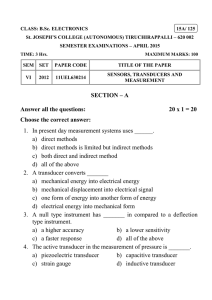

Application Note P35 Issue Date November 18, 2002 P35 Pressure Transducer and VFD66 Control Application IMPORTANT: The P35 Pressure Transducer is intended to provide an input to equipment under normal operating conditions. Where failure or malfunction of a P35 Pressure Transducer could lead to an abnormal operating condition that could cause personal injury or damage to the equipment or other property, other devices (limit or safety controls), or systems (alarm or supervisory) intended to warn of, or protect against, failure of the P35 Pressure Transducer must be incorporated into and maintained as part of the control system. The P35 Pressure Transducer provides a control signal to the VFD66 Series Condenser Fan Speed Control. The P35 transducer and VFD66 control work together to vary the speed of the condenser fan based on refrigerant pressure and to provide the optimum head pressure for the given load demand on the refrigeration or air conditioning system. Installation Dimensions Side View 3-3/4 (97) 2-1/8 (54) Two Mounting Holes Along Back Side 2-15/16 (74) 1-1/16 (27) Top View Range Adjustment Screw 1 (25) Turn range adjustment screw clockwise to raise Setpoint. Turn range adjustment screw counterclockwise to lower Setpoint. Figure 2: Dimensions of the P35 Pressure Transducer, in. (mm) Figure 1: P35 Pressure Transducer © 2002 Johnson Controls, Inc. Code No. LIT-121418 Part No. 24-7664-1792, Rev. C 1 www.johnsoncontrols.com Holes for Attaching to P35 Transducer A B Connect the P35 transducer to the VFD66 control using three 16-22 gauge wires, each less than 50 ft (15 m) in length. Insert the wires through the terminal block housing and connect the wires to the terminal block. Wiring the P35 Transducer Terminal Block P35 Transducer 1/2 (13) Terminal Block Housing Fastening Screw 2-3/8 (60) Holes for Surface Mount 1-5/16 in. 33 mm Figure 3: Dimensions of the Mounting Bracket, in. (mm) Mounting IMPORTANT: Improper mounting of the P35 transducer can result in malfunction of or damage to the transducer. Mount the transducer upright and level. Locate pressure tap points on the top side of the refrigerant lines. Mount the transducer where it is not exposed to rain or other moisture. IMPORTANT: If the P35 pressure transducer is installed on equipment that contains hazardous or regulated materials, such as refrigerants or lubricants, the installer and user should observe all regulations governing the handling and containment of those materials. The P35 transducer has an integral Schrader depressor and mounts directly to a 1/4 in. SAE male flare fitting. Mount the P35 transducer downstream from the coil, away from severe pressure pulsation and mechanical vibrations, which can occur near the compressor discharge. Use the holes in the mounting bracket to attach the transducer to a flat surface. See Figure 3. Use only the screws provided to mount the transducer and mounting bracket. Wiring ! WARNING: Risk of Electrical Shock. Disconnect power supply before making electrical connections to avoid possible electrical shock. 2 Small Slot 2 1 Metal Spacer Threaded Bushing 3 Front Rubber Grommet Insert Wires Figure 4: Terminal Block Assembly Use the following instructions when assembling and wiring the terminal block assembly: (See Figure 4.) 1. Remove the fastening screw. 2. Locate the small slot on the side of the terminal block and use a small standard screwdriver or similar tool to carefully remove the terminal block. 3. Remove the threaded bushing and insert the wires through the bushing, spacer, grommet, and terminal block housing as shown in Figure 4. 4. Connect the wires to the terminal block. Note the numbering sequence molded into the front of the terminal block, shown in Figure 4. 5. Insert the terminal block into the housing, and secure both to the P35 transducer with the fastening screw. 6. Tighten the threaded bushing. Wiring the VFD66 Control Refer to Table 1 and Figure 5 for proper wiring configuration for single or dual-transducer applications. For further information, refer to Wiring in the VFD66 Series Condenser Fan Speed Controls Product/Technical Bulletin (LIT-125467). P35 Pressure Transducer and VFD66 Control Application Note Table 1: Connecting the P35 Transducer to the VFD66 Control Input Device Input Device Terminal P35AG-9200R Transducer 1 1 2 2 (or 3)* 3 4 * VFD66 Control TB3 Terminal P35 Transducer When used with a VFD66 control, the P35 transducer setpoint is the pressure required to operate the condenser fan motor at full speed. Reducing the sensed pressure at the transducer below setpoint reduces the fan motor speed. 2 3 IMPORTANT: After adjusting control settings and before leaving installation, cycle the controlled system at least three times at normal operating conditions using reliable pressure gauges to verify proper transducer operation and settings. Standard Input mode is the most commonly used mode. The majority of input devices compatible with the VFD66 controls are used with this mode. The input device determines the setpoint and proportional band. Use Terminal 3 for input from a second input device. 1 Setup and Adjustments TB3 1 234 The setpoint is factory set at 232 psi (1600 kPa) but may be adjusted between 203 and 350 psi (1400 to 2314 kPa). The fixed throttling range is 46 psi (317 kPa). At 46 psi below setpoint, the fan motor shuts off. Figure 5: Wiring P35 Transducers to the VFD66 Control Turn the range adjustment screw clockwise to raise the setpoint, and counterclockwise to lower the setpoint. Refer to Figure 2 for the location of the range adjustment screw and Figure 6 for graphical representation of throttling and setpoint ranges. RPM Pressure Connections Connect the refrigerant-side flare connector to the appropriate high-side pressure tap point. Follow the guidelines below when making pressure connections: • Use Pressure Tap Points Located on the Top Side of the Refrigerant Lines. This reduces the possibility of oil, liquids, or sediment accumulating at the pressure connection, which could cause transducer malfunction. • Do Not Overtighten Flare Nuts on Pressure Connection Line Fittings. Overtightening flare connections may damage the threads on the flare nuts or flare connectors and result in refrigerant leaks. Do not exceed 9 lb⋅ft (12 N⋅m) of torque when tightening brass flare connections. • Setpoint 203 to 350 psig (1400 to 2413 kPa) 100% Curve A P1=40% P2=CCW Curve B P1=30% P2=CW 50% 40% Idle 30% Curve C P1=0% P2=CCW or CW 0% Minimum Motor Speed Set by P1 Pressure Proportional Band Fixed Throttling Range 46 psig (317 kPa) Factory Setpoint 232 psig (1600 kPa) Figure 6: Setpoint Range for the P35AG-9200R Avoid Severe Pressure Pulsation at Pressure Tap Points. Install pressure connection lines to pressure tap points away from the compressor discharge to minimize the effects of pressure pulsation from reciprocating compressors. P35 Pressure Transducer and VFD66 Control Application Note 3 Table 2: Standard Input Mode J2 Jumper Position J3 Jumper Position P1: Minimum Motor Speed Installed Removed Can be set at 0-50% of maximum motor speed. Repairs and Replacement P2: Motor Action at Minimum Speed CCW: Motor idles. CW: Motor shuts off. Do not attempt to repair or recalibrate the P35 transducer. A replacement transducer is available through your local Johnson Controls/PENN™ representative. Table 3: Replacement Part Product Code Number P35AG-9200R P1 adjusts the minimum speed of the motor. The minimum speed is adjustable from 0 to 50% of total motor speed. P2 determines whether the motor idles at minimum speed or shuts off at minimum speed. P2 must be set at full Counterclockwise (CCW) or full Clockwise (CW) position; intermediate settings have no effect. Figure 6 illustrates three possible motor speed curves. When P2 is rotated fully CCW, the motor idles at the minimum speed set by P1 at input values below the end of the proportional band (Curve A in Figure 6). When P2 is rotated fully CW, the motor shuts off at the minimum speed set by P1 when the input is below the bottom end of the proportional band (Curve B in Figure 6). In Curve C, the minimum motor speed (P1) is set at 0% of maximum motor speed, and the position of P2 has no effect. For applications with a single input, install the supplied jumper on both pins of Terminal J8 on the VFD66 control. For dual input applications, place jumper on one pin of Terminal J8. Refer to Adjusting the Control Settings in the VFD66 Series Condenser Fan Speed Controls Product/Technical Bulletin (LIT-125467) for further instructions. Operation The VFD66 control supplies a constant 5 VDC source to the P35 transducer. The transducer responds to refrigerant pressure changes by varying a proportional signal (0.5-4.5 VDC) to the VFD66 control. As the pressure increases, the P35 transducer increases the DC voltage signal to the VFD66 control. The VFD66 control responds by increasing the condenser fan motor speed proportionally. Increased airflow over the condenser reduces the refrigerant pressure. As the pressure decreases, the P35 transducer decreases the DC voltage signal to the VFD66 control, which slows the fan motor. 4 P35 Pressure Transducer and VFD66 Control Application Note Description Direct-mount pressure transducer Technical Specifications Product Setpoint Range Fixed Throttling Range Output Power Requirements Operating Conditions Ambient Storage Conditions Agency Compliance P35 Pressure Transducer 203-350 psig (1400-2413 kPa) 46 psi (317 kPa) 0.5 VDC to 4.5 VDC 5 VDC from VFD66 Control -31-131°F (-35-55°C), 0-95% RH (noncondensing) -40-158°F (-40-70°C), 0-95% RH (noncondensing) UL Recognized, File E29374, CCNs NKPZ2 (US), NKPZ8 (Canada) The performance specifications are nominal and conform to acceptable industry standards. For application at conditions beyond these specifications, consult Johnson Controls/Penn Application Engineering at (800) 275-5256. Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. Controls Group 507 E. Michigan Street P.O. Box 423 Milwaukee, WI 53201 Printed in U.S.A. www.johnsoncontrols.com P35 Pressure Transducer and VFD66 Control Application Note 5